Abstract

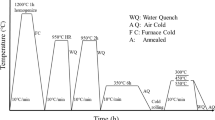

Inconel 718 modified by magnesium and calcium was investigated in order to improve the ductile fracture properties of the alloy. Three different types of Inconel 718 containing 50 ppm Mg, 40 ppm Ca, and no trace elements were prepared by vacuum induction melting processes, rolled, and heat-treated. Tension and impact properties were tested at the room temperature and in the longitudinal and transverse directions. Fractographic and microstructural analyses were done by FESEM examinations. Reduction in area and impact energy was improved by 10–50% in the transverse direction, whereas strength was not changed by adding Ca and Mg. Also, these properties did not show any significant variations in longitudinal specimens. MC-type carbide was formed in solidification and rearranged as stringer during the rolling process, significantly reducing the impact energy of Inconel 718 on transverse samples. Ductile anisotropy was modified as the carbide shape and size were refined in the as-cast microstructure of Mg and Ca alloys.

Similar content being viewed by others

References

A. Mitchell, Primery carbidea in alloy 718, in Proceedings of the Superalloy 718 and Derivatives, ed. by E.A. Ott, R. Groh, A. Banik, I. Dempster, T.P. Gabb, R. Helmink, X. Liu (Wiley, New York, 2010), pp. 161–167

S.-H. Kang, Y. Deguchi, K. Yamamoto, K. Ogi, M. Shirai, Solidification process and behavior of alloying elements in Ni-based superalloy Inconel718. Mater. Trans. 45(8), 2728–2733 (2004)

Y. Zhang, Z. Li, P. Nie, Y. Wu, Carbide and nitride precipitation during laser cladding of Inconel 718 alloy coatings. Opt. Laser Technol. 52, 30–36 (2013)

L. Xiao, M.C. Chaturvedi, D. Chen, Effect of boron and carbon on the fracture toughness of IN 718 superalloy at room temperature and 650°C. J. Mater. Eng. Perform. 14(4), 528–538 (2005)

W.-J. Zheng, X.-P. Wei, Z.-G. Song, Q.-L. Yong, F. Han, Q.-C. Xie, Effects of carbon content on mechanical properties of Inconel 718 alloy. J. Iron. Steel Res. Int. 22(1), 78–83 (2015)

J. Yang, Q. Zheng, X. Sun, H. Guan, Z. Hu, Relative stability of carbides and their effects on the properties of K465 superalloy. Mater. Sci. Eng. A 429(1), 341–347 (2006)

C. Joseph, M. Hornqvist, C. Persson, Anisotropy of room temperature ductility in Haynes 282 forgings, in Proceedings of the Superalloy 718 and Derivatives, ed. by E. Ott, A. Banik, X. Liu, I. Dempster, K. Heck, J. Andersson (Wiley, New York, 2014), pp. 601–609

K. Mo, G. Lovicu, X. Chen, H.-M. Tung, J.B. Hansen, J.F. Stubbins, Mechanism of plastic deformation of a Ni-based superalloy for VHTR applications. J. Nucl. Mater. 44(1), 695–703 (2013)

G. Liu, D.K. Rehbein, O. Buck, Anisotropy of the fracture toughness in aged Inconel 718, in Review of Progress in Quantitative Nondestructive Evaluation, ed. by D.O. Thompson, D.E. Chimenti (Plenum Press, New York, 1997), pp. 1451–1457

G. Meetham, Trace elements in superalloys—an overview. Metals Technol. 11(1), 414–418 (1984)

K. Banerjee, The role of magnesium in superalloys—a review. Mater. Sci. Appl. 2(9), 1243–1255 (2011)

G. Chen, Q. Zhu, D. Wang, X. Xie, Effects of magnesium on niobium segregation and impact toughness in cast alloy 718, in Proceedings of Superalloys 718 and Derivatives, ed. by E.A. Loria (TMS, Pennsylvania, 1989), pp. 545–551

X. Liu, J. Dong, X. Xie, K.-M. Chang, The appearance of magnesium and its effect on the mechanical properties of Inconel 718 with low sulfur content. Mater. Sci. Eng. A 303(1), 262–266 (2001)

X.-C. Chen, C.-B. Shi, H.-J. Guo, F. Wang, H. Ren, D. Feng, Investigation of oxide inclusions and primary carbonitrides in Inconel 718 superalloy refined through electroslag remelting process. Metall. Mater. Trans. B 43(6), 1596–1607 (2012)

BS EN 10247 (2007), Micrographic Examination of the Non-metallic Inclusion Content of Steels Using Standard Pictures

H. Bor, C. Ma, C. Chao, The influence of Mg on creep properties and fracture behaviors of Mar-M247 superalloy under 1255 K/200 MPa. Metall. Mater. Trans. A 31(5), 1365–1373 (2000)

H. Bor, C. Chao, C. Ma, The influence of magnesium on carbide characteristics and creep behavior of the Mar-M247 superalloy. Scr. Mater. 38(2), 329–335 (1997)

Y. Ono, T. Yuri, H. Sumiyoshi, E. Takeuchi, S. Matsuoka, T. Ogata, High-cycle fatigue properties at cryogenic temperatures in Inconel 718 nickel-based superalloy. Mater. Trans. 45(2), 342–345 (2004)

W. Mills, L. Blackburn, Variations in fracture toughness for alloy 718 given a modified heat treatment. J. Eng. Mater. Technol. 112, 116–123 (1990)

J. Zhu, Z. Cheng, H. Ye, The distribution and morphology of trace Mg at a grain boundary in a Ni-base superalloy. Scr. Mater. 23(9), 1537–1542 (1989)

Dong, J.X., Thompson, R.G., Xie, X.S.: Mult-component intergranular and interfacial segregation in alloy 718 with correlations to stress rupture behavior. In: Loria, E.A. (eds.) Proceedings of the Superalloy 718 and Derivatives, pp. 553–566. The Society, Pennsylvania (1997)

A. Bhambri, T. Kattamis, J. Morral, Cast microstructure of Inconel 713C and its dependence on solidification variables. Metall. Trans. B 6(4), 523–537 (1975)

B.H. Kear, Effect of uncombined calcium and magnesium on the malleability of nickel alloys, in Proceedings of Superalloys, ed. by J.J. de Barbadillo (Claitors, Baton Rouge, 1976), pp. 95–107

J. Dong, X. Xie, R. Thompson, The influence of sulfur on stress-rupture fracture in Inconel 718 superalloys. Metall. Mater. Trans. A 31(9), 2135–2144 (2000)

G. Bernard, P. Riboud, G. Urbain, Investigation of the plasticity of oxide inclusions. Rev. de Metall. 78(5), 421–433 (1981)

T. Baker, K. Gave, J. Charles, Inclusion deformation and toughness anisotropy in hot-rolled steels. Metals Technol. 3(1), 183–193 (1976)

A. Pineau, A.A. Benzerga, T. Pardoen, Failure of metals I: brittle and ductile fracture. Acta Mater. 107, 424–483 (2016)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Teimouri, J., Hosseini, S.R. & Farmanesh, K. Effect of Magnesium and Calcium Addition on Carbides Characterizations and Anisotropy Ductile Fracture of Inconel 718. Metallogr. Microstruct. Anal. 7, 268–276 (2018). https://doi.org/10.1007/s13632-018-0449-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13632-018-0449-y