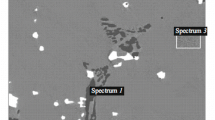

We study specific features of the distributions of alloying elements in secondary carbides for the Ni–13.5Cr–5Co–3.4Al–4.8Ti–7.3W–0.8Mo–0.015B–0.12C multicomponent system. The thermodynamic processes of crystallization are modeled by the CALPHAD method. The results of numerical analyses of the chemical composition of carbides are compared with the experimental data obtained with the help of a РЕМ-106І microscope with a system of energy-dispersive X-ray microanalysis. The influence of alloying elements on the temperature of precipitation of the secondary carbides is analyzed.

Similar content being viewed by others

References

E. N. Kablov, Cast High-Temperature Alloys. Kishkin Effect: Collection of Scientific and Engineering Works Devoted to the 100th Birthday of S. Т. Kishkin [in Russian], Nauka, Moscow (2006).

A. Balitskii, V. Vytvytskyii, L. Ivaskevich, and J. Eliasz, “The high- and low-cycle fatigue behaviour of Ni-contain steels and Nialloys in high pressure hydrogen,” Int. J. Fatigue, 39, 32–37 (2012); https://doi.org/10.1016/j.ijfatigue.2011.05.017.

E. N. Kablov, Cast Blades of Gas Turbine Engines (Alloys, Technology, and Coatings) [in Russian], MISIS, Moscow (2001).

S. T. Kishkin, G. B. Stroganov, and A. V. Logunov, Refractory Cast Alloys Based on Nickel [in Russian], Mashinostroenie, Moscow (1987).

N. Saunders, M. Fahrmann, and C. J. Small, “The application of CALPHAD calculations to Ni-based superalloys,” in: K. A. Green, T. M. Pollock, and R. D. Kissinger (editors), Proc. of the Conf. on Superalloys, 2000, TMS, Warrendale (2000), pp. 803–811.

A. I. Balitskii, V. I. Vytvytskyi, and L. M. Ivaskevich, “The low-cycle fatigue of corrosion-resistant steels in high pressure hydrogen,” Proced. Eng., 2, No. 1, 2367–2371 (2010). https://doi.org/10.1016/j.proeng.2010.03.253.

L. Z. He, Q. Zheng, X. F. Sun, H. R. Guan, Z. Q. Hu, A. K. Tieu, C. Lu, H. T. Zhu, “Effect of carbides on the creep properties of a Ni-base superalloy M963,” Mater. Sci. Eng. A, 397, Issues 1-2, 297–304 (2005). https://doi.org/10.1016/j.msea.2005.02.038.

A. Balitskii and L. Ivaskevich, “Hydrogen effect on cumulation of failure, mechanical properties and fracture toughness of Ni–Cr alloys,” Adv. Mater. Sci. Eng., 2019, Article ID 3680253 (2019); https://doi.org/10.1155/2019/3680253.

А. D. Koval', S. B. Belikov, and А. G. Andrienko, Certificate on (ZMI-3U (KhN64VMKYuT) High-Temperature Corrosion-Resistant Nickel Alloy [in Russian], Zaporozh’e (1995).

C. Sommitsch, R. Radis, A. Krumphals, M. Stockinger, and D. Huber, “Microstructure control in processing nickel, titanium, and other special alloys,” in: J. Lin, D. Balint, and M. Pietrzyk (editors), Microstructure Evolution in Metal Forming Processes, Woodhead Publ., Oxford (2012), pp. 337–383; https://doi.org/10.1533/9780857096340.3.337.

A. Nowotnik, Reference Module in Materials Science and Materials Engineering, Rzeszow University of Technology, Rzeszow (2016). https://doi.org/10.1016/B978-0-12-803581-8.02574-1.

H. Kitaguchi, “Microstructure-property relationship in advanced Ni-based superalloys,” in: Y. Pardhi (editor), Metallurgy-Advances in Materials and Processes, Chapter 2, InTech, Rijeka, Croatia (2012), pp. 19–42; https://doi.org/10.5772/52011.

B. G. Choi, I. S. Kim, D. H. Kim, and J. C. Yong, “MC carbide decomposition during thermal exposure of polycrystalline Ni-base superalloys,” Solid State Phenom., 124–126, 1505–1508 (2007); https://doi.org/10.4028/www.scientific.net/SSP.124-126.1505.

R. Hu, G. Bai, J. Li, J. Zhang, T. Zhang, and H. Fu., “Precipitation behavior of grain boundary M23C6 and its effect on tensile properties of Ni–Cr–W based superalloy,” Mater. Sci. Eng. A, 548, 83–88 (2012); https://doi.org/10.1016/j.msea.2012.03.092.

S. Xiang, S. Mao, Z. Shen, H. Long, H. Wei, S. Ma, J. X. Zhang, Y. Chen, J. Zhang, B.-B. Zhang, and Y. Liu, “Site preference of metallic elements in M23C6 carbide in a Ni-based single crystal superalloy,” Mater. Design, No. 129, 457–468 (2017); https://doi.org/10.1016/j.matdes.2017.05.023.

X. B. Hu, Y. L. Zhu, L. Z. Zhou, B. Wu, and X. L. Ma, “Atomic imaging of the interface between M23C6-type carbide and matrix in a long-term ageing polycrystalline Ni-based superalloy,” Philos. Mag. Lett., No. 95(4), 237–244 (2015); https://doi.org/10.1080/09500839.2015.1039621.

R. Yong-Hua, G. Yong-Xiang, and H. G. Xiang, “Characterization of M23C6 carbide precipitated at grain boundaries in a superalloy,” Metallography, No. 22(1), 47–55 (1989); https://doi.org/10.1016/0026-0800(89)90021-9.

O. I. Balyts’kyi, V. M. Mochul’s’kyi, and L. M. Ivas’kevych, “Evaluation of the influence of hydrogen on mechanical characteristics of complexly alloyed nickel alloys,” Fiz.-Khim. Mekh. Mater., 51, No. 4, 91–99 (2015); English translation: Mater. Sci., 51, No. 4, 538–547 (2016).

A. L. Balitskii and V. I. Vitvitskii, “Determination of stainless steel mechanical properties in high-pressure hydrogen,” in: Proc. of the 7th Internat. Hydrogen Conf. on “Effects of Hydrogen on Materials,” (September 7–10, 2008, Jackson Lake Lodge, WY, USA), ASM International, Materials Park, Ohio (2009), pp. 421–428.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Fizyko-Khimichna Mekhanika Materialiv, Vol. 56, No. 5, pp. 124–131, September–October, 2020.

Rights and permissions

About this article

Cite this article

Glotka, О.А. Distribution of Alloying Elements in Carbides of Refractory Nickel Alloys under the Conditions of Equiaxial Crystallization. Mater Sci 56, 714–721 (2021). https://doi.org/10.1007/s11003-021-00487-5

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11003-021-00487-5