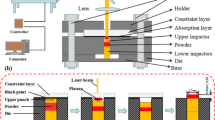

A compaction process using self-propagating high-temperature synthesis (SHS) has been developed. The process includes preparation of a composite powder billet in conditions that promote uniform pore distribution over the synthesized product, followed by barothermal SHS and compaction of the billet by plastic deformation. To determine the ultimate strain of the synthesized billet, a hereditary damage accumulation model is proposed to consider two competing processes during compaction: accumulation of microdamage induced by plastic deformation and partial healing of the accumulated microdamage through structural changes. Areas of theoretical studies to intensify the compaction process are identified.

Similar content being viewed by others

References

A. G. Merzhanov and A. S. Mukas’yan, Gasless Combustion [in Russian], Torus Press, Moscow (2007), p. 336.

S. M. Vaitsekhovich and A. A. Mishulin, “Experience with manufacture of hard-alloy cutting tools by the method of self-propagating high-temperature synthesis,” Powder Metall. Met. Ceram., 31, No. 3, 270–274 (1992).

S. M. Vaitsekhovich, “Mold for pressing of powder billets,” Kuzn. Shtamp. Proizv., No. 12, 27–28 (1991).

Self-Propagating High-Temperature Synthesis: Theory and Practice [in Russian], Territoriya, Chernogolovka (2001), p. 176.

E. T. Dolbenko, S. M. Vaitsekhovich, A. A. Mishulin, et al., Multiple Mold for Pressing Powder Articles [in Russian], USSR Inventor’s Certificate 1206000, IPC B 22 F 3/02, B 30 B 15/02, No. 3747060/22-02, Bulletin No. 3; applied June 1, 1984; publ. January 23 (1986).

S. M. Vaitsekhovich, “Studying compaction of powder materials and combustion products in pressing of combustible media,” in: Proc. Rep. Sci. Tekh. Conf. Theoretical and Applied Problems in Developing High- Technology and Low-Waste Metal Forming Processes [in Russian], Vinnitsa (1991), p. 30.

S. M. Vaitsekhovich, “Molds for large products made of powder materials,” Powder Metall. Met. Ceram., 32, No. 8, 744–747 (1993).

M. S. Kovalchenko, Theory Underlying Hot Pressing of Porous Materials [in Russian], Naukova Dumka, Kiev (1980), p. 240.

V. M. Mikhalevich, Tensor Damage Accumulation Models [in Russian], Universum-Vinnitsa, Vinnitsa (1998), p. 195.

V. M. Mikhalevich and V. O. Kraevskii, “Statement of a variational problem for the damage accumulation model in hot pressing,” in: Pressing of Materials (Collected Scientific Papers) [in Ukrainian], Issue 2(21), Kramatorsk (2009), pp. 12–16.

V. Mikhalevich and V. Kraevskii, “Variational problems for damage accumulation models of heritable type,” in: Proc. Int. Sci. Conf. Nonlinear Analysis and Application 2009 (April 2–4, 2009), NTUU KPI, Kiev (2009), pp. 109–110.

V. M. Mikhalevich, V. A. Kraevskii, and Yu. V. Dobranyuk, “Modeling ultimate strains on the free surface in axially symmetric setting,” in: Proc. Int. Sci. Tekh. Conf. Progressive Methods and Equipment for Metal Forming Processes [in Russian], Balt. Gos. Tekh. Univ., Saint Petersburg (2009), pp. 108–112.

V. M. Mikhalevich, V. A. Kraevskii, and Yu. V. Dobranyuk, “Modeling ultimate strains on the free surface and optimization of stepped compaction,” in: Status, Issues, and Prospects of Press and Die Forging [in Russian], Ryazan (2010), pp. 367–378.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Poroshkovaya Metallurgiya, Vol. 52, No. 1–2 (489), pp. 3–10, 2013.

Rights and permissions

About this article

Cite this article

Vaitsekhovich, S.M., Mikhalevich, V.M. & Kraevskii, V.A. Theory and technology of barothermal self-propagating high-temperature synthesis based on damage accumulation modeling. Powder Metall Met Ceram 52, 1–6 (2013). https://doi.org/10.1007/s11106-013-9489-7

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11106-013-9489-7