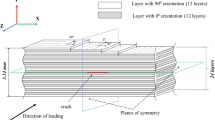

For the first time, analysis of thermal stress distribution arising in a layered ZrB2– SiC – ZrO2 ceramic disk during manufacturing was performed using numerical and analytical methods. The numerical modeling was implemented by the finite-element method considering the temperature dependence of properties of composite components. The residual stress distribution across the layers has a sawtooth character, in which stresses take both negative and positive values. A new analytical solution based on a simplified one-dimensional formulation of the problem for the central part of the disk was proposed. This solution shows that the residual stresses are determined not only by the thermal expansion coefficients and biaxial elastic moduli of the connected materials, but also by a thickness and location of the layers. The results of analytical solution obtained and numerical modeling were in a good agreement. It is shown that, for estimating the residual stress in a laminated composite with assumption that the properties of composite components are temperature-independent, it is appropriate to apply the thermomechanical characteristics corresponding to a high temperature rather than a room or average ones. The porosity effect on the residual stresses in a ceramic laminate was studied. It is found that the consideration of porosity decreased the residual stresses only in the layers where it was entered. Results of the study provide a basis for analyzing residual stresses in the laminates of different compositions and in specific engineering applications.

Similar content being viewed by others

References

D. Ni, Y. Cheng, J. Zhang, J.-X. Liu, J. Zou, B. Chen, H. Wu, H. Li, S. Dong, J. Han, X. Zhang, Q. Fu, and G.-J. Zhang, “Advances in ultra-high temperature ceramics, composites, and coatings,” J. Adv. Ceram., 11, No. 1, 1-56 (2022). https://doi.org/10.1007/s40145-021-0550-6

B. R. Golla, A. Mukhopadhyay, B. Basu, and S. K. Thimmappa, “Review on ultra-high temperature boride ceramics,” Prog. Mater. Sci., 111, 100651 (2020). https://doi.org/10.1016/j.pmatsci.2020.100651

S. C. Zhang, G. E. Hilmas, and W. G. Fahrenholtz, “Mechanical properties of sintered ZrB2–SiC ceramics,” J. Eur. Ceram. Soc., 31, No. 5, 893-901 (2011). https://doi.org/10.1016/j.jeurceramsoc.2010.11.013

X. H. Zhang, W. J. Li, C. Q. Hong, and W. B. Han, “Microstructure and mechanical properties of ZrB2-based composites reinforced and toughened by zirconia,” Int. J. Appl. Ceram. Technol., 5, 499-504 (2008). https://doi.org/10.1111/j.1744-7402.2008.02199.x

B. Saleh, J. Jiang, R. Fathi, T. Al-hababi, Q. Xu, L. Wang, D. Song, and A. Ma, “30 years of functionally graded materials: An overview of manufacturing methods, applications and future challenges,” Compos., Part B, 201, 108376 (2020). https://doi.org/10.1016/j.compositesb.2020.108376

A. G. Burlachenko, Yu. A. Mirovoy, E. S. Dedova, and S. P. Buyakova, “Mechanical response of ZrB2 – SiC – ZrO2 composite laminate,” Russ. Phys. J., 62, No. 8, 1438—1444 (2019). https://doi.org/10.1007/s11182-019-01861-2

R. R. Balokhonov, A. S. Kulkov, A. V. Zemlyanov, V. A. Romanova, E. P. Evtushenko, D. D. Gatiyatullina, and S. N. Kulkov, “Evolution of residual stresses and fracture in thermomechanically loaded particle-reinforced metal matrix composites,” Phys. Mesomech., 24, No. 5, 503-512 (2021). https://doi.org/10.1134/S1029959921050015

M. H. Bayati Chaleshtari, H. Khoramishad, and F. Berto, “Analytical thermal stress analysis of perforated symmetric composite laminates containing a quasi-triangular hole,” Phys. Mesomech., 23, No. 6, 514-530 (2020). https://doi.org/10.1134/S1029959920060077

S. C Her and C. H. Lin, “Thermal stress analysis of a multi-layered structure,” Key Eng. Mater., 467-469, 275-278 (2011). https://doi.org/10.4028/www.scientific.net/kem.467-469.275

Y. Song, W. Wu, F. Xie, Y. Liu, and T. Wang, “A theoretical model for predicting residual stress generation in fabrication process of double-ceramic-layer thermal barrier coating system,” PLoS ONE, 12, No. e0169738, 1-20 (2017). https://doi.org/10.1371/journal.pone.0169738

X. C. Zhang, B. S. Xu, H. D. Wang, Y. X. Wu, “An analytical model for predicting thermal residual stresses in multilayer coating systems,” Thin Solid Films, 488, 274-282 (2005). https://doi.org/10.1016/J.TSF.2005.04.027

B. N. Fedulov, D. A. Bondarchuk, A. N. Fedorenko, and E. V. Lomakin, “Residual stresses near the free edge of composite materials,” Acta Mech., 233, 417-435 (2022). https://doi.org/10.1007/s00707-021-03113-2

E. D’Amato, “Numerical modelling and experimental studies for shape and dimensional control in the curing process of textile composites,” Compos. Struct., 81, 11-20 (2007). https://doi.org/10.1016/j.compstruct.2005.10.001

W. Nowacki, Thermoelasticity, 2nd Edition, Pergamon Press, Oxford (1986).

Y. Yang, Temperature-dependent thermoelastic analysis of multidimensional functionally graded materials, Doctoral Thesis, University of Pittsburgh (2015). http://d-scholarship.pitt.edu/26481/

M. Lugovy, V. Slyunyayev, N. Orlovskaya, E. Mitrentsis, C. G. Aneziris, T. Graule, and J. Kuebler, “Temperature dependence of elastic properties of ZrB2–SiC composites,” Ceram. Int., 42, 2439-2445 (2016). https://doi.org/10.1016/j.ceramint.2015.10.044

V. V. Skripnyak and V. A. Skripnyak, “Predicting the mechanical properties of ultra-high temperature ceramics,” Lett. Mater., 7, No. 4, 407-411 (2017). https://doi.org/10.22226/2410-3535-2017-4-407-411

J. W. Zimmermann, G. E. Hilmas, W. G. Fahrenholtz, R. B. Dinwiddie, W. D. Porter, and H. Wang, “Thermophysical properties of ZrB2 and ZrB2–SiC ceramics,” J. Am. Ceram. Soc., 91, No. 5, 1405-1411 (2008). https://doi.org/10.1111/j.1551-2916.2008.02268.x

V. N. Demidov and A. G. Knyazeva, “Stressed-strain state of multilayer foil under one-axis tension,” Appl. Mech. Mater., 756, 540-545 (2015). https://doi.org/10.4028/www.scientific.net/AMM.756.540

W. Pabst and E. Gregorová, “Young’s modulus of isotropic porous materials with spheroidal pores,” J. Eur. Ceram. Soc., 34, No. 13, 3195-3207 (2014). https://doi.org/10.1016/j.jeurceramsoc.2014.04.009

A. Roberts and E. Garboczi, “Elastic properties of model porous ceramics,” J. Am. Ceram. Soc., 83, No. 12, 3041-3048 (2000). https://doi.org/10.1111/j.1151-2916.2000.tb01680.x

T. Uhlířová and W. Pabst, “Poisson’s ratio of porous and cellular materials with, randomly distributed isometric pores or cells,” J. Am. Ceram. Soc., 103, 6961-6977 (2020). https://doi.org/10.1111/jace.17139

R. W. Rice, Porosity of Ceramics: Properties and Applications, CRC Press, Boca Raton (1998). https://doi.org/10.1201/9781315274539

Z. H. Shui, R. Zhang, W. Chen, and D. Xuan, “Effects of mineral admixtures on the thermal expansion properties of hardened cement paste,” Constr. Build. Mater., 24, No. 9, 1796-1798 (2010). https://doi.org/10.1016/j.conbuildmat.2010.03.006

S. Ghabezloo, “Effect of porosity on the thermal expansion coefficient of porous materials,” Proc. Fifth Biot Conf. on Poromechanics, Vienna, Austria, 10-12 July, 2013. https://doi.org/10.1061/9780784412992.220

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Mekhanika Kompozitnykh Materialov, Vol. 58, No. 6, pp. 1175-1192, November-December, 2022. Russian DOI: https://doi.org/10.22364/mkm.58.6.05.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Smolin, I.Y., Zimina, V.A. & Buyakova, S.P. Estimation of Residual Thermal Stresses in a Layered Ceramic Composite. Mech Compos Mater 58, 823–834 (2023). https://doi.org/10.1007/s11029-023-10071-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11029-023-10071-4