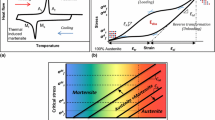

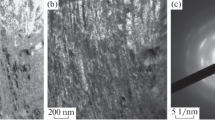

The effect of the microstructure formed in different stages of softening under annealing after moderate cold deformation on martensitic transformations and functional properties of alloy Ti – 50.2 at.% Ni used for actuators is studied. The work consists of two ports. The first part presents the results of diffraction and calorimetric studies reflecting the influence of a long hold (10 h) at the temperature of effective aging (430°C) on the characteristic temperatures of martensitic transformations. The second part is devoted to the influence of structural evolution and martensitic transformations on the characteristics of shape recovery. The conditions of implementation of anomalously high characteristics of shape recovery induced by nonisothermal loading are determined and analyzed.

Similar content being viewed by others

References

J. M. Jani, M. Leary, and A. Subic, “Shape memory alloys in automotive applications,” Appl. Mech. Mater., 663, 248 – 253 (2014).

A. Razov and A. Cherniavsky, “Application of SMAs in modern spacecraft and devices,” J. de Physique IV, 112(10), 1173 – 1176 (2003).

E. P. Ryklina, I. Ya. Khmelevskaya, and S. D. Prokoshkin, “Application of thermomechanically treated titanium nickelide to development of medical implants and tools,” Metalloved. Term. Obrab. Met., No. 5, 3 – 7 (2004).

Jani J. Mohd, M. Leary, A. Subic, and Mark A. Gibson, “A review of shape memory alloy research, applications and opportunities,” Mater. Des., 56, 1078 – 1113 (2014).

N. Sabahi, W. Chen, C. H. Wang, et al., “A review on additive manufacturing of shape-memory materials for biomedical applications,” JOM, 2(3), 1229 – 1253 (2020).

S. Belyaev, S. Resnina, A. Saveleva, et al., “Influence of the grain size on the strain variation in cooling and heating of Ni50.2Ti49.8 alloy under stress,” Mater. Sci. Eng. A, 759, 778 – 784 (2019).

V. N. Grishkov, A. I. Lotkov, A. A. Baturin, et al., “Comparative analysis of inelastic strain recovery and plastic deformation in a Ti49.1Ni50.9 (at.%) alloy under torsion and bending,” AIP Conf. Proc., 1683, 020067 (2015).

A. M. Bragov, A. N. Danilov, A. Yu. Konstantinov, et al., “Mechanical and structural aspects of high-strain-rate deformation of NiTi alloy,” Phys. Met. Metallogr., 116(4), 385 – 392 (2015).

A. Lotkov, V. Grishkov, D. Zhapova, et al., “Temperature dependence of inelastic strain recovery in TiNi-based alloys under torsion,” AIP Conf. Proc., 183, 020125 (2015).

V. Komarov, I. Khmelevskaya, R. Karelin, et al., “Effect of biaxial cyclic severe deformation on structure and properties of Ti – Ni alloys,” J. Alloys Compd., 797, 842 – 848 (2019).

S. Prokoshkin, I. Khmelevskaya, V. Andreev, et al., “Manufacturing of long-length rods of ultrafine-grained Ti – Ni shape memory alloys,” Mater. Sci. Forum., 918, 71 – 76 (2018).

I. Khmelevskaya, S. D. Prokoshkin, V. G. Shipsha, et al., “Thermomechanical strengthening of titanium nickelide and structure changes upon generation and forced isothermal relaxation of reactive stress,” Phys. Met. Metallogr., 93(2), 189 – 195 (2002).

C. Urbina, S. de la Flor, F. Gispert-Guirado, and F. Ferrando, “New understanding of the influence of the pre-training phase transformation behavior on the TWSME in NiTi SMA wires,” Exper. Mech., 53(8), 1415 – 1436 (2013).

E. Ryklina, K. Polyakova, and S. Prokoshkin, “Comparative study of the shape memory effects in Ni-rich Ti – Ni alloy after training in various phase states,” Shape Mem. Superplast., 6(2), 157 – 169.

E. P. Ryklina, S. D. Proloshkin, A. A. Chernavina, and N. N. Perevoshchikova, “Investigation on the influence of thermomechanical conditions of induction and structure on the shape memory effects of Ti – Ni alloy,” Inorg. Mater. Appl., 1(3), 188 – 194 (2010).

E. P. Ryklina, S. D. Prokosjkin, and A. A. Chernavina, “Peculiarities of implementation of abnormally high shape memory effects in thermomechanically treated Ti – Ni alloys,” Inorg. Mater. Appl., 4(4), 348 – 355 (2013).

E. P. Ryklina, I. Yu. Khmelevskaya, S. D. Prokoshkin, et al., “Effects of strain aging on two-way shape memory effect in a nickel-titanium alloy for medical application,” Mater. Sci. Eng. A, 438, 1093 – 1096 (2006).

A. Y. Kolobova, E. P. Ryklina, S. D. Prokoshkin, et al., “Study of the evolution of the structure and kinetics of martensitic transformations in a titanium nickelide upon isothermal annealing after hot helical rolling,” Phys. Met Metallogr., 119(2), 134 – 145 (2018).

K. A. Polyakova-Vachiyan, E. P. Ryklina S. D. Prokoshkin, and S. M. Dubinskii, “Dependence of the functional characteristics of thermomechanically processed titanium nickelide on the size of the structural elements of austenite,” Phys. Met. Metallogr., 117(8), 817 – 827 (2016).

E. Ryklina, A. Korotitskiy, I. Khmelevskaya, et al., “Control of phase transformations and microstructure for optimum realization of one-way and two-way shape memory effects in removable surgical clips,” Mater. Des., 136, 174 – 184 (2017).

E. Ryklina, S. Prokoshkin, and K. Vachiyan, “Nanostructured titanium nickelide: Realization of abnormally high recovery srtain,” IOP Conf. Ser., Mater. Sci. Eng., 63, 012110(1) (2014).

V. Brailovski, I. Yu. Khmelevskaya, S. D. Prokoshkin, et al., “Foundations of heat and thermomechanical treatments and their effect on the structure and properties of titanium nickelide-based alloys,” Phys. Met. Metallogr., 97(1), 23 – 27 (2004).

Ravari B. Karbakhsh, S. Farjami, and M. Nishida, “Effects of Ni concentration and aging conditions on multistage martensitic transformation in aged Ni-rich Ti – Ni alloys,” Acta Mater., 69, 17 – 29 (2014).

E. P. Ryklina, K. A. Polyakova, N. Yu. Tabatchikova, et al., “Effect of B2 austenite grain size and aging time on microstructure and transformation behavior of thermomechanically treated titanium nickelide,” J. Alloys Compd., 764, 626 – 638 (2018).

K. A. Polyakova, E. P. Ryklina, and S. D. Prokoshkin, “Effect of grain size and ageing-induced microstructure on functional characteristics of a Ti – 50.7 at.% Ni alloy,” Shape Mem. Superplast., 6(1), 139 – 147.

E. P. Ryklina, S. D. Prokoshkin, and A. Yu. Kreitsberg,” “Possibilities of attainment of ultimately high shape memory effects in alloy Ti – 50.0 at.% Ni in different structural states of the austenite,” Izv. Ross. Akad. Nauk, Ser. Fiz., 77(11), 1644 – 1652 (2013).

W. Huang, “On the selection of shape memory alloys for actuators,” Mater. Des., 23(1), 11 – 19 (2002).

M. Leary, S. Huang, T. Ataalla, et al., “Design of shape memory alloy actuators for direct power by an automotive battery,” Mater. Des., 43, 460 – 466 (2013).

S. D. Prokoshkin, V. Brailovski, A. V. Korotitskiy, et al., “Specific features of the formation of the microstructure of titanium nickelide upon thermomechanical treatment including cold plastic deformation to degrees from moderate to severe,” Phys. Met. Metallogr., 110(3), 305 – 320 (2010).

V. Brailovski, S. Prokoshkin, K. Inaekyan, and V. Demers, “Functional properties of nanocrystalline, submicrocrystalline and polygonized Ti – Ni alloys processed by cold rolling and post-deformation annealing,” J. Alloys Compd., 509(5), 2066 – 2075 (2011).

I. Yu. Khmelevskaya, R. D. Karelin, S. D. Prokoshkin, et al., “Features of nanostructure and functional properties formation in Ti – Ni shape memory alloys subjected to quasi-continuous equal channel angular pressing,” IOP Conf. Ser., Mater. Sci. Eng., 503(1), 012024 (2019).

V. G. Pushin (ed.), Shape Memory Titanium Nickelide Alloys. Pt. 1. Structure and Phase Transformations [in Russian], Izd. RAN, Ekaterinburg (2006), 440 p.

ASTM F(2004)-17, Standard Test Method for Transformation Temperature of Nickel-Titanium Alloys by Thermal Analysis, ASTM Int., West Conshohocken, PA (2017).

K. Polyakova, E. Ryklina, and S. Prokoshkin, “Thermomechanical response of titanium nickelide on austenite grain/subgrain size,” Mater. Today, Proc., 4(3), 4836 – 4840 (2017).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 4, pp. 34 – 41, April, 2021.

Rights and permissions

About this article

Cite this article

Ryklina, E.P., Abduraimova, N.U. & Resnina, N.N. Alloy Ti – 50.2 at.% Ni for Actuators: Evolution of Structure and Shape Memory Effects Under Post-Deformation Annealing. Part 1. Structure and Phase Transformations. Met Sci Heat Treat 63, 203–209 (2021). https://doi.org/10.1007/s11041-021-00671-z

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11041-021-00671-z