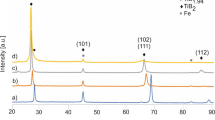

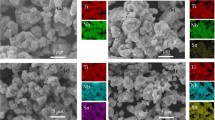

In this study, nickel-magnesium (Ni–Mg) alloys with a 97% Ni–3% Mg compositions were successfully borided with packet boriding at temperatures from 900 to 1000°C and treatment time 1.5–4.5 h. The properties, surface roughness, and density of the resulting boride layers were determined by X-ray diffraction (XRD) analysis, scanning electron microscopy (SEM), energy-dispersive X-ray spectroscopy (EDS), and microhardness tests. XRD analysis revealed NiB, Ni3B, and Ni2B phases after boriding. The coated boride layer in the alloy resulted in a smooth, dense SEM-approved property. In Ni–Mg alloys, the diffusion of boron atoms from the surface to the matrix accelerated with increasing temperature and treatment time. As such, boride layer thicknesses increased. It has been observed that Mg does not prevent the diffusion of the boron atom. Based on the treatment time and temperature, the thickness of the boride layer of the NM alloy varied between 96.74 and 248.36 μm. The hardness of the boride layer ranged between 1675 and 1832 HV0.05 for the Ni–Mg alloy, while the Vickers hardness value of untreated nickel amounted to 98 HV0.05. The surface roughness of Ni–Mg alloys ranged between 0.25 and 0.58 μm, and its densities were 8.4–8.68 g/cm3. Surface roughness values increased with increasing boride layer thickness. The wear tests were carried out in a ball–disc arrangement under dry friction conditions at room temperature with an applied load of 10 N and a sliding speed of 0.3 m/sec at a sliding distance of 250 m. The coefficient of friction of the borided Ni–Mg alloys ranged from 0.42 to 0.64, while that of the unborided alloys was 0.86. It was observed that the wear rate of borided and unborided Ni–Mg alloys ranged from 21.86 ⋅ 10–5 mm3/N ⋅ m to 89.92 ⋅ 10–5 mm3/N ⋅ m.

Similar content being viewed by others

References

X. Lirong, C. Xuefei, W. Kang, Y. Liu, D. Yin, Z. Hu, H. Zhou, and Y. Zhu, “Effect of dislocation configuration on Ag segregation in subgrain boundary of a Mg–Ag alloy,” Scrip. Mater., 191, 219–224 (2021).

S. Sandeep, S. Gurpreet, and B. Niraj, “Electrophoretic deposition of Fe3O4 nanoparticles incorporated hydroxyapatite-bioglass-chitosan nanocomposite coating on AZ91 Mg alloy,” Mater. Today Commun., 26, 101870 (2021).

I. Gunes, T. Uygunoglu, and M. Erdogan, “Effect of sintering duration on some properties of pure magnesium,” Powder Metall. Metal Ceram., 54, 156–165 (2015).

R.K. Koju and Y. Mishin, “Atomistic study of grain-boundary segregation and grain-boundary diffusion in Al–Mg alloys,” Acta Materialia.,. 201, 596–603 (2020).

L. Dan-yang, W. Jie-xia, and L. Jin-feng, “The effect of Ag element on the microstructure characteristic evolution of an Al–Cu–Li–Mg alloy,” J. Mater. Research and Technol., 9, No. 5, 11121–11134 (2020).

X. Bingqian, S. Jiapeng, and Y. Zhenquan, “A near-isotropic ultrafine-grained Mg–Gd–Ag alloy with high strength-ductility synergy,” J. Mater. Research and Technol., 9, No. 6, 13616–13624 (2020).

Z. Hua, R. Shuai, L. Xia, L. Wang, J. Fan, S. Chen, L. Zhu, F. Meng, Y. Tong, H.J. Roven, S. Zhang, and L. Jiang, “Dramatically enhanced stamping formability of Mg–3Al–1Zn alloy by weakening (0001) basal texture,” J. Mater. Research and Technol., 9, No. 6, 14742–14753 (2020).

C. Hukui and J. Hongli, “Oxidation of molten AZ91D Mg alloy in hexafluoropropylene/air atmospheres,” Corros. Sci., 179, 109148 (2021).

M. Long, W. Zhe, W. Lu, L. Guo, and Z. Guo, “Novel and efficient purification of scrap Al–Mg alloys using supergravity technology,” Waste Managem., 119, 22–29 (2021).

P.A. Pulido-Suárez, K.S. Uñate-González, J.G. Tirado-González, A. Esguerra-Arce, and J. Esguerra-Arce, “The evolution of the microstructure and properties of ageable Al–Si–Zn–Mg alloy during the recycling of milling chips through powder metallurgy,” J. Mater. Research and Technol., 9, No. 5, 11769–11777 (2020).

Z. Lei, M. Guojun, J. Peipeng, and Y. Zihan, “Role of Y on the microstructure, texture and mechanical properties of Mg–Zn–Zr alloys by powder metallurgy,” J. Alloys Compd., 810, 151843 (2019).

N. Makuch, M. Kulka, P. Dziarski, S. Taktak, “The influence of chemical composition of Ni-based alloys on microstructure and mechanical properties of plasma paste borided layers,” Surf. & Coat. Technol., 367, 187–202 (2019).

V.I. Dybkov, “Thermochemical boriding of Fe–5% Cr Alloy,” Powder Metall. Metal Ceram., 54, No. 9–10, 652–664 (2016).

I. Yildiz, A.G. Çelik, and I. Gunes, “Characterization and diffusion kinetics of borided Ni–Mg alloys. Protection of Metals and Physical Chemistry of Surfaces. 56, No. 5, 1015–1022 (2020).

D. Liu, Y. Duan, W. Bao, and M. Peng, “Characterization and growth kinetics of boride layers on Ti–5Mo–5V–8Cr–3Al alloy by pack boriding with CeO2,” Mater. Charac., 164, 110362 (2020).

J. Li, S. Jeffs, M. Whittaker, and N. Martin, “Boride formation behaviour and their effect on tensile ductility in cast TiAl-based alloys,” Mater. Design, 195, 109064 (2020).

R. Chegroune, M. Keddam, Z.N. Abdellah, S. Ulker, S. Taktak, and I. Gunes, “Characterization and kinetics of plasma-paste-borided AISI 316 steel,” Materiali in Tehnologije, 50, 263–268 (2016).

I. Gunes, M. Keddam, R. Chegroune, and M. Ozcatal, “Growth kinetics of boride layers formed on 99.0% purity nickel,” Bull. Mater. Sci.,. 38, 1113–1118 (2015).

Y.S. Zhu, Y.X. Yin, J.Y. Wu, F. Liu, W. Lu, D. Zuo, H. Xiao, D. Cao, and T. Jo Ko, “Effect of RE on accelerating the kinetics of boride layer growth on titanium alloy,” J. Alloys Compd. 844, 156091 (2020).

P.V.S. Muralikrishna, P.S. Kishore, N. Ramanaiah, and V.V.S.P.K. Pathanjali, “Nickel base alloy with metal matrix composite zirconium boride with inorganic coatings for high temperature environments,” Mater. Today: Proceed., 39, 1287–1290 (2021).

E.J. Hernández-Ramírez, A. Guevara-Morales, U. Figueroa-López, and I. Campos-Silva, “Wear resistance of diffusion annealed borided AISI 1018 steel,” Mater. Lett., 277, 128297 (2020).

A. Erdogan, A. Günen, M.S. Gok, and S. Zeytin, “Microstructure and mechanical properties of borided CoCrFeNiAl0.25Ti0.5 high entropy alloy produced by powder metallurgy,” Vacuum, 183, 109820 (2021).

I. Gunes, M. Erdogan, and A.G. Celik, “Corrosion behavior and characterization of plasma nitrided and borided AISI M2 steel,” Mater. Research., 17, 612–618 (2014).

J.H. Oha, M. Kima, Y.L. Lee, S.H. Hong, S.S. Park, T.H. Kim, and S. Choi, “Synthesis of cobalt boride nanoparticles and h-BN nanocage encapsulation by thermal plasma,” Ceram. Internat., 46, 28792–28799 (2020).

I. Gunes and A.G. Celik, “Surface characterization of borided S220 rebar,” J. Charact., 1, 66–70 (2021).

M.C. Paulisch, N. Wanderka, G. Miehe, D. Mukherji, J. Rösler, and J. Banhart, “Characterization of borides in Co–Re–Cr-based high-temperature alloys,” J. Alloys Compd., 569, 82–87 (2013).

M. Kulka, P. Dziarski, N. Makuch, A. Piasecki, and A. Miklaszewski, “Microstructure and properties of laser-borided Inconel 600-alloy,” Appl. Surf. Sci., 284, 757–771 (2013).

N. Makuch, “Nanomechanical properties and fracture toughness of hard ceramic layer produced by gas boriding of Inconel 600 alloy,” Trans. Nonferrous Metal. Soc. China,” 30, 428–448 (2020).

N. Makuch, M. Kulka, and M. Paczkowska, “Nanomechanical properties of gas-borided layer produced on Nimonic 80A-alloy,” Ceram. Int., 43, 8255–8261 (2017).

I. Mejía-Caballero, N. Sebastian-Cardenas, U. Figueroa-Lopez, J. Martínez-Trinidad, and I. Campos-Silva, “The effect of aging treatment on the indentation properties of a nickel boride layer,” Mater. Today Commun., 26, 101907 (2021).

S. Sahin, “Effects of boronizing process on the surface roughness and dimensions of AISI 1020, AISI 1040 and AISI 2714,” J. Mater. Process. Technol., 209, No. 4, 1736–1741 (2009).

I. Gunes, “Wear behavior of plasma paste boronized of AISI 8620 steel with borax and B2O3 paste mixtures,” J. Mater. Sci. & Technol., 29, No. 7, 662–668 (2013).

M. Tarakci, Y. Gencer, and A. Calik, “The pack-boronizing of pure vanadium under a controlled atmosphere,” Appl. Surf. Sci. 256, 7612–7618 (2010).

Acknowledgment

This study was supported by Afyon Kocatepe University BAPK 17.MYO.05. The authors highly appreciate the support of the Committee on Scientific Research Projects.

Author information

Authors and Affiliations

Corresponding author

Additional information

Published in Poroshkova Metallurgiya, Vol. 60, Nos. 11–12 (542), pp. 80–90, 2021.

Rights and permissions

About this article

Cite this article

Gunes, I., Yildiz, I. & Çelik, A.G. Wear Resistance and Characterization of Borided Ni-Based Alloys. Powder Metall Met Ceram 60, 717–726 (2022). https://doi.org/10.1007/s11106-022-00283-z

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11106-022-00283-z