Abstract

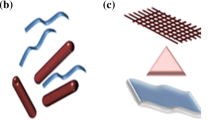

Nickel nanoparticles are an attractive ingredient for preparing metal-based conductive pastes. In particular, using a mixture of nanoparticles containing two different particle sizes as the paste fillers is an effective way to improve the microstructure as well as the electrical conductivity of the printed films after sintering. This study presents a facile solvent-directed chemical reduction method for the synthesis of nickel nanoparticles with bimodal size distribution in one-pot. Through simply adjusting the volume ratio of alcohol (methanol, ethanol or n-propanol) to water and nickel precursor concentration in a mixed solvent system (alcohol and water), the size and size distribution of the synthesized nickel nanoparticles could be controlled. The bimodal nickel nanoparticles obtained at a volume ratio of methanol to water of 2 were used as fillers for a screen-printing paste. After sintering at a temperature of 600 ℃, the printed film exhibited a compact structure with a relatively low volume resistivity of 167.3 µΩ∙cm.

Similar content being viewed by others

References

Karthik KV, Raghu AV, Reddy KR, Ravisshankar R, Sangeeta M, Shetti NP, Reddy CV (2022) Green synthesis of Cu-doped ZnO nanoparticles and its application for the photocatalytic degradation of hazardous organic pollutants. Chemosphere 287:132081. https://doi.org/10.1016/j.chemosphere.2021.13208

Madhavi J, Prasad V, Reddy KR, Reddy CV, Raghu AV (2021) Facile synthesis of Ni-doped ZnS-CdS composite and their magnetic and photoluminescence properties. J Environ Chem Eng 9:106335. https://doi.org/10.1016/j.jece.2021.106335

Matsui I (2005) Nanoparticles for electronic device applications: a brief review. J Chem Eng Jpn 38:535–546. https://doi.org/10.1252/jcej.38.535

Cano-Raya C, Denchev ZZ, Cruz SF, Viana JC (2019) Chemistry of solid metal-based inks and pastes for printed electronics – a review. Appl Mater Today 15:416–430. https://doi.org/10.1016/j.apmt.2019.02.012

Nayak L, Mohanty S, Nayak SK, Ramadoss A (2019) A review on inkjet printing of nanoparticle inks for flexible electronics. J Mater Chem C 7:8771–8795. https://doi.org/10.1039/c9tc01630a

Tomotoshi D, Kawasaki H (2020) Surface and interface designs in copper-based conductive inks for printed/flexible electronics. Nanomaterials 10:1689. https://doi.org/10.3390/nano10091689

Zhang ZL, Zhang XY, Xin ZQ, Deng MM, Wen YQ, Song YL (2011) Synthesis of monodisperse silver nanoparticles for ink-jet printed flexible electronics. Nanotechnology 22:425601. https://doi.org/10.1088/0957-4484/22/42/425601

Kwon J, Cho H, Eom H et al (2016) Low-temperature oxidation-free selective laser sintering of Cu nanoparticle paste on a polymer substrate for the flexible touch panel applications. ACS Appl Mater Interfaces 8:11575–11582. https://doi.org/10.1021/acsami.5b12714

Mody VV, Siwale R, Singh A, Mody HR (2010) Introduction to metallic nanoparticles. J Pharm Bioallied Sci 2:282–289. https://doi.org/10.4103/0975-7406.72127

Pajor-Świerzy A, Pawłowski R, Warszyński P, Szczepanowicz K (2020) The conductive properties of ink coating based on Ni–Ag core–shell nanoparticles with the bimodal size distribution. J Mater Sci Mater Electron 31:12991–12999. https://doi.org/10.1007/s10854-020-03852-3

Liu ZY, Ji HJ, Wang S, Zhao WW, Huang Y, Feng HH, Wei J, Li MY (2018) Enhanced electrical and mechanical properties of a printed bimodal silver nanoparticle ink for flexible electronics. Phys Status Solidi A 215:1800007. https://doi.org/10.1002/pssa.201800007

Li MY, Xiao Y, Zhang ZH, Yu J (2015) Bimodal sintered silver nanoparticle paste with ultrahigh thermal conductivity and shear strength for high temperature thermal interface material applications. ACS Appl Mater Interfaces 7:9157–9168. https://doi.org/10.1021/acsami.5b01341

German RM (1992) Prediction of sintered density for bimodal powder mixtures. Metall Mater Trans A 23:1455–1465. https://doi.org/10.1007/BF02647329

Ye XJ, Li YP, Ai YL, Nie Y (2018) Novel powder packing theory with bimodal particle size distribution-application in superalloy. Adv Powder Technol 29:2280–2287. https://doi.org/10.1016/j.apt.2018.06.012

Xiao Y, Cao Y, Zhang ZH, Yang M, Wang S, Li MY (2017) Low-temperature sintering of bimodal Ag nanoparticles for power electronics applications. Proc IEEE-ICEPT:535–538. https://doi.org/10.1109/ICEPT.2017.8046511

Park JS, Song Y, Park D, Kim Y, Kim YJ (2018) Flexible transparent conducting films with embedded silver networks composed of bimodal-sized nanoparticles for heater application. Nanotechnology 29:255302. https://doi.org/10.1088/1361-6528/aabbc0

Gao Y, Li WL, Zhang H, Jiu JT, Hu DW, Suganuma K (2018) Size-controllable synthesis of bimodal Cu particles by polyol method and their application in die bonding for power devices. IEEE Trans Compon Packag Manuf Technol 8:2190–2197. https://doi.org/10.1109/TCPMT.2018.2866107

Dang TMD, Le TTT, Fribourg-Blanc E, Dang MC (2011) Synthesis and optical properties of copper nanoparticles prepared by a chemical reduction method. Adv Nat Sci Nanosci Nanotechnol 2:015009. https://doi.org/10.1088/2043-6262/2/1/015009

Quintero-Quiroz C, Acevedo N, Zapata-Giraldo J, Botero LE, Quintero J, Zárate-Triviño D, Saldarriaga J, Pérez VZ (2019) Optimization of silver nanoparticle synthesis by chemical reduction and evaluation of its antimicrobial and toxic activity. Biomater Res 23:27. https://doi.org/10.1186/s40824-019-0173-y

Daruich De Souza C, Ribeiro Nogueira B, Rostelato MECM (2019) Review of the methodologies used in the synthesis gold nanoparticles by chemical reduction. J Alloys Compd 798:714–740. https://doi.org/10.1016/j.jallcom.2019.05.153

Guo W, Zeng Z, Zhang XY, Peng P, Tang SP (2015) Low-temperature sintering bonding using silver nanoparticle paste for electronics packaging. J Nanomater 2015:897142. https://doi.org/10.1155/2015/897142

Yang XJ, He W, Wang SX, Zhou GY, Tang Y, Yang JH (2012) Effect of the different shapes of silver particles in conductive ink on electrical performance and microstructure of the conductive tracks. J Mater Sci Mater Electron 23:1980–1986. https://doi.org/10.1007/s10854-012-0691-z

Sohn JH, Pham LQ, Kang HS, Park JH, Lee BC, Kang YS (2010) Preparation of conducting silver paste with ag nanoparticles prepared by e-beam irradiation. Radiat Phys Chem 79:1149–1153. https://doi.org/10.1016/j.radphyschem.2010.06.005

Thakur N, Murthy H (2021) Nickel-based inks for inkjet printing: a review on latest trends. Am J Mater Sci 11:20–35. https://doi.org/10.5923/j.materials.20211101.03

Liu SN, Tam SK, Ng KM (2021) Dual-reductant synthesis of nickel nanoparticles for use in screen-printing conductive paste. J Nanopart Res 23:78. https://doi.org/10.1007/s11051-021-05191-8

Zheng HG, Liang JH, Zeng JH, Qian YT (2001) Preparation of nickel nanopowders in ethanol-water system (EWS). Mater Res Bull 36:947–952. https://doi.org/10.1016/s0025-5408(01)00569-4

Ali M, Remalli N, Gedela V, Padya B, Jain PK, Al-Fatesh A, Rana UA, Srikanth VVSS (2017) Ni nanoparticles prepared by simple chemical method for the synthesis of Ni/NiO-multi-layered graphene by chemical vapor deposition. Solid State Sci 64:34–40. https://doi.org/10.1016/j.solidstatesciences.2016.12.007

Kim KH, Lee YB, Choi EY, Park HC, Park SS (2004) Synthesis of nickel powders from various aqueous media through chemical reduction method. Mater Chem Phys 86:420–424. https://doi.org/10.1016/j.matchemphys.2004.04.011

Chen HI, Chang HY (2004) Homogeneous precipitation of cerium dioxide nanoparticles in alcohol/water mixed solvents. Colloids Surf A Physicochem Eng Asp 242:61–69. https://doi.org/10.1016/j.colsurfa.2004.04.056

Zheng YY, Dou ZJ, Fang YX, Li MW, Wu X, Zeng JH, Hou ZH, Liao SJ (2016) Platinum nanoparticles on carbon-nanotube support prepared by room-temperature reduction with H2 in ethylene glycol/water mixed solvent as catalysts for polymer electrolyte membrane fuel cells. J Power Sources 306:448–453. https://doi.org/10.1016/j.jpowsour.2015.12.077

Taubert A, Wiesler U, Müllen K (2003) Dendrimer-controlled one-pot synthesis of gold nanoparticles with a bimodal size distribution and their self-assembly in the solid state. J Mater Chem 13:1090–1093. https://doi.org/10.1039/b207895c

Thanh NTK, Maclean N, Mahiddine S (2014) Mechanisms of nucleation and growth of nanoparticles in solution. Chem Rev 114:7610–7630. https://doi.org/10.1021/cr400544s

Ali RF, Gates BD (2018) Synthesis of lithium niobate nanocrystals with size focusing through an Ostwald ripening process. Chem Mater 30:2028–2035. https://doi.org/10.1021/acs.chemmater.7b05282

Roy NK, Foong CS, Cullinan MA (2018) Effect of size, morphology, and synthesis method on the thermal and sintering properties of copper nanoparticles for use in microscale additive manufacturing processes. Addit Manuf 21:17–29. https://doi.org/10.1016/j.addma.2018.02.008

Joseph N, Varghese J, Teirikangas M, Vahera T, Jantunen H (2019) Ultra-low-temperature cofired ceramic substrates with low residual carbon for next-generation microwave applications. ACS Appl Mater Interfaces 11:23798–23807. https://doi.org/10.1021/acsami.9b07272

Mori T, Okuda M, Katou R, Hashidate S, Minami J, Sakurai T, Fukui T (2021) Effect of sintering density on thermal reliability by non-pressure sintering die attach. Proc IEEE-ECTC:590–596. https://doi.org/10.1109/ECTC32696.2021.00105

Im DH, Hyun SH, Park SY, Lee BY, Kim YH (2006) Preparation of high dispersed nickel pastes for thick film electrodes. J Mater Sci 41:6425–6430. https://doi.org/10.1007/s10853-006-0715-2

Acknowledgements

The authors appreciate the technical assistance from Material Characterization & Preparation Facilities (MCPF) and Materials Service (MAT) in Materials Design & Manufacturing Facilities (MDMF) at HKUST.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Liu, S., Tam, S.K. & Ng, K.M. Facile one-pot synthesis of bimodal-sized nickel nanoparticles in a solvent-directed reaction system. J Nanopart Res 24, 136 (2022). https://doi.org/10.1007/s11051-022-05520-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11051-022-05520-5