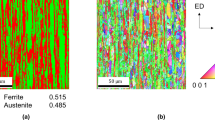

The effect of the temperature and rate of hot deformation on the structure and strain resistance of duplex stainless steel DSS 2205 is considered. Tests for hot compression of specimens are conducted at a temperature of 1223 – 1473 K and deformation rate 0.01 – 30 sec–1 to a degree of 0.4 and 0.8. Maps of deformation mechanisms are plotted. It is shown that the strain resistance decreases after attaining a maximum value in the flow curve, and the flow stress increases with decrease of the temperature and increase of the rate of the deformation. The activation energy of the hot deformation is shown to vary in accordance with the partitioning of strain between the two phases (ferrite and austenite) in the structure of the steel. The rate and the temperature of the deformation affect the deformability of the duplex steel considerably. Continuous dynamic recrystallization of ferrite is activated strongly in the range of flow stability. The range of flow instability is characterized by weak continuous dynamic recrystallization in the ferrite and discontinuous dynamic recrystallization in the austenite.

Similar content being viewed by others

References

C. M. Garzon and A. P. Tschiptschin, “EBSD texture analyses of a high temperature gas nitride duplex stainless steel,” Mater. Sci. Eng. A, 441(1 – 2), 230 – 238 (2006).

J. M. Cabrera, A. Mateo, L. Lanes, et al., “Hot deformation of duplex stainless steels,” J. Mater. Process. Technol., 143 – 144, 321 – 325 (2003).

A. L. Filho, J. M. D. A. Rollo, R. V. Silva, and G. Martinez, “Alternative process to manufacture austenitic(ferritic stainless steel wires,” Mater. Lett., 59(10), 1192 – 1194 (2005).

E. Evangelista, H. J. McQueen, M. Niewczas, and M. Cabibbo, “Hot workability of 2304 and 2205 duplex stainless steels,” Can. Met. Quart., 43, 39 – 353 (2004).

A. Momeni, S. M. Abbasi, and A. Shokuhfar, “Hot compression behavior of as-cast precipitation-hardening stainless steel,” J. Iron Steel Res. Int., 14, 66 – 70 (2014).

O. A. Zambrano, J. Valdés, Y. Aguilar, et al., “Hot deformation of a Fe – Mn – Al – C steel susceptible of k-carbide precipitation,” Mater. Sci. Eng. A, 689, 269 – 285 (2017).

Q. A. Gao, H. L. Zhang, H. J. Li, and C. C. Jiang, “Hot deformation of alumina-forming austenitic steel: EBSD study and flow behavior,” J. Mater. Sci., 54(11), 8760 – 8777 (2017).

N. D. Ryan and H. J. McQueen, “Flow stress, dynamic restoration, strain hardening and ductility in hot working of 316 steel,” J. Mater. Process. Technol., 21(2), 177 – 199 (1990).

A. I. Rudskoy, A. A. Kononov, S. Yu. Kondrat’ev, and M. A. Matveev, “Texture formation in hot rolling of electrical anisotropic steel,” Met. Sci. Heat Treat., 60(11 – 12), 689 – 694 (2019).

O. Balancin, W. A. M. Hoffmann, and J. J. Jonas, “Influence of microstructure on the flow behavior of duplex stainless steels at high temperatures,” Metall. Mater. Trans. A, 31A, 1353 – 1364 (2000).

A. Iza-Mendia, A. Pinol-Juez, J. J. Urcola, and I. Gutierrez, “Microstructural and mechanical behavior of a duplex stainless steel under hot working conditions,” Metall. Mater. Trans. A, 29A, 2975 – 2986 (1998).

Y. Y. Liu, H. T. Yan, X. N.Wang, and M. Yan, “Effect of hot deformation mode on the microstructure evolution of lean duplex stainless steel 2101,” Mater. Sci. Eng. A, 575, 41 – 47 (2013).

G. W. Fan, J. Liu, P. D. Han, and G. J. Qiao, “Hot ductility and microstructure in casted 2205 duplex stainless steels,” Mater. Sci. Eng. A, 515(1 – 2), 108 – 112 (2009).

Y.Wang, Q. L. Pan, Y. F. Song, et al., “Hot deformation and processing maps of X-t50 nickel-based superalloy,” Mater. Des., 51, 154 – 160 (2013).

Y. H. Liu, Y. Q. Ning, Z. K. Yao et al., “Effect of true strains on processing map for isothermal compression of Ni – 20.0Cr – 2.5Ti – 1.5Nb – 1.0Al Ni-base superalloy,” J. Alloy Compd., 612, 56 – 63 (2014).

C. Zener and J. H. Hollomon, “Effect of strain rate upon plastic flow of steel,” J. Appl. Phys., 15(1), 22 – 32 (1944).

C. M. Sellars andW. J. McG, “Hot workability,” Int. Metal., 17, 1 – 24 (1972).

Y. H. Yang and B. Yan, “The microstructure and flow behavior of 2205 duplex stainless steels during high temperature compression deformation,” Mater. Sci. Eng. A, 579, 194 – 201 (2013).

A. Momeni, K. Dehghani, and M. C. Poletti, “Law of mixture used to model the flow behavior of a duplex stainless steel at high temperatures,” Mater. Chem. Phys., 139(2 – 3), 747 – 755 (2013).

B. Eghbali, A. Abdollah-Zadeh, H. Beladi, and P. D. Hodgson, “Characterization on ferrite microstructure evolution during large strain warm torsion testing of plain low carbon steel,” Mater. Sci. Eng. A, 435 – 436, 499 – 503 (2006).

J. C. Tan and M. J. Tan, “Dynamic continuous recrystallization characteristics in two stage deformation of Mg – 3Al – 1Zn alloy sheet,” Mater. Sci. Eng. A, 339, 124 – 132 (2003).

M. Martins and L. C. Casteletti, “Heat treatment temperature influence on ASTM A890 GR 6A super duplex stainless steel microstructure,” Mater. Charact., 55(3), 225 – 233 (2005).

H. Hallberg, B. Svendsen, T. Kayser, and M. Ristinmaa, “Microstructure evolution during dynamic discontinuous recrystallization in particle-containing Cu,” Comp. Mater. Sci., 84, 327 – 338 (2014).

D. G. Cram, X. Y. Fang, H. S. Zurob, et al., “The effect of solute on discontinuous dynamic recrystallization,” Acta Mater., 60(18), 6390 – 6404 (2012).

P. Zhang, C. Hu, C. G. Ding, et al., “Plastic deformation behavior and processing maps of a Ni-based superalloy,” Mater. Des., 65, 575 – 584 (2015).

Y. V. R. K. Prasad, H. L. Gegel, S. M. Doraivelu, et al., “Modeling of dynamic material behavior in hot deformation: Forging of Ti-6242,” Metall. Mater. Trans. A, 5A, 1883 – 1892 (1984).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 2, pp. 3 – 12, February, 2023.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Li, Z., Wu, J., Li, Q. et al. Effect of the Rate and Temperature of Hot Deformation on Strain Resistance of Duplex Stainless Steel. Met Sci Heat Treat 65, 65–73 (2023). https://doi.org/10.1007/s11041-023-00893-3

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11041-023-00893-3