Abstract

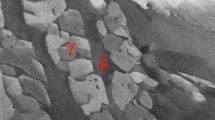

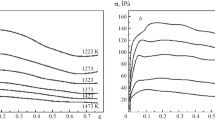

Hot compression tests were carried out in the temperature range of 1223—1473 K and strain rate range of 0.01—30 s–1 to investigate the flow behavior and microstructural evolution of super duplex stainless steel 2507 (SDSS2507). It is found that most of the flow curves exhibit a characteristic of dynamic recrystallization (DRX) and the flow stress increases with the decrease of temperature and the increase of strain rate. The apparent activation energy Q of SDSS2507 with varying true strain and strain rate is determined. As the strain increases, the value of Q declines in different ways with varying strain rate. The microstructural evolution characteristics and the strain partition between the two constituent phases are significantly affected by the Zener-Hollomon parameter (Z). At a lower InZ, dynamic recovery (DRV) and continuous dynamic recrystallization (CDRX) of the ferrite dominate the softening mechanism during the compression. At this time, steady state deformation takes place at the last stage of deformation. In contrast, a higher InZ will facilitate the plastic deformation of the austenite and then activate the discontinuous dynamic recrystallization (DDRX) of the austenite, which leads to a continuous decline of the flow stress even at the last deformation stage together with CDRX of the ferrite.

Similar content being viewed by others

References

C. M. Garzon, A. P. Tschiptschin, Mater. Sci. Eng. A 441 (2006) 230–238.

J. M. Cabrera, A. Mateo, L. Lanes, J. M. Prado, M. Anglada, J. Mater. Process. Technol. 143–144 (2003) 321–325.

Z. G. Song, W. J. Zheng, H. Feng, Z. Z. Wu, H. S. Guo, F. Yu, J. Iron Steel Res. Int. 20 (2013) No. 8, 83–86.

J. O. Nilsson, Mater. Sci. Technol. 8 (1992) 685–700.

A. Iza-Mendia, A. Pinol-Juez, J. J. Urcola, I. Gutierrez, Metall. Mater. Trans. A 29 (1998) 2975–2986.

E. Evangelista, H. J. McQueen, M. Niewczas, M. Cabibbo, Can. Met. Quart. 43 (2004) 339–353.

O. Balancin, W. A. M. Hoffmann, J.J. Jonas, Metall. Mater. Trans. A 31 (2000) 1353–1364.

A. Momeni, S. M. Abbasi, A. Shokuhfar, J. Iron Steel Res. Int. 14 (2007) No. 5, 66–70.

L. F. Li, W. Y. Wang, Z. Q. Sun, Acta Metall. Sin. 39 (2003) 419–425.

D. Zhang, Y. Z. Liu, L. Y. Zhou, Q. Han, B. Jiang, Z. Z. Li, J. Iron Steel Res. Int. 21 (2014) No. 11, 1042–1048.

S. L. Zhu, H. Z. Cao, J. S. Ye, W. H. Hu, G. Q. Zheng, J. Iron Steel Res. Int. 22 (2015) No. 3, 264–271.

L. Chen, X. C. Ma, X. Liu, L. M. Wang, Mater. Des. 32 (2011) 1292–1297.

J. W. Zhao, H. Ding, W.J. Zhao, M. L. Huang, D. B. Wei, Z. Y. Jiang, Comp. Mater. Sci. 92 (2014) 47–56.

Y. H. Yang, B. Yan, Mater. Sci. Eng. A 579 (2013) 194–201.

D. N. Zou, K. Wu, Y. Han, W. Zhang, B. Cheng, G. J. Qiao, Mater. Des. 51 (2013) 975–982.

Y. Y. Liu, H. T. Yan, X. H. Wang, M. Yan, Mater. Sci. Eng. A 575 (2013) 41–47.

G. W. Fan, J. Liu, P. D. Han, G. J. Qiao, Mater. Sci. Eng. A 515 (2009) 108–112.

J. Z. Wang, Z. D. Liu, S. C. Chang, B. H. Sheng, J. Iron Steel Res. Int. 18 (2011) No. 10, 54–58, 79.

X. R. Lei, Q. F. Ding, Y. Y. Chen, X. L. Rui, S. R. Li, Q. F. Wang, J. Iron Steel Res. Int. 20 (2013) No. 6, 38–44.

Y. H. Yang, B. Yan, Mater. Sci. Eng. A 579 (2013) 194–201.

M. Martins, L. C. Casteletti, Mater. Charact. 55 (2005) 225–233.

R. Kaibyshev, K. Shipilova, F. Musin, Y. Motohashi, Mater. Sci. Eng. A 396 (2005) 341–351.

B. Eghbali, A. Abdollah-Zadeh, H. Beladi, P. D. Hodgson, Mater. Sci. Eng. A 435–436 (2006) 499–503.

J. C. Tan, M. J. Tan, Mater. Sci. Eng. A 339 (2003) 124–132.

H. Hallberg, B. Svendsen, T. Kayser, M. Ristinmaa, Comp. Mater. Sci. 84 (2014) 327–338.

H. Beladi, P. Cizek, P. D. Hodgson, Metall. Mater. Trans. A 40 (2009) 1175–1189.

L. Priester, Mater. Sci. Eng. A 309–310 (2001) 430–439.

A. Mirzaei, A. Zarei-Hanzaki, N. Haghdadi, A. Marandi, Mater. Sci. Eng. A 589 (2014) 76–82.

R. C. Souza, E. S. Silva, A. M. Jorge Jr., J. M. Cabrera, O. Balancin, Mater. Sci. Eng. A 582 (2013) 96–107.

P. Cizek, B. P. Wynne, Mater. Sci. Eng. A 230 (1997) 88–94.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation Item: Item Sponsored by National Key Technology Research and Development Program of China (2012BAE04B01)

Rights and permissions

About this article

Cite this article

Ma, M., Ding, H., Tang, Zy. et al. Effects of temperature and strain rate on flow behavior and microstructural evolution of super duplex stainless steel under hot deformation. J. Iron Steel Res. Int. 23, 244–252 (2016). https://doi.org/10.1016/S1006-706X(16)30041-3

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1016/S1006-706X(16)30041-3