Abstract

In this work, the fabrication of undoped ZnO (ZO) and 3 at.% aluminum (Al) doped ZnO (AZO) thin films (TFs) based transparent photodetectors (PDs) was reported. Both films were spin-coated on fluorine-doped tin oxide (FTO) substrates to investigate the influence of Al doping on the ultraviolet (UV) detection performance of the devices. The systematic characterizations reveal that Al doping positively affects the characteristics of ZO-TFs. The Al doping leads to slight shift in crystalline peaks and induces an enhancement in grain size. In addition, the surface roughness of ZO-TFs gets lower on Al doping. Further, the Al doping improved the transparency and widening of band gap of TFs. The PDs having metal–semiconductor-metal (MSM) configuration were achieved by screen-printing of Ag paste onto ZO and AZO-TFs. The current–voltage (I-V) profiles of the fabricated PDs were measured in the dark and under UV excitation of 365 nm. The AZO-TFs based MSM PD exhibits a spectral responsivity of 326.82 mA/W and an external quantum efficiency of 111.03%. The reproducibility of the fabricated PDs was tested by performing time-dependent photo-response measurements.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Metal oxide semiconductors are captivating materials for fabricating a wide range of devices, including phototransistors, photodetectors, photovoltaic cells, gas sensors, etc. (Lee et al. 2020; Patel et al. 2015; Ozel and Yildiz 2021a). Of all the metal oxide semiconductors, ZnO is the most enthralling n-type material with its outstanding optoelectrical properties along with its high stability (Fortunato et al. 2008; Atilgan et al. 2023). Taking advantage of eligibility to work in the UV region owing to its wide band gap, ZO TFs have been extensively utilized in UV PD applications. UV PDs can be used in various application areas, including chemical sensing, communication, light sensing, national defense, etc. (Al Fattah et al. 2021; Li et al. 2013). Comparing their counterparts, ZO-TFs-based UV PDs demonstrate advantageous characteristics due to combination of desirable properties such as high absorption, excellent stability, favorable carrier mobility, etc. (Ozel 2024).

Up to now, different types of UV PDs, such as Schottky barrier, p–n junction, metal–semiconductor-metal (MSM), etc. have been reported based on ZO-TFs (Lee et al. 2019; Ozel and Yildiz 2022; Das et al. 2020). Amongst them, MSM-based UV PDs have garnered vast interest because of fabrication simplicity, scalability, and low manufacturing cost (Shan et al. 2009; Ali and Chakrabarti 2010). To fabricate MSM-based UV PDs, metal oxide TFs can be deposited on polymeric substrates, glass slides, sapphire substrates, silicon wafers, transparent conductive oxide materials, etc. (Liu et al. 2010). Previously reported works of ZO-TFs-based MSM UV PDs emphasize that tuning the properties of ZO-TFs can play a determining role in the detection performance of the fabricated UV PDs (Rosli et al. 2020). In this regard, it can be considered that doping will be an effective technique to increase the performance of MSM-based UV PDs. Numerous investigations have been conducted on ZO-TFs with various elements such as In, Ga, B, Co, Sn, etc. (Serin et al. 2011a; Sbeta et al. 2018a; Yildiz et al. 2016). Specifically, Al-doped ZO (AZO)-TFs are collecting significant attention because of their high transparency and low electrical resistivity (Ozel 2024). In addition, the ionic radius of Al (0.054 nm) is smaller than that of Zn (0.074 nm), hence Al3+ ions substitute the site of Zn2+ in the lattice of ZnO (Suwanboon et al. 2008). Therefore, one can expect that Al doping amends the optoelectrical features of ZO-TFs by providing additional electrons.

The development of transparent PDs is of utmost importance for fabricating state-of-the-art sensors and “see-through” optoelectronics. In the last decade, diligent efforts have been made to develop transparent PDs exhibiting high performance. Recently, many researchers have adapted transparent PDs to special applications, including 3D cameras, multispectral photodetectors, UV communication systems etc. (Ma et al. 2023). The PDs having transparency over 70% can be called transparent PDs. To achieve high performance, these devices satisfy both high transparency and large responsivity (Fang et al. 2019; Abbas et al. 2018).

Compared with traditional opaque PDs, transparent PDs required for special applications have been less reported. Thanks to the existence of high-density carriers and low-density defect states, large band gap values, higher electrical conductivity, superb optical property, and lower conduction band offset, AZO TFs-based devices are highly responsive to UV light. Therefore, AZO TFs are well suited to the design of transparent PDs functioning in different UV ranges (Kumar et al. 2020; Singh 2016; Mamat et al. 2012; Inamdar et al. 2015). Herein, we reported an inexpensive and simple manufacturing way for manufacturing of transparent PDs. Simply, the ZO and AZO TFs were coated on FTO substrates to fabricate UV PDs using the spin-coating method, and then Ag metal contacts were formed on TFs through shadow mask. Ultimately, ZO and AZO-based UV PDs were manufactured in MSM architecture. The effect of Al doping on the characteristics of TFs and MSM-based UV PDs was analyzed and discussed.

2 Experimental

The undoped (ZO) and 3 at.% Al doped ZnO (AZO) TFs were spin coated on FTO substrates. The solutions for ZO and AZO TFs were prepared by dissolving 0.2 M of zinc acetate and 3 at.% of aluminum nitrate in ethanol, and then ethanolamine was added as a stabilizer (Atilgan et al. 2023). After stirring for 2 h at 60 °C, the homogenous mixtures were obtained as the resultant spin-coating solutions. The spin-coating process was carried out by dispersing the solution onto the precleaned FTO substrates with a spin-coating speed of 2000 rpm. After coating the ZO and AZO solutions, the samples were heated at 350 C for 5 min. The heating and coating cycles were repeated five times, and then the samples were annealed at 500 °C for 1 h. To complete the MSM structured devices, Ag paste was screen-printed on TFs to form metal contacts through shadow mask. Figure 1 demonstrates the schematic illustration of ZO and AZO-based MSM UV PDs.

X-ray diffractometer (XRD) (Rigaku Miniflex 600) with Cu Kα (λ = 0.154 nm) was utilized to characterize the crystalline structure of ZO and AZO TFs. The surface topographies of ZO and AZO TFs were investigated by atomic force microscopy (AFM) equipment. Morphological characterizations were accomplished by scanning electron microscopy (SEM) (Hitachi SU5000). The elemental composition was determined by energy dispersive spectroscopy (EDS) (Oxford X-MaxN 80). The electrical properties of the films were characterized by using a four-point probe measurement system (Lucas Labs Pro-4). The optical transmittance profiles of TFs were determined by UV–Vis-IR spectrophotometer (Shimadzu 1700). Electrical characterizations of the devices were investigated at room temperature employing Keithley-2400 source meter. The photo-response spectra of MSM-based UV PDs were collected under on/off switching of the UV light source (365 nm) using a photo-response characterization system.

3 Results and discussion

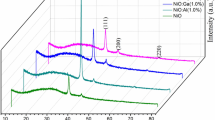

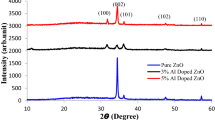

Figure 2 represents X-ray diffractograms of the ZO and AZO TFs coated on FTO substrates. Both the ZO and AZO TFs have a wurtzite structure showing a preferential orientation along (002) plane (Artegiani et al. 2019). According to XRD patterns, the crystal phase of ZO is not affected by Al doping and no additional peaks coming from aluminum are appeared for AZO-TF, suggesting Al ions have successfully substituted the Zn ions in hexagonal lattice (Shewale et al. 2015). As observed, the intensity of (002) peak diminished after Al doping and slightly shift to lower angles has been observed because of the difference in ionic radius of Al and Zn. On the other hand, it is also noticed that the value of full width at half maximum (FWHM) is reduced by Al doping, implying that Al incorporation in ZnO leads to an improvement in crystallinity. From the data of (002) peak, one can calculate the average crystalline size by utilizing the Debye Scherrer equation (Serin et al. 2011b). Once the crystalline size is known, the dislocation density can be determined to evaluate the quantity of defects in the films (Williamson and Smallman 1956). The values of the average crystalline size and the dislocation density are found to be 27.38 nm and 1.334 × 1015 lines/m2 for ZO TF, and 27.71 nm and 1.302 × 1015 lines/m2 for AZO TF, respectively.

Figure 3a, b demonstrates the AFM images of the ZO and AZO TFs coated on FTO substrates. From AFM images, the root-mean-square roughness (rms) values of the samples are determined to be 24.4 nm and 22.5 nm for the ZO and AZO TFs, respectively, indicating that the surface structure has somehow affected by Al incorporation in ZnO lattice. Chen et al. (Chen et al. 2011) reported the similar smoothing observation for Ti doped ZnO films. Obviously, the AZO TF is comparatively more uniform and smoother surface, which probably contributes to improve the transparency of the film by reducing the surface scattering (Ozel et al. 2024).

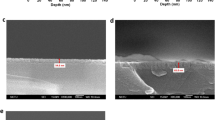

Figure 4a, b presents the top-view SEM images of the ZO and AZO TFs, respectively. As seen from the images, both films have uniform surface without any crack and well-packed granular morphology. In line with the XRD and AFM results, the surface structure of ZO film has slightly influenced by Al doping owing to the strain induced in hexagonal ZnO lattice. As mentioned in XRD and AFM findings, the grain size is increased, and the smoothened surface is observed. It is noteworthy to say that larger grain size and smoother surface are demanded to provide improved optical and electrical properties in TF-based devices (Thirumoorthi and Prakash 2015).

The typical EDS spectrum of the AZO TF deposited on FTO substate is illustrated in Fig. 5. The observed spectrum displays the presence of Sn, O, Zn, Al, and C elements, which ensures the nonexistence of any other elements in the deposited TFs. Nonetheless, the Sn element originates from the FTO substrate, while the signal of C probably come from the environmental influences and contaminations in the manufacturing process. In addition, EDS spectrum confirms the insertion of Al into ZnO lattice.

The optical transmittance spectra of the ZO and AZO TFs coated on FTO substrates are shown in Fig. 6. The average transmittance for wavelength range of 400–800 nm of the samples is found to be 74.23% and 82.38% for the ZO and AZO TFs, respectively. The observed results demonstrate that transmittance values of the films are sufficiently high to fabricate transparent devices. The improved transmittance of the AZO TF might be ascribed to the smoother and compact surface of this sample with respect to the ZO TF. To determine the influence of Al doping on the band gap size (\(E_g\)) values of the films, the plots of \(\left( {\alpha h\upsilon } \right)^2\) as a function of \((h\upsilon )\) is presented in the inset of Fig. 6. The \(E_g\) values are found to be 3.24 eV for the ZO TF and 3.28 eV for the AZO TF. As observed, a blue shift in \(E_g\) value of the AZO TF is obtained after doping ZnO with Al dopant. The broadening in \(E_g\) value is explained by the change of Fermi level after doping of Al (Jun et al. 2012; Benzarouk et al. 2012). In addition, the blue shift in \(E_g\) with Al doping can be investigated by Urbach energy calculation (Benhaoua et al. 2014). The Urbach energy plot (inset of Fig. 6) can give information about the excess disorders presented in the film, creating localized trap states. Based on the Urbach rule, the absorption coefficient \(\alpha \left( \upsilon \right)\) is exponentially related to the incident photon energy and this relationship is defined by the formula (1) (Ghosh et al. 2019):

where \(E_u\) stands for the Urbach energy calculated from the slope of the Urbach energy plot. \(\alpha_0\) and \(E_0\) refer to the characteristic constants. The \(E_u\) values are computed to be 0.53 and 0.42 eV for the ZO and AZO TFs, respectively. The decrement in \(E_u\) for AZO TF suggests the presence of a lower amount of intrinsic defects, which demonstrates that the recombination probability of charge carriers is reduced (Mondal et al. 2021).

The figure of merit (FOM) is considered as a numerical metric to assess the quality of thin films in terms of electrical and optical properties (Jalal et al. 2024). To calculate the FOM values of the investigated films, the sheet resistance (Rsh) values of ZO and AZO TFs are needed to be determined using the following Eq. (2) (Sbeta et al. 2018b):

where, 4.532, V and I stand for the correction factor, measured voltage, and current passing through the TFs, respectively. Based on the determined Rsh values, the FOM values of the films are calculated using the formula of \(FOM = - 1/\left[ {R_{sh} \ln (T)} \right]\) (Sbeta et al. 2018b). The FOM values are found to be 0.428 µΩ−1 and 0.705 µΩ−1 for ZO and AZO TFs, respectively. A larger value of FOM notifies that AZO sample has better quality in point of electrical conductivity and optical characteristic (Rezaie et al. 2017).

The current–voltage (I-V) profiles of the ZO and AZO-TFs based MSM PDs are measured in the dark and under UV excitation of 365 nm. Figure 7 manifests the dark (\(I_{dark}\)) and photocurrent (\(I_{photo}\)) curves of the ZO and AZO-TFs based MSM PDs from − 5 to 5 V, from which one can notice that the fabricated MSM PDs have nearly symmetrical behavior, confirming the formation of ohmic contacts between Ag metal and the ZO and AZO-TFs. Note that the formation of ohmic contacts is desirable for enhanced device performance (Hu et al. 2012). Also, it is concluded that symmetric and linear I-V characteristics of the samples indicate the presence of the same Schottky barrier height (SBH) at two contacts of Ag/ZO or AZO/Ag. Upon UV exposure (365 nm, 0.5 mW/cm2), one can observe that the photocurrent values of both samples are greater than the dark current values. Specifically, the remarkable enhancement in photocurrent values of the AZO-TFs based MSM PD is presumably stemmed from the increased carriers owing to the substituting of Al ions into Zn cations (Shinde et al. 2015). In addition, the increased slope value of the I-V profile for the AZO-TFs based MSM PD suggests the reduced electrical resistivity.

The specific responsivity (\(R_\lambda\)), detectivity (D*) and external quantum efficiency (EQE) are important parameters for quantifying the photodetection performance of the PDs. The specific responsivity is defined as a ratio of the photocurrent yielded per unit of the intensity of optical light power. The D* characterizes the competency of PD to detect the illuminating light. The EQE appraises the number of electron–hole pairs photo-induced by per absorbed photon. The values of \(R_\lambda\), D*, and EQE are evaluated by the following Eqs. (3)–(5) (Ozel and Yildiz 2021b):

where A, q, h, c, \(P_{in}\) and λ stand for the effective area, charge of electron, Planck’s constant, light velocity, power intensity and wavelength of incident light, respectively. Consequently, the \(R_\lambda\), D* and EQE values are found to be 126,08 mA/W, 1.64 × 1010 Jones, 42.83% for the ZO-TF based MSM PD, 326,82 mA/W, 4.16 × 1010 Jones, 111.03% for the AZO-TF based MSM PD. As seen, the estimated parameters of AZO-TF based MSM PD are much higher than that of undoped device. Such improvements might be ascribed to the high optical transparency, low electrical resistivity as well as improved crystallinity (Shewale et al. 2015). Moreover, it can be said that the photoexcitation facilitates by the electrons introduced to the defect levels with doping process, resulting in ameliorated photocurrent.

The working mechanism of the fabricated PDs is shown in Fig. 8a, b. The valence band and conduction band of ZnO are − 4.2 and − 7.6 eV with respect to vacuum, respectively (Norouzi et al. 2016). It is reported that both the valence band and conduction band edge of ZnO move downwards after Al doping (Sun et al. 2019). The electron affinity (χ) of ZnO and AZO is ~ 4.2 eV and ~ 4.6 eV (Lahmar et al. 2016). Park et al. examined the conduction band offset \((\Delta E_{CB} )\) values of pure ZnO and various concentrations (1,3,4,8 and 10 at%) of Al-doped ZnO by x-ray absorption spectroscopy, and reported that the conduction band offset \((\Delta E_{CB} )\) value was 0.16 eV for pure ZnO and decreased to 0.09 eV for 3 at.% Al-doped ZnO (Park et al. 2015). The work function (ɸ) of Ag is 4.26 eV (Wang et al. 2017). Knowing \(\Delta E_{CB}\) values, one can estimate the ɸ values for the ZO or AZO films by utilizing \({{\upphi }}_{ZO or AZO} = \chi_{ZO or AZO} + \Delta E_{CB}\) (Rahman et al. 2020). After the Ag metal contacts are combined with the ZO or AZO absorber layer, the \({{\upphi }}_{Ag} < {{\upphi }}_{ZO or AZO}\) condition is achieved, so an ohmic contact occurs in both cases. When contact is made, the electrons flow from the Ag metal contacts to ZO or AZO until the equilibrium of two layer is formed. Under equilibrium, the depletion layers are generated at the interfaces of Ag contacts and ZO or AZO layer. In addition, the bending of energy bands is established due to the difference in work function (ɸ) values of Ag metal and ZO or AZO. When the incident light with energy higher than the \(E_g\) of ZO or AZO absorber layer impinges on the designed MSM PDs, the photo-induced carriers (electron–hole pairs) are generated in the ZO or AZO absorber layer. If the photo-induced carriers are separated by inherent electric field at the interfaces of Ag metal contacts and ZO or AZO layer, the photocurrent starts to flow through an external circuit of the fabricated MSM PDs (An et al. 2017).

Compared to its undoped counterpart, AZO based MSM PD exhibits a considerable performance, which can be attributed to the following: (i) It is worth emphasizing that the properties of semiconductor layer play a determining role in the performance of MSM based optoelectronic devices. In our case, the higher FOM value of AZO sample due to the improved crystallinity and low resistivity indicates its higher quality in point of both optical and electrical characteristics. (ii) The decrease in Urbach energy for AZO based device points out the lessening of intrinsic defects, thereby reducing the likelihood of recombination of charge carriers. This results in an enhancement in photocurrent. (iii) The ascent in concentration of mobile electrons provided by Al doping leads to the improvement of photocurrent and responsivity as well. (iv) As seen from Fig. 8b, there is a relatively larger difference between the work function of Ag contact and AZO with respect to one between Ag contact and ZO layer, which facilitates electron transport, also boosting photocurrent.

To further determine the response speed of the ZO and AZO-TFs based MSM PDs, the real-time photoresponse characteristics of the devices are studied under on/off switching illumination. Figure 9 demonstrates the four-repeat current–time (I-t) cycles of the samples. It can be concluded that the fabricated devices exhibit excellent reproducibility with high stability. The values of rise time (\(\tau_r\), the time interval for the photocurrent value to change from 10 to 90%) and the decay time (\(\tau_d\), the time interval for the photocurrent value to change from 90 to 10%) are estimated to be 0.153 s and 0.215 s, respectively, for the ZO-TF based MSM PD and 0.134 s and 0.151 s, respectively, for the AZO-TF based MSM PD. Understandably, the fast photoresponse speed of the AZO-TF based device could be associated with the improved electrical characteristics after Al doping.

In summary, the findings reveal that AZO-TFs based MSM PD exhibits superior performance over ZO-TFs based MSM PD. Table 1 demonstrates the performance parameters and properties of the fabricated AZO-TFs based MSM PD together with the reported ones. As observed, our device offers high performance with facile fabrication. Basically, it can be inferred that the properties of absorber layer of MSM based PDs strongly affect the photodetection performance. Ultimately, it can be said that the enhanced structural, optical, and electrical properties of AZO-TFs endow the AZO-TFs based MSM PD with high performance.

4 Conclusion

In summary, the ZO and AZO-TFs have been deposited on FTO substrates by cost-effective spin coating process. After formation of metallic Ag electrodes, the UV detection performance of the designed MSM based structures were investigated. XRD patterns show that the crystal phase of ZO is not affected by Al doping and no additional peaks coming from aluminum are appeared for AZO-TF, suggesting Al ions have successfully substituted the Zn ions in hexagonal lattice. AFM results show that the AZO TF is comparatively more uniform and smoother surface, indicating the surface structure has somehow affected by Al incorporation in ZnO lattice. UV–Vis records reveal that the transparency of the AZO TF is improved after doping. Eventually, the AZO-TF based MSM PD exhibits \(R_\lambda\) of 326.82 mA/W, D* of 4.16 × 1010 Jones, EQE of 111.03% with decent photoresponse speed of 0.134 s.

Data availability

No datasets were generated or analysed during the current study.

References

Abbas, S., Kumar, M., Kim, J.: All metal oxide-based transparent and flexible photodetector. Mater. Sci. Semicond. Process. 88, 86–92 (2018)

Abbasi, F., Zahedi, F., Yousefi, M.H.: Performance improvement of UV photodetectors using Cd-doped ZnO nanostructures. J. Mater. Sci. Mater. Electron. 32(14), 19614–19625 (2021)

Al Fattah, M.F., Khan, A.A., Anabestani, H., Rana, M.M., Rassel, S., Therrien, J., Ban, D.: Sensing of ultraviolet light: a transition from conventional to self-powered photodetector. Nanoscale 13(37), 15526–15551 (2021)

Ali, G.M., Chakrabarti, P.: ZnO-based interdigitated MSM and MISIM ultraviolet photodetectors. J. Phys. D Appl. Phys. 43(41), 415103 (2010)

Alshamarti, H.A., Alkhayatt, A.H.O.: Enhancement characterization of the MSM detector based on Mn doped-ZnO NRS synthesized by microwave assisted chemical bath deposition. Mater. Sci. Semicond. Process. 114, 105068 (2020)

An, Q., Meng, X., Xiong, K., Qiu, Y.: Self-powered ZnS nanotubes/Ag nanowires MSM UV photodetector with high on/off ratio and fast response speed. Sci. Rep. 7(1), 4885 (2017)

Artegiani, E., Leoncini, M., Barbato, M., Meneghini, M., Meneghesso, G., Cavallini, M., Romeo, A.: Analysis of magnesium zinc oxide layers for high efficiency CdTe devices. Thin Solid Films 672, 22–25 (2019)

Atilgan, A., Ozel, K., Sbeta, M., Yildiz, A.: Engineering the visible light absorption of one-dimensional photonic crystals based on multilayers of Al-doped ZnO (AZO) thin films. Mater. Sci. Semicond. Process. 166, 107747 (2023)

Benhaoua, B., Rahal, A., Benramache, S.: The structural, optical and electrical properties of nanocrystalline ZnO: Al thin films. Superlattices Microstruct. 68, 38–47 (2014)

Benzarouk, H., Drici, A., Mekhnache, M., Amara, A., Guerioune, M., Bernède, J.C., Bendjffal, H.: Effect of different dopant elements (Al, Mg and Ni) on microstructural, optical and electrochemical properties of ZnO thin films deposited by spray pyrolysis (SP). Superlattices Microstruct. 52(3), 594–604 (2012)

Chen, H., Ding, J., Ma, S.: Violet and blue-green luminescence from Ti-doped ZnO films deposited by RF reactive magnetron sputtering. Superlattices Microstruct. 49(2), 176–182 (2011)

Das, M., Sarmah, S., Barman, D., Sarma, B.K., Sarkar, D.: Distinct band UV–Visible photo sensing property of ZnO-Porous silicon (PS): p-Si hybrid MSM heterostructure. Mater. Sci. Semicond. Process. 118, 105188 (2020)

Fang, H., Zheng, C., Wu, L., Li, Y., Cai, J., Hu, M., Wang, H.: Solution-processed self-powered transparent ultraviolet photodetectors with ultrafast response speed for high-performance communication system. Adv. Funct. Mater. 29(20), 1809013 (2019)

Fortunato, E., Raniero, L., Silva, L., Goncalves, A., Pimentel, A., Barquinha, P., Martins, R.: Highly stable transparent and conducting gallium-doped zinc oxide thin films for photovoltaic applications. Sol. Energy Mater. Sol. Cells 92(12), 1605–1610 (2008)

Ghosh, A., Murkute, P., Lahiri, R., Chakrabarti, S., Chattopadhyay, K.K., Mondal, A.: GLAD synthesised erbium doped In2O3 nano-columns for UV detection. J. Mater. Sci. Mater. Electron. 30, 12739–12752 (2019)

Gordon, R.G.: Criteria for choosing transparent conductors. MRS Bull. 25(8), 52–57 (2000)

Hu, L., Chen, M., Shan, W., Zhan, T., Liao, M., Fang, X., Wu, L.: Stacking-order-dependent optoelectronic properties of bilayer nanofilm photodetectors made from hollow ZnS and ZnO microspheres. Adv. Mater. 24(43), 5872–5877 (2012)

Huang, W.L., Yang, C.C., Chang, S.P., Chang, S.J.: Photoresponses of zinc tin oxide thin-film transistor. J. Nanosci. Nanotechnol. 20(3), 1704–1708 (2020)

Inamdar, S., Ganbavle, V., Shaikh, S., Rajpure, K.: Effect of the buffer layer on the metal–semiconductor–metal UV photodetector based on Al-doped and undoped ZnO thin films with different device structures. Phys. Status Solidi (a) 212(8), 1704–1712 (2015)

Jalal, R., Ozel, K., Atilgan, A., Yildiz, A.: UV photodetectors based on W-doped ZnO thin films. Nanotechnology 35(26), 265705 (2024)

Jun, M.C., Park, S.U., Koh, J.H.: Comparative studies of Al-doped ZnO and Ga-doped ZnO transparent conducting oxide thin films. Nanoscale Res. Lett. 7, 1–6 (2012)

Kumar, C., Kushwaha, B.K., Kumar, A., Jarwal, D.K., Upadhyay, R.K., Singh, A.P., Jit, S.: Fibrous Al-doped ZnO thin film ultraviolet photodetectors with improved responsivity and speed. IEEE Photonics Technol. Lett. 32(6), 337–340 (2020)

Lahmar, H., Azizi, A., Schmerber, G., Dinia, A.: Effect of the thickness of the ZnO buffer layer on the properties of electrodeposited p-Cu2O/n-ZnO/n-AZO heterojunctions. RSC Adv. 6(73), 68663–68674 (2016)

Lee, Y., Kim, D.Y., Lee, S.: Low-power graphene/ZnO Schottky UV photodiodes with enhanced lateral schottky barrier homogeneity. Nanomaterials 9(5), 799 (2019)

Lee, J., Kim, H.O., Pi, J.E., Nam, S., Kang, S.Y., Kwon, K.H., Cho, S.H.: Transparent phototransistor with high responsivity, sensitivity, and detectivity from heterojunction metal oxide semiconductors. Appl. Phys. Lett. 117(11), (2020)

Li, Q., Wei, L., Xie, Y., Zhang, K., Liu, L., Zhu, D., Mei, L.: ZnO nanoneedle/H 2 O solid-liquid heterojunction-based self-powered ultraviolet detector. Nanoscale Res. Lett. 8, 1–7 (2013)

Liu, H., Avrutin, V., Izyumskaya, N., Özgür, Ü., Morkoç, H.: Transparent conducting oxides for electrode applications in light emitting and absorbing devices. Superlattices Microstruct. 48(5), 458–484 (2010)

Ma, H., Fang, H., Liu, Y., Li, J., Jing, K., Hong, J., Wang, H.: Fully transparent ultraviolet photodetector with ultrahigh responsivity enhanced by MXene-induced photogating effect. Adv. Opt. Mater. 11(12), 2300393 (2023)

Mamat, M.H., Khusaimi, Z., Zahidi, M.M., Bakar, S.A., Yusop, M.Z., Tanemura, M., Mahmood, M.R.: Effects of aluminium doping and electrode distance on the performance of aligned zinc oxide nanorod array-based ultraviolet photoconductive sensors. Jpn. J. Appl. Phys. 51(6S), 06FE04 (2012)

Mondal, S., Ghosh, C., Dwivedi, S.D., Ghosh, A., Sushama, S., Chakrabarti, S., Mondal, A.: An experimental and theoretical understanding of a UV photodetector based on Ag nanoparticles decorated Er-doped TiO2 thin film. Ceram. Int. 47(10), 14879–14891 (2021)

Norouzi, M., Kolahdouz, M., Ebrahimi, P., Ganjian, M., Soleimanzadeh, R., Narimani, K., Radamson, H.: Thermoelectric energy harvesting using array of vertically aligned Al-doped ZnO nanorods. Thin Solid Films 619, 41–47 (2016)

Ozel, K.: Ag nanoparticles decorated AZO/p-Si heterojunction UV photodetector. Opt. Laser Technol. 174, 110621 (2024)

Ozel, K., Yildiz, A.: Comprehensive understanding of the role of emitter layer thickness for metal–oxide–semiconductors based solar cells. IEEE J. Photovolt. 12(1), 251–258 (2021a)

Ozel, K., Yildiz, A.: High-detectivity ultraviolet-B photodetector based on SnO2 thin film/Si heterojunction. Semicond. Sci. Technol. 36(9), 095001 (2021b)

Ozel, K., Yildiz, A.: Estimation of maximum photoresponsivity of n-SnO2/p-Si heterojunction-based UV photodetectors. Phys. Status Solidi RRL Rapid Res. Lett. 16(2), 2100490 (2022)

Ozel, K., Atilgan, A., Yildiz, A.: Multi-layered blocking layers for dye sensitized solar cells. J. Photochem. Photobiol., A 448, 115297 (2024)

Park, H.W., Chung, K.B., Park, J.S., Ji, S., Song, K., Lim, H., Jang, M.H.: Electronic structure of conducting Al-doped ZnO films as a function of Al doping concentration. Ceram. Int. 41(1), 1641–1645 (2015)

Patel, M., Kim, H.S., Kim, J.: All transparent metal oxide ultraviolet photodetector. Adv. Electron. Mater. 1(11), 1500232 (2015)

Rahman, D.S., Pal, S.K., Singha, S.S., Kundu, S., Basu, S., Ghosh, S.K.: Spectral characteristics upon harvesting plasmonic hot electrons at the Ag/ZnO heteromicrostructures. Mater. Adv. 1(8), 2897–2907 (2020)

Raj, I.L.P., Valanarasu, S., Hariprasad, K., Ponraj, J.S., Chidhambaram, N., Ganesh, V., Khairy, Y.: Enhancement of optoelectronic parameters of Nd-doped ZnO nanowires for photodetector applications. Opt. Mater. 109, 110396 (2020)

Rezaie, M.N., Manavizadeh, N., Nadimi, E., Boroumand, F.A.: Quality enhancement of AZO thin films at various thicknesses by introducing ITO buffer layer. J. Mater. Sci. Mater. Electron. 28, 9328–9337 (2017)

Rosli, N., Halim, M.M., Chahrour, K.M., Hashim, M.R.: Incorporation of zinc oxide on macroporous silicon enhanced the sensitivity of macroporous silicon MSM photodetector. ECS J. Solid State Sci. Technol. 9(10), 105005 (2020)

Sbeta, M., Serin, T., Yildiz, A.: Determination of the critical carrier concentration for the metal–insulator transition in Ga-doped ZnO. J. Mater. Sci. Mater. Electron. 29, 14111–14115 (2018a)

Sbeta, M., Atilgan, A., Atli, A., Yildiz, A.: Influence of the spin acceleration time on the properties of ZnO: Ga thin films deposited by sol–gel method. J. Sol-Gel Sci. Technol. 86, 513–520 (2018b)

Serin, T., Yildiz, A., Uzun, Ş, Çam, E., Serin, N.: Electrical conduction properties of In-doped ZnO thin films. Phys. Scr. 84(6), 065703 (2011a)

Serin, T., Yildiz, A., Şahin, ŞH., Serin, N.: Extraction of important electrical parameters of CuO. Phys. B 406(3), 575–578 (2011b)

Shan, C.X., Zhang, J.Y., Yao, B., Shen, D.Z., Fan, X.W., Choy, K.L.: Ultraviolet photodetector fabricated from atomic-layer-deposited ZnO films. J. Vac. Sci. Technol. B Microelectron. Nanometer Struct. Process. Meas. Phenom. 27(3), 1765–1768 (2009)

Shewale, P.S., Lee, N.K., Lee, S.H., Kang, K.Y., Yu, Y.S.: Ti doped ZnO thin film based UV photodetector: Fabrication and characterization. J. Alloy. Compd. 624, 251–257 (2015)

Shinde, S.D., Date, S.K., Deshmukh, A.V., Das, A., Misra, P., Kukreja, L.M., Adhi, K.P.: Role of Al doping in structural, microstructural, electrical and optical characteristics of as-deposited and annealed ZnO thin films. RSC Adv. 5(31), 24178–24187 (2015)

Singh, S.: Simulation, fabrication, and characterization of Al-doped ZnO-based ultraviolet photodetectors. J. Electron. Mater. 45, 535–540 (2016)

Singh, K., Berwal, N., Rawal, I., Dahiya, S., Punia, R., Dhar, R.: Determination of valence and conduction band offsets in Zn0. 98Fe0.02O/ZnO hetero-junction thin films grown in oxygen environment by pulsed laser deposition technique: a study of efficient UV photodetectors. J. Alloy. Compd. 768, 978–990 (2018)

Sun, S.M., Liu, W.J., Golosov, D.A., Gu, C.J., Ding, S.J.: Investigation of energy band at atomic layer deposited AZO/β-Ga2O3 (2¯ 01 2 01) heterojunctions. Nanoscale Res. Lett. 14, 1–6 (2019)

Suwanboon, S., Amornpitoksuk, P., Haidoux, A., Tedenac, J.C.: Structural and optical properties of undoped and aluminium doped zinc oxide nanoparticles via precipitation method at low temperature. J. Alloy. Compd. 462(1–2), 335–339 (2008)

Thirumoorthi, M., Prakash, J.T.J.: Structural, morphological characteristics and optical properties of Y doped ZnO thin films by sol–gel spin coating method. Superlattices Microstruct. 85, 237–247 (2015)

Wang, X., Liu, K., Chen, X., Li, B., Jiang, M., Zhang, Z., Shen, D.: Highly wavelength-selective enhancement of responsivity in Ag nanoparticle-modified ZnO UV photodetector. ACS Appl. Mater. Interfaces 9(6), 5574–5579 (2017)

Williamson, G.K., Smallman, R.E.: III. Dislocation densities in some annealed and cold-worked metals from measurements on the X-ray debye-scherrer spectrum. Philos. Mag. 1(1), 34–46 (1956)

Yildiz, A., Uzun, S., Serin, N., Serin, T.: Influence of grain boundaries on the figure of merit of undoped and Al, In, Sn doped ZnO thin films for photovoltaic applications. Scripta Mater. 113, 23–26 (2016)

Young, S.J., Liu, Y.H.: Ultraviolet photodetectors with Ga-doped ZnO nanosheets structure. Microelectron. Eng. 148, 14–16 (2015)

Funding

Open access funding provided by the Scientific and Technological Research Council of Türkiye (TÜBİTAK). No funding was received for conducting this study.

Author information

Authors and Affiliations

Contributions

K. Ozel: Conceptualization, Methodology, Data curation, Writing - original draft A. Yildiz: Investigation, Resources, Writing-review & editing, Supervision

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Ozel, K., Yildiz, A. High-performance transparent AZO UV photodetectors. Opt Quant Electron 56, 1258 (2024). https://doi.org/10.1007/s11082-024-07169-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11082-024-07169-x