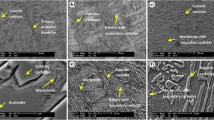

The fracture toughness of powder chromium sintered in magnesium vapor is higher by a factor of 53 than that of powder chromium sintered in hydrogen and by a factor of 5 than that of deformed low-alloy chromium VKh2K castings. This high fracture toughness is due to the skeleton formed of plastic interlayers of high-purity chromium. Chromium becomes highly ductile after fine purification in Cr–MgO alloys to remove interstitial impurities. The interlayers form on the surface of chromium powder particles under the refining action of magnesium vapor. Auger electron microscopy and data on fracture, chemical composition, and etching resistance lead to the conclusion that there are interlayers made of pure chromium. The high fracture toughness remains after annealing for 1 h at 1500°C.

Similar content being viewed by others

References

N. P. Lyakishev and M. I. Gasik, Metallurgy of Chromium [in Russian], Eliz, Moscow (1999), p. 582.

A. H. Sully and E. A. Brandes, Chromium, Butterworths, London (1967).

C. T. Sims and W. C. Hagel, The Superalloys, John Wiley and Sons, New York (1972).

V. I. Trefilov and V. F. Moiseev, Dispersed Particles in Refractory Metals [in Russian], Naukova Dumka, Kyiv (1978), p. 240.

N. P. Brodnikovskii, L. S. Igolkina, V. A. Pisarenko, et al., “Influence of stress concentrators on the fracture of chromium at ductile–brittle transition,” in: Electron Microscopy and Strength of Materials [in Russian], Inst. Probl. Materialoved. NAN Ukrainy, Kyiv (1994), pp. 102–112.

L. S. Igolkina, L. S. Kosachev, and B. A. Mochalov, “Influence of dynamic strain aging on the hardening parameters of low-alloyed chromium,” Metallofizika, 7, No. 4, 89–93 (1985).

D. E. Crutchley and C. N. Reid, “Mechanical properties of chromium single crystals,” in: F. Benesovsky (ed.), Proc. 6th Plansee Seminar on High Temperature Materials (June 24–28, 1968, Reutte), Springer-Verlag, New York (1969), pp. 57–66.

V. I. Trefilov, A. N. Rakitskii, N. P. Brodnikovskii, et al., “Dynamic strain aging in chromium and its alloys,” in: Structural Alloys of Chromium [in Russian], Inst. Probl. Materialoved. NAN Ukrainy, Kyiv (1986), pp. 46–59.

D. D. Abanin, A. I. Evstyukhin, V. P. Maslov, et al., “Metals,” Izv. AN SSSR, No. 1, 27–31 (1974).

R. Wadsack, R. Pippan, and B. Schedler, “Chromium—a material for fusion technology,” Fusion Eng. Design, 58–59, 743–748 (2001).

D. M. Scruggs, “Chromium composites are ductile,” Mater. Design. Eng., 56, No. 7, 115–119 (1962).

G. C. Reed and W. L. Schalliol, “Chromium–magnesia composites,” J. Met., 16, No. 2, 175–179 (1964).

R. F. Decker and R. R. Dewitt, “Trends in high-temperature superalloys,” J. Met., February, 139–145 (1965).

V. I. Khodkin, Powder Metallurgy [in Russian], Vysshaya Shkola, Minsk (1966), pp. 358–361.

V. S. Rakovskii, A. F. Silaev, V. I. Khodkin, and O. Kh. Faktulin, Powder Metallurgy of Creep-Rupture Resistant Alloys and Refractory Metals [in Russian], Metallurgiya, Moscow (1974), p. 195.

K. I. Portnoi and B. N. Babich, Dispersion-Hardened Materials [in Russian], Metallurgiya, Moscow (1974), p. 200.

I. M. Fedorchenko and S. M. Solonin, “The sinterability of chromium powder,” Powder Metall. Met. Ceram., 4, No. 11, 891–895 (1965).

A. N. Rakitskii and V. I. Trefilov, “Optimum alloying of chromium with highly active elements. A survey,” Powder Metall. Met. Ceram., 16, No. 9, 703–711 (1977).

A. N. Volchkov, V. A. Belov, I. V. Kurkin, and A. B. Ol’shanskii, “Selection of refining additions for powder metallurgy alloys of chromium,” Powder Metall. Met. Ceram., 29, No. 3, 210–212 (1990).

G. V. Samsonov and V. P. Perminov, Magnesium Reduction [in Russian], Metallurgiya, Moscow (1971), p. 176.

I. M. Fedorchenko, I. G. Slys, and L. A. Sosnovskii, “Technology of sintering of powder metallurgical materials without a circulating protective atmosphere,” Powder Metall. Met. Ceram., 11, No. 5, 361–366 (1972).

I. G. Slys, V. I. Trefilov, and I. M. Fedorchenko, A Method for the Production of Sintered Dispersion-Hardened Alloys [in Russian], Inventor’s Certificate No. 633436 USSR, Byul. Izobr., No. 7 (1978).

A. A. Sotnik, A. D. Vasil’ev, and I. G. Slys, “Influence of porosity on the crack resistance of brittle powder materials,” in: Electron Microscopy and Strength of Materials [in Russian], Inst. Probl. Materialoved. NAN Ukrainy, Kyiv (1989), pp. 34–40.

A. D. Vasil’ev, A. A. Sotnik, S. A. Firstov, et al., “Influence of porosity on the fracture toughness of chippable materials,” in: Fracture Mechanics and Physics of Brittle Materials [in Russian], Inst. Probl. Materialoved. NAN Ukrainy, Kyiv (1990), pp. 95–100.

I. V. Oryshich, N. E. Poryadchenko, I. G. Slys, et al., “Air oxidation of chromium-based composites,” Powder Metall. Met. Ceram., 56, No. 3–4, 189–193 (2007).

A. N. Rakitskii and V. I. Trefilov, “Advances in the development of structural chromium alloys: Capabilities and limitations,” in: Structural Chromium Alloys [in Russian], Naukova Dumka, Kyiv (1986), pp. 5–32.

O. V. Bakun, O. N. Samgina, G. F. Sarzhan, et al., “Structure and mechanical properties of sintered chromium with a magnesia addition,” Powder Metall. Met. Ceram., 20, No. 4, 279–282 (1981).

N. P. Brodnikovskii, A. A. Onoprienko, V. A. Pisarenko, et al., “Structural sensitivity of the mechanical properties of chromium–nitrogen alloys after annealing,” Metallofizika, 6, No. 6, 79–84 (1984).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Poroshkovaya Metallurgiya, Vol. 51, No. 5–6 (485), pp. 30–41, 2012.

Rights and permissions

About this article

Cite this article

Slys, I.G., Brodnikovskii, N.P., Kossko, I.A. et al. High fracture toughness of powder chromium sintered in magnesium vapor. Powder Metall Met Ceram 51, 273–281 (2012). https://doi.org/10.1007/s11106-012-9428-z

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11106-012-9428-z