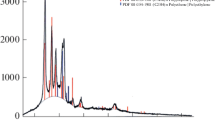

The effect of a filler on the structure, thermal stability, strength, elongation, and impact strength before and after freezing in compositions based on polypropylene modified with a polyolefin elastomer is considered. It is found that the presence of filler reduces the effective activation energy of the thermooxidative destruction of composites and the technological characteristics of thermal stability, which indicated a decrease in the structuredness of the system. The study showed a tendency to increase the melting and crystallization temperatures of polypropylene with a filler content of up to 20 wt%, as well as to a certain narrowing of the temperature range of melting and crystallization with increasing calcite concentration. This was probably associated with the formation of polymer crystallites more uniform in size. It is found that, at a filler content up to 5 wt%, modified calcite particles can serve as additional nucleators. This was reflected in the increasing strength and impact strength by 5 and 6%, respectively, compared with those of the unfilled one.

Similar content being viewed by others

References

M. T. Nguen, N. M. Chalaya, and V. S. Osipchik, “Modification of polypropylene with metallocene ethylene propylene elastomer,”Uspekhi Khimii i Khim. Tekhnol., XXXI, No. 11, 79-81 (2017).

M. T. Nguyen, N. M. Chalaya, and V. S. Osipchik, “Structure and physicomechanical properties of mixtures of polypropylene and a metallocene ethylene-propylene elastomer,” Plast. Massy, 10, No. 9, 12-16 (2017).

L. Gargallo, and D. Radic, Physicochemical Behavior and Supramolecular Organization of Polymers, Springer, (2009).

W. Sitticharoen, A. Chainawakul, T. Sangkas, and Y. Kuntham, “Rheological and mechanical properties of silica-based bagasse-fiber-ash-reinforced recycled HDPE composites,” Mech. Compos. Mater., 52, No. 3, 421-432 (2016).

M. Xanthos, Functional Fillers for Plastic, Weinheim: Wiley-VCH (2010).

S. E. Mambish, “Calcium carbonates in polyolefins,” Plast. Massy, No. 5, 3-6 (2008).

Toxic and Dangerous Properties, Handbook of Pollution Prevention and Cleaner Production: Best Practices in the Agrochemical Industry, Eds. N. Cheremisinoff and P. E. Rosenfeld, William Andrew, 81-213 (2010).

Y.-C. Yang, S.-B. Jeong, S.-Y. Yang, Y.-B. Chae, and H.-S. Kim, “The changes in surface properties of the calcite powder with stearic acid treatment,” Mater. Trans., 50, No. 3, 695-701 (2009).

Z. Cao, M. Daly, L. Clémence, L. M. Geever, I. Major, C. I. Higginbotham, and D. M. Devine, “Chemical surface modification of calcium carbonate particles with stearic acid using different treating methods,” Appl. Surface Sci., 378, 320-329 (2016).

S. N. Ermakov, T. P. Kravchenko, “Molecular polymer-polymer compositions. Some aspects of their obtaining,” Plast. Massy, No. 12, 21-26 (2003).

Ya. A. Kuriptya, O. O. Sleptsov, T. S. Shostak, and B. M. Savchenko, “Electrically conductive hybrid composites based on polyolefins,” Vestn. Kyiv. Nation. Univ. Technol. Design., 80, No. 6, 89-97 (in Ukrainian) (2014).

M. Batistella, B. Otazaghine, R. Sonnier, C. Petter, and J.-M. Lopez-Cuesta, “Fire retardancy of polypropylene/kaolinite composites,” Polym. Degrad. Stabil., No. 129, 260-267 (2016).

N. Yang, Z.-C. Zhang, N. Ma, H.-L. Liu, X.-Q. Zhan, B. Li, W. Gao, F.-C. Tsai, T. Jiang, C.-J. Chang, T.-C. Chiang, and D. Shi, “Effect of surface modified kaolin on properties of polypropylene grafted maleic anhydride,” Results in Phys., 7, 969-974 (2017).

C. Srivabut, T. Ratanawilai, and S. Hiziroglu, “Effect of nanoclay, talcum, and calcium carbonate as filler on properties of composites manufactured from recycled polypropylene and rubberwood fiber,” Construction Building Mater., 162, 450-458 (2018).

E. G. Shushlyaeva, G. V. Minkhaidarova, G. V. Nesyn, E. N. Cherezova, and A. G. Liakumovich, “Modification of polypropylene with a high-molecular-weight polyoctene, Vestn. Kazan. Tekhnol. University, No. 3, 39-44 (2008).

I. I. Salakhov, N. P. Boreiko, M. G. Fatykhov, and S. A. Fedosova, “Modification of polypropylene with cyclic peroxide,” Plast. Massy, No. 2, 22-25 (2012).

S. Saitarly, V. Plavan, N. Rezanova, and N. Sova, “Regulation of rheological and mechanical properties of polypropylene compositions for automotive parts,” Technol. Audit Production Reserves, 6/3, No. 44, 9-14 (2018).

“Impact modifiers: how to make your compound tougher,” Plastics, Additives and Compounding, 6, No. 3, 46-49 (2004).

“ExxonMobil Chemical’s new specialty elastomers provide polymer modification,” Additives for Polymers, No. 9, 2-3 (2009).

G. S. Deshmukh, S. U. Pathak, D. R. Peshwe, and J. D. Ekhe, “Effect of uncoated calcium carbonate and stearic acid coated calcium carbonate on mechanical, thermal and structural properties of poly(butylene terephthalate) (PBT)/calcium carbonate composites,” Bull. Mater. Sci., 33, 277-284 (2010).

A. N. Kovalenko and A. V. Gurova, “The whole truth about chalk additives,” Polymer Materials: Products, Equipment, Technologies, No. 8, 6-12 (2015).

O. T. Shipina, V. K. Mingazova, V. A. Petrov, and A. V. Kostochko Thermal Analysis in Studying Polymers: Textbook, Kazan: Publishing House of KNRTU (2014).

N. R. Prokopchuk, “Determination of the activation energy of polymer destruction according to thermogravimetry data,” Plast. Massy, No. 10, 24-25 (1983).

V. A. Bernshtein and V. M. Egorov, Differential Scanning Calorimetry in the Physicochemistry of Polymers [in Russian], L.: Khimiya (1990).

A. M. Kochnev, A. E. Zaikin, S. S. Galibeev, and V. P. Arkhireev, Physicochemistry of Polymers [in Russian], Kazan: Feng Publishing House (2003).

I. I. Salakhov, N. P. Boreiko, A. Z. Batyrshin, M. V. Shuiskii, E. V. Temnikova, and M. G. Fatykhov, “The effect of a nucleator based on potassium salt of 1,2-cyclohexane-dicarboxylic acid on the thermophysical and physicomechanical properties of polypropylene,” Plast. Massy, No. 12, 9-12 (2012).

D. G. Papageorgiou, K. Chrissafis, and D. N. Bikiaris, “β-Nucleated polypropylene: processing, properties and nanocomposites,” Polym. Rev., 55, No. 4, 596-629 (2015).

K. Shirvanimoghaddam, K. V. Balaji, R. Yadav, O. Zabihi, M. Ahmadi, P. Adetunji, and M. Naebe, “Balancing the toughness and strength in polypropylene composites,” Composites: Part B, 223, 1-33 (2021).

Particulate-filled Polymer Composites, Ed. R. N. Rothon - 2nd ed. — Shawbury: Rapra Technol. Ltd. (2003).

K. Premphet and P. Horanont, “Phase structure of ternary polypropylene/elastomer/filler composites: effect of elastomer polarity,” Polym., 41, 9283-9290 (2000).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Mekhanika Kompozitnykh Materialov, Vol. 58, No. 2, pp. 321-334, March-April, 2022. Russian DOI: https://doi.org/10.22364/mkm.58.2.05.

Rights and permissions

About this article

Cite this article

Saitarly, S., Dzubenko, L., Plavan, V. et al. Influence of Filler on the Structure, Thermal Stability, and Mechanical Properties of Compositions Based on a Modified Polypropylene. Mech Compos Mater 58, 227–236 (2022). https://doi.org/10.1007/s11029-022-10023-4

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11029-022-10023-4