Abstract

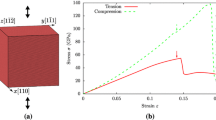

This paper reports atomistic simulation studies of tensile and compressive behavior of nanowires of a model quinary high entropy face-centered cubic (FCC) alloy. The simulations employ empirical interatomic potentials and use massively parallel molecular dynamics techniques at the atomistic level to study the deformation mechanisms. The studies consider pristine cylindrical nanowires oriented along various crystallographic directions. The focus is the role that local composition fluctuations in the random alloy plays in the deformation response. The deformation behavior observed for the complex random alloy is compared with a corresponding “average atom” material that has the same average properties but no local compositional fluctuations. In all cases, deformation is governed by dislocations emitted from the free surface. Twinning was also found, depending on the crystallographic orientation and loading mode. We show that for all orientations, the high entropy alloy (HEA) wires show the onset of plasticity at lower stress levels than the average atom material. However, after the onset of plasticity, the HEA presents a higher strength, mostly driven by the fact that the dislocations emitted from the surface do not glide as easily in the random alloy as they do in the average atom material.

Similar content being viewed by others

References

Park HS, Cai W, Espinosa HD, Huang HC (2009) Mechanics of Crystalline Nanowires. Mrs. Bulletin 34:178. https://doi.org/10.1557/mrs2009.49

Froseth AG, Derlet PM, Van Swygenhoven H (2005) Twinning in nanocrystalline fcc metals. Adv Eng Mater 7:16. https://doi.org/10.1002/adem.200400163

Hyde B, Espinosa HD, Farkas D (2005) An atomistic investigation of elastic and plastic properties of Au nanowires. Jom 57:62. https://doi.org/10.1007/s11837-005-0118-x

Jennings AT, Weinberger CR, Lee SW, Aitken ZH, Meza L, Greer JR (2013) Modeling dislocation nucleation strengths in pristine metallic nanowires under experimental conditions. Acta Mater 61:2244. https://doi.org/10.1016/j.actamat.2012.12.044

Jiang JW, Leach AM, Gall K, Park HS, Rabczuk T (2013) A surface stacking fault energy approach to predicting defect nucleation in surface-dominated nanostructures. J Mech Phys Solids 61:1915. https://doi.org/10.1016/j.jmps.2013.04.008

Kim H-K, Kim S-H, Ahn J-P, Lee J-C (2018) Deformation criterion for face-centered-cubic metal nanowires. Mater Sci Eng, A 736:431. https://doi.org/10.1016/j.msea.2018.08.108

Monk J, Farkas D (2007) Tension-compression asymmetry and size effects in nanocrystalline Ni nanowires. Phil Mag 87:2233. https://doi.org/10.1080/14786430701361404

Mordehai D, David O, Kositski R (2018) Nucleation-controlled plasticity of metallic nanowires and nanoparticles. Adv Mater. https://doi.org/10.1002/adma.201706710

Park HS, Gall K, Zimmerman JA (2006) Deformation of FCC nanowires by twinning and slip. J Mech Phys Solids 54:1862. https://doi.org/10.1016/j.jmps.2006.03.006

Roos B, Kapelle B, Richter G, Volkert CA (2014) Surface dislocation nucleation controlled deformation of Au nanowires. Appl Phys Lett. https://doi.org/10.1063/1.4902313

Weinberger CR, Cai W (2012) Plasticity of metal nanowires. J Mater Chem 22:3277. https://doi.org/10.1039/c2jm13682a

Rabkin E, Srolovitz DJ (2007) Onset of plasticity in gold nanopillar compression. Nano Lett 7:101. https://doi.org/10.1021/nl0622350

Muskeri S, Choudhuri D, Jannotti PA et al (2020) Ballistic impact response of Al0. 1CoCrFeNi high-entropy alloy. Adv Eng Mater 22:2000124. https://doi.org/10.1002/adem.202000124

Muskeri S, Hasannaeimi V, Salloom R, Sadeghilaridjani M, Mukherjee S (2020) Small-scale mechanical behavior of a eutectic high entropy alloy. Sci Rep 10:1. https://doi.org/10.1038/s41598-020-59513-2

Zhang Y, Zuo TT, Tang Z et al (2014) Microstructures and properties of high-entropy alloys. Prog Mater Sci 61:1. https://doi.org/10.1016/j.pmatsci.2013.10.001

Gludovatz B, Hohenwarter A, Catoor D, Chang EH, George EP, Ritchie RO (2014) A fracture-resistant high-entropy alloy for cryogenic applications. Science 345:1153. https://doi.org/10.1126/science.1254581

Gludovatz B, George EP, Ritchie RO (2015) Processing, Microstructure and Mechanical Properties of the CrMnFeCoNi High-Entropy Alloy. Jom 67:2262. https://doi.org/10.1007/s11837-015-1589-z

Ding J, Asta M, Ritchie RO (2018) Melts of CrCoNi-based high-entropy alloys: Atomic diffusion and electronic/atomic structure from ab initio simulation. Appl Phys Lett 113:111902. https://doi.org/10.1063/1.5045216

Ding J, Yu Q, Asta M, Ritchie RO (2018) Tunable stacking fault energies by tailoring local chemical order in CrCoNi medium-entropy alloys. Proc Natl Acad Sci USA 115:8919. https://doi.org/10.1073/pnas.1808660115

Li ZZ, Zhao ST, Ritchie RO, Meyers MA (2019) Mechanical properties of high-entropy alloys with emphasis on face-centered cubic alloys. Prog Mater Sci 102:296. https://doi.org/10.1016/j.pmatsci.2018.12.003

Miracle DB, Senkov ON (2017) A critical review of high entropy alloys and related concepts. Acta Mater 122:448. https://doi.org/10.1016/j.actamat.2016.08.081

Macdonald BE, Fu Z, Zheng B et al (2017) Recent Progress in High Entropy Alloy Research. Jom 69:2024. https://doi.org/10.1007/s11837-017-2484-6

Cantor B, Chang I, Knight P, Vincent A (2004) Microstructural development in equiatomic multicomponent alloys. Mater Sci Eng, A 375:213. https://doi.org/10.1016/j.msea.2003.10.257

Otto F, Yang Y, Bei H, George EP (2013) Relative effects of enthalpy and entropy on the phase stability of equiatomic high-entropy alloys. Acta Mater 61:2628. https://doi.org/10.1016/j.actamat.2013.01.042

Basu I, De Hosson JM (2020) High entropy alloys: ready to set sail? Metals 10:194. https://doi.org/10.3390/met10020194

Varvenne C, Luque A, N W., WA Curtin, (2016) Average-atom interatomic potential for random alloys. Physical Review B B 93:104201. https://doi.org/10.1103/PhysRevB.93.104201

Farkas D, Caro A (2018) Model interatomic potentials and lattice strain in a high-entropy alloy. J Mater Res 33:3218. https://doi.org/10.1557/jmr.2018.245

Pasianot R, Farkas D (2020) Atomistic modeling of dislocations in a random quinary high-entropy alloy. Comput Mater Sci. https://doi.org/10.1016/j.commatsci.2019.109366

Choi W-M, Jo YH, Sohn SS, Lee S, Lee B-J (2018) Understanding the physical metallurgy of the CoCrFeMnNi high-entropy alloy: an atomistic simulation study. Npj Comput Mater 4:1. https://doi.org/10.1038/s41524-017-0060-9

Daw MS, Baskes MI (1984) Embedded-atom method - derivation and application to impurities, surfaces, and other defects in metals. Phys Rev B 29:6443. https://doi.org/10.1103/PhysRevB.29.6443

Jian W-R, Xie Z, Xu S, Su Y, Yao X, Beyerlein IJ (2020) Effects of lattice distortion and chemical short-range order on the mechanisms of deformation in medium entropy alloy CoCrNi. Acta Mater 199:352. https://doi.org/10.1016/j.actamat.2020.08.044

Xu S, Hwang E, Jian W-R, Su Y, Beyerlein IJ (2020) Atomistic calculations of the generalized stacking fault energies in two refractory multi-principal element alloys. Intermetallics 124:106844. https://doi.org/10.1016/j.intermet.2020.106844

Guo S, Hu Q, Ng C, Liu CT (2013) More than entropy in high-entropy alloys: Forming solid solutions or amorphous phase. Intermetallics 41:96. https://doi.org/10.1016/j.intermet.2013.05.002

Mishin Y, Farkas D, Mehl MJ, Papaconstantopoulos DA (1999) Interatomic potentials for monoatomic metals from experimental data and ab initio calculations. Phys Rev B 59:3393. https://doi.org/10.1103/PhysRevB.59.3393

Farkas D (2020) Grain boundary structure in high-entropy alloys. J Mater Sci 55:9173. https://doi.org/10.1007/s10853-020-04387-y

Deluigi O, Pasianot R, Valencia F, Caro A, Farkas D, Bringa E (2021) Simulations of primary damage in a high entropy alloy: probing enhanced radiation resistance. Acta Mater 213:116951. https://doi.org/10.1016/j.actamat.2021.116951

Liu J (2020) Molecular dynamic study of temperature dependence of mechanical properties and plastic inception of CoCrCuFeNi high-entropy alloy. Phys Lett A 384:126516. https://doi.org/10.1016/j.physleta.2020.126516

Parrinello M, Rahman A (1981) Polymorphic transitions in single crystals: A new molecular dynamics method. J Appl Phys 52:7182. https://doi.org/10.1063/1.328693

Martyna GJ, Tobias DJ, Klein ML (1994) Constant pressure molecular dynamics algorithms. J Chem Phys 101:4177. https://doi.org/10.1063/1.467468

Shinoda W, Shiga M, Mikami M (2004) Rapid estimation of elastic constants by molecular dynamics simulation under constant stress. Phys Rev B 69:134103. https://doi.org/10.1103/PhysRevB.69.134103

Schneider T, Stoll E (1978) Molecular-dynamics study of a three-dimensional one-component model for distortive phase transitions. Phys Rev B 17:1302. https://doi.org/10.1103/PhysRevB.17.1302

Plimpton S (1995) Fast parallel algorithms for short-range molecular-dynamics. J Comput Phys 117:1. https://doi.org/10.1006/jcph.1995.1039

Stukowski A (2010) Visualization and analysis of atomistic simulation data with OVITO-the open visualization tool. Model Simul Mater Sc. https://doi.org/10.1088/0965-0393/18/1/015012

Stukowski A, Albe K (2010) Extracting dislocations and non-dislocation crystal defects from atomistic simulation data. Model Simul Mater Sc. https://doi.org/10.1088/0965-0393/18/8/085001

Honeycutt JD, Andersen HC (1987) Molecular-dynamics study of melting and freezing of small lennard-jones clusters. J Phys Chem-Us 91:4950. https://doi.org/10.1021/j100303a014

Stukowski A (2012) Structure identification methods for atomistic simulations of crystalline materials. Model Simul Mater Sc. https://doi.org/10.1088/0965-0393/20/4/045021

Stukowski A, Bulatov VV, Arsenlis A (2012) Automated identification and indexing of dislocations in crystal interfaces. Model Simul Mater Sc. https://doi.org/10.1088/0965-0393/20/8/085007

Van Swygenhoven H, Derlet P, Hasnaoui A (2002) Atomic mechanism for dislocation emission from nanosized grain boundaries. Phys Rev B 66:024101. https://doi.org/10.1103/PhysRevB.66.024101

Van Swygenhoven H, Spaczer M, Caro A, Farkas D (1999) Competing plastic deformation mechanisms in nanophase metals. Phys Rev B 60:22. https://doi.org/10.1103/PhysRevB.60.22

Van Swygenhoven H, Derlet P, Frøseth A (2006) Nucleation and propagation of dislocations in nanocrystalline fcc metals. Acta Mater 54:1975. https://doi.org/10.1016/j.actamat.2005.12.026

Smith L, Farkas D (2018) Connecting interatomic potential characteristics with deformation response in FCC materials. Comput Mater Sci 147:18. https://doi.org/10.1016/j.commatsci.2018.01.055

Stukowski A, Albe K, Farkas D (2010) Nanotwinned fcc metals: Strengthening versus softening mechanisms. Phys Rev B 82:224103. https://doi.org/10.1103/PhysRevB.82.224103

Nöhring WG, Möller JJ, Xie Z, Bitzek E (2016) Wedge-shaped twins and pseudoelasticity in fcc metallic nanowires under bending. Extreme Mechanics Letters 8:140. https://doi.org/10.1016/j.eml.2016.03.001

Van Swygenhoven H, Derlet PM, Frøseth A (2004) Stacking fault energies and slip in nanocrystalline metals. Nat Mater 3:399. https://doi.org/10.1038/nmat1136

Zimmerman JA, Gao H, Abraham FF (2000) Generalized stacking fault energies for embedded atom FCC metals. Model Simul Mater Sc 8:103. https://doi.org/10.1088/0965-0393/8/2/302

Siegel DJ (2005) Generalized stacking fault energies, ductilities, and twinnabilities of Ni and selected Ni alloys. Appl Phys Lett 87:121901. https://doi.org/10.1063/1.2051793

Li W, Fan H, Tang J, Wang Q, Zhang X, El-Awady JA (2019) Effects of alloying on deformation twinning in high entropy alloys. Mater Sci Eng, A 763:138143. https://doi.org/10.1016/j.msea.2019.138143

Deng Y, Tasan CC, Pradeep KG, Springer H, Kostka A, Raabe D (2015) Design of a twinning-induced plasticity high entropy alloy. Acta Mater 94:124. https://doi.org/10.1016/j.actamat.2015.04.014

Wang YQ, Liu B, Yan K et al (2018) Probing deformation mechanisms of a FeCoCrNi high-entropy alloy at 293 and 77 K using in situ neutron diffraction. Acta Mater 154:79. https://doi.org/10.1016/j.actamat.2018.05.013

Huang S, Huang H, Li W et al (2018) Twinning in metastable high-entropy alloys. Nat Commun 9:1. https://doi.org/10.1038/s41467-018-04780-x

Tucker GJ, Foiles SM (2015) Quantifying the influence of twin boundaries on the deformation of nanocrystalline copper using atomistic simulations. Int J Plast 65:191. https://doi.org/10.1016/j.ijplas.2014.09.006

Larsen PM, Schmidt S, Schiøtz J (2016) Robust structural identification via polyhedral template matching. Model Simul Mater Sc 24:055007. https://doi.org/10.1088/0965-0393/24/5/055007

Liang H, Upmanyu M, Huang H (2005) Size-dependent elasticity of nanowires: nonlinear effects. Phys Rev B 71:241403. https://doi.org/10.1103/PhysRevB.71.241403

Diao J, Gall K, Dunn ML (2004) Atomistic simulation of the structure and elastic properties of gold nanowires. J Mech Phys Solids 52:1935. https://doi.org/10.1016/j.jmps.2004.03.009

Gall K, Diao J, Dunn ML (2004) The strength of gold nanowires. Nano Lett 4:2431. https://doi.org/10.1021/nl048456s

McDowell MT, Leach AM, Gall K (2008) On the elastic modulus of metallic nanowires. Nano Lett 8:3613. https://doi.org/10.1021/nl801526c

Wu Z, Zhang Y, Jhon M, Greer J, Srolovitz D (2013) Nanostructure and surface effects on yield in Cu nanowires. Acta Mater 61:1831. https://doi.org/10.1016/j.actamat.2012.11.053

Diao J, Gall K, Dunn ML, Zimmerman JA (2006) Atomistic simulations of the yielding of gold nanowires. Acta Mater 54:643. https://doi.org/10.1016/j.actamat.2005.10.008

Li W, Rao SI, Wang Q, Fan H, Yang J, El-Awady JA (2020) Core structure and mobility of edge dislocations in face-centered-cubic chemically complex NiCoFe and NiCoFeCu equiatomic solid-solution alloys. Materialia 9:2589. https://doi.org/10.1016/j.mtla.2020.100628

Varvenne C, Leyson GPM, Ghazisaeidi M, Curtin WA (2017) Solute strengthening in random alloys. Acta Mater 124:660. https://doi.org/10.1016/j.actamat.2016.09.046

Varvenne C, Curtin WA (2017) Strengthening of high entropy alloys by dilute solute additions: CoCrFeNiAlx and CoCrFeNiMnAlx alloys. Scripta Mater 138:92. https://doi.org/10.1016/j.scriptamat.2017.05.035

Nohring WG, Curtin WA (2017) Dislocation cross-slip in fcc solid solution alloys. Acta Mater 128:135. https://doi.org/10.1016/j.actamat.2017.02.027

Varvenne C, Luque A, Curtin WA (2016) Theory of strengthening in fcc high entropy alloys. Acta Mater 118:164. https://doi.org/10.1016/j.actamat.2016.07.040

Meyers MA, Chawla KK (2008) Mechanical behavior of materials. Cambridge University Press

Ji C, Park HS (2006) Geometric effects on the inelastic deformation of metal nanowires. Appl Phys Lett 89:181916. https://doi.org/10.1063/1.2372748

Cao A, Ma E (2008) Sample shape and temperature strongly influence the yield strength of metallic nanopillars. Acta Mater 56:4816. https://doi.org/10.1016/j.actamat.2008.05.044

Ding Q, Zhang Y, Chen X et al (2019) Tuning element distribution, structure and properties by composition in high-entropy alloys. Nature 574:223. https://doi.org/10.1038/s41586-019-1617-1

Ding Q, Fu X, Chen D et al (2019) Real-time nanoscale observation of deformation mechanisms in CrCoNi-based medium- to high-entropy alloys at cryogenic temperatures. Mater Today 25:21. https://doi.org/10.1016/j.mattod.2019.03.001

Acknowledgements

This work (DF) was supported by the National Science Foundation, Division of Materials Research (Grant number 1507846). CJR acknowledges support by SiiP-UNCuyo. The simulations in this paper were run using the LAMMPS software package (lammps.sandia.gov) at TOKO-FCEN-UNCuyo HPC cluster and on a Tesla Titan X Pascal donated by the NVIDIA Corporation. Figures were generated using OVITO (www.ovito.org). The authors thank the anonymous reviewers for their valuable comments.

Funding

This study was funded by NSF, Division of Materials Research (Grant number 1507846).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Handling Editor: Avinash Dongare.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Ruestes, C.J., Farkas, D. Deformation response of high entropy alloy nanowires. J Mater Sci 56, 16447–16462 (2021). https://doi.org/10.1007/s10853-021-06314-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-021-06314-1