Abstract

An experiment was conducted to examine the impact of blending third-generation biodiesel waste cooking biodiesel (WCO biodiesel) and Azolla pinnata microalgae biodiesel (APO biodiesel) with cerium oxide nanoparticles (CeO2 NPs) at 40 ppm concentration, encompassing sizes of 20, 50, and 100 nm. These biodiesels were generated via methanol-KOH trans-esterification. The investigation was carried out on a Kirloskar TV1 single-cylinder four-stroke variable compression ratio (VCR) diesel engine across load variations (0–100%) and compression ratios (i.e., CRs 16, 17, and 18) at a consistent 1500 rpm engine speed. Among various test fuel blends, D80W10A10CNP50 (Diesel 80% + WCO 10% + APO 10% + 40 ppm CeO2 50 nm) yielded optimized results across all conditions. Incorporating CeO2 NPs boosted brake thermal efficiency (BTE) by reducing brake-specific energy consumption (BSEC), and it facilitated efficient combustion as a catalyst, leading to decreased emissions. NP size notably influenced these enhancements. Specifically, employing 50 nm NPs yielded optimal performance parameters and reduced exhaust emissions across all CRs. At CR-17, as compared to additive-free D80W10A10, the fuel formulation, including 50 nm NPs, resulted in an 11.1% BTE increase and a 6.03% BSEC decrease. Also, emission parameters revealed that carbon monoxide (CO), unburnt hydrocarbons (UBHC), nitrogen oxides (NOX), and smoke opacity decreased by 30.76%, 25.44%, 9.12%, and 13.64%, respectively, while carbon dioxide (CO2) emissions increased by 10.09%. These results may help elucidate the chemical mechanism of action of NPs and open the way for developing a more effective fuel additive.

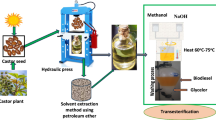

Graphical abstract

Similar content being viewed by others

Availability of data and materials

The datasets used and/or analyzed during the current study are available from the corresponding author on reasonable request. Authors will ensure data transparency.

Abbreviations

- CI:

-

Compression ignition

- ICE:

-

Internal combustion engine

- BTE:

-

Brake thermal efficiency

- BSFC:

-

Brake-specific fuel consumption

- FFA:

-

Free fatty acids

- BSEC:

-

Brake-specific energy consumption

- ID:

-

Ignition delay

- CO:

-

Carbon monoxide

- UBHC:

-

Unburnt hydrocarbons

- NOX :

-

Nitric oxide

- EGT:

-

Exhaust gas temperature

- HRR:

-

Heat release rate

- RPR:

-

Rate of pressure rise

- aTDC:

-

After top dead center

- bTDC:

-

Before top dead center

- VCR:

-

Variable compression ratio

- DEE:

-

Diethyl-ether

- CV:

-

Calorific value

- CRs:

-

Compression ratios

- FTIR:

-

Fourier transform infrared

- EDS:

-

Energy-dispersive spectrum

- XRD:

-

X-ray diffractometer

- SEM:

-

Scanning electron microscopy

- NPs:

-

Nanoparticles

- CeO2 :

-

Cerium oxide

- WCO:

-

Waste cooking oil

- APO:

-

Azolla pinnata Oil

- D100:

-

Pure diesel

- W100:

-

Waste cooking oil biodiesel

- A100:

-

Azolla pinnata Algae biodiesel

- D80W20:

-

80%Diesel + 20% WCO biodiesel

- D80A20:

-

80%Diesel + 20% algae biodiesel

- D80W10A10:

-

80%Diesel + 10%WCO biodiesel + 10%algae biodiesel

- D80W10A10CNP20:

-

80%Diesel + 10% WCO biodiesel + 10% algae biodiesel + CeO2 NPs 20 nm

- D80W10A10CNP50:

-

80%Diesel + 10% WCO biodiesel + 10% algae biodiesel + CeO2 NPs 50 nm

- D80W10A10CNP100:

-

80%Diesel + 10% WCO biodiesel + 10% algae biodiesel + CeO2 NPs 100 nm

- ppm:

-

Parts per million

- SA/V:

-

Surface area to volume

- w.r.t:

-

With respect to

- CA:

-

Crank angle

References

Soltanian S, Aghbashlo M, Almasi F, Hosseinzadeh-Bandbafha H, Nizami A-S, Ok YS, et al. A critical review of the effects of pretreatment methods on the exergetic aspects of lignocellulosic biofuels. Energy Convers Manag. 2020;212:112792. https://doi.org/10.1016/j.enconman.2020.112792.

Bhatt AN, Shrivastava N. Application of artificial neural network for internal combustion engines: a state of the art review. Archiv Comput Methods Eng. 2022;29:897–919. https://doi.org/10.1007/s11831-021-09596-5.

Elkelawy M, Bastawissi HA-E, El Shenawy EA, Taha M, Panchal H, Sadasivuni KK. Study of performance, combustion, and emissions parameters of DI-diesel engine fueled with algae biodiesel/diesel/n-pentane blends. Energy Convers Manag X. 2021;10:100058. https://doi.org/10.1016/j.ecmx.2020.100058.

Steiner S, Bisig C, Petri-Fink A, Rothen-Rutishauser B. Diesel exhaust: current knowledge of adverse effects and underlying cellular mechanisms. Arch Toxicol. 2016;90:1541–53. https://doi.org/10.1007/s00204-016-1736-5.

Rajendran S. A comparative study of performance and emission characteristics of neat biodiesel operated diesel engine: a review. J Therm Anal Calorim. 2021;146:1015–25. https://doi.org/10.1007/s10973-020-10121-2.

Elkelawy M, Bastawissi HA-E, Esmaeil KK, Radwan AM, Panchal H, Sadasivuni KK, et al. Maximization of biodiesel production from sunflower and soybean oils and prediction of diesel engine performance and emission characteristics through response surface methodology. Fuel. 2020;266:117072. https://doi.org/10.1016/j.fuel.2020.117072.

Elkelawy M, Bastawissi HA-E, Abdel-Rahman AK, Abou El-Yazied A, Mostafa El Malla S. Effect of multifunctional fuel additive in diesel/waste oil biodiesel blends on industrial burner flame performance and emission characteristics. Int J Ambient Energy. 2023;44:1382–95. https://doi.org/10.1080/01430750.2023.2173652.

Singh A, Sinha S, Choudhary AK, Panchal H, Elkelawy M, Sadasivuni KK. Optimization of performance and emission characteristics of CI engine fueled with Jatropha biodiesel produced using a heterogeneous catalyst (CaO). Fuel. 2020;280: 118611. https://doi.org/10.1016/j.fuel.2020.118611.

Elkelawy M, Etaiw SEH, Bastawissi HA-E, Marie H, Elbanna A, Panchal H, et al. Study of diesel-biodiesel blends combustion and emission characteristics in a CI engine by adding nanoparticles of Mn (II) supramolecular complex. Atmos Pollut Res. 2020;11:117–28. https://doi.org/10.1016/j.apr.2019.09.021.

Rajpoot AS, Choudhary T, Chelladurai HM, Dwivedi G. A novel comprehensive energy, exergy and sustainability analysis of a diesel engine powered by binary blends of juliflora biodiesel and nanoparticles. J Therm Anal Calorim. 2023;148:11981–97. https://doi.org/10.1007/s10973-023-12473-x.

Nalgundwar A, Paul B, Sharma SK. Comparison of performance and emissions characteristics of DI CI engine fueled with dual biodiesel blends of palm and jatropha. Fuel. 2016;173:172–9. https://doi.org/10.1016/j.fuel.2016.01.022.

Kumar A, Bhansali S, Gupta N, Sharma M. Bioenergy and climate change: greenhouse gas mitigation. Prospects Renew Bioprocess Future Energy Syst. 2019. https://doi.org/10.1007/978-3-030-14463-0_10.

Chaudhary A, Panchal SH, Surana A, Sreekanth M, Ismail S, Feroskhan M. Performance, emission and combustion characteristics of various biodiesel blends. J Therm Anal Calorim. 2022. https://doi.org/10.1007/s10973-021-10642-4.

Agarwal D, Sinha S, Agarwal AK. Experimental investigation of control of NOx emissions in biodiesel-fueled compression ignition engine. Renew Energy. 2006;31:2356–69. https://doi.org/10.1016/j.renene.2005.12.003.

Singh A, Sinha S, Choudhary AK, Sharma D, Panchal H, Sadasivuni KK. An experimental investigation of emission performance of heterogenous catalyst jatropha biodiesel using RSM. Case Stud Therm Eng. 2021;25: 100876. https://doi.org/10.1016/j.csite.2021.100876.

Moorthi M, Murugesan A, Alagumalai A. Effect of nanoparticles on DI-CI engine characteristics fueled with biodiesel–diesel blends—a critical review. J Therm Anal Calorim. 2022;147:9163–79. https://doi.org/10.1007/s10973-022-11234-6.

Kodate SV, Yadav AK, Kumar GN. Combustion, performance and emission analysis of preheated KOME biodiesel as an alternate fuel for a diesel engine. J Therm Anal Calorim. 2020;141:2335–45. https://doi.org/10.1007/s10973-020-09814-5.

Zainudin A, Winaya A, Rahmadesi Y. Biodiesel generated from Jatropha (Jatropha curcas Linn.) seeds selected based on various genotypes crossbred. Energy Rep. 2020;6:345–50. https://doi.org/10.1016/j.egyr.2020.11.160.

Zhang S, Zhang L, Xu G, Li F, Li X. A review on biodiesel production from microalgae: influencing parameters and recent advanced technologies. Front Microbiol. 2022;13: 970028. https://doi.org/10.3389/fmicb.2022.970028.

Radakovits R, Jinkerson RE, Darzins A, Posewitz MC. Genetic engineering of algae for enhanced biofuel production. Eukaryot Cell. 2010;9:486–501. https://doi.org/10.1128/ec.00364-09.

Ahmad S, Jafry AT, Haq M, ul, Asif M, Ahmad K, Zafar FU,. Experimental study of castor biodiesel ternary blends with ethanol, butanol, diethyl ether and dibutyl ether in a diesel engine. J Therm Anal Calorim. 2023;148:927–41. https://doi.org/10.1007/s10973-022-11786-7.

Silitonga AS, Masjuki HH, Ong HC, Mahlia TMI, Kusumo F. Optimization of extraction of lipid from Isochrysis galbana microalgae species for biodiesel synthesis. Energy Sources Part A Recov Util Environ Effects. 2017;39:1167–75. https://doi.org/10.1080/15567036.2017.1310957.

El Maghraby DM, Fakhry EM. Lipid content and fatty acid composition of mediterranean macro-algae as dynamic factors for biodiesel production. Oceanologia. 2015;57:86–92. https://doi.org/10.1016/j.oceano.2014.08.001.

Rajpoot AS, Chelladurai H, Choudhary AK, Ambade B, Choudhary T. Thermal and environmental assessment of Botryococcus braunii green biodiesel with nanoparticles using energy-exergy-emission-sustainability (3ES) analysis in a diesel engine. Sustain Energy Technol Assess. 2023;60: 103473. https://doi.org/10.1016/j.seta.2023.103473.

Muralidharan K, Vasudevan D. Performance, emission and combustion characteristics of a variable compression ratio engine using methyl esters of waste cooking oil and diesel blends. Appl Energy. 2011;88:3959–68. https://doi.org/10.1016/j.apenergy.2011.04.014.

Dorado MP, Ballesteros E, Arnal JM, Gomez J, Lopez FJ. Exhaust emissions from a diesel engine fueled with transesterified waste olive oil☆. Fuel. 2003;82:1311–5. https://doi.org/10.1016/S0016-2361(03)00034-6.

Tizvir A, Shojaeefard MH, Zahedi A, Molaeimanesh GR. Performance and emission characteristics of biodiesel fuel from Dunaliella tertiolecta microalgae. Renew Energy. 2022;182:552–61. https://doi.org/10.1016/j.renene.2021.10.018.

Al-Lwayzy SH, Yusaf T. Chlorella protothecoides microalgae as an alternative fuel for tractor diesel engines. Energies. 2013;6:766–83. https://doi.org/10.3390/en6020766.

Rajpoot AS, Choudhary T, Chelladurai H, Verma TN, Pugazhendhi A. Sustainability analysis of spirulina biodiesel and their bends on a diesel engine with energy, exergy and emission (3E’s) parameters. Fuel. 2023;349: 128637. https://doi.org/10.1016/j.fuel.2023.128637.

Rajpoot AS, Saini G, Chelladurai HM, Shukla AK, Choudhary T. Comparative combustion, emission, and performance analysis of a diesel engine using carbon nanotube (CNT) blended with three different generations of biodiesel. Environ Sci Pollut Res. 2023. https://doi.org/10.1007/s11356-023-28965-0.

Balasubramanian K, Purushothaman K. Effect of acetylene addition on performance, emission and combustion characteristics of neem biodiesel and corn biodiesel-fueled CI engine. J Therm Anal Calorim. 2019;138:1405–14. https://doi.org/10.1007/s10973-019-08269-7.

Saini P, Gupta C, Shankar R. Characterization of corn oil biodiesel and its application in diesel engine. Energy Sources Part A Recov Util Environ Effects. 2019. https://doi.org/10.1080/15567036.2019.1679913.

Chisti Y. Biodiesel from microalgae. Biotechnol Adv. 2007;25:294–306. https://doi.org/10.1016/j.biotechadv.2007.02.001.

Saikia S, Kumar D, Bhoumik S, Paul A. Influence of fuel injection timing and pressure on the performance, combustion and exhaust emissions of a compression ignition engine fueled by titanium dioxide-doped biodiesel. J Therm Anal Calorim. 2023. https://doi.org/10.1007/s10973-023-12169-2.

Bin RA. Utilization of nanotechnology and nanomaterials in biodiesel production and property enhancement. J Nanomater. 2023;2023:1–14. https://doi.org/10.1155/2023/7054045.

Bidir MG, Millerjothi NK, Adaramola MS, Hagos FY. The role of nanoparticles on biofuel production and as an additive in ternary blend fuelled diesel engine: a review. Energy Rep. 2021;7:3614–27. https://doi.org/10.1016/j.egyr.2021.05.084.

Elkelawy M, Etaiw SEH, Bastawissi HA-E, Marie H, Radwan AM, Dawood MM, et al. WCO biodiesel production by heterogeneous catalyst and using cadmium (II)-based supramolecular coordination polymer additives to improve diesel/biodiesel fueled engine performance and emissions. J Therm Anal Calorim. 2022. https://doi.org/10.1007/s10973-021-10920-1.

Srinivas Rao D, Kishora DR. Effect of nanomaterials sizes on the dispersion stability of biodiesel based nanofluids. Adv Mater Lett. 2015;6:247–51. https://doi.org/10.5185/amlett.2015.5638.

Prabu A. Nanoparticles as additive in biodiesel on the working characteristics of a DI diesel engine. Ain Shams Eng J. 2018;9:2343–9. https://doi.org/10.1016/j.asej.2017.04.004.

Sundar SP, Palanimuthu V, Sathyamurthy R, Hemalatha D, Kumar RS, Bharathwaaj R, et al. Feasibility study of neat plastic oil with TiO2 nanoadditive as an alternative fuel in internal combustion engine. J Therm Anal Calorim. 2022;147:2567–78. https://doi.org/10.1007/s10973-021-10657-x.

Elkelawy M, El Shenawy ESA, Bastawissi HA-E, Shams MM. Impact of carbon nanotubes and graphene oxide nanomaterials on the performance and emissions of diesel engine fueled with diesel/biodiesel blend. Processes. 2023;11:3204. https://doi.org/10.3390/pr11113204.

Prabakaran S, Mohanraj T. Optimization of biodiesel production from Azolla pinnata: investigation of CI engine characteristics using nano dosed biodiesel. J Mech Sci Technol. 2021;35:4765–73. https://doi.org/10.1007/s12206-021-0942-0.

Bose N. Production and characterization of biodiesel using Azolla pinnata. Jr Ind Pollut Contr. 2018;34:1833–8.

Park SH, Khan N, Lee S, Zimmermann K, DeRosa M, Hamilton L, et al. Biodiesel production from locally sourced restaurant waste cooking oil and grease: synthesis, characterization, and performance evaluation. ACS Omega. 2019;4:7775–84. https://doi.org/10.1021/acsomega.9b00268.

Wakil MA, Kalam MA, Masjuki HH, Atabani AE, Fattah IR. Influence of biodiesel blending on physicochemical properties and importance of mathematical model for predicting the properties of biodiesel blend. Energy Convers Manag. 2015;94:51–67. https://doi.org/10.1016/j.enconman.2015.01.043.

Senthil Kumar J, Ganesan S, Raja KSS. Experimental analysis of the effects of cerium oxide nanoparticles on a single-cylinder diesel engine using biofuel blended with diesel as fuel. Int J Ambient Energy. 2019;40:490–3. https://doi.org/10.1080/01430750.2017.1410230.

Malavasi L, Fisher CA, Islam MS. Oxide-ion and proton conducting electrolyte materials for clean energy applications: structural and mechanistic features. Chem Soc Rev. 2010;39:4370–87. https://doi.org/10.1039/b915141a.

Goharshadi EK, Samiee S, Nancarrow P. Fabrication of cerium oxide nanoparticles: characterization and optical properties. J Colloid Interface Sci. 2011;356:473–80. https://doi.org/10.1016/j.jcis.2011.01.063.

Zarezadeh Mehrizi M, Ahmadi S, Beygi R, Asadi M. Fabrication of cerium oxide nanoparticles by solution combustion synthesis and their cytotoxicity evaluation. Russ J Non Ferr Met. 2018;59:111–6. https://doi.org/10.3103/S1067821218010170.

Kašpar J, Graziani M, Fornasiero P. Ceria-containing three-way catalysts. Handb Phys Chem Rare Earths. 2000;29:159–267. https://doi.org/10.1016/S0168-1273(00)29007-7.

Gschneidner KA, Bunzli J-CG, Pecharsky VK. Handbook on the physics and chemistry of rare earths, vol. 34. Amsterdam: Elsevier; 2005.

Dinesha P, Mohan S, Kumar S. Impact of alumina and cerium oxide nanoparticles on tailpipe emissions of waste cooking oil biodiesel fuelled CI engine. Cogent Eng. 2021;8:1902067. https://doi.org/10.1080/23311916.2021.1902067.

Elkelawy M, El Shenawy EA, Panchal H, Elbanna A, Bastawissi HA-E, Sadasivuni KK. Experimental investigation on the influences of acetone organic compound additives into the diesel/biodiesel mixture in CI engine. Sustain Energy Technol Assess. 2020;37:100614. https://doi.org/10.1016/j.seta.2019.100614.

Deshmukh S, Kumar R, Bala K, Chandra R. Comparison and testing of cerium oxide nanoparticle added Pongamia and Scenedesmus microalgae biodiesel blends. Chem Eng Res Des. 2023. https://doi.org/10.1016/j.cherd.2023.08.026.

Soudagar MEM, Nik-Ghazali N-N, Kalam MA, Badruddin IA, Banapurmath NR, Akram N. The effect of nano-additives in diesel-biodiesel fuel blends: a comprehensive review on stability, engine performance and emission characteristics. Energy Convers Manag. 2018;178:146–77. https://doi.org/10.1016/j.enconman.2018.10.019.

Doğan B, Erol D. The investigation of energy and exergy analyses in compression ignition engines using diesel/biodiesel fuel blends-a review. J Therm Anal Calorim. 2023;148:1765–82. https://doi.org/10.1007/s10973-022-11862-y.

Razzaq L, Abbas MM, Waseem A, Jauhar TA, Fayaz H, Kalam MA, et al. Influence of varying concentrations of TiO2 nanoparticles and engine speed on the performance and emissions of diesel engine operated on waste cooking oil biodiesel blends using response surface methodology. Heliyon. 2023. https://doi.org/10.1016/j.heliyon.2023.e17758.

Lu X, Li X, Qian J, Chen Z. The surfactant-assisted synthesis of CeO2 nanowires and their catalytic performance for CO oxidation. Powder Technol. 2013;239:415–21. https://doi.org/10.1016/j.powtec.2013.01.060.

Murugapoopathi S, Vasudevan D. Energy and exergy analysis on variable compression ratio multi-fuel engine. J Therm Anal Calorim. 2019;136:255–66. https://doi.org/10.1007/s10973-018-7761-2.

Kumar P, Srivastava VC, Gläser R, With P, Mishra IM. Active ceria-calcium oxide catalysts for dimethyl carbonate synthesis by conversion of CO2. Powder Technol. 2017;309:13–21. https://doi.org/10.1016/j.powtec.2016.12.016.

Elkelawy M, Bastawissi HA-E, Esmaeil KK, Radwan AM, Panchal H, Sadasivuni KK, et al. Experimental studies on the biodiesel production parameters optimization of sunflower and soybean oil mixture and DI engine combustion, performance, and emission analysis fueled with diesel/biodiesel blends. Fuel. 2019;255:115791. https://doi.org/10.1016/j.fuel.2019.115791.

Mei D, Li X, Wu Q, Sun P. Role of cerium oxide nanoparticles as diesel additives in combustion efficiency improvements and emission reduction. J Energy Eng. 2016;142:04015050. https://doi.org/10.1061/(ASCE)EY.1943-7897.0000329.

Appavu P, Venkata RM. Study of emission characteristics of a diesel engine using cerium oxide nanoparticle blended pongamia methyl ester. Int J Ambient Energy. 2020;41:524–7. https://doi.org/10.1080/01430750.2018.1477063.

Jeyakumar N, Narayanasamy B. Effect of Basil antioxidant additive on the performance, combustion and emission characteristics of used cooking oil biodiesel in CI engine. J Therm Anal Calorim. 2020;140:457–73. https://doi.org/10.1007/s10973-019-08699-3.

Rajpoot AS, Choudhary T, Chelladurai H, Patel NK. Effect of graphene nanoparticles on the behavior of a CI engine fueled with Jatropha biodiesel. Mate Today Proc. 2023. https://doi.org/10.1016/j.matpr.2023.03.785.

Rangabashiam D, Logesh K, Yashvanth U, Subbiah G, Selvam C. Detailed study on the effect of nano-particle size on emission characteristics of diesel engine. Pet Sci Technol. 2019. https://doi.org/10.1080/10916466.2019.1613430.

Chinnasamy C, Tamilselvam P, Ranjith R. Influence of aluminum oxide nanoparticle with different particle sizes on the working attributes of diesel engine fueled with blends of diesel and waste plastic oil. Environ Sci Pollut Res. 2019;26:29962–77. https://doi.org/10.1007/s11356-019-06139-1.

Dinesha P, Kumar S, Rosen MA. Effects of particle size of cerium oxide nanoparticles on the combustion behavior and exhaust emissions of a diesel engine powered by biodiesel/diesel blend. Biofuel Res J. 2021;8:1374–83. https://doi.org/10.18331/BRJ2021.8.2.3.

Rajpoot AS, Choudhary T, Chelladurai H, Rajak U, Sahu MK. Comparison of the effect of CeO2 and CuO2 nanoparticles on performance and emission of a diesel engine fueled with Neochloris oleoabundans algae biodiesel. Mater Today Proc. 2023. https://doi.org/10.1016/j.matpr.2023.03.233.

Acknowledgements

The author and his co-researcher would like to express their gratitude to the staff of the Department of Mechanical Engineering at IIT(ISM) in Dhanbad, Jharkhand, India, for their assistance in carrying out this research investigation, as well as the Central Research Facility at IIT(ISM) for characterization of CeO2 NPs and different fuel samples.

Funding

This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors.

Author information

Authors and Affiliations

Contributions

NU conceived of the experiential idea. NU and RKD conducted the experiments and have done the calculations. NU and SKG wrote the manuscript with abstract, literature review, experimental fuel and methodology, and interpretation of the results. SKG helped to draw all the graphs and interpretation of the results. All authors (NU, RKD, and SKG) discussed the results and contributed to the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Ethics approval

We the authors, Nikunj Upadhyay, Randip Kumar Das, and Subrata Kumar Ghosh, hereby declare that the manuscript in part or in full has not been submitted or published anywhere. This manuscript is original and not have been published elsewhere in any form or language (partially or in full). The paper is not currently being considered for publication elsewhere. The paper reflects the authors’ own research and analysis in a truthful and complete manner. The paper properly credits the meaningful contributions of co-authors and co-researchers.

Consent for publication

I hereby submit the manuscript for publication in “Environmental Science and Pollution Research” and assure that this manuscript has neither been published in any other journal nor submitted for publication in any other journal. I also undertake along with the other authors that animal/human study (if any) was taken after the prior approval of relevant country/institutional ethical committee. Kindly consider the manuscript for publication in your journal. I abide all rules and regulations of the journal. In future, if any litigation arises in this article, I will cooperate with the editor to resolve the issue. I accept the decision of the editor would be final.

Consent to participate

All authors (Nikunj Upadhyay, Randip Kumar Das, and Subrata Kumar Ghosh) agreed with the content all gave explicit consent to submit and they obtained consent from the responsible authorities at the institute/organization where the work has been carried out before the work is submitted.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix

Appendix

Formulations used

The general equations used for different performance parameters such as BTE, BSFC, and BSEC are given from Eqs. (6)–(11).

Calculations

-

(a)

Brake power (BP) in kW

$${\text{BP}} = \frac{{2{\uppi }.{\text{N}}.{\text{T}}}}{60 \times 1000} = \frac{{2{\uppi }.{\text{N}}.{\text{W}}.{\text{g}}.{\text{R}}}}{60 \times 1000}{\text{ kW}}$$(6)where N: engine speed in RPM, T: torque in Nm, W: load on dynamometer in kg, R: dynamometer arm length = 0.185 m, g: acceleration due to gravity = 9.81 m s−2.

-

(b)

Total fuel consumption (TFC, \(\dot{m}_{{\text{f}}}\)) in kg h−1

$${\text{TFC}}\left( {\dot{m}_{{\text{f}}} } \right) = \frac{{20 \times \rho_{{{\text{oil}}}} \times 3600}}{{t \times 10^{6} }} = \frac{{0.072 \times \rho_{{{\text{oil}}}} }}{t} \;{\text{kg}}/{\text{h}}$$(7)where t: time for consumption of 20 cc of fuel, \(\rho_{{{\text{oil}}}}\): density of fuel = 830 kg m−3 for diesel.

-

(c)

Brake-specific fuel consumption (BSFC) in kg kW−1 h−1

$${\text{BSFC}} = \frac{{{\text{Total}}\;{\text{Fuel}}\;{\text{Consumption}}}}{{{\text{Brake}}\;{\text{Power}}}} = \frac{{0.072 \times \rho_{{{\text{oil}}}} }}{{t \times {\text{BP}}}} \;\frac{{{\text{kg}}}}{{{\text{kW}}\;{\text{h}}}}$$(8) -

(d)

Brake thermal efficiency (\(\eta\) bth)

$$\eta_{{{\text{bth}}}} \left( \% \right) = \frac{{{\text{Brake}}\;{\text{Power}}\;{\text{in}}\;{\text{kW}}}}{{{\text{Rate}}\;{\text{of}}\;{\text{heat}}\;{\text{input}}}} = \frac{{{\text{Brake}}\;{\text{Power}}}}{{{\text{Fuel}}\;{\text{consumption}}\;{\text{in}}\;{\text{kg }}{\text{s}}^{-1} \times {\text{HV}}}}$$(9)$$\eta_{{{\text{bth}}}} \left( \% \right) = \frac{{{\text{Brake}}\;{\text{Power}} \times 3600}}{{\dot{m}_{{\text{f}}} \times {\text{HV}}}} \times 100$$(10)where \(\dot{m}_{{\text{f}}}\): total fuel consumption in kg h−1, HV: heating value of fuel in kJ kg−1.

-

(e)

Brake-specific energy consumption (BSEC)

$${\text{BSEC}} = \frac{{{\text{Heating}}\;{\text{value}} \times {\text{Total}}\;{\text{Fuel}}\;{\text{Consumption}}}}{{{\text{Brake}}\;{\text{Power}}}}$$(11)

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Upadhyay, N., Das, R.K. & Ghosh, S.K. Size impact of cerium oxide nanoparticles (CeO2) on ternary fuel blend using third-generation biodiesel in VCR diesel engine. J Therm Anal Calorim 149, 3851–3876 (2024). https://doi.org/10.1007/s10973-024-12958-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-024-12958-3