ABSTRACT

Purpose

To mechanistically explain the origin of two distinct non-isothermal crystallization modes, single-peak (unimodal) and two-peak (bimodal), of organic glasses.

Methods

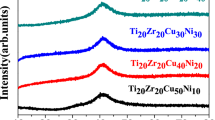

Glasses of ten organic molecules were prepared by melt-quenching and cryogenic milling of crystals. Non-isothermal crystallization of glasses was monitored using differential scanning calorimetry and powder X-ray diffractometry.

Results

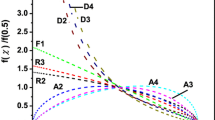

The non-isothermal crystallization of glass, generated by milling, is either unimodal or bimodal, while that of melt-quenched glass without being milled is always unimodal. The mode of crystallization of amorphous phase depends on the relative position of the crystallization onset (T c ) with respect to glass transition temperature (T g ), and can be explained by a surface crystallization model. Bimodal crystallization event is observed when T c is below or near T g , due to the fast crystallization onset at milled glass surfaces. Unimodal crystallization is observed when T c is well above T g . We have verified this model by intentionally inducing flip between the two crystallization modes for several compounds through manipulating glass surface area and T c .

Conclusions

The two modes of crystallization of organic glasses is a result of the combined effects of faster surface crystallization and variation in specific surface area by milling.

Similar content being viewed by others

REFERENCES

Yu L. Amorphous pharmaceutical solids: preparation, characterization and stabilization. Adv Drug Del Rev. 2001;48:27–42.

Hilden LR, Morris KR. Physics of amorphous solids. J Pharm Sci. 2001;93:3–12.

Levine H, Slade L, Levine H. Progress in food processing and storage, based on amorphous product technology. Cambridge: The Royal Society of Chemistry; 2002.

Blanshard JMV, Lillford P. The glassy state in foods. Nottingham: Nottingham University Press; 1993.

Crowe JH, Carpenter JF, Crowe LM. The role of vitrification in anhydrobiosis. Annu Rev Physiol. 1998;60:73–103.

Greer AL. Metallic glasses. Science. 1995;267:1947–53.

Fan GJ, Guo FQ, Hu ZQ, Quan MX, Lu K. Amorphization of selenium induced by high-energy ball milling. Phys Rev B. 1997;55:11010–3.

Lin ZJ, Zhuo MJ, Sun ZQ, Veyssiere P, Zhou YC. Amorphization by dislocation accumulation in shear bands. Acta Mater. 2009;57:2851–7.

Huttenrauch R, Fricke S, Zeilke P. Mechanical activation of pharmaceutical systems. Pharm Res. 1985:302–306.

Willart JF, Descamps M. Solid state amorphization of pharmaceuticals. Mol Pharm. 2008;5:905–20.

Willart JF, De Gusseme A, Hemon S, Odou G, Danede F, Descamps M. Direct crystal to glass transformation of trehalose induced by ball milling. Solid State Comm. 2001;119:501–5.

Suryanarayana C. Mechanical alloying and milling. Progr Mater Sci. 2001;46:1.

Tromans D, Meech JA. Enhanced dissolution of minerals: Stored energy, amorphism and mechanical activation. Miner Eng. 2001;14:1359–77.

Liu J, Rigsbee DR, Stotz C, Pikal MJ. Dynamics of pharmaceutical amorphous solids: the study of enthalpy relaxation by isothermal microcalorimetry. J Pharm Sci. 2002;91:1853–62.

Hodge IM. Enthalpy relaxation and recovery in amorphous materials. J Non-Cryst Solids. 1994;169:211–66.

Crowley KJ, Zografi G. Polymorphs and solvates: assessment of amorphous phase formation and amorphous phase physical stability. J Pharm Sci. 2002;91:492–507.

Bhugra C, Rambhatla S, Bakri A, Duddu SP, Miller DP, Pikal MJ, Lechuga-Ballesteros D. Prediction of the onset of crystallization of amorphous sucrose below the calorimetric glass transition temperature from correlations with mobility. J Pharm Sci. 2007;96:1258–69.

Bhugra C, Pikal MJ. role of thermodynamic, molecular, and kinetic factors in crystallization from the amorphous state. J Pharm Sci. 2008;97:1329–49.

Roberts CJ, Debenedetti PG. Engineering pharmaceutical stability with amorphous solids. AIChE J. 2002;48:1140–4.

Feng T, Pinal R, Carvajal MT. Process induced disorder in crystalline materials: differentiating defective crystals from the amorphous form of griseofulvin. J Pharm Sci. 2008;97:3207–21.

Feng T, Bates S, Carvajal MT. Toward understanding the evolution of griseofulvin crystal structure to a mesophase after cryogenic milling. Int J Pharm. 2008;367:16–9.

Chamarthy SP, Pinal R. The nature of crystal disorder in milled pharmaceutical materials. Colloid Surface A. 2008;331:68–75.

Trasi NS, Boerrigter SXM, Byrn SR. Investigation of the milling-induced thermal behavior of crystalline and amorphous griseofulvin. Pharm Res. 2010;27:1377–89.

Yu L, Mishra D, Rigsbee DR. Determination of glass properties of mannitol using sorbitol as an impurity. J Pharm Sci. 1998;87:774–7.

Zhou D, Schmitt EA, Zhang GG, Law D, Vyazovkin S, Wright CA, Grant DJW. Crystallization kinetics of amorphous nifedipine studied by model-fitting and model-free approaches. J Pharm Sci. 2003;92:1779–92.

Lefort R, De Gusseme A, Willart JF, Danede F, Descamps M. Solid state NMR and DSC methods for quantifying the amorphous content in solid dosage forms: an application to ball-milling of trehalose. Int J Pharm. 2004;280:209–19.

Grisedale LC, Jamieson MJ, Belton PS, Barker SA, Craig DQM. Characterization and quantification of amorphous material in milled and spray-dried salbutamol sulfate: a comparison of thermal, spectroscopic, and water vapor sorption approaches. J Pharm Sci. 2011;100:3114–29.

Saleki-Gerhardt A, Ahlneck C, Zografi G. Assessment of disorder in crystalline solids. Int J Pharm. 1994;101:237–47.

Patterson JE, James MB, Forster AH, Lancaster RW, Butler JM, Rades T. The influence of thermal and mechanical preparative techniques on the amorphous state of four poorly soluble compounds. J Pharm Sci. 2005;94:1998–2012.

Wu T, Yu L. Surface crystallization of indomethacin below Tg. Pharm Res. 2006;23:2350–5.

Zhu L, Jona J, Nagapudi K, Wu T. Fast surface crystallization of amorphous griseofulvin below Tg. Pharm Res. 2010;27:1558–67.

Zhu L, Wong L, Yu L. Surface-enhanced crystallization of amorphous nifedipine. Mol Pharm. 2008;5:921–6.

Sun Y, Zhu L, Kearns KL, Ediger MD, Yu L. Glasses crystallize rapidly at free surfaces by growing crystals upward. Proc Natl Acad Sci U S A. 2011;108:5990–5.

Zhu L, Brian CW, Swallen SF, Straus PT, Ediger MD, Yu L. Surface self-diffusion of an organic glass. Phys Rev Lett. 2011;106:256103-1–4.

Schmelzer J, Pascova R, Moller J, Gutzow I. Surface-induced devitrification of glasses: the influence of elastic strains. J Non-Cryst Solids. 1993;162:26–39.

Gunn EM, Guzei IA, Yu L. Does crystal density control fast surface crystal growth in glasses? A study with polymorphs. Cryst Growth Des. 2011;11:3979–84.

Bhugra C, Shmeis R, Pikal MJ. Role of mechanical stress in crystallization and relaxation behavior of amorphous indomethacin. J Pharm Sci. 2007;97:4446–58.

Ozawa T. Critical investigation of methods for kinetic analysis of thermoanalytical data. J Therm Anal. 1975;7:601–17.

Sun CC, Grant DJW. Compaction properties of L-lysine salts. Pharm Res. 2001;18:281–6.

Sun CC. Mechanism of moisture induced variations in true density and compaction properties of microcrystalline cellulose. Int J Pharm. 2008;346:93–101.

Acknowledgments & DISCLOSURES

We thank Boehringer-Ingelheim Pharmaceuticals Inc, Ridgefield, CT for financial support to this work. Some of the experiments were performed at the University of Minnesota I.T. Characterization Facility, which receives partial support from the NSF through the NNIN program.

Author information

Authors and Affiliations

Corresponding author

Electronic Supplementary Materials

Below is the link to the electronic supplementary material.

Supplementary information

(DOC 5448 kb)

Rights and permissions

About this article

Cite this article

Chattoraj, S., Bhugra, C., Telang, C. et al. Origin of Two Modes of Non-isothermal Crystallization of Glasses Produced by Milling. Pharm Res 29, 1020–1032 (2012). https://doi.org/10.1007/s11095-011-0644-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11095-011-0644-x