Abstract

We compare the heat extraction efficiency for a standard Vertical External Cavity Surface-Emitting Laser and the distributed Bragg reflector (DBR)-free structure employing a single and double diamond heat-spreaders, respectively. Both heterostructures grown by Molecular Beam Epitaxy employ two identical active regions designed for emission at 980 nm. We show that the thermal resistance has been decreased 15 times when there is no DBR and heat is extracted from both side of active region. For DBR-free laser no thermal rollover of power conversion characteristic was observed in the range of considered input powers.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Vertical External Cavity Surface-Emitting Laser (VECSEL) known also as optically pumped semiconductor disc laser (SDL) gains both from the possibility offered by modern semiconductor epitaxial techniques and flexibility of the design of an external resonator (Kuznetsov et al. 1999). The variety of the semiconductor alloy compositions and the quantum structures such as quantum wells and dots allows for on demand design of the emission wavelength in a broad spectral range. So far, the emission of VECSEL between 440 nm and 5.3 \(\upmu\)m was demonstrated in Kuznetsov (2010) and Rahimi-Iman (2016). A standard semiconductor structure used in the VECSEL lasers consists of an active region and a Distributed Bragg Reflector (DBR) grown in a single epitaxial run. Such structure is often called an active mirror. The active region is a set of quantum wells or layers of quantum dots separated by thick barriers according to the resonant periodic gain approach (Raja et al. 1989). On the surface side the active region is enclosed by a window layer of a larger bandgap to prevent the carrier diffusion towards the surface and non-radiative recombination.

For high power emission of the VECSEL, efficient heat extraction has to be provided. Otherwise, when temperature of the active region increases during the laser operation, the shrinkage of the bandgap and the separation of the Fermi levels change both the emission wavelength and the gain amplitude resulting in a thermal roll-over. In case of the heterostructures emitting in the 1 \(\upmu\)m range which are grown on GaAs substrates the DBR consists of binary layers of GaAs and AlAs or of low-GaAs content AlGaAs. The thermal resistivity of such DBR is relatively low and heat can be extracted through it. Such structures can be mounted directly, or with a highly heat conductive heat-spreader, on a copper heat-sink. This requires the inverted growth of the heterostructure where the active region is placed directly on the substrate followed by a DBR. After the growth, the structure is first soldered to heat-sink or heat-spreader with epitaxial side down and later the substrate is removed by lapping and etching which gives optical access to the active region. This schema of heat extraction permitted over 100 W emission at 1016 nm (Heinen et al. 2012). In that case the thermal resistance was 0.68 K/W for the 1100 \(\upmu\)m spot diameter. An attempt to further decrease the thermal resistance of the DBR was undertaken when a hybrid mirror was used. A hybrid DBR consisted of reduced to 14 AlAs/AlGaAs layer pairs and a gold layer deposited on the top. Reduction in DBR thickness and the use of the AlGaAs transparent for the pump beam resulted in resistance of 2.16 K/W for 270 \(\upmu \hbox {m}\) of beam diameter (Gbele et al. 2016).

At longer wavelengths this schema of heat extraction is not equally efficient. The long wavelength emitting lasers require the active regions to be grown on InP or GaSb. For the DBR consisting of AIII-BV alloys lattice matched to those substrates the thermal resistance is much higher. This has one of two reasons: either the low refraction index contrast of the alloys or the enlarged thickness of the quarter-wavelength layers. For those structures the transparent intracavity heat-spreader has to be used (Calvez et al. 2010). The diamond plates are most suitable because of the highest thermal conductivity of this material equal to 2000 W/mK and the high optical quality (low absorption and low birefringence) (Loon et al. 2006). Small distance of the diamond plate from the active region permits to dissipate the heat from the excitation/emission spot outside i.e. towards the holder. Since the thermal resistivity of the diamond heat-spreader is much lower than that of the DBR, most of the heat is extracted this way.

Recently, to further improve heat extraction two new designs of the VECSEL laser have been proposed (Iakovlev et al. 2014; Yang et al. 2015). In both of those designs the active region was separated from the DBR. Iakovlev et al. (2014) proposed an active region to be enclosed from both sides by two transparent diamond heat-spreaders (after removing the substrate) and that a mirror was engraved as High Contrast Grating on the outside surface of one of those diamonds. The second mirror enclosing the resonator was designed as a self-standing dielectric one. In turn, Yang et al. (2015) has experimentally shown that a DBR-free VECSEL, i.e. a laser with a resonator enclosed within two external dielectric mirrors, can be operated at high power. For a DBR-free heterostructure capillary bounded to a single diamond the maximum power of 6 W was demonstrated (Yang et al. 2016). The authors of both papers claimed that the enclosure of the active region by two diamond plates is expected to enhance the heat dissipation efficiency further. Such laser has been demonstrated already but no clear evidence of the heat extraction improvement has been given and no increase in power emission has been shown (Kahle et al. 2016; Baumgärtner et al. 2015).

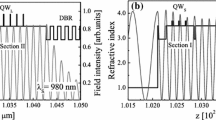

Optical characterization of the DBR-free structure after post-growth processing (a), and the as-grown standard VECSEL structure (b). The optical characterization of the standard VECSEL structure reflectivity, photoluminescence taken from surface and the edge of the sample as well as the calculated fit and longitudinal confinement factor (\(\Gamma\)) are plotted

2 Experimental

The efficiency of heat extraction by double diamond heat-spreaders was tested by using InGaAs/GaAs DBR-free and standard VECSEL heterostructures. The heterostructures were grown on GaAs substrates by Molecular Beam Epitaxy at standard growth conditions most suitable for the indium-containing layers. The active regions of both heterostructures consisted of eight 8 nm thick InGaAs/GaAs QWs with composition adjusted for emission at 970 nm range. The QWs were separated by GaAs barriers with thickness corresponding to a half-wavelength i.e. the QWs position was supposed to be coincident with subsequent antinode positions of the emitted light wave. In case of the DBR-free structure the active region was enclosed from both sides by an Al\(_{x}\)Ga\(_{1-x}\)As, (x \({=}\) 0.34) window layers while in the case of the standard VECSEL structure an active region was enclosed by the \(\hbox {Al}_{x}\hbox {Ga}_{1-x}\)As, (x \({=}\) 0.34) window layer and a DBR of 27 GaAs/AlAs layer pairs. The standard VECSEL structure was of a resonant type. The surface morphologies of epitaxial wafers and the diamonds were investigated by Atomic Force Microscope (AFM). The registered RMS coefficient (Root Mean Square of surface height) in the squares of 10 \(\times\) 10 \(\upmu\)m was excellent for both surfaces. It was equal to 0.25and 0.54 nm for the semiconductor and diamond, respectively. Also the Nomarski contrast microscope has shown that the surfaces were smooth in long range scale.

The CVD-grown diamonds were with an area of 3 \(\times\) 3 \(\hbox {mm}^2\) and of 300 \(\upmu\)m thickness. The 2 \(\times\) 2 \(\hbox {mm}^2\) samples separated from the wafers were joined with the diamond plates using capillary bonding (Liau 2000). The shapes of the semiconductor samples were intentionally irregular in order to suppress possible lasing in the lateral direction (Bedford et al. 2005). The bonding took place at the room temperature and the samples were left under tension in order to totally accomplish the process.

After that the DBR-free sample substrate was lapped and later completely etched off using \(\hbox {NH}_3\hbox {OH}{:}\hbox {H}_2\hbox {O}_2{:}\hbox {H}_2\)O solution. The etching was stopped on the AlAs etch-stop layer which was deposited during the epitaxial process as the first one, just after the buffer layer. The AlAs layer was removed in \(\hbox {HF:H}_2\hbox {O}\) solution. After removing the substrate the structures have become symmetric, i.e. the active region was enclosed from both sides by identical windows and 10 nm thin GaAs cap layers. After the post-growth processing the photoluminescence was measured and indicated the 971 nm emission (Fig. 1a). The photoluminescence (PL) and the reflectivity of the unprocessed standard VECSEL structure were also investigated. For this sample PL was also measured from the edge in order to reveal the spectral position of the emission unmodified by the microcavity. The equal wavelength of the surface- and edge-emitting PL signals indicate the perfect tuning of the QW emission and the microcavity mode (Fig. 1b).

The sandwiches consisting of diamonds and the heterostructures were inserted into large size copper mounts. In case of the DBR-free sample the second diamond was attached by firmly pressing it against the heterostructure surface. The mount prepared for this sample permitted the light to pass through and the heat to be extracted from both diamond heat-spreaders. The mount-openings for the optical access were 2 mm in diameter. The temperature of the mounts was controlled by a very efficient thermoelectric cooler and water flow. The lasers were optically pumped using 808 nm a high power semiconductor laser bar with an emission coupled to a multimode fiber. The pump beam collimator on the fiber end defined the Gaussian-like excitation spot. The small angle resulted in only slightly elliptical shape of this spot. In case of a standard VECSEL the resonator was enclosed by a single external mirror, whereas in case of the DBR-free structure two mirrors were used (Fig. 2). The mirror radius was 90 or 100 mm and the reflectivity was 0.96–0.99. The resonator length was always adjusted to the 200 \(\upmu\)m beam waist which was located at the active region. The lasers were operated in the multimode regime. However, the bell-like beam shape observed by a CCD camera clearly indicated that the emission was dominated by TEM\(_{00}\) mode. The power conversion is shown in Fig. 3. The threshold power of 1.5 W was smaller for the standard VECSEL than for the DBR-free heterostructure for which it was 2.5 W. For both devices similar maximum emission power was registered (2.75 and 2.55 W for a standard VECSEL and DBR free heterostructure, respectively). However, in case of the DBR-free laser there was no thermal rollover in contrast to the standard VECSEL for which the power conversion curve bends down at 22 W of excitation. For DBR free laser the maximum power was limited only by the available pump power. Since the DBR-free laser was set with two external mirrors there was a unique possibility to extract the emission from both of them. In such a case the maximum power of 3.5 W was achieved for the mirrors out-coupling 7% (i.e. the sum of 3 and 4% transmission of front and back mirrors transparency).

Since neither of the diamond surfaces was covered by the antireflection layers nor the diamonds were of a wedge shape, the spectra were dominated by the Fabry-Perot modes. In case of the DBR-free laser the modes were separated by 0.67 nm which was more then 0.27 nm observed in the case of the standard VECSEL with a single diamond. This was because of a spectral mismatch of the Fabry-Perot modes induced by each diamond heat-spreader-etalon.

For the DBR-free heterostructures a strong broadening of the spectra was observed at high power excitation. The total width of a standard VECSEL spectra was lower than for the DBR-free one due to the filtering by a Fabry-Perot mode of the microcavity imposed by a DBR and the high refractive index change at the semiconductor/diamond interface. When the excitation power was raised, the emission was redshifted due to the temperature increase. The spectral drift is, however, much lower than in the case of a standard VECSEL with a single diamond heat-spreader (Fig. 4a, b). The spectral drift in case of the DBR-free laser depends exclusively on the change of the QWs band gap whereas in the case of the standard VECSEL the drift depends on the thermal change of refractive index. Thus, the same thermal drift corresponds to a different change of the active region temperature. Since the temperature-shrinkage of the bandgap corresponds to 0.33 nm/K change of the emission wavelength, the thermal resistance below 0.2 K/W can be expected. Assuming that the change in the refractive index corresponds to 0.11 nm/K drift, thermal resistance of 2.9 K/W can be derived for the standard VECSEL employing single diamond heat-spreader. For the DBR-free heterostructures only the broadening of the spectra is observed at the high power excitation and there was no drift.

To prove the thermal origin of the spectral redshift in case of the DBR-free laser, the emission from the edge of the wafer was registered as the function of the mount temperature (Fig. 5a). The broad peak of a spontaneous emission and the narrow line of a scattered stimulated emission drifted spectrally with the coefficients of 0.33 and 0.11 nm/K, respectively.

Those values are characteristic for the change of the bandgap and the refractive index. Surprisingly, the stimulated emission took place at the wavelength different from that observed for the maximum of the PL emission. These phenomena have been already observed, however a clear explanation has not been given Yang et al. (2015). In our samples the High Resolution X-ray Diffraction analysis has shown that the thicknesses of GaAs barriers and \(\hbox {In}_{x}\hbox {Ga}_{1-x}\) As, x \({=}\) 0.168 QW were 133.5 and 8.4 nm, respectively, i.e. the period of the Resonant Periodic Gain (RPG) was 141.9 nm (Fig. 5b). This period corresponds to the 1003 nm wavelength assuming the indexes of 3.52 and 3.73 for GaAs and InGaAs QWs, respectively.

Emission registered from the edge of the DBR-free laser as a function of the mount temperature (12, 22, 32, 42, 48 \(^{\circ }\)C) (a). Measured HRXRD characterization of the DBR-free structure bottom line and simulated curve assuming 8 QW of InxGa1-xAs, x \({=}\) 0.168 and thickness 8.4 nm and GaAs barrier 133.5 nm thick (b)

3 Conclusion

In conclusion we have shown a DBR-free VECSEL-type laser employing two diamond transparent heat-spreaders has demonstrated high power emission without the thermal rollover in the range of available input pump powers. The spectral drift of the stimulated emission was strongly reduced in comparison with a standard VECSEL structure employing a single diamond intracavity heat-spreader. The thermal resistance was estimated to be below 0.2 K/W. Thus, the limit imposed by high thermal resistivity of a DBR is overcame and opportunity appears to realize a semiconductor laser operating at the wavelengths which nowadays are not well penetrated by semiconductor surface-emitting devices.

References

Baumgärtner, S., Kahle, H., Bek, R., Schwarzbäck, T., Jetter, M., Michler, P.: Comparison of algainp-vecsel gain structures. J. Cryst. Growth 414, 219–222 (2015)

Bedford, R.G., Kolesik, M., Chilla, J.L.A., Reed, M.K., Nelson, T.R., Moloney, J.V.: Power-limiting mechanisms in vecsels. Proc. SPIE 5814, 199–208 (2005)

Calvez, S., Hastie, J.E., Kemp, A.J., Laurand, N., Dawson, M.D.: Thermal management, structure design, and integration considerations for vecsels. In: Okhotnikov, O.G. (ed.) Semiconductor Disk Lasers. Physics and Technology, Chap. 2, pp. 73–117. Wiley-VCH, Weinheim (2010)

Gbele, K., Laurain, A., Hader, J., Stolz, W., Moloney, J.V.: Design and fabrication of hybrid metal semiconductor mirror for high-power vecsel. IEEE Photon. Technol. Lett. 28(7), 732–735 (2016)

Heinen, B., Wang, T.L., Sparenberg, M., Weber, A., Kunert, B., Hader, J., Koch, S.W., Moloney, J.V., Koch, M., Stolz, W.: 106 w continuous-wave output power from vertical external-cavity surface-emitting laser. Electron. Lett. 48(9), 516–517 (2012)

Iakovlev, V., Walczak, J., Gębski, M., Sokół, A., Wasiak, M., Gallo, P., Sirbu, A., Sarzała, R., Dems, M., Czyszanowski, T., Kapon, E.: Double-diamond high-contrast-gratings vertical external cavity surface emitting laser. J. Phys. D Appl. Phys. 47(6), 065104 (2014)

Kahle, H., Mateo, C.M.N., Brauch, U., Tatar-Mathes, P., Bek, R., Jetter, M., Graf, T., Michler, P.: Semiconductor membrane external-cavity surface-emitting laser (mecsel). Optica 3(12), 1506–1512 (2016)

Kuznetsov, M.: VECSEL semiconductor lasers: A path to high-power, quality beam and UV to IR wavelength by design. In: Okhotnikov, O.G. (ed.) Semiconductor Disk Lasers. Physics and Technology, Chap. 1, pp. 1–71. Wiley-VCH, Weinheim (2010)

Kuznetsov, M., Hakimi, F., Sprague, R., Mooradian, A.: Design and characteristics of high-power (\(<\)0.5 w cw) diode-pumped vertical-external-cavity surface-emitting semiconductor lasers with circular tem beams. IEEE J. Sel. Top. Quantum Electron. 5(4), 561–573 (1999)

Liau, Z.L.: Semiconductor wafer bonding via liquid capillarity. Appl. Phys. Lett. 77(5), 651–653 (2000)

Rahimi-Iman, A.: Recent advances in vecsels. J. Opt. 18, 093003 (2016)

Raja, M.Y.A., Brueck, S.R.J., Osinski, M., Schaus, C.F., McInerney, J.G., Brennan, T.M., Hammons, B.E.: Resonant periodic gain surface-emitting semiconductor lasers. IEEE J. Quantum Electron. 25(6), 1500–1512 (1989)

Van Loon, F., Kemp, A.J., Maclean, A.J., Calvez, S., Hopkins, J.M., Hastie, J.E., Dawson, M., Burns, D.: Intracavity diamond heatspreaders in lasers: the effects of birefringence. Opt. Express 14(20), 9250–9260 (2006)

Yang, Z., Albrecht, A.R., Cederberg, J.G., Sheik-Bahae, M.: DBR-free optically pumped semiconductor disk lasers. Proc. SPIE 9439, 934905 (2015)

Yang, Z., Albrecht, A.R., Cederberg, J.G., Hackett, S., Sheik-Bahae, M.: Broadly tunable DBR-free semiconductor disk lasers. Proc. SPIE 9734, 97340I (2016)

Acknowledgements

The Project was supported by Polish National Science Centre Grant No. 2014/15/N/ST7/04742 and the statutory project at Institute of Electron Technology. The authors want to express they gratitude to Mr. Lech Rządca for the technical help and heatsinks preparation and to Krzysztof Hejduk for clean room assistance.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Broda, A., Kuźmicz, A., Rychlik, G. et al. Highly efficient heat extraction by double diamond heat-spreaders applied to a vertical external cavity surface-emitting laser. Opt Quant Electron 49, 287 (2017). https://doi.org/10.1007/s11082-017-1129-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11082-017-1129-x