Abstract

Purpose

To compare the prediction accuracy of two models used to characterize the complete disordering potential of materials after extensive cryogenic milling.

Methods

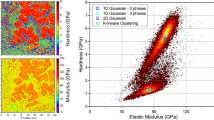

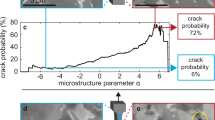

Elastic shear moduli (μs) were simulated in silico. Comparison with available literature values confirmed that computations were reasonable. Complete disordering potential was predicted using the critical dislocation density (ρcrit) and bivariate empirical models. To compare the prediction accuracy of the models, each material added for dataset expansion was cryomilled for up to 5 hr. Mechanical disordering after comminution was characterized using PXRD and DSC, and pooled with previously published results.

Results

Simulated μs enabled predictions using the ρcrit model for 29 materials. This model mischaracterized the complete disordering behavior for 13/29 materials, giving an overall prediction accuracy of 55%. The originally published bivariate empirical model classification boundary correctly grouped the disordering potential for 31/32 materials from the expanded dataset. Recalibration of this model retained a 94% prediction accuracy, with only 2 misclassifications.

Conclusions

Prediction accuracy of the ρcrit model decreased with dataset expansion, relative to previously published results. Overall, the ρcrit model was considerably less accurate relative to the bivariate empirical model, which retained very high prediction accuracy for the expanded dataset. Although the empirical model does not imply a mechanism, model robustness suggests the importance of glass transition temperature (Tg) and molar volume (Mv) on formation and persistence of amorphous materials following extensive cryomilling.

Similar content being viewed by others

References

Wildfong PLD, Haware RV, Xu T, Morris KR. Secondary processing of organic crystals. In: Li T, Mattei A, editors. Pharmaceutical crystals: science and engineering. Hoboken, NJ: John Wiley & Sons, Inc.; 2018. p. 361–426.

Wildfong PLD, Haware RV, Xu T, Morris KR. Primary processing of organic crystals. In: Li T, Mattei A, editors. Pharmaceutical crystals: science and engineering. Hoboken, NJ: John Wiley & Sons, Inc.; 2018. p. 297–359.

Morris KR, Griesser UJ, Eckhardt CJ, Stowell JG. Theoretical approaches to physical transformations of active pharmaceutical ingredients during manufacturing processes. Adv Drug Deliv Rev. 2001;48(1):91–114.

Bezzon VDN, da Silva PR, de Araújo GLB, de Lima JC, Ferreira FF. Describing the influence of ball-milling on the amorphization of flubendazole using the PDF and RMC methods with X-ray powder diffraction data. J Pharm Sci. 2022;111(11):3054–63.

Latreche M, Willart J-F, Guerain M, Hédoux A, Danede F. Using milling to explore physical states: the amorphous and polymorphic forms of sulindac. J Pharm Sci. 2019;108(8):2635–42.

Terban MW, Russo L, Pham TN, Barich DH, Sun YT, Burke MD, et al. Local structural effects due to micronization and amorphization on an HIV treatment active pharmaceutical ingredient. Mol Pharm. 2020;17(7):2370–89.

Caron V, Willart J-F, Lefort R, Derollez P, Danède F, Descamps M. Solid state amorphization kinetic of alpha lactose upon mechanical milling. Carbohydr Res. 2011;346(16):2622–8.

Chamarthy SP, Pinal R. The nature of crystal disorder in milled pharmaceutical materials. Colloids Surf A: Physicochem Eng Asp. 2008;331(1-2):68–75.

Colombo I, Grassi G, Grassi M. Drug mechanochemical activation. J Pharm Sci. 2009;98(11):3961–86.

Lin Y, Cogdill RP, Wildfong PLD. Informatic calibration of a materials properties database for predictive assessment of mechanically activated disordering potential for small molecule organic solids. J Pharm Sci. 2009;98(8):2696–708.

Hu Y, Macfhionnghaile P, Caron V, Tajber L, Healy AM, Erxleben A, et al. Formation, physical stability, and quantification of process-induced disorder in cryomilled samples of a model polymorphic drug. J Pharm Sci. 2013;102(1):93–103.

Xu K, Xiong X, Zhai Y, Wang L, Li S, Yan J, et al. Effect of milling conditions on solid-state amorphization of glipizide, and characterization and stability of solid forms. J Pharm Bio Anal. 2016;129:367–77.

Ngono F, Willart J-F, Cuello G, Jimenez-Ruiz M, Affouard F. Lactulose: a model system to investigate solid state amorphization induced by milling. J Pharm Sci. 2019;108(2):880–7.

Abouhakim H, Quayle MJ, Norberg ST, Nilsson Lill SO, Asachi M, Schroeder SLM, et al. Mechanically induced amorphization of diaqua-bis (omeprazolate)-magnesium dihydrate. Cryst Growth Des. 2020;20(9):6057–68.

Iyer J, Brunsteiner M, Modhave D, Paudel A. Role of crystal disorder and mechanoactivation in solid-state stability of pharmaceuticals. J Pharm Sci. 2023;

Kestur U, Patel A, Badawy S, Mathias N, Zhang L. Strategies for managing solid form transformation risk in drug product. J Pharm Sci. 2022;112(4):909–21.

Yu L. Amorphous pharmaceutical solids: preparation, characterization and stabilization. Adv Drug Deliv Rev. 2001;48(1):27–42.

Brittain HG. Effects of mechanical processing on phase composition. J Pharm Sci. 2002;91(7):1573–80.

Hancock BC, Zografi G. Characteristics and significance of the amorphous state in pharmaceutical systems. J Pharm Sci. 1997;86(1):1–12.

Willart JF, Descamps M. Solid state amorphization of pharmaceuticals. Mol Pharm. 2008;5(6):905–20.

Chattoraj S, Bhugra C, Telang C, Zhong L, Wang Z, Sun CC. Origin of two modes of non-isothermal crystallization of glasses produced by milling. Pharm Res. 2012;29(4):1020–32.

Yu LX. Pharmaceutical quality by design: product and process development, understanding, and control. Pharm Res. 2008;25:781–91.

Wildfong PLD, Hancock BC, Moore MD, Morris KR. Towards an understanding of the structurally based potential for mechanically activated disordering of small molecule organic crystals. J Pharm Sci. 2006;95(12):2645–56.

Tromans D, Meech J. Enhanced dissolution of minerals: stored energy, amorphism and mechanical activation. Miner Eng. 2001;14(11):1359–77.

Griffith AA. The phenomena of rupture and flow in solids. Phil Trans Royal Soc A. 1921;221:163–98.

Parrott EL. Milling of pharmaceutical solids. J Pharm Sci. 1974;63(6):813–29.

Hull D, Bacon DJ. Introduction to dislocations. 4th ed. Woburn, MA: Butterworth-Heinemann; 2001.

Hiestand EN. Mechanics and physical principles for powders and compacts. 2nd ed. West Lafayette, IN: SSCI, Inc.; 2002. p. 110.

Dujardin N, Willart JF, Dudognon E, Danède F, Descamps M. Mechanism of solid state amorphization of glucose upon milling. J Phys Chem B. 2013;117(5):1437–43.

Otte A, Carvajal MT. Assessment of milling-induced disorder of two pharmaceutical compounds. J Pharm Sci. 2011;100(5):1793–804.

Luisi BS, Medek A, Liu Z, Mudunuri P, Moulton B. Milling-induced disorder of pharmaceuticals: one-phase or two-phase system? J Pharm Sci. 2012;101(4):1475–85.

Adrjanowicz K, Grzybowska K, Kaminski K, Hawelek L, Paluch M, Zakowiecki D. Comprehensive studies on physical and chemical stability in liquid and glassy states of telmisartan (TEL): solubility advantages given by cryomilled and quenched material. Philos Mag. 2011;91(13-15):1926–48.

Sun H, Jin Z, Yang C, Akkermans RLC, Robertson SH, Spenley NA, et al. COMPASS II: extended coverage for polymer and drug-like molecule databases. J Mol Model. 2016;22(2):47.

Mura P, Manderioli A, Bramanti G, Furlanetto S, Pinzauti S. Utilization of differential scanning calorimetry as a screening technique to determine the compatibility of ketoprofen with excipients. Int J Pharm. 1995;119(1):71–9.

Wang C, Sun CC. Identifying slip planes in organic polymorphs by combined energy framework calculations and topology analysis. Cryst Growth Des. 2018;18(3):1909–16.

Osborn JC, York P, Rowe RC, Roberts RJ, editors. Proceedings from the 14th international symposium on industrial crystallization. 1999; Cambridge, UK.

Roberts RJ, Rowe RC, York P. The Poisson's ratio of microcrystalline cellulose. Int J Pharm. 1994;105(2):177–80.

Dowling NE. Mechanical behavior of materials: engineering methods for deformation, fracture, and fatigue. 1st ed. Upper Saddle River, NJ: Prentice Hall; 1993.

Bowman K. Mechanical behavior of materials. 1st ed. Hoboken, NJ: John Wiley & Sons, Inc.; 2004.

Roberts RJ, Rowe RC, York P. The relationship between Young's modulus of elasticity of organic solids and their molecular structure. Powder Technol. 1991;65(1-3):139–46.

Roberts RJ, Rowe RC. Influence of polymorphism on the Young's modulus and yield stress of carbmazepine, sulfathiazole and sulfanilamide. Int J Pharm. 1996;129(1-2):79–94.

Bassam F, York P, Rowe RC, Roberts RJ. Young's modulus of powders used as pharmaceutical excipients. Int J Pharm. 1990;64(1):55–60.

Ridgway K, Shotton E, Glasby J. The hardness and elastic modulus of some crystalline pharmaceutical materials. J Pharm Pharmacol. 1969;21(S1):19S–23S.

Duncan-Hewitt WC, Weatherly GC. Evaluating the hardness, Young's modulus and fracture toughness of some pharmaceutical crystals using microindentation techniques. J Mater Sci Lett. 1989;8(11):1350–2.

Maughan MR, Carvajal MT, Bahr DF. Nanomechanical testing technique for millimeter-sized and smaller molecular crystals. Int J Pharm. 2015;486(1-2):324–30.

Egart M, Janković B, Lah N, Ilić I, Srčič S. Nanomechanical properties of selected single pharmaceutical crystals as a predictor of their bulk behaviour. Pharm Res. 2015;32:469–81.

Wang C, Sun CC. The landscape of mechanical properties of molecular crystals. CrystEngComm. 2020;22(7):1149–53.

Feng T, Pinal R, Carvajal MT. Process induced disorder in crystalline materials: differentiating defective crystals from the amorphous form of griseofulvin. J Pharm Sci. 2008;97(8):3207–21.

Pas T, Bergonzi A, Michiels E, Rousseau F, Schymkowitz J, Koekoekx R, et al. Preparation of amorphous solid dispersions by cryomilling: chemical and physical concerns related to active pharmaceutical ingredients and carriers. Mol Pharm. 2020;17(3):1001–13.

Descamps M, Willart JF, Dudognon E, Caron V. Transformation of pharmaceutical compounds upon milling and comilling: the role of Tg. J Pharm Sci. 2007;96(5):1398–407.

Baird JA, Van Eerdenbrugh B, Taylor LS. A classification system to assess the crystallization tendency of organic molecules from undercooled melts. J Pharm Sci. 2010;99(9):3787–806.

Alhalaweh A, Alzghoul A, Kaialy W, Mahlin D, Bergstrom CA. Computational predictions of glass-forming ability and crystallization tendency of drug molecules. Mol Pharm. 2014;11(9):3123–32.

Descamps M, Willart JF. Perspectives on the amorphisation/milling relationship in pharmaceutical materials. Adv Drug Deliv Rev. 2016;100:51–66.

Crowley KJ, Zografi G. Cryogenic grinding of indomethacin polymorphs and solvates: assessment of amorphous phase formation and amorphous phase physical stability. J Pharm Sci. 2002;91(2):492–507.

Bauer-Brandl A. Polymorphic transitions of cimetidine during manufacture of solid dosage forms. Int J Pharm. 1996;140(2):195–206.

Raimi-Abraham BT, Moffat JG, Belton PS, Barker SA, Craig DQM. Generation and characterization of standardized forms of trehalose dihydrate and their associated solid-state behavior. Cryst Growth Des. 2014;14(10):4955–67.

Bettinetti GP, Sorrenti M, Rossi S, Ferrari F, Mura P, Faucci MT. Assessment of solid-state interactions of naproxen with amorphous cyclodextrin derivatives by DSC. J Pharm Bio Anal. 2002;30(4):1173–9.

Neau SH, Shinwari MK, Hellmuth EW. Melting point phase diagrams of free base and hydrochloride salts of bevantolol, pindolol and propranolol. Int J Pharm. 1993;99(2-3):303–10.

Tong B, Tan Z-C, Shi Q, Li Y-S, Yue D-T, Wang S-X. Thermodynamic investigation of several natural polyols (I): heat capacities and thermodynamic properties of xylitol. Thermochim Acta. 2007;457(1-2):20–6.

Löbmann K, Laitinen R, Grohganz H, Gordon KC, Strachan C, Rades T. Coamorphous drug systems: enhanced physical stability and dissolution rate of indomethacin and naproxen. Mol Pharm. 2011;8(5):1919–28.

Funding

This research did not receive any specific grant from funding agencies in the public, commercial, or not- for-profit sectors.

Author information

Authors and Affiliations

Contributions

The manuscript was written through contributions of all authors. All authors have given approval to the final version of the manuscript.

Corresponding author

Ethics declarations

Conflict of Interest Statement

The authors declare no competing financial interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

ESM 1

(DOCX 833 kb)

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Bookwala, M., Wildfong, P.L.D. Re-visitation of Two Models for Predicting Mechanically-Induced Disordering after Cryogenic Impact Milling. Pharm Res 40, 2887–2902 (2023). https://doi.org/10.1007/s11095-023-03569-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11095-023-03569-y