Abstract

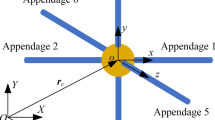

The space assembly of two flexible beams by a dual-arm space robot is a typical assembly scenario to construct ultra-large space structure. Yet, previous studies mainly focused on the assembly of small structures, neglecting the influences of space perturbations. Two models are developed in this research to investigate the effects of space perturbations on the space assembly process of ultra-large space structures. Firstly, a theoretical modelling method is proposed based on quasi-static hypothesis and linear structural mechanics. The theoretical model can be utilized for analytically estimating the transverse and axial distributed forces of the flexible beams, structural vibrations, and the control moments of the space robot. An orbit–attitude–structure coupled simulation model is then established to validate the theoretical model and study the dynamic behaviours more accurately, using absolute nodal coordinate formulation and natural coordinate formulation. Finally, the effects of the attitude angle, orbital radius, and lengths of beams on the dynamic responses during assembly are investigated. Theoretical and simulation results show that the control moments and structural vibration amplitude increase dramatically with the length of the beams. The effects of Coriolis force and gravity gradient must be considered for ultra-large space structures during assembly, otherwise the control moments and structural vibrations would be substantially underestimated. The results are instructive to the assembly strategy design as well as modular component design of ultra-large space structures.

Similar content being viewed by others

References

Li, W., Cheng, D., Liu, X., Wang, Y., Shi, W., Tang, Z., Gao, F., Zeng, F., Chai, H., Luo, W., Cong, Q., Gao, Z.: On-orbit service (OOS) of spacecraft—a review of engineering developments. Prog. Aerosp. Sci. 108, 32–120 (2019)

Houghton, N., Fulton, J., Mazarr, A., Park, S., Williams, P.: Utilizing in-space assembly to add artificial gravity capabilities to mars exploration mission vehicles. In: AIAA SciTech Forum, Orlando (2020)

Jaffe, P.: A study of defense applications of space solar power. AIP Conf. Proc. 1208, 585–592 (2010)

Glaser, P.: Power from the sun: its future. Science 162, 857–861 (1968)

Çelik, O., McInnes, C.: An analytical model for solar energy reflected from space with selected applications. Adv. Space Res. 69, 647–663 (2022)

Bonetti, F., McInnes, C.: Space-enhanced terrestrial solar power for equatorial regions. J. Spacecr. Rocket. 56, 33–43 (2018)

Dorsey, J., Watson, J.: Space assembly of large structural system architectures (Salssa). In: AIAA Space and astronautics forum and exposition. AIAA. Long Beach, CA, United states (2016)

Staritz, P., Skaff, S., Urmson, C., Whittaker, W.: Skyworker: A robot for assembly, inspection and maintenance of large scale orbital facilities. In: Proceedings 2001 ICRA. IEEE International Conference on Robotics and Automation (2001)

Mukherjee, R., Siegler, N., Thronson, H.: The future of space astronomy will be built: results from the in-space astronomical telescope (Isat) assembly design study. In: 70th International Astronautical Congress (IAC). Washington D.C., United States (2019)

Xue, Z., Liu, J., Wu, C., Tong, Y.: Review of in-space assembly technologies. Chin. J. Aeronaut. 34, 21–47 (2021)

Gralla, E., de Weck, O.: On-Orbit Assembly Strategies for Next-Generation Space Exploration. In: The 57th International Astronautical Congress. (2012)

McInnes, C.: Distributed control of maneuvering vehicles for on-orbit assembly. J. Guid. Control. Dyn. 18, 1204–1206 (1995)

Chen, T., Wen, H., Hu, H., Jin, D.: Output consensus and collision avoidance of a team of flexible spacecraft for on-orbit autonomous assembly. Acta Astronaut. 121, 271–281 (2016)

Wang, E., Wu, S., Wu, Z., Radice, G.: Distributed adaptive vibration control for solar power satellite during on-orbit assembly. Aerosp. Sci. Technol. 94, 1–10 (2019)

Wang, E., Wu, S., Xun, G., Liu, Y., Wu, Z.: Active vibration suppression for large space structure assembly: a distributed adaptive model predictive control approach. J. Vib. Control 27, 365–377 (2020)

Cao, K., Li, S., She, Y., Biggs, J., Liu, Y., Bian, L.: Dynamics and on-orbit assembly strategies for an orb-shaped solar array. Acta Astronaut. 178, 881–893 (2021)

Flores-Abad, A., Ma, O., Pham, K., Ulrich, S.: A review of space robotics technologies for on-orbit servicing. Prog. Aerosp. Sci. 68, 1–26 (2014)

Boning, P., Dubowsky, S.: Coordinated control of space robot teams for the on-orbit construction of large flexible space structures. Adv. Robot. 24, 303–323 (2010)

Xu, W., Meng, D., Chen, Y., Qian, H., Xu, Y.: Dynamics modeling and analysis of a flexible-base space robot for capturing large flexible spacecraft. Multibody Syst.Dyn. 32, 357–401 (2014)

Meng, D., Lu, W., Xu, W., She, Y., Wang, X., Liang, B., Yuan, B.: Vibration suppression control of free-floating space robots with flexible appendages for autonomous target capturing. Acta Astronaut. 151, 904–918 (2018)

Meng, D., Liu, H., Li, Y., Xu, W., Liang, B.: Vibration suppression of a large flexible spacecraft for on-orbit operation. Sci. Chin. Inf. Sci. 60, 050203 (2017)

Lu, Y., Huang, Z., Zhang, W., Wen, H., Jin, D.: Experimental investigation on automated assembly of space structure from cooperative modular components. Acta Astronaut. 171, 378–387 (2020)

Ishijima, Y., Tzeranis, D., Dubowsky, S.: The on-orbit maneuvering of large space flexible structures by free-flying robots. In: The 8th International Symposium on Artificial Intelligence, Robotics and Automation in Space. Munich, Germany (2005)

Mu, R., Tan, S., Wu, Z., Qi, Z.: Coupling dynamics of super large space structures in the presence of environmental disturbances. Acta Astronaut. 148, 385–395 (2018)

Li, Q., Sun, T., Li, J., Deng, Z.: Gravity-gradient-induced transverse deformations and vibrations of a sun-facing beam. AIAA J. 57, 5491–5502 (2019)

Li, Q., Deng, Z.: Coordinated orbit–attitude–vibration control of a sun-facing solar power satellite. J. Guid. Control. Dyn. 42, 1863–1869 (2019)

Tzeranis, D., Ishijima, Y., Dubowsky, S.: Manipulation of large flexible structural modules by space robots mounted on flexible structures. In: The 8th International Symposium on Artificial Intelligence, Robotics and Automation in Space - iSAIRAS. Munich, Germany (2005)

Otsuka, K., Makihara, K., Sugiyama, H.: Recent advances in the absolute nodal coordinate formulation: literature review from 2012 to 2020. J. Comput. Nonlinear Dyn. 17, 080803 (2022)

Shabana, A.: The Large Deformation Problem Dynamics of Multibody Systems. Cambridge University Press, Cambridge (2013)

Nachbagauer, K.: State of the art of ancf elements regarding geometric description, interpolation strategies, definition of elastic forces, validation and the locking phenomenon in comparison with proposed beam finite elements. Arch. Comput. Methods Eng. 21, 293–319 (2014)

Shabana, A., Eldeeb, A.: Motion and shape control of soft robots and materials. Nonlinear Dyn. 104, 165–189 (2021)

Luo, K., Tian, Q., Hu, H.: Dynamic modeling, simulation and design of smart membrane systems driven by soft actuators of multilayer dielectric elastomers. Nonlinear Dyn. 102, 1–21 (2020)

Atif, M., Chi, S.-W., Grossi, E., Shabana, A.: Evaluation of breaking wave effects in liquid sloshing problems: Ancf/Sph comparative study. Nonlinear Dyn. 97, 45–62 (2019)

Shabana, A., Eldeeb, A.: Relative orientation constraints in the nonlinear large displacement analysis: application to soft materials. Nonlinear Dyn. 101, 2551–2575 (2020)

Shabana, A., Zhang, D.: Ancf curvature continuity: application to soft and fluid materials. Nonlinear Dyn. 100, 1497–1517 (2020)

Escalona, J., Hussien, H., Shabana, A.: Application of the absolute nodal co-ordinate formulation to multibody system dynamics. J. Sound Vib. 214, 833–850 (1998)

Li, Q., Deng, Z., Zhang, K., Huang, H.: Unified modeling method for large space structures using absolute nodal coordinate. AIAA J. 56, 1–12 (2018)

Otsuka, K., Makihara, K.: Deployment simulation using absolute nodal coordinate plate element for next-generation aerospace structures. AIAA J. 56, 1266–1276 (2018)

Liu, C., Tian, Q., Hu, H., García-Vallejo, D.: Simple formulations of imposing moments and evaluating joint reaction forces for rigid-flexible multibody systems. Nonlinear Dyn. 69, 127–147 (2012)

de Jalón, J.G.: Twenty-five years of natural coordinates. Multibody Syst. Dyn. 18, 15–33 (2007)

García-Vallejo, D., Escalona, J., Mayo, J., Domínguez, J.: Describing rigid-flexible multibody systems using absolute coordinates. Nonlinear Dyn. 34, 75–94 (2003)

Xu, X., Luo, J., Feng, X., Peng, H., Wu, Z.: A generalized inertia representation for rigid multibody systems in terms of natural coordinates. Mech. Mach. Theory 157, 104174 (2021)

Xu, X., Luo, J., Wu, Z.: The numerical influence of additional parameters of inertia representations for quaternion-based rigid body dynamics. Multibody Syst. Dyn. 49, 237–270 (2020)

Zhao, J., Tian, Q., Hu, H.: Deployment dynamics of a simplified spinning Ikaros solar sail via absolute coordinate based method. Acta. Mech. Sin. 29, 132–142 (2013)

de Jalón, J.G., Bayo, E.: Dynamic Analysis. Mass Matrices and External Forces. In: Kinematic and Dynamic Simulation of Multibody Systems. (1994)

Li, Q., Wang, B., Deng, Z., Ouyang, H., Wei, Y.: A simple orbit-attitude coupled modelling method for large solar power satellites. Acta Astronaut. 145, 83–92 (2018)

Longman, R., Lindbergt, R., Zedd, M.: Satellite-mounted robot manipulators — new kinematics and reaction moment compensation. Int. J. Robot. Res. 6, 87–103 (1987)

She, Y., Li, S., Liu, Y., Cao, M.: In-orbit robotic assembly mission design and planning to construct a large space telescope. J. Astron. Telesc., Instrum., Syst. 6, 1–18 (2020)

Acknowledgements

This work is supported by the National Natural Science Foundation of China (12202508, 12232015), Young Elite Scientists Sponsorship Program by China Association for Science and Technology (2021QNRC001), and the Fundamental Research Funds for the Central Universities, Sun Yat-sen University (No. 22qntd0703).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Funding

National Natural Science Foundation of China, 12202508, Qingjun Li, 12232015, Qingjun Li, Young Elite Scientists Sponsorship Program by China Association for Science and Technology, 2021QNRC001, Qingjun Li, Fundamental Research Funds for the Central Universities, Sun Yat-sen University, No. 22qntd0703, Qingjun Li.

Conflict of interest

The authors declare that they have no conflict of interest. This article does not contain any studies with human participants or animals performed by any of the authors. Informed consent was obtained from all individual participants included in the study.

Data availability

All data generated or analyzed during this study are included in this article.

Ethical approval

I certify that this manuscript is original and has not been published and will not be submitted elsewhere for publication while being considered by Nonlinear Dynamics. And the study is not split up into several parts to increase the quantity of submissions and submitted to various journals or to one journal over time. No data have been fabricated or manipulated (including images) to support your conclusions. No data, text, or theories by others are presented as if they were our own. The submission has been received explicitly from all co-authors. And authors whose names appear on the submission have contributed sufficiently to the scientific work and therefore share collective responsibility and accountability for the results.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix

Appendix

The quasi-static vibration of Beam KI \(v_{{{\text{KI}}}}\) is obtained by integrating Eq. (24) with the boundary conditions in Eq. (25)

Similarly, the quasi-static vibration of Beam MN \(v_{{{\text{MN}}}}\) is

The results of Eqs. (28)–(33) are

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Yang, G., Zhang, L., Yu, S. et al. Influences of space perturbations on robotic assembly process of ultra-large structures. Nonlinear Dyn 111, 10025–10048 (2023). https://doi.org/10.1007/s11071-023-08395-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11071-023-08395-w