Abstract

Paralinear oxidative behavior, i.e., concurrent parabolic scale growth (kp) and linear scale volatility (kl or kv), was analyzed by an alternative to the Tedmon equation. A convenient COSP for Windows cyclic oxidation program analyzed published data for Cr, NiCr, Pb, SiC, Si3N4, and BN. All of these exhibit scale volatility due to CrO3, CrO2(OH)2, PbCl2, Si(OH)4, or HBO2. The ‘cyclic’ model used an iterative constant outer layer loss formalism, whereby a normalized spall constant, Q0 /Δt, defined the scale volatility rate, kl (or kv). Optimized trial inputs (fitting maximum mass gain (ΔWmax at tmax) and time to reach ΔW = 0) generated accurate kp and kl values. COSP models replicated ideal paralinear form. Simple approximations for kp and kl are also found as ~ 4.1 (ΔWmax2/ tmax) and ~ 1.2 (ΔWmax/tmax), respectively, for most scales. Alternatively, ΔWmax and tmax can be predicted by kp and kl. High or low volatility extremes (e.g., burner tests, short times, or Al2O3 scales) may mask classic paralinear weight change features.

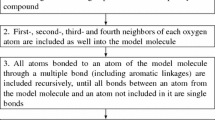

Similar content being viewed by others

Data Availability

The raw/processed data required to reproduce these findings cannot be shared at this time due to technical or time limitations.

Abbreviations

- k p :

-

Parabolic growth rate, gas (oxidant) reacted (mg2/cm4h)

- k l (or k v):

-

Linear volatility rate of scale (oxide) removed (mg/cm2h)

- α :

-

Spall exponent, set to -1 in COSP algorithm: Δwspall = Q0(Δwretained)(α+1)

- Q 0 :

-

‘Spall constant,’ set here for constant differential scale removal (mg/cm2)

- Δ t :

-

‘Cycle’ duration, defined here as a differential time increment (h)

- S, S eff :

-

Stoichiometric constant, MW ratio of scale to gas (e.g., oxide/(oxygen-C or N))

- γ :

-

Stoichiometric constant, MW ratio of scale to compound (e.g., oxide/carbide)

- Δ W, Δ W max :

-

Specific net weight change of substrate, or weight at maximum (mg/cm2)

- t max, t 0 :

-

Time to reach maximum or zero weight change, (h)

- T.S.:

-

Terminal negative slope (final, steady state; mg/cm2h)

References

C. S. Tedmon, The effect of oxide volatilization on the oxidation kinetics of Cr and Fe-Cr alloys. J. Electrochem. Soc. 113, 1966 (766). https://doi.org/10.1149/1.2424115.

E. J. Opila, Oxidation and volatilization of silica-formers in water vapor. J. Am. Ceram. Soc. 86, 2003 (1238–1248). https://doi.org/10.1111/j.1151-2916.2003.tb03459.x.

E. J. Opila and R. E. Hann, Paralinear oxidation of CVD SiC in water vapor. J. Am. Ceram. Soc. 80, 1997 (197–205). https://doi.org/10.1111/j.1151-2916.1997.tb02810.x.

E. J. Opila and N. S. Jacobson, SiO(g) formation from SiC in mixed oxidizing-reducing gases. Oxid. Met. 44, 1995 (527–544). https://doi.org/10.1007/BF01051042.

C.A. Barrett, A.F. Presler, COREST: a FORTRAN computer program to analyze paralinear oxidation behavior and its application to chromic oxide forming alloys, Cleveland, OH, 1976. https://ntrs.nasa.gov/citations/19760010136.

D. S. Fox, E. J. Opila, Q. G. N. Nguyen, D. L. Humphrey, and S. M. Lewton, Paralinear oxidation of silicon nitride in a water-vapor/oxygen environment. J. Am. Ceram. Soc. 86, 2003 (1256–1261). https://doi.org/10.1111/j.1151-2916.2003.tb03461.x.

N. Jacobson, S. Farmer, A. Moore, and H. Sayir, High-temperature oxidation of boron nitride: I, monolithic boron nitride. J. Electrochem. Soc. Soc. 82, 1999 (393–398). https://doi.org/10.1111/j.1551-2916.1999.tb20075.x.

B. Pujilaksono, T. Jonsson, M. Halvarsson, I. Panas, J. E. Svensson, and L. G. Johansson, Paralinear oxidation of chromium in O2+H2O environment at 600–700 °C. Oxid. Met. 70, 2008 (163–188). https://doi.org/10.1007/s11085-008-9114-1.

H. Asteman, J.-E. Svensson, M. Norell, and L.-G. Johansson, Influence of water vapor and flow rate on the high-temperature oxidation of 304l; effect of chromium oxide hydroxide evaporation. Oxid. Met. 54, 2000 (11–26).

R. Peraldi, and B. A. Pint, Effect of Cr and Ni contents on the oxidation behavior of ferritic and austenitic model alloys in air with water vapor. Oxid. Met. 61, 2004 (463–483). https://doi.org/10.1023/B:OXID.0000032334.75463.da

D. J. Young and B. A. Pint, Chromium volatilization rates from Cr2O3 scales into flowing gases containing water vapor. Oxid. Met. 66, 2006 (137–153). https://doi.org/10.1007/s11085-006-9030-1.

C. E. Lowell, C. A. Barrett, R. W. Palmer, J. V. Auping, and H. B. Probst, COSP: a computer model of cyclic oxidation. Oxid. Met. 36, 1991 (81–112). https://doi.org/10.1007/BF00938457.

J.L. Smialek, Relative Ti2AlC scale volatility under 1300 °C combustion conditions, Coatings. 10 (2020). doi:https://doi.org/10.3390/coatings10020142.

J. L. Smialek and J. V. Auping, COSP for windows - strategies for rapid analyses of cyclic-oxidation behavior. Oxid. Met. 57, 2002 (559–581). https://doi.org/10.1023/A:1015308606869.

D. Wajszel, A method for calculating paralinear constants for the formation of volatile scale. J. Electrochem. Soc. 110, 1963 (504–507). https://doi.org/10.1149/1.2425801.

S. Wu, S. Ma, Y. Chen, B. Cao, and G. Zhang, Paralinear oxidation of Cr-Si-C-Coated C/SiC at 1300°C in wet and dry air environments. Jom. 72, 2020 (361–367). https://doi.org/10.1007/s11837-019-03841-w.

P. Berthod, Kinetics of high temperature oxidation and chromia volatilization for a binary Ni-Cr alloy. Oxid. Met. 64, 2005 (235–252). https://doi.org/10.1007/s11085-005-6562-8.

R. C. Robinson and J. L. Smialek, SiC recession caused by SiO2 scale volatility under combustion conditions: I, experimental results and empirical model. J. Am. Ceram. Soc. 82, 1999 (1817–1825). https://doi.org/10.1111/j.1151-2916.1999.tb02004.x.

I. Yuri, T. Hisamatsu, Recession rate prediction for ceramic materials in combustion gas flow, in: Am. Soc. Mech. Eng. Int. Gas Turbine Institute, Turbo Expo IGTI, ASME, 2003: pp. 633–642. doi:https://doi.org/10.1115/GT2003-38886.

E. J. Opila, J. L. Smialek, R. C. Robinson, D. S. Fox, and N. S. Jacobson, SiC Recession caused by SiO2 scale volatility under combustion conditions: II, thermodynamics and gaseous diffusion model. J. Am. Ceram. Soc. 82, 1999 (1826–1834). https://doi.org/10.1111/j.1151-2916.1999.tb02004.x.

J. L. Smialek, Kinetic aspects of Ti 2 AlC MAX phase oxidation. Oxid. Met. 83, 2015 (351–366). https://doi.org/10.1007/s11085-015-9526-7.

Q. N. Nguyen, C. W. Bauschlicher, D. L. Myers, N. S. Jacobson, and E. J. Opila, Computational and experimental study of thermodynamics of the reaction of Titania and water at high temperatures. J. Phys. Chem. A. 121, 2017 (9508–9517). https://doi.org/10.1021/acs.jpca.7b08614.

E. J. Opila and D. L. Myers, Alumina volatility in water vapor at elevated temperatures. J. Am. Ceram. Soc. 87, 2004 (1701–1705). https://doi.org/10.1111/j.1551-2916.2004.01701.x.

Y. Chen, T. Tan, and H. Chen, Oxidation companied by scale removal: Initial and asymptotical kinetics. J. Nucl. Sci. Technol. 45, 2008 (662–667). https://doi.org/10.1080/18811248.2008.9711466.

W. C. Hagel, Factors affecting the high temperature oxidation of Cr. ASM Trans. Q. 56, 1963 (583–599).

Acknowledgements

The author appreciates many helpful discussions with N.S. Jacobson. J. Auping is gratefully acknowledged for creating the versatile COSP for Windows program that enabled this study. The scale volatility fundamentals covered herein had received sustained support from the Fundamental Aeronautics Program at the NASA Glenn Research Center and many contributions from the environmental durability team.

Funding

This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors.

Author information

Authors and Affiliations

Contributions

JLS explored the concept, applied it to existing paralinear data sets, reviewed the literature, and wrote the paper.

Corresponding author

Ethics declarations

Conflict of interest

The author declares no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

James L. Smialek—Retired, NASA Glenn Research Center.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Appendices

Appendix 1

Analytical Predictions for Paralinear Features

\(\overline{W}\)= ΔWmax at maximum weight gain and \(\overline{t}\)= tmax (at maximum weight gain) in COSP) can be obtained from the original paralinear solution espoused by Wajszel[15], as utilized by Barrett/Presler [5]

And where, from Barrett/Pressler,[5] p.3:

with stoichiometric ratios for gas and metal reactants in the scale:

Using these conversions and kp, kl(or v) from the published paralinear and fitted COSP parameters, ΔWmax and tmax are calculated and compared in Table 3.

Lastly, the terminal or final slope can be obtained from kl(v), as stated in Eq. 4:

where γ is the MW scale/MW compound stoichiometric ratio. Thus, the steady-state slopes of the weight change curve predicted from scale volatility rates are shown for the published paralinear and fitted COSP kl(v) in Table 3.

Also, the A, B, a, b Wajszel parameters above are used to obtain conventional paralinear kp, kl(v) for Pb/PbCl2 in Table 2 according to:

A = 4.2E-11 g2/cm4/s | = 0.1512 | mg2/cm4h |

B = 2.8E-9 g/cm2/s | = 0.01008 | mg/cm2h |

kp = 2A/a2 | = 0.0356 | mg2/cm4h |

kl,v) = bB/a | = 0.0135 | mg/cm2h |

a = metal/gas (MW) | = 2.922 | |

b = scale/gas (MW) | = 3.922 |

In general, the paralinear rate constants can also be determined from knowing the stoichiometric factor b of the oxide, (S or Seff), and the data point coordinates at maximum (ΔWmax, tmax). By combining Eqs. 11–16, one obtains the paralinear rate constants as simple functions of the coordinates at maximum:

The stoichiometric factor coefficients, Fp and Fv, preceding the max point quotients are tabulated in Table 4. A regular progression of model oxide stoichiometries and those for a selection of actual oxides are listed (for S only, not Seff). It is found that the Fp and Fv factors remain relatively tight over the range considered in the present analyses. An average factor of Fp ~ 4.1 ± 1.1% is obtained for the parabolic rate constant, kp in Eq. 18, and Fv ~ 1.2 ± 7.5% for the linear volatility constant, kv in Eq. 19. More precisely, Fp and Fv are equal to 4.13 and 1.28, respectively, for low MW oxides with S ≤ 3 and equal to 4.01, 1.07 for high MW oxides with S ≥ 3. The overall consistency of both Eqns. 18 and 19 relations is displayed in Figs. 11 and 12 for all the cases examined. A log–log presentation was used to illustrate details across the full range of paralinear parameters examined. It is seen that the dependencies do not differ appreciably between relations using exact and average F coefficients. The average and precise Fp data points are seen to essentially coincide in Fig. 11, whereas the average and precise Fv data points sometimes show minor vertical offsets in Fig. 12. Furthermore, these F factors do not vary at all with kp or kl. Regression analyses of these model cases (log–log plots) yielded:

thus, verifying that kp and kv are linearly equivalent to and can be reasonably estimated from \({F}_{\mathrm{p}}\frac{{\Delta W}_{\mathrm{max}}^{2}}{{t}_{\mathrm{max}}}\) and \({F}_{\mathrm{v}}\frac{{\Delta W}_{\mathrm{max}}}{{t}_{\mathrm{max}}}\), respectively. While these were generated from model COSP curves, they also apply to experimental data, insofar as the data reflect ideal behavior, Figs. 7 and 8.

More specifically, the paralinear analysis of Cr oxidized in O2-10%H2O (e.g., CrO2(OH)2) was shown to produce rate constants as a function of ΔWmax and tmax (Pujilaksono et al.) [8]. The derivations were constructed using thickness parameters, so direct comparisons with weight change curves were indirect and problematic. Thus, the data summarized in Table 5, indicating max data point coordinates from plots and rate parameters, are shown both as-reported and converted to various units. Conversion of scale volatility from thickness to weight could be made easily using the density of the Cr2O3 scale, ~ 5.22 g/cm3. Linear volatility, labeled ks, was converted and equivalent to kl (kv). But conversion of scale growth is less transparent in that the accrued weight is only from oxygen gain, whereas the scale thickness is composed of Cr2O3. Thus, the conversion of parabolic growth, labeled kd, then k´´, to traditional kp for weight change was not readily apparent. The same conversion factor, implied for kd conversion to k´´ from the data obtained in dry air, was therefore used. The final results for kl (kv) and kp in mg/cm2h and mg2/cm4/h are seen to agree within 10–15% of those obtained by typical COSP analyses. The relative discrepancies are likely due in part to the extremely low values of overall weight change and low values of tmax.

Appendix 2

COSP and the Tedmon Study

The original Tedmon paralinear study [1] derived the analytical, transcendental solution and compared it to experimental data for Fe–Cr and Cr alloys. The data were presented as log (weight gain) vs log (time), or weight change vs log (time). These are less-familiar presentations than typical weight change vs time linear plots. Such data are shown for Cr-0.2%Y, Fig.

Comparisons for paralinear and COSP fits to ΔW/A vs log t results for Cr-Cr2O3 oxidation at 1200 °C (Tedmon [1]). COSP Model #3 is a better fit for most long-time data (> 30–280 h). Model #4 (~ Tedmon curve) fits better for short times (1–10 h): (1) solid, black: parabolic: kp = 0.54 mg2/cm4/h, also used in #4, #5. (2) Large circles, blue: experimental data points. (3) Small circles, teal: data matched at Δw(max), Δw(final) using kp = 0.34 mg2/cm4/h, kv = Q0 /Δt = 0.0273 mg/cm2/h. (4) Long dash, blue: Tedmon analytical curve matched, but using kv = Q0 /Δt = 0.048 mg/cm2/h. (5) Short dash, red: using kv = Qo /Δt = 0.058 mg/cm2/h from [Hagel, 1966][25], but curve underestimates data

13. The weight gain data exhibit a maximum, then decrease in units of mg/cm2 vs log time (s). Parabolic kinetics were extracted from the initial portion of the curve, then combined with kv from the Hagel 1963 volatility study for bulk Cr2O3: [25]

The calculated paralinear curve shown was similar in form but did not fit the data closely. Unlike the data, the curve produced a lower maximum in weight gain, at shorter times, and approached 0 mg/cm2 at the end of test.

Appropriate COSP model curves are provided in a similar mg/cm2 vs log time (s) format, Fig. 13. They were based on Tedmon/Hagel parameters or specific characteristics of the plots in Tedmon [1], with stoichiometric factors given in Table 1. The shape of the COSP model curves is consistent with the Tedmon plot, but the characteristic parameters show some discrepancies. The results are summarized in Table

6. Curve 1 just represents parabolic growth with no volatility based on the initial portion of the curve. Curve 2, open circles, is the original data. Curve 3 (small, filled circles, teal) is the best COSP fit to the experimental data, but with lower kp = 0.34 mg2/cm4h and kv = 0.0273 mg/cm2h than those stated in Tedmon. COSP curve 4, large dash, blue) matched the paralinear curve in Tedmon, but needed kv = 0.048 mg/cm2h; and the lowest curve 5, small dash, red) used the kp and kv prescribed by Tedmon (0.540 mg2/cm4h, 0.058 mg/cm2h), which underpredicts the data.

This suggests inconsistencies in the original analysis. It appears that the experimental data correspond to slightly lower kp and kv parameters:

-

(1)

An effective reduction in kp can be generated by cubic-linear behavior, where grain growth over time simultaneously decreases scale growth controlled by short circuit paths. This produces subparabolic behavior. Attempts at a COSP cubic-linear fit produced an improved fit but did not match the entire curve, nor did the ‘perturbation’ solution offered by Chen et al., in their Fig. 5[24]. Barrett and Presler [5] found best fits for the Tedmon kp to vary from 0.29 to 0.44 mg2/cm4h, depending on the portion of the curve being fit, in general agreement with present findings (0.34 mg2/cm4h).

-

(2)

The kv for the scale may be different than that measured by Hagel for bulk Cr2O3 [25]. This can occur for test conditions containing different gas flow rates or moisture content, both of which affect kv. With little experimental detail available, no further speculation is offered. The COSP model curves parallels the Tedmon plot but implies kp and kv parameters ~ 50% less than those quoted. Barrett and Presler [5] found best fits for the Tedmon kv to vary from 0.023 to 0.034 mg/cm2h, depending on the portion of the curve being fit, in general agreement with present findings (kv = 0.027 mg/cm2h).

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Smialek, J.L. Simplified Paralinear Oxidation Analyses. High Temperature Corrosion of mater. 99, 431–457 (2023). https://doi.org/10.1007/s11085-023-10156-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11085-023-10156-4