Abstract

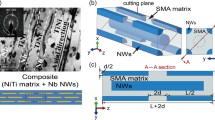

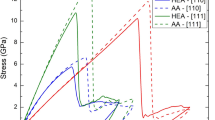

The objective of this paper is to provide new insight into the dynamic thermo-mechanical properties of shape memory alloy (SMA) nanowires subjected to multi-axial loadings. The phase-field model with Ginzburg–Landau energy, having appropriate strain based order parameter and strain gradient energy contributions, is used to study the martensitic transformations in the representative 2D square-to-rectangular phase transformations for FePd SMA nanowires. The microstructure and mechanical behavior of martensitic transformations in SMA nanostructures have been studied extensively in the literature for uniaxial loading, usually under isothermal assumptions. The developed model describes the martensitic transformations in SMAs based on the equations for momentum and energy with bi-directional coupling via strain, strain rate and temperature. These governing equations of the thermo-mechanical model are numerically solved simultaneously for different external loadings starting with the evolved twinned and austenitic phases. We observed a strong influence of multi-axial loading on dynamic thermo-mechanical properties of SMA nanowires. Notably, the multi-axial loadings are quite distinct as compared to the uniaxial loading case, and the particular axial stress level is reached at a lower strain. The SMA behaviors predicted by the model are in qualitative agreements with experimental and numerical results published in the literature. The new results reported here on the nanowire response to multi-axial loadings provide new physical insight into underlying phenomena and are important, for example, in developing better SMA-based MEMS and NEMS devices

Similar content being viewed by others

References

Shu S, Lagoudas D, Hughes D, Wen J (1997) Modeling of a flexible beam actuated by shape memory alloy wires. Smart Mater Struct 6:265

Kahn H, Huff M, Heuer A (1998) The TiNi shape-memory alloy and its applications for MEMS. J Micromech Microeng 8:213

Fu Y, Du H, Huang W, Zhang S, Hu M (2004) TiNi-based thin films in MEMS applications: a review. Sens Actuators A 112(2):395–408

Juan J, No M, Schuh C (2009) Nanoscale shape-memory alloys for ultrahigh mechanical damping. Nature Nanotechnol 4(7):415–419

Barcikowski S, Hahn A, Guggenheim M, Reimers K, Ostendorf A (2010) Biocompatibility of nanoactuators: stem cell growth on laser-generated Nickel–Titanium shape memory alloy nanoparticles. J Nanopart Res 12(5):1733–1742

Bayer BC, Sanjabi S, Baehtz C, Wirth CT, Esconjauregui S, Weatherup RS, Barber ZH, Hofmann S, Robertson J (2011) Carbon nanotube forest growth on NiTi shape memory alloy thin films for thermal actuation. Thin Solid Films 519(18):6126–6129

Bhattacharya K (2003) Microstructure of martensite: why it forms and how it gives rise to the shape-memory effect. Oxford University Press, Qxford

Smith R (2005) Smart material systems: model development, vol 32. Society for Industrial Mathematics, Philadelphia

Lagoudas D, Brinson L, Patoor E (2006) Shape memory alloys, part II: modeling of polycrystals. Mech Mater 38(5–6):430–462

Lagoudas D (2008) Shape memory alloys: modeling and engineering applications. Springer, London

Yoneyama T, Miyazaki S (2008) Shape memory alloys for biomedical applications. Woodhead Publishing

Otsuka K, Wayman C (1998) Shape memory materials. Cambridge University Press, New York

Kohl M (2004) Shape memory microactuators. Springer, Berlin

Miyazaki S, Fu Y, Huang W (2009) Thin film shape memory alloys: fundamentals and device applications. Cambridge University Press, Cambridge

Ozbulut O, Hurlebaus S, DesRoches R (2011) Seismic response control using shape memory alloys: a review. J Intell Mater Syst Struct 22(14):1531–1549

Elahinia M, Hashemi M, Tabesh M, Bhaduri S (2011) Manufacturing and processing of NiTi implants: a review. Prog Mater Sci

Fang D, Lu W, Hwang K (1998) Pseudoelastic behavior of CuAINi single crystal under biaxial loading. Met Mater Int 4(4):702–706

Shan Y, Dodson J, Abraham S, Speich JE, Rao R, Leang KK (2007) A biaxial shape memory alloy actuated cell/tissue stretching system. In: ASME 2007 international mechanical engineering congress and exposition, American Society of Mechanical Engineers, pp. 161–169.

Niendorf T, Lackmann J, Gorny B (2011) H. Maier, Scr Mater, In-situ characterization of martensite variant formation in Nickel-Titanium shape memory alloy under biaxial loading. Scripta Materialia

Tokuda M, Petr S, Takakura M, Ye M (1995) Experimental study on performances in Cu-based shape memory alloy under multi-axial loading conditions. Mater Sci Res Int 1(4):260–265

Sittner P, Hara Y, Tokuda M (1995) Experimental study on the thermoelastic martensitic transformation in shape memory alloy polycrystal induced by combined external forces. Metall Mater Trans A 26(11):2923–2935

Lim T, McDowell D (1999) Mechanical behavior of an Ni-Ti shape memory alloy under axial-torsional proportional and nonproportional loading. J Eng Mater Technol 121:9

Bouvet C, Calloch S, Lexcellent C (2002) Mechanical behavior of a Cu–Al–Be shape memory alloy under multiaxial proportional and nonproportional loadings. J Eng Mater Technol 124:112

McNaney J, Imbeni V, Jung Y, Papadopoulos P, Ritchie R (2003) An experimental study of the superelastic effect in a shape-memory Nitinol alloy under biaxial loading. Mech Mater 35(10):969–986

Lavernhe-Taillard K, Calloch S, Arbab-Chirani S, Lexcellent C (2009) Multiaxial shape memory effect and superelasticity. Strain 45(1):77–84

Grabe C, Bruhns O (2009) Path dependence and multiaxial behavior of a polycrystalline NiTi alloy within the pseudoelastic and pseudoplastic temperature regimes. Int J Plast 25(3):513–545

Birman V (1997) Review of mechanics of shape memory alloy structures. Appl Mech Rev 50(11):629–645

Paiva A, Savi M (2006) An overview of constitutive models for shape memory alloys. Math Probl Eng 2006:1–30

Khandelwal A, Buravalla V (2009) Models for shape memory alloy behavior: an overview of modeling approaches. Int J Struct Changes Solids 1(1):111–148

Tokuda M, Ye M, Takakura M, Sittner P (1999) Thermomechanical behavior of shape memory alloy under complex loading conditions. Int J Plast 15(2):223–239

Bouvet C, Calloch S, Lexcellent C (2004) A phenomenological model for pseudoelasticity of shape memory alloys under multiaxial proportional and nonproportional loadings. Eur J Mech-A/Solids 23(1):37–61

Thiebaud F, Collet M, Foltete E, Lexcellent C (2007) Implementation of a multi-axial pseudoelastic model to predict the dynamic behavior of shape memory alloys. Smart Mater Struct 16:935

Pan H, Thamburaja P, Chau F (2007) Multi-axial behavior of shape-memory alloys undergoing martensitic reorientation and detwinning. Int J Plast 23(4):711–732

Arghavani J, Auricchio F, Naghdabadi R, Reali A, Sohrabpour S (2010) A 3-D phenomenological constitutive model for shape memory alloys under multiaxial loadings. Int J Plast 26(7):976–991

Saleeb A, Padula S II, Kumar A (2011) A multi-axial, multimechanism based constitutive model for the comprehensive representation of the evolutionary response of SMAs under general thermomechanical loading conditions. Int J Plast 27(5):655–687

Raniecki B, Lexcellent C, Tanaka K (1992) Thermodynamic models of pseudoelastic behaviour of shape memory alloys. Arch Mech 44:261–284

Khachaturian A (1983) Theory of structural transformations in solids. Wiley, New York

Melnik R, Roberts A, Thomas K (1999) Modelling dynamics of shape-memory-alloys via computer algebra. Proc SPIE Math Control Smart Struct 3667:290–301

Melnik R, Roberts A, Thomas KA (2000) Computing dynamics of copper-based SMA via center manifold reduction models. Comput Mat Sci 18:255–268

Artemev A, Jin Y, Khachaturyan A (2001) Three-dimensional phase field model of proper martensitic transformation. Acta Mater 49(7):1165–1177

Chen L (2002) Phase field models for microstructure evolution. Annu Rev Mater Res 32:113–140

Levitas V, Preston D (2002) Three-dimensional Landau theory for multivariant stress-induced martensitic phase transformations. II. Multivariant phase transformations and stress space analysis. Phys Rev B 66(134206):1–15

Ahluwalia R, Lookman T, Saxena A (2006) Dynamic strain loading of cubic to tetragonal martensites. Acta Materialia 54:2109–2120

Wang L, Melnik R (2007) Finite volume analysis of nonlinear thermo-mechanical dynamics of shape memory alloys. Heat Mass Transf 43(6):535–546

Bouville M, Ahluwalia R (2008) Microstructure and mechanical properties of constrained shape memory alloy nanograins and nanowires. Acta Mater 56(14):3558–3567

Daghia F, Fabrizio M, Grandi D (2010) A non isothermal Ginzburg–Landau model for phase transitions in shape memory alloys. Meccanica 45:797–807

Dhote R, Fabrizio M, Melnik R, Zu J (2013) Hysteresis phenomena in shape memory alloys by non-isothermal Ginzburg–Landau models. Commun Nonlinear Sci Numer Simul 18:2549–2561

Idesman A, Cho J, Levitas V (2008) Finite element modeling of dynamics of martensitic phase transitions. Appl Phys Lett 93(4):043102

Melnik R, Roberts A, Thomas KA (2002) Phase transitions in shape memory alloys with hyperbolic heat conduction and differential-algebraic models. Comput Mech 29(1):16–26

Melnik R, Roberts A (2003) Modelling nonlinear dynamics of shape-memory-alloys with approximate models of coupled thermoelasticity. Z Angew Math Mech 83(2):93–104

Mahapatra D, Melnik R (2006) Finite element analysis of phase transformation dynamics in shape memory alloys with a consistent Landau–Ginzburg free energy model. Mech Adv Mater Struct 13:443–455

Wang L, Melnik R (2010) Low dimensional approximations to ferroelastic dynamics and hysteretic behavior due to phase transformations. J Appl Mech 77:031015

Dhote R, Melnik R, Zu J (2012) Dynamic thermo-mechanical coupling and size effects in finite shape memory alloy nanostructures. Comput Mat Sci 63:105–117

Wang L, Melnik R (2007) Thermo-mechanical wave propagation in shape memory alloy rod with phase transformations. Mech Adv Mater Struct 14(8):665–676

Melnik R, Wang L (2009) International conference on computational methods for coupled problems in science and engineering coupled problems 2009, CIMNE, Barcelona pp. 1–4.

Dhote RP, Melnik RVN, Zu JW (2011) Dynamic thermo-mechanical properties of shape memory alloy nanowires upon multi-axial loading. ASME conference on smart materials, adaptive structures and intelligent systems pp. 411–417

Dhote R, Gomez H, Melnik R, Zu J. 3D coupled thermo-mechanical phase-field modeling of shape memory alloy dynamics via isogeometric analysis (submitted for evaluation, available as arXiv:1403.5612)

Dhote R, Gomez H, Melnik R, Zu J. Shape memory alloy nanostructures with coupled dynamic thermo-mechanical effects, 2014, (available as arXiv:1403.6133)

Falk F (1980) Model free energy, mechanics, and thermodynamics of shape memory alloys. Acta Metall 28(12):1773–1780

Carstensen C (1996) On the computational of crystalline microstructure. Acta Numer 5:191–256

Rabe K, Ahn C, Triscone J (2007) Physics of ferroelectrics: a modern perspective. Springer, Berlin

Clayton JD, Knap J (2011) A phase field model of deformation twinning: nonlinear theory and numerical simulations. Phys D 240(9):841–858

Hildebrand F, Miehe C (2012) A phase field model for the formation and evolution of martensitic laminate microstructure at finite strains. Philos Mag 92(34):4250–4290

Levin VA, Levitas VI, Zingerman KM, Freiman EI (2013) Phase-field simulation of stress-induced martensitic phase transformations at large strains. Int J Solids Struct 50(19):2914–2928

Phillips R (2001) Crystals, defects and microstructures: modeling across scales. Cambridge University Press, Cambridge

Clayton JD (2011) Nonlinear mechanics of crystals, vol 177. Springer, Dordrecht

Waitz T, Antretter T, Fischer F, Simha N, Karnthaler H (2007) Size effects on the martensitic phase transformation of NiTi nanograins. Acta Mater 55(2):419–444

Gadaj S, Nowacki W, Pieczyska E (2002) Temperature evolution in deformed shape memory alloy. Infrared Phys Technol 43(3–5):151–155

Pieczyska E, Gadaj S, Nowacki W, Tobushi H (2006) Phase-transformation fronts evolution for stress-and strain-controlled tension tests in TiNi shape memory alloy. Exp Mech 46(4):531–542

Pieczyska EA, Tobushi H (2010) Temperature evolution in shape memory alloy during loading in various conditions. 10’th international conference on quantitative infrared thermography, pp. 1–6.

Ricci A, Ricciardi A (2010) A new finite element approach for studying the effect of surface stress on microstructures. Sens Actuators A 159:141–148

Comsol Multi-Physics Modeling and Simulation Software (2012). URL http://www.comsol.com. Accessed May 2013

Park K, Banerjee P (2002) Two-and three-dimensional transient thermoelastic analysis by BEM via particular integrals. Int J Solids Struct 39(10):2871–2892

Wang L, Melnik R (2006) Differential-algebraic approach to coupled problems of dynamic thermoelasticity. Appl Math Mech 27(9):1185–1196

Sapriel J (1975) Domain-wall orientations in ferroelastics. Phys Rev B 12(11):5128

Yasuda H, Komoto N, Ueda M, Umakoshi Y (2002) Microstructure control for developing Fe–Pd ferromagnetic shape memory alloys. Sci Technol Adv Mater 3(2):165–169

Ma Y, Setzer A, Gerlach JW, Frost F, Esquinazi P, Mayr SG (2012) Freestanding single crystalline Fe–Pd ferromagnetic shape memory membranes—role of mechanical and magnetic constraints across the martensite transition. Adv Funct Mater 22(12):2529–2534

Liu Y (2001) Detwinning process and its anisotropy in shape memory alloys. Smart materials and MEMS, International Society for Optics and Photonics, pp. 82–93.

Rejzner J, Lexcellent C, Raniecki B (2002) Pseudoelastic behaviour of shape memory alloy beams under pure bending: experiments and modelling. Int J Mech Sci 44(4):665–686

Reedlunn B, Churchill CB, Nelson EE, Shaw JA, Daly SH (2014) Tension, compression, and bending of superelastic shape memory alloy tubes. J Mech Phys Solids 63:506–537

Dhote R, Gomez H, Melnik R, Zu J (2013) Isogeometric analysis of coupled thermo-mechanical phase-field models for shape memory alloys using distributed computing. Proc Comput Sci 18:1068–1076

Acknowledgments

RPD, JZ and RNVM were supported by NSERC and CRC program, Canada. RM thanks colleagues at Mevlana University for their hospitality during his visit there and TÜBITAK for its support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Dhote, R.P., Melnik, R.N.V. & Zu, J. Dynamic multi-axial behavior of shape memory alloy nanowires with coupled thermo-mechanical phase-field models. Meccanica 49, 1561–1575 (2014). https://doi.org/10.1007/s11012-014-9938-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11012-014-9938-5