Abstract

This paper analyzes the effect of both solidification and heat treatment process on microstructure, microhardness, electrical resistivity and electrical conductivity (ρ and σ) in an Al–3Cu–5Nb alloy (mass/%). In this sense, an unsteady-state horizontal solidification experiment was carried out using a water-cooled solidification device and as-cast samples were subjected to various T6-type heat treatment conditions. The solidification thermal parameters investigated were the growth and cooling rates (VL and TR), and those of the thermal treatment were the temperatures and times in the solution and aging stages. Techniques by optical and scanning electron microscopy differential scanning calorimetry (DSC) and X-ray diffractometry (XRD) were applied for microstructural and thermal analysis. The DSC results showed the plateau corresponding to the beginning and end of the formation of the Al-rich solid solution (Alα), indicated by the TLα and TS/eutectic temperatures of the alloy (~ 645 °C and ~ 530 °C). An increase in the HV values with the application of the T6-heat treatment in the as-cast samples was observed for all assumed conditions and the best condition found was for 500 °C/3 h of solution, and 155 °C/5 h for the aging in which the hardness increased from 61.4 to 90.33 HV, equivalent to the increase of ~ 47%. It was observed that macrostructure consisting of columnar grains favor electric current flow contributing to the decrease of ρ, as a consequence increased σ. For the total length of the ingot, the electrical conductivity increased from 23.8 × 106 S m−1 in the solidified conditions to 40.1 × 106 S m−1 (~ 68.5%) in the T6 conditions equal to 490 °C/3 h and 155 °C/3 h in the solution and aging stages, respectively, as well as higher σ values were found in the region formed by columnar grains in which higher VL and TR values and lower secondary dendritic spacing (λ2) were obtained.

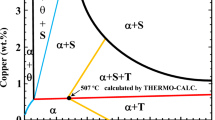

Source: Adapted from [54]

Similar content being viewed by others

References

ASM Handbook Committee, editor. Properties and selection: nonferrous alloys and special-purpose materials. Materials Park: ASM International; 1990.

ASM Handbook Committee, editor. ASM Handbook Volume 4E: Heat Treating of Nonferrous Alloys. 10th ed. Materials Park: ASM International; 1990.

Cochard A, Zhu K, Joulié S, Douin J, Huez J, Robbiola L, et al. Natural aging on Al–Cu–Mg structural hardening alloys—investigation of two historical duralumins for aeronautics. Mater Sci Eng A. 2017;690:259–69.

Barbosa CR, Machado GH, Azevedo HM, Rocha FS, José Filho C, Pereira AA, et al. Tailoring of processing parameters, dendritic microstructure, Si/intermetallic particles and microhardness in as-cast and heat-treated samples of Al7Si0.3Mg alloy. Met Mater Int. 2020;26:370–83.

Barros AS, Magno IA, Souza FA, Mota CA, Moreira AL, Silva MA, et al. Measurements of microhardness during transient horizontal directional solidification of Al-Rich Al–Cu alloys: Effect of thermal parameters, primary dendrite arm spacing and Al2Cu intermetallic phase. Met Mater Int. 2015;21:429–39.

Costa MO, Barbosa CR, Azevedo HM, Machado GH, Rocha FS, Moreira AS, et al. Thermal analysis via horizontal solidification of Al3Cu2Si (mass%) alloy: thermal and microstructural parameters, intermetallic compounds and microhardness. J Therm Anal Calorim. 2021;146:2059–71.

Brito C, Vida T, Freitas E, Cheung N, Spinelli JE, Garcia A. Cellular/dendritic arrays and intermetallic phases affecting corrosion and mechanical resistances of an Al–Mg–Si alloy. J Alloys Compd. 2016;673:220–30.

Çadırlı E. Effect of solidification parameters on mechanical properties of directionally solidified Al-rich Al–Cu alloys. Met Mater Int. 2013;19:411–22.

Chen M, Kattamis TZ. Dendrite coarsening during directional solidification of Al–Cu–Mn alloys. Mater Sci Eng A. 1998;247:239–47.

Costa TA, Dias M, Gomes LG, Rocha OL, Garcia A. Effect of solution time in T6 heat treatment on microstructure and hardness of a directionally solidified Al–Si–Cu alloy. J Alloys Compd. 2016;683:485–94.

Moreira Coutinho M, Saraiva Silva JI, Primo Sousa T, Monteiro RD. Upward unsteady-state solidification of dilute Al–Nb alloys: microstructure characterization, microhardness, dynamic modulus of elasticity, damping, and XRD analyses. Metals. 2019;9:713.

Cui X, Wu Y, Liu X, Zhao Q, Zhang G. Effects of grain refinement and boron treatment on electrical conductivity and mechanical properties of AA1070 aluminum. Mater Des. 2015;86:397–403.

Lima JO, Barbosa CR, Magno IAB, Nascimento JM, Barros AS, Oliveira MC, et al. Microstructural evolution during unsteady-state horizontal solidification of Al–Si–Mg (356) alloy. Trans Nonferrous Met Soc China. 2018;28:1073–83.

Ebhota WS, Jen T-C. Effects of modification techniques on mechanical properties of Al–Si cast alloys. In: Sivasankaran S, editor. Alum alloys—recent trends process charact mech behav appl. London: IntechOpen; 2017.

Reinhart G, Nguyen-Thi H, Mangelinck-Noël N, Baruchel J, Billia B. In Situ investigation of dendrite deformation during upward solidification of Al-7mass/%Si. JOM. 2014;66:1408–14.

Wang SC, Starink MJ. Two types of S phase precipitates in Al–Cu–Mg alloys. Acta Mater Elsevier. 2007;55:933–41.

Wang SC, Starink MJ, Gao N. Precipitation hardening in Al–Cu–Mg alloys revisited. Scr Mater. 2006;54:287–91.

Li S, Zhang J, Yang J, Deng Y, Zhang X. Influence of Mg contents on aging precipitation behavior of Al–3.5 Cu–xMg alloy. Acta Metall Sin Engl Lett. 2014;27:107–14.

Poirier DR, Yeum K, Maples AL. A thermodynamic prediction for microporosity formation in aluminum-rich Al–Cu alloys. Metall Trans A. 1987;18:1979–87.

Polmear IJ, Chester RJ. Abnormal age hardening in an Al–Cu–Mg alloy containing silver and lithium. Scr Metall. 1989;23:1213–7.

Rosa DM, Spinelli JE, Garcia A. Tertiary dendrite arm spacing during downward transient solidification of Al–Cu and Al–Si alloys. Mater Lett. 2006;60:1871–4.

Shih H-C, Ho N-J, Huang JC. Precipitation behaviors in Al–Cu–Mg and 2024 aluminum alloys. Metall Mater Trans A. 1996;27:2479–94.

Sjölander E, Seifeddine S. The heat treatment of Al–Si–Cu–Mg casting alloys. J Mater Process Technol. 2010;210:1249–59.

Zamani M, Toschi S, Morri A, Ceschini L, Seifeddine S. Optimisation of heat treatment of Al–Cu–(Mg–Ag) cast alloys. J Therm Anal Calorim. 2020;139:3427–40.

Starke EA, et al. Aluminum alloys: alloy, heat treatment, and temper designation. In: Buschow KHJ, Cahn RW, Flemings MC, Ilschner B, Kramer EJ, Mahajan S, et al., editors. Encycl mater sci technol. Elsevier; 2001. p. 106–7.

Tash M, Samuel FH, Mucciardi F, Doty HW. Effect of metallurgical parameters on the hardness and microstructural characterization of as-cast and heat-treated 356 and 319 aluminum alloys. Mater Sci Eng A. 2007;443:185–201.

Chen YT, Nieh GY, Wang JH, et al. Effects of Cu/Mg ratio and heat treatment on microstructures and mechanical properties of Al–4.6 Cu–Mg–0.5 Ag alloys. Mater Chem Phys. 2015;162:764–70.

Chen C-Y, Hwang W-S. Effect of annealing on the interfacial structure of aluminum-copper joints. Mater Trans. 2007;48(7):1938–47.

Souza FA, Costa MO, Magno IA, Nascimento JM, Silva AP, Costa TS, Rocha OL. Investigation on microstructural and microhardness evolution in as-cast and T6/heat-treated samples of a horizontally solidified. J Mater Res Technol. 2019;8(5):5046–52.

Barros A, Cruz C, Silva AP, Cheung N, Garcia A, Rocha O, Moreira A. Horizontally solidified Al–3 wt%Cu–(0.5 wt%Mg) alloys: tailoring thermal parameters, microstructure, microhardness, and corrosion behavior. Act Metall Sin. 2019;32:695–709.

Barros A, Cruz C, Silva AP, Cheung N, Garcia A, Rocha O, Moreira A. Length scale of solidification microstructure tailoring corrosion resistance and microhardness in T6 heat treatment of an Al–Cu–Mg alloy. Corros Eng Sci Technol. 2020;55(6):471–9.

Samuel FH. Incipient melting of Al5Mg8Si6Cu2 and Al2Cu intermetallics in unmodified and strontium-modified Al–Si–Cu–Mg (319) alloys during solution heat treatment. J Mater Sci. 1998;33:2283–97.

Ghosh KS, Tripati K. Microstructural characterization and electrochemical behavior of AA2014 Al–Cu–Mg–Si alloy of various tempers. J Mater Eng Perform. 2018;27:5926–37.

Li X, Yan H, Wang Z-W, Li N, Liu J-L, Nie Q. Effect of heat treatment on the microstructure and mechanical properties of a composite made of Al–Si–Cu–Mg aluminum alloy reinforced with SiC particles. Metals. 2019;9:1205.

Cai Q, Mendis CL, Wang S, Chang IT, Fan Z. Effect of heat treatment on microstructure and tensile properties of die-cast Al–Cu–Si–Mg alloys. J Alloys Compd. 2021;881:160559.

Zou Y, Yan H, Hu Z, Ran Q. Effect of (Pr + Ce) addition and T6 heat treatment on microhardness and corrosion of AlSi5Cu1Mg alloy. Mater Res Express. 2020;7:026526.

Reis DA, Couto AA, Domingues Jr NI, Hirschmann AC, Zepka S, de Moura Neto C. Effect of artificial aging on the mechanical properties of an aerospace aluminum alloy 2024. In: Defect Diffusion Forum. Trans Tech Publ; 2012. p. 193–8.

Medrano-Prieto HM, Garay-Reyes CG, Gómez-Esparza CD, Aguilar-Santillán J, Maldonado-Orozco MC, Martínez-Sánchez R. Evolution of microstructure in Al–Si–Cu system modified with a transition element addition and its effect on hardness. Mater Res SciELO Brasil. 2016;19:59–66.

Samuel AM, Doty HW, Valtierra S, Samuel FH. Relationship between tensile and impact properties in Al–Si–Cu–Mg cast alloys and their fracture mechanisms. Mater Des. 2014;53:938–46.

Böyük U, Maraşlı N, Çadırlı E, Kaya H, Keşlioğlu K. Variations of microhardness with solidification parameters and electrical resistivity with temperature for Al–Cu–Ag eutectic alloy. Curr Appl Phys. 2012;12:7–10.

Kaya H, Böyük U, Çadırlı E, Maraşlı N. Measurements of the microhardness, electrical and thermal properties of the Al–Ni eutectic alloy. Mater Des. 2012;34:707–12.

Büyük U, Engin S, Kaya H, Çadırlı E, Maraşlı N. Directionally solidified Al–Cu–Si–Fe quaternary eutectic alloys. Phys Met Metallogr. 2020;121:78–83.

Kaygısız Y, Maraşlı N. Microstructural, mechanical and electrical characterization of directionally solidified Al–Si–Mg eutectic alloy. J Alloys Compd. 2015;618:197–203.

Engin S, Büyük U, Maraşlı N. The effects of microstructure and growth rate on microhardness, tensile strength, and electrical resistivity for directionally solidified Al–Ni–Fe alloys. J Alloys Compd. 2016;660:23–31.

Kaygısız Y, Maraşlı N. Microstructural, mechanical, and electrical characterization of directionally solidified Al–Cu–Mg eutectic alloy. Phys Met Metallogr. 2017;118:389–98.

Kaya H, Böyük U, Çadırlı E, Maraşlı N. Influence of growth rate on microstructure, microhardness, and electrical resistivity of directionally solidified Al-7 wt% Ni hypo-eutectic alloy. Met Mater Int. 2013;19:39–44.

Kaya H, Böyük U, Engin S, Çadirli E, Maraşli N. Measurements of microhardness and thermal and electrical properties of the binary Zn-0.7 mass/% Cu hypoperitectic alloy. J Electron Mater. 2010;39:303–11.

Mulazimoglu MH, Drew RAL, Gruzleski JE. The electrical conductivity of cast Al−Si alloys in the range 2 to 12.6 wt pct silicon. Metall Trans A. 1989;20:383–9.

Khangholi SN, Javidani M, Maltais A, Chen X-G. Effect of Ag and Cu addition on the strength and electrical conductivity of Al–Mg–Si alloys using conventional and modified thermomechanical treatments. J Alloys Compd. 2022;914:165242.

Nikzad Khangholi S, Javidani M, Maltais A, Chen X-G. Investigation on electrical conductivity and hardness of 6xxx aluminum conductor alloys with different Si levels. In: De Geuser F, Deschamps A, Ehrström J-C, Jarry P, Salloum-Abou-Jaoude G, Salvo L, et al., editors. MATEC Web Conf. 2020;326:08002

Han Y, Shao D, Chen BA, Peng Z, Zhu ZX, Zhang Q, et al. Effect of Mg/Si ratio on the microstructure and hardness–conductivity relationship of ultrafine-grained Al–Mg–Si alloys. J Mater Sci. 2017;52:4445–59.

Karabay S. Modification of AA-6201 alloy for manufacturing of high conductivity and extra high conductivity wires with property of high tensile stress after artificial aging heat treatment for all-aluminium alloy conductors. Mater Des. 2006;27:821–32.

Khangholi SN, Javidani M, Maltais A, Chen X-G. Effects of natural aging and pre-aging on the strength and electrical conductivity in Al–Mg–Si AA6201 conductor alloys. Mater Sci Eng A. 2021;820:141538.

Mendes G, Azevedo H, Dillon T, Rodrigues H, Hoffmann E. Rocha O The Cu/Nb ratio influencing microstructure, mechanical and electrical properties in as-cast Al3CuxNb alloys. Trans Indian Inst Met. 2023. https://doi.org/10.1007/s12666-022-02863-4.

Dillon T, Mendes G, Azevedo H, Rodrigues H, Pereira P, Rocha O. Effects of growth and cooling rates via horizontal solidification of an AlCuNb alloy: a thermal, microstructural and mechanical analysis. Trans Indian Inst Met. 2022;75:1429–39.

McCartney DG, Hunt JD. Measurements of cell and primary dendrite arm spacing in directionally solidified aluminium alloys. Acta Metall. 1981;29:1851–63.

Sousa SMA, de Gouveia GL, Spinelli JE. Evaluating grain size, dendritic scale, and tensile properties of a NbB-inoculated 6201 alloy using solidification rate. Mater Sci Eng A. 2022;835:142680.

Bouchard D, Kirkaldy JS. Prediction of dendrite arm spacing in unsteady-and steady-state heat flow of unidirectionally solidified binary alloys. Metall Mater Trans B. 1997;28:651–63.

Vilar R, Conde O, Franco S. Crystallographic structure of Al3Nb in laser-processed Al–Nb alloys. Intermetallics. 1999;7:1227–33.

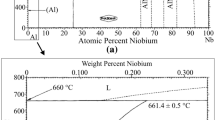

Elliott RP, Shunk FA. The Al–Nb system (Aluminum–Niobium). Bull Alloy Phase Diagr. 1981;2:75–81.

Mahdouk K, Gachon J-C, Bouirden L. Enthalpies of formation of the Al–Nb intermetallic compounds. J Alloys Compd. 1998;268:118–21.

Munitz A, Gokhale AB, Abbaschian R. The effect of supercooling on the microstructure of Al–Nb alloys. J Mater Sci. 2000;35:2263–71.

Nandi P, Chattopadhyay PP, Pabi SK, Manna I. Solid state synthesis of Al-based amorphous and nanocrystalline Al–Cu–Nb alloys. Mater Sci Eng A. 2003;359:11–7.

Novakovic R. Thermodynamics, surface properties and microscopic functions of liquid Al–Nb and Nb–Ti alloys. J Non-Cryst Solids. 2010;356:1593–8.

Zhu Z, Du Y, Zhang L, Chen H, Xu H, Tang C. Experimental identification of the degenerated equilibrium and thermodynamic modeling in the Al–Nb system. J Alloys Compd. 2008;460:632–8.

Totten GE, MacKenzie DS, editors. Handbook of Aluminum. New York: M Dekker; 2003.

Hatch JE, editor. Aluminum: properties and physical metallurgy. Metals Par: American Society for Metals; 1984.

Cook R, Kearns M, Cooper P. Effects of residual transition metal impurities on electrical conductivity and grain refinement of EC grade aluminium. In: The Minerals, Metals & Materials Society (TMS), Aluminum Committee, editors. Light Met. Warrendale, Pa: Minerals, Metals & Materials Society; 1997

Acknowledgements

The authors acknowledge the financial support provided by IFPA—Federal Institute of Education, Science and Technology of Pará, UFPA—Federal University of Pará, and CNPq—National Council for Scientific and Technological Development (Grants 304924/2020-2 and 160474/2021-3).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Azevedo, H.M., Mendes, G.H., Rodrigues, H.C. et al. Effects of solidification, solution and aging processes on an AlCuNb alloy: thermal and microstructural analysis, microhardness, electrical resistivity and conductivity. J Therm Anal Calorim 149, 953–966 (2024). https://doi.org/10.1007/s10973-023-12739-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-023-12739-4