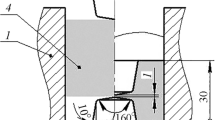

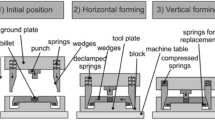

The hot forging of porous preforms in a closed die with a cone-shaped flash gutter is numerically simulated. The cross-sectional distribution of strains and density over the preform substantially differs at various stages of the process. The maximum axial and radial strains, as well as intermediate density values, are observed near the flash gap.

Similar content being viewed by others

References

Yu. G. Dorofeev, Dynamic Hot Pressing of Porous Powder Preforms [in Russian], Metallurgiya, Moscow (1977), p. 216.

Yu. G. Dorofeev, B. G. Gasanov, V. Yu. Dorofeev, et al., Industrial Technology of Hot Pressing of Powder Parts [in Russian], Metallurgiya, Moscow (1990), p. 206.

L. I. Zhivov, A. V. Sypko, and N. I. Dolgii, “Experience in die forging of titanium powder parts,” Kuzn. Shtamp. Proizv., No. 3, 47 (1975).

G. Baglyuk, “Densification and shape change of porous billets in closed and open dies,” in: Recent Developments in Computer Modeling of Powder Metallurgy Processes, NATO Science Series, IOS Press, Amsterdam (2001), pp. 163–168.

G. A. Baglyuk, “Modeling deformation of a porous blank in open-die forging,” Powder Metall. Met. Ceram., 36, No. 9–10, 459–461 (1997).

M. S. Éduardov, Closed-Die Forging [in Russian], Mashinostroenie, Leningrad (1971), p. 240.

V. A. Pavlov and M. I. Nosenko, “An investigation of the processes of hot deformation of porous blanks of titanium, copper, and aluminum and optimization of them,” Powder Metall. Met. Ceram., 32, No. 9–10, 768–772 (1993).

V. A. Pavlov and M. I. Nosenko, “Effect of the stress-strain state on the densification of metal powders (powder preforms) during hot forging,” Powder Metall. Met. Ceram., 31, No. 2, 103–107 (1992).

G. A. Baglyuk, “Consolidation of a porous material in hot pressing in a closed mold fitted with a compensator,” Powder Metall. Met. Ceram., 37, No. 5–6, 249–252 (1998).

G. A. Baglyuk, L. O. Poznyak, G. Yu. Mazharova, and S. M. Kaplya, Die for Hot Forging of Powder Blanks [in Ukrainian], Ukrainian Patent 29502, Bulletin No. 6, Publ. November 15 (2000).

S. Shima and M. Oyane, “Plasticity theory for porous metals,” J. Mech. Sci., 18, 285–291 (1976).

Sh. Kobayashi, S.-I. Oh, and T. Altan, Metal Forming and the Finite-Element Method, Oxford University Press, New York–Oxford (1989), p. 377.

A. R. Khoei, Computational Plasticity in Powder Forming Processes, Elsevier Science, Amsterdam (2005), p. 449.

G. A. Baglyuk, I. D. Radomysel’skii, M. B. Shtern, and V. V. Mizyuk, “Densification and change in the shape of a hollow porous cylinder during hot compression in a container,” Powder Metall. Met. Ceram., 25, No. 3, 179–181 (1986).

G. A. Baglyuk, “Modeling the process of upsetting a porous ring in a die with contact friction taken into account,” Powder Metall. Met. Ceram., 33, No. 1–2, 14–17 (1995).

G. A. Baglyuk, “Improving the densification of porous blanks through intensification of shear deformation,” in: Rheology, Structure, and Properties of Powder and Composite Materials (Collected Scientific Papers) [in Ukrainian], Lutsk Derzh. Tekh. Univ., Lutsk (2004), pp. 35–48.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Poroshkovaya Metallurgiya, Vol. 51, No. 3–4 (484), pp. 29–37, 2012.

Rights and permissions

About this article

Cite this article

Baglyuk, G.A., Mikhailov, O.V. Hot forging of porous preforms in a closed die with a cone-shaped flash gutter: numerical simulation. Powder Metall Met Ceram 51, 150–156 (2012). https://doi.org/10.1007/s11106-012-9410-9

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11106-012-9410-9