Abstract

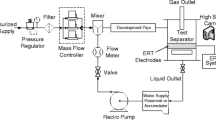

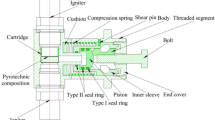

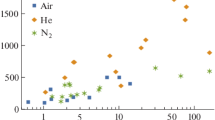

Separation devices are widely used in satellites and rockets, where mechanical properties of the devices have significant influences on connection and separation behaviors. Compared to a pyrotechnically actuated separation device, a gas-driven separation device employs preloads, instead of explosions, to actuate separation of the aircrafts, which has advantages of reusability and low impacts. Dynamic modeling of the gas-driven separation device can be used to optimize its separation behaviors, where flexibility is considered since preloads stored in deformations play important roles in separations. Complex interactions of interfaces occur during the separation process in a short time, which raises issues of convergence and computational time when a finite element method is in use. In this work, we firstly develop a simplified model of a gas-driven separation device, where flexibility is introduced only on the interfaces of components, and their bodies are still rigid. We apply the LZB multipoint method to deal with repeated impacts of the interfaces in the separation process and establish a variable-constraint technique to rebuild contact-point pairs when contact areas vary. Simulations of the dynamic model describe detailed interactions of the separation process. The results illustrate that the separation time decreases when the preload increases, and the decreasing rate gets lower due to reactions of split nuts. We develop a test bench of the gas-driven separation device, by which experimental results validate that the proposed dynamic model can accurately predict the separation time and speeds at different preloads.

Similar content being viewed by others

Data Availability

This declaration is not applicable.

Materials Availability

This declaration is not applicable.

References

Interbartolo, M., Nasa Technical Reports Server: Apollo spacecraft and Saturn V launch vehicle pyrotechnics/explosive devices (2009)

Moening, C.J.: Pyrotechnic shock flight failures. In: Institute of Environmental Sciences Pyrotechnic Shock Tutorial Program, 31st Annual Technical Meeting. Citeseer, Las Vegas, NV, USA (1985)

Daniel, R.M.: Pyroshock test criteria. Technical report, NASA-STD-7003, NASA Report, USA (1999)

Girard, A., Pont, C., Courau, E.: Very first results from pyroshock database for satellites. In: Spacecraft Structures, Materials and Mechanical Testing 2005, vol. 581 (2005)

Zhang, X., Yan, X., Yang, Q.: Design and experimental validation of compact, quick-response shape memory alloy separation device. J. Mech. Des. 136(1), 011009 (2014)

Ik Yoo, Y., Won Jeong, J., Hyuk Lim, J., Kim, K.-W., Hwang, D.-S., Lee, J.J.: Development of a non-explosive release actuator using shape memory alloy wire. Rev. Sci. Instrum. 84(1), 015005 (2013)

Brauer, K.O.: Handbook of Pyrotechnics (1974)

Barbour, R.T.: Pyrotechnics in Industry. Pyrotechnics in Industry (1981)

Bement, L.J., Schimmel, M.L., Mr, T., Schulze, N.R., Headquarters, N.: A manual for pyrotechnic design, development and qualification (1998)

Yang, M.: Space Pyrotechnics Devices. Spacecraft Recovery & Remote Sensing (1999)

Sahli, M.L., Necib, B.: Characterisation and modelling of behaviour of a shape memory alloys. Int. J. Adv. Manuf. Technol. 70(9–12), 1–11 (2013)

Sanchez Cebrian, A., Halter, B.-U., Gerngross, T.: Ruag’s approach to develop a modular low shock separation and jettison system (2019)

Kumar, A., Bhowmik, R.:. A review on design features of the Falcon-9 space launch vehicle

Dalton, E., Burton, S.: Analysis and validation testing of impulsive load response in complex, multi-compartmented structures. In: 36th Structures, Structural Dynamics and Materials Conference, p. 1243 (1995)

Hwang, D.-H., Park, H.-S., Han, J.-H.: Development of a miniature point source pyroshock simulator. J. Sound Vib. 481, 115438 (2020)

Yan, H., Qin, Z., Chu, F., Zhang, W., Yang, Z., Ming, A., Wang, X.: Dynamic response of aluminum honeycomb panels to high-frequency laser shock excitations. J. Spacecr. Rockets 57(1), 198–201 (2020)

Benson, D.J.: Computational methods in Lagrangian and Eulerian hydrocodes. Comput. Methods Appl. Mech. Eng. 99(2–3), 235–394 (1992)

Lee, J.-R., Chia, C.C., Kong, C.-W.: Review of pyroshock wave measurement and simulation for space systems. Measurement 45(4), 631–642 (2012)

Velmurugan, R., Mohamed Najeeb, E.: Study of far-field pyroshock responses of composite panels. J. Vib. Acoust. 136(3), 031014 (2014)

Wang, X., Qin, Z., Ding, J., Chu, F.: Finite element modeling and pyroshock response analysis of separation nuts. Aerosp. Sci. Technol. 68, 380–390 (2017)

Zhao, H., Liu, W., Ding, J., Sun, Y., Li, X., Liu, Y.: Numerical study on separation shock characteristics of pyrotechnic separation nuts. Acta Astronaut. 151(OCT.), 893–903 (2018)

García-Pérez, A., Sorribes-Palmer, F., Alonso, G., Ravanbakhsh, A.: Overview and application of FEM methods for shock analysis in space instruments. Aerosp. Sci. Technol. 80, 572–586 (2018)

Lee, J., Han, J.-H., Lee, Y., Lee, H.: Separation characteristics study of ridge-cut explosive bolts. Aerosp. Sci. Technol. 39, 153–168 (2014)

Jang, S., Lee, H., Oh, J.: Performance modeling of a pyrotechnically actuated pin puller. Int. J. Aeronaut. Space Sci. 15(1), 102–111 (2014)

Wang, J.T., Nefske, D.J.: A new CAL3D airbag inflation model. SAE Transact. 97, 697–706 (1988)

Blaise, H.P., Gonthier, K.A.: Analysis of gas-dynamic effects in explosively actuated valves. J. Propuls. Power 26(3), 479–496 (2010)

Lee, H.S.: Unsteady gasdynamics effects in pyrotechnic actuators. J. Spacecr. Rockets 41(5), 877–886 (2004)

Han, D.-H., Sung, H.-G., Jang, S.-G., Ryu, B.-T.: Parametric analysis and design optimization of a pyrotechnically actuated device. Int. J. Aeronaut. Space Sci. 17(3), 409–422 (2016)

Li, J., Yan, S., Tan, X.: Dynamic-envelope analysis of clamp-band joint considering pyroshock of satellite separation. J. Spacecr. Rockets 51(5), 1390–1400 (2014)

Woo, J., Cha, S.W., Cho, J.Y., Kim, J.H., Roh, T., Jang, S., Lee, H., Yang, H.W.: Prediction of pyroshock-reduced separation nut behaviors. J. Propuls. Power 34(5), 1240–1255 (2018)

Hwang, D.-H., Lee, J., Han, J.-H., Lee, Y., Kim, D.: Mathematical model for the separation behavior of low-shock separation bolts. J. Spacecr. Rockets 55(5), 1208–1221 (2018)

Hwang, D.-H., Han, J.-H., Lee, J., Lee, Y., Kim, D.: A mathematical model for the separation behavior of a split type low-shock separation bolt. Acta Astronaut. 164, 393–406 (2019)

Hwang, D.-H., Han, J.-H., Lee, J., Lee, Y., Kim, D.: Performance optimization of a split-type low-shock separation bolt. J. Spacecr. Rockets 58(1), 232–239 (2021)

Xiaojun, Y., Dawei, H., Xiaoyong, Z., Ying, L., Qiaolong, Y.: A one-stage, high-load capacity separation actuator using anti-friction rollers and redundant shape memory alloy wires. Rev. Sci. Instrum. 86(12), 125 (2015)

Gao, B.: Analyses of key design parameters for separation nuts. Spacecraft Recoery & Remote Sensing (2001)

Zhang, Y., Yang, S.B., Wang, J., Yang, A.M., Wen, C., Rui-De, W.U.: Design on the low shock separation device of direct thrust model. Init. Pyrotech. 16(6), 33–34 (2007)

Lee, M.J., Lee, Y.K., Oh, H.U.: Performance evaluation of hinge driving separation nut-type holding and releasing mechanism triggered by nichrome burn wire. Int. J. Aeronaut. Space Sci. 16(4), 602–613 (2015)

Yamamoto, A.: The Theory and Computation of Threads Connection. Yokendo, Tokyo (1980)

Sopwith, D.G.: The Theory and Computation of Threads Connection, vol. 159 (1948)

Liu, C., Zhao, Z., Brogliato, B.: Frictionless multiple impacts in multibody systems. I. Theoretical framework. Proc. R. Soc. A, Math. Phys. Eng. Sci. 464(2100), 3193–3211 (2008)

Liu, C., Zhao, Z., Brogliato, B.: Frictionless multiple impacts in multibody systems. II. Numerical algorithm and simulation results. Proc. R. Soc. A, Math. Phys. Eng. Sci. 465(2101), 1–23 (2009)

Naotake, O., Huping, Z., Mitsuru, S., Kiyoshi, K.: Study and suggestions on flow-rate characteristics of pneumatic components In: The 4th International Conference on Fluid Power Transmission and Control (2003)

Cai, M.L.: Modern pneumatic technology theory and practice lecture 1: flow characteristics of pneumatic components. Hydraul. Pneumat. Seal. 02, 44–48 (2007)

Nassar, S.A., Yang, X.: Novel formulation of the tightening and breakaway torque components in threaded fasteners. J. Press. Vessel Technol. 129(4), 653–663 (2006)

Funding

This work was performed under the support of the National Natural Science Foundation of China (NSFC:11932001, 12111530108, and U2241264).

Author information

Authors and Affiliations

Contributions

C. Liu conceived the study and supervised the project. J. Lin, X. Wang conceived the experiments and the numerical modelling. C. Liu, J. Lin and X. Wang jointly performed the analysis and wrote the paper.

Corresponding author

Ethics declarations

Ethical Approval

This declaration is not applicable.

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendices

Appendix A: Mass matrices and angular velocity matrices

The mass matrix of the separation ring and separation plate is expressed as

where \(m_{\mathrm{p}}\) and \(m_{\mathrm{r}}\) are the masses of the separation ring and separation plate, respectively.

The mass matrix of the bolt is expressed as

where \(m_{\mathrm{b}}\) is the mass of the bolt, \(J_{\mathrm{bx}}\), \(J_{\mathrm{by}}\), and \(J_{\mathrm{bz}}\) are inertia of the bolt about \(\boldsymbol{e}_{{\mathrm{b}},1}\)-axis, \(\boldsymbol{e}_{{\mathrm{b}},2}\)-axis, and \(\boldsymbol{e}_{{\mathrm{b}},3}\)-axis, respectively. \(B_{\mathrm{b}}\) is the angular velocity matrix of the bolt, denoted as

The mass matrix of the \(k\)th nut is expressed as

where \(m_{\mathrm{n}}\) is the mass of the nut, \(J_{{\mathrm{n}}k,{\mathrm{x}}}\), \(J_{{\mathrm{n}}k,{\mathrm{y}}}\), and \(J_{{\mathrm{n}}k,{\mathrm{z}}}\) are inertia of the nut about \(\boldsymbol{e}_{{\mathrm{n}}k,1}\)-axis, \(\boldsymbol{e}_{{\mathrm{n}}k,2}\)-axis, and \(\boldsymbol{e}_{{\mathrm{n}}k,3}\)-axis, respectively, and \(B_{{\mathrm{n}}k},k=1,2,3\), is the angular velocity matrix of the \(k\)th nut, denoted as

Appendix B: Jacobian matrices and contact force matrices

Jacobian matrices \(\boldsymbol{N}_{n}(q)\) and \(\boldsymbol{N}_{\tau }(q)\) are defined as

respectively. The matrices of contact forces \(\boldsymbol{F}_{n}\) and \(\boldsymbol{F}_{\tau}\) are defined as

respectively, where all contact force components are calculated by the method in Sect. 4.2.

Appendix C: Contact points on the other interfaces of nuts

(1) Contact points on the surface of the separation ring

The contact-point pair with the order of \(\xi \eta \) between nuts and the separating ring is \((P_{{\mathrm{r}},\xi \eta},P_{{\mathrm{r}},\xi \eta}^{\prime})\) with \(\xi =1,2,\dots ,n_{{\mathrm{r}}z}\) in the axial direction and \(\eta =1,2,\dots ,n_{{\mathrm{r}}h}\) in the circumferential direction, where \(n_{{\mathrm{r}}z}\) and \(n_{{\mathrm{r}}h}\) are numbers of discrete points along their directions, respectively. As shown in Fig. 31, the normal unit vector of the contact pair is \(\boldsymbol{e}_{{\mathrm{nr}},\xi \eta ,3}=[\cos \theta _{{\mathrm{r}},\xi \eta},\ - \sin \theta _{{\mathrm{r}},\xi \eta},\ 0]\), where \(\xi =1,2,\dots ,n_{rz}\), \(\eta =1,2,\dots ,n_{{\mathrm{r}}h}\), and \(\theta _{{\mathrm{r}},\xi \eta}\) is the turning angle of separation ring contact point in circumferential direction. The coordinates of \(P_{{\mathrm{r}},\xi \eta}\) and \(P_{{\mathrm{r}},\xi \eta}^{\prime}\) are \(\boldsymbol{r}_{OP_{{\mathrm{r}},\xi \eta}}(q) = \boldsymbol{r}_{OO_{{\mathrm{n}}k}}(q) + \boldsymbol{r}_{OO_{{\mathrm{n}}k}}(q) \boldsymbol{r}_{O_{{\mathrm{n}}k}P_{{\mathrm{r}},\xi \eta}}\) and \(\boldsymbol{r}_{OP_{{\mathrm{r}},\xi \eta}^{\prime}}(q) = \boldsymbol{r}_{OO_{\mathrm{r}}}(q) + \boldsymbol{r}_{O_{\mathrm{r}}P_{{\mathrm{r}},\xi \eta}^{\prime}}\), respectively.

(2) Contact points on the surface of separation plate and supporting base

The contact-point pair with the order of \(\xi \eta \) between nuts and the separating plate is \((P_{i,\xi \eta},P_{i,\xi \eta}^{\prime})\), where \(i={\mathrm{p}}\) and \(i={\mathrm{m}}\) are contact pairs of the separation plate and the supporting base, respectively, \(\xi =1,2,\dots ,n_{iz}\) is in the axial direction, and \(\eta =1,2,\dots ,n_{ih}\) is in the circumferential direction, where \(n_{iz}\) and \(n_{ih}\) are the numbers of discrete points along the two directions, respectively. As shown in Figs. 32 and 33, the normal unit vector of the \(\xi \eta \)th contact pair is \(\boldsymbol{e}_{{\mathrm{n}}i,\xi \eta ,3}=[\cos (\theta _{i,\xi \eta})\sin ( \gamma _{i}),\ \sin (\theta _{i,\xi \eta})\sin (\gamma _{i}),\ \cos ( \gamma _{i})]\), where \(\xi =1,2,\dots ,n_{iz}\), \(\eta =1,2,\dots ,n_{ih}\), and \(\theta _{i,\xi \eta}\) is the turning angle of contact point in circumferential direction, \(\gamma _{\mathrm{p}}=\gamma \), \(\gamma _{\mathrm{m}}=\pi -\gamma \). The coordinates of \(P_{{\mathrm{p}},\xi \eta}\) and \(P_{{\mathrm{p}},\xi \eta}^{\prime}\) are \(\boldsymbol{r}_{OP_{{\mathrm{p}},\xi \eta}}(q) = \boldsymbol{r}_{OO_{\mathrm{r}}}(q) + \boldsymbol{r}_{O_{ \mathrm{r}}P_{{\mathrm{p}},\xi \eta}}\) and \(\boldsymbol{r}_{OP_{{\mathrm{p}},\xi \eta}^{\prime}}(q) = \boldsymbol{r}_{OO_{{\mathrm{n}}k}}(q) + \boldsymbol{r}_{O_{{\mathrm{n}}k}P_{{\mathrm{p}},\xi \eta}^{\prime}}\), respectively, and the coordinates of \(P_{{\mathrm{m}},\xi \eta}\) and \(P_{{\mathrm{m}},\xi \eta}^{\prime}\) are \(\boldsymbol{r}_{O_{{\mathrm{n}}k}P_{{\mathrm{m}},\xi \eta}^{\prime}}\) and \(\boldsymbol{r}_{OP_{{\mathrm{m}},\xi \eta}^{\prime}}(q) = \boldsymbol{r}_{OO_{{\mathrm{n}}k}}(q)+ \boldsymbol{r}_{O_{{\mathrm{n}}k}P_{{\mathrm{m}},\xi \eta}^{\prime}}\), respectively.

Appendix D: Parameters

Table 1 shows the geometric parameters of the static model. Table 2 shows the mass and inertia parameters of the bolt, nuts, the separation ring, and the separation plate as well as the friction and restitution coefficients of interfaces. Table 3 shows the kinematic parameters of the initial configuration. Table 4 shows the geometric and gas parameters of the gas pressure model.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Lin, J., Wang, X. & Liu, C. Modeling and experimental study on dynamics of a gas-driven split nut device. Multibody Syst Dyn 58, 365–395 (2023). https://doi.org/10.1007/s11044-022-09873-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11044-022-09873-6