The first part of the paper is devoted to regular features of microstructure formation and evolution of martensitic transformations during post-deformation annealing at 400 – 700°C. The second part presents results of a study of shape recovery characteristics reflecting their evolution as a function of the varying structural state and features of martensitic transformation during post-deformation annealing. Conditions for implementation of anomalously high characteristics of shape recovery under bending with nonisothermal loading are determined and analyzed.

Similar content being viewed by others

Notes

Here and subsequently in the test the element content is given in atomic fractions expressed as a %.

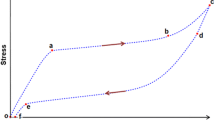

The straight line εt in Fig. 1 is provided for clarity of comparing determined parameters with the value for induced strain and lines denote elastic recovery.

References

E. P. Ryklina, S. D. Prokoshkin, A. A. Chernavina, and N. N. Perevoshchikova, “Investigation on the influence of thermomechanical conditions of induction and structure on the shape memory effects in Ti – Ni alloy,” Inorg. Mater. Appl., 1(3), 188 – 194 (2010).

K. A., Polyakova-Vachiyan, E. P. Ryklina, S. D. Prokoshkin, and S. M. Dubinskii, “Dependence of the functional characteristics of thermomechanically processed titanium nickelide on the size of the structural elements of austenite,” Phys. Met. Metallogr., 117(8), 817 – 827 (2016).

K. Polyakova, E. Ryklina, and S. Prokoshkin, “Thermomechanical response of titanium nickelide on austenite grain-subgrain size,” Mater. Today: Proc., 4(3), 4836 – 4840 (2017).

K. A. Polyakova, E. P. Ryklina, and S. D. Prokoshkin, “Effect of grain size and ageing-induced microstructure on functional characteristics of a Ti – 50.7 at.% Ni alloy,” Shap. Mem. Superelasticity, 6(1), 139 – 147.

A. Y. Kolobova, E. P. Ryklina, S. D. Prokoshkin, et al., “Study of the evolution of the structure and kinetics of martensitic transformations in a titanium nickelide upon isothermal annealing after hot helical rolling,” Phys. Met. Metallogr., 119(2), 134 – 145 (2018).

E. Ryklina, A. Korotitskiy, I. Khmelevskaya, et al., “Control of phase transformations and microstructure for optimum realization of one-way and two-way shape memory effects in removable surgical clips,” Mater. Des., 136, 174 – 184 (2017).

E. Ryklina, S. Prokoshkin, and K. Vachiyan, “Nanostructured titanium nickelide: Realization of abnormally high recovery strain,” IOP Conf. Ser.: Mater. Sci. Eng., 63[012110(1)], 902 – 915 (2014).

E. Ryklina, K. Polyakova, and S. Prokoshkin, “Comparative study of the shape memory effects in Ni-rich Ti – Ni alloy after training in various phase states,” Shap. Mem. Superelasticity, 6(2), 157 – 169.

K. Otsuka and X. Ren, “Physical metallurgy of Ti – Ni-based shape memory alloys,” Progr. Mater. Sci., 50, 511 (2005).

S. Belyaev, N. Resnina, A. Saveleva, et al., “Influence of the grain size on the strain variation on cooling and heating of Ni50.2Ti49.8 alloy under stress,” Mater. Sci. Eng. A, 759, 778 – 784 (2019).

S. Belyaev, N. Resnina, V. Pilyugin, et al., “Shape memory effects in Ti – 50.2 at.% Ni alloy with different grain size,” Mater. Sci. Eng. A, 706, 64 – 70 (2017).

A. Lotkov, V. Grishkov, D. Zhapova, et al., “Superelasticity and shape memory effect after warm abc-pressing of TiNi-based alloy,” Mater. Today: Proc., 4, 4814 – 4818 (2017).

E. P. Ryklina, S. D. Prokoshkin, and A. Yu. Kreistberg, “Possibility of achieving very good shape memory effects in alloy Ti – 50.0 at.% Ni in different austenite structural conditions,” Izv. Ross. Akad. Nauk, Ser. Fiz., 77(11), 1644 – 1652 (2013).

Work was performed with support of the Russian Ministry of Education and Science within the scope of state assignment (project code 0718-2020-0030).

The authors thank SPbGU aspirant A. M. Ivanov for help in performing tensile tests.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 5, pp. 35 – 39, May, 2021.

Rights and permissions

About this article

Cite this article

Ryklina, E.P., Abduraimova, N.U. Alloy Ti – 50.2 at.% Ni for Actuators: Evolution of Structure and Shape Memory Effects During Post-Deformation Annealing. Part 2. Influence of Structure and Phase Transformation Special Features on Shape Memory Effects. Met Sci Heat Treat 63, 264–268 (2021). https://doi.org/10.1007/s11041-021-00681-x

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11041-021-00681-x