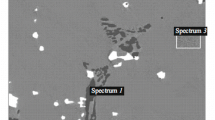

Specific features of alloying element distribution within carbides of multicomponent alloys with the basic composition Ni – 5% Cr – 9% Co – 6% Al – 8.3% W – 4% Re – 4% Ta – 1% Mo – 1.5% Nb – 0.15% C are studied. Thermodynamic processes of crystallization are modelled using the CALPHAD method. Dependences are obtained for carbide dissolution (precipitation) temperature on alloying element content. Results of thermodynamic computations of the chemical composition of carbides are compared with experimental data obtained by electron microscopy (an RÉM-106I microscope with a system for energy dispersion x-ray spectrum analysis). The structure-energy condition of the carbide–matrix interphase boundaries is assessed. It is shown that the dependences derived correlate closely with thermodynamic processes occurring within the system.

Similar content being viewed by others

References

E. N. Kablov (ed.), Cast Heat-Resistant Alloys. S. T. Kishkin Effect, 100th Anniversary of the Birth of S. T. Kishkin [in Russian], Nauka, Moscow (2006).

E. N. Kablov, Cast Gas Turbine Engine Blades: Alloys, Technology, Coatings [in Russian], MiSIS, Moscow (2001).

K. G. Buchanan, M. V. Kral, and C. M. Bishop, “Crystallography and morphology of MC carbides in niobium-titanium modified as-cast HP alloys,” Metall. Mater. Trans. A: Phys. Metall. Mater. Sci., 45A, 3373 – 3385 (2014).

G. F. Vander Voort, G. M. Lucas, and E. P. Manilova, “Metallography and microstructures of heat-resistant alloys,” in: J. R. Davis and Davis & Associates, (eds.), Metallography and Microstructures, ASM Handbook, Vol. 9, ASM International (2004).

O. I. Balyts’kyi, V. M. Mochul’s’kyi, and I. M. Ivas’kevych, “Evaluation of the influence of hydrogen on the mechanical characteristics of complexly alloyed nickel alloys,” Mater Sci., 51, 538 – 547 (2016) (https: doi.org10.1007s11003-016-9873-9).

E. N. Eremen, Yu. O. Filippov, and A. E. Eremen, “Effect of modification on alloying element liquation in chromium-nickel alloy,” Omsk. Nauch. Vest., No. 3(113), 52 – 57 (2012).

Bao-ping Wu, Lin-han Li, Jian-tao Wu, et al., “Microstructure and stress rupture properties of polycrystal and directionally solidified castings of nickel-based superalloys,” Int. J. Minerals, Metall. Mater., 21, 58 – 64 (2014) (DOI: https://doi.org/10.1007/s12613-014-0865-1).

A. A. Glotka and S. V. Gaiduk, “Alloying element distribution within the structure of heat-resistant nickel alloys in secondary carbides,” Zh. Prikl. Spektrosk., 87(5), 732 – 740 (2020).

V. N. Toloraya, E. N. Kablov, and I. L. Svetlov, “Growing texture of during directional crystallization of nickel heat-resistant alloys,” Metalloved. Term. Obrab. Met., No. 8(614), 25 – 32 (2006).

S. Yu. Kondrat’ev, E. V. Sviatysheva, G. P. Anastasiadi, and S. N. Petrov, “Fragmented structure of niobium carbide particles in as-cast modified HP alloys,” Acta Mater., 127, 267 – 276 (2017).

S. Y. Kondrat’ev, G. P. Anastasiadi, S. N. Petrov, and A. V. Ptashnik, “Kinetics of the formation of intermetallic phases in HP-type heat-resistant alloys at long-term high-temperature exposure,” Metall. Mater. Trans. A: Phys. Metall. Mater. Sci., 48(1), 482 – 492 (2017).

A. L. Talis, V. S. Kraposhin, S. Y. Kondrat’ev, et al., “Non-crystallographic symmetry of liquid metal, flat crystallographic faults and polymorph transformation of the M7C3 carbide,” Acta Cryst. Sect. A: Foundations and Advances, A73(3), 209 – 217 (2017).

A. A. Glotka and S. V. Gaidyuk, “Distribution of elements in carbide multicomponent nickel alloys,” Metallofiz. Noveish. Tekhnol., 42(6), 869 – 884 (2020) (DOI: 10.15407mfint.42.06.0869).

N. Saunders, M. Fahrmann, and C. J. Small, “The application of CALPHAD calculations to Ni-based superalloys,” in: K. A. Green, T. M. Pollock, and R. D. Kissinger (eds.), Superalloys 2000, TMS, Warrendale (2000).

C. T. Sims, L. S. Stollof, and U. K. Hagel, Superalloys II. Heat-Resistant Materials for Aerospace and Industrial Power Installation [Russian translation], Metallurgiya, Moscow (1995).

P. Jonšta, Z. Jonšta, and J. Sojka, “Structural characteristics of nickel super alloy INCONEL 713LC after heat treatment,” J. Achiev. Mater. Manuf. Eng., 21, 29 – 32 (2007).

B. G. Choi, “MC Carbide decomposition during thermal exposure of polycrystalline Ni-base superalloys,” Solid State Phenom., 124 – 126, 1505 – 1508 (2007) (https://doi.org/10.4028/www.scientific.net/SSP.124-126.1505).

O. G. Ospenniikova, “Creation of new generation of heat-resistant cast and wrought alloys of steels—record of successful development of domestic engine building,” Metall. Mashin., No. 4, 17 – 20 (2017).

Li Jiang, Wen-Zhu Zhang, Zhou-Feng Xu, et al., “M2C and M6C carbide precipitation in Ni – Mo – Cr based superalloys containing silicon,” Materials & Design, 112, 300 – 308 (2016) (https://doi.org/10.1016/j.matdes.2016.09.075).

E. B. Chabina, E. V. Filonova, B. S. Lomberg, and G. I. Morozova, “Evolution of the structure and phase composition of wrought GTE disk heat-resistant nickel alloys with complication of their alloying,” Metalloved. Term. Obrab. Met., No. 3(717), 8 – 12 (2015).

B. Seiser, R. Drautz, and D. G. Pettifor, “TCP phase predictions in Ni-based superalloys: Structure maps revisited,” Acta Mater., 59, 749 – 763 (2011) (https://doi.org/10.1016/j.actamat.2010.10.013).

Rui Hu, Jinshan Li, and Guanghai Bai, “Precipitation behavior of grain boundary M23C6 and its effect on tensile properties of Ni – Cr – W based superalloy,” Mater. Sci. and Eng. A, 548, 83 – 88 (2012) (DOI: 10.1016/j.msea.2012.03.092).

S. Yu. Kondrat’ev, V. S. Kraposhin, G. P. Anastasiadi, and A. L. Talis, “Experimental observation and crystallographic description of M7C3 carbide transformation in Fe – Cr – Ni – C HP type alloy, Acta Mater., 100, 275 – 281 (2015).

S. Yu. Kondrat’ev, A. V. Ptashnik, G. P. Anastasiadi, and S. N. Petrov, “Analysis of transformations of carbide phases in alloy 25Cr35Ni by the method of quantitative electron microscopy,” Metal Sci. Heat Treat., 57(7 – 8), 402 – 409 (2015).

Z. A. Buyagina, V. E. Ol’shanetskii, and Yu. I. Kononenko, Structure-Energy Condition of Internal and External Interfaces in Metal Systems: Monograph [in Ukrainian], Izd. Lvov Politech., Lvov (2013).

V. E. Ol’shanetskii, “Evaluation of the average relative energy in some model boundary precipitates,” Metallofiz., 50, 89 – 94 (1974).

V. V. Gaiduk, B. S. Natapov, and V. E Ol’shanetskii, “Effect of intergranular boundary composition on properties of alloy type ZhS containing a horophilic impurity,” Fiz. Metall. Metalloved., 26(5), 853 – 859 (1968).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 6, pp. 28 – 36, June, 2021.

Rights and permissions

About this article

Cite this article

Ol’shanetskii, V.E., Glotka, A.A. Distribution of Elements Within Carbides of Multicomponent Alloys of the Ni – Cr – Co – Al – W – Re – Ta – Mo – Nb – C System. Met Sci Heat Treat 63, 318–326 (2021). https://doi.org/10.1007/s11041-021-00689-3

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11041-021-00689-3