Abstract

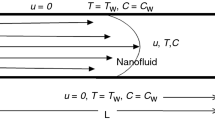

The effects of different nanoparticle shapes and uncertainty in the nanofluid thermophysical properties on the optimal operating conditions of MHD flow of Al2O3/water nanofluid through a horizontal microchannel with a porous medium considering hydrodynamic slip, suction/injection and thermal radiation were investigated. The momentum and heat transfer equations were solved analytically using the methods of undetermined coefficients and variation of constants, respectively. From the exact solutions of the velocity and temperature fields, the global entropy \(\left\langle {\text{S}} \right\rangle\) and Nusselt number Nu were computed. The impacts of hydrodynamic slip \(\alpha\), Biot number \(Bi\), nanoparticle concentration \(\phi\) and Darcy number \(Da\) on entropy production and heat transport were investigated. The results revealed that optimum values of \(\mathrm{\text{Bi}}\) and \(\alpha\) with minimum global entropy and maximum heat transport were achieved for symmetric slip conditions and asymmetric heat transfer. The platelet shape of nanoparticles was the most effective to achieve the optimum conditions with the lowest minimum value of \(\left\langle {\text{S}} \right\rangle\) , while the blade shape was the most effective to reach the optimum conditions with the highest maximum value of heat transport. Thus, optimum values of both Biot number of bottom plate equal to 0.01 and slip equal to 0.045 with the smallest values of \(\left\langle {\text{S}} \right\rangle\) were achieved for the platelet shape. Also, optimum slip value of 0.15 with the largest maximum Nu at top plate of 5.13 was achieved for the blade shape. On the other hand, when \(\phi\) increased from 0 to 0.045, \(\left\langle {\text{S}} \right\rangle\) always decreased and Nu always increased. The greatest decrease of entropy from 0.133 to 0.088 (33%) occurred for the platelet shape, while the greatest increase of Nu at top plate from 4.96 to 5.57 (12.3%) occurred for the blade shape. When \(\phi\) was varied from 0 to 0.01, \(\left\langle {\text{S}} \right\rangle\) decreased 9.2% for the platelet shape compared to spherical shapes, and Nu at top plate increased 2.6% for the blade shape compared to spherical shapes. The results also indicated that the greatest variations of optimum operating conditions occurred when the experimental correlations of viscosity and thermal conductivity were used compared to theoretical correlations. This is because the estimated values of viscosity and conductivity using the different theoretical correlations differ very little from each other. Thus, the maximum value of Nu at top plate increased from 5.067 for SM1 model to 5.092 for SM6 model (0.5%), while it increased from 4.96 for EM3 model to 5.17 for EM6 model (4.2%). Finally, the effects of Al2O3, Cu and TiO2 nanoparticles in water as base fluid on the optimum conditions were investigated. Both the lowest entropy production and the highest heat transfer were reached for Cu nanoparticles. When \(\alpha\) was varied, the minimum value of \(\left\langle {\text{S}} \right\rangle\) achieved for Cu was 0.47 and 0.64% lower than the minimum value of TiO2 and Al2O3, respectively. Also, the maximum value of Nu achieved for Cu improved by approximately 0.2 and 0.4% compared to Al2O3 and TiO2, respectively.

Similar content being viewed by others

Abbreviations

- a :

-

Characteristic length (m) (distance between plates)

- Bi:

-

Biot number

- Bo :

-

Magnetic field (T)

- Br:

-

Brinkman number

- C :

-

Specific heat (J kg−1 K−1)

- Da:

-

Darcy number

- Ec:

-

Eckert number

- H :

-

Convective heat transfer coefficient (W m−2 K−1)

- M :

-

Hartmann number

- K :

-

Thermal conductivity (W m−1 K−1)

- K :

-

Porous medium permeability (m2)

- k* :

-

Mean Rosseland absorption coefficient (1 m−1)

- Nu:

-

Nusselt number

- P :

-

Pressure (N m−2)

- P :

-

Dimensionless pressure gradient

- Pe:

-

Peclet number

- Pr:

-

Prandtl number

- Rd:

-

Radiation parameter

- Re:

-

Reynolds number

- S :

-

Local entropy generation (W m−3·K−1)

- \(\left\langle {\text{S}} \right\rangle\) :

-

Global entropy generation

- T :

-

Temperature (K)

- u :

-

Velocity (m s−1)

- x :

-

Axial coordinate (m)

- y :

-

Transverse coordinate (m)

- ν 0 :

-

Uniform suction/injection velocity (m s−1)

- α :

-

Slip length (m)

- ϵ :

-

Surface emissivity

- η :

-

Dynamic viscosity (kg ms−1)

- θ :

-

Dimensionless temperature

- ρ :

-

Density (kg m−3)

- σ :

-

Electrical conductivity (S m−1)

- σ * :

-

Stefan‐Boltzmann constant (W m−2 K−4)

- ϕ :

-

Nanoparticle concentration

- ψ :

-

Sphericity factor

- 1:

-

Bottom plate

- 2:

-

Top plate

- f :

-

Base fluid

- nf :

-

Nanofluid

- s :

-

Solid nanoparticle

References

Ramezanpour M, Siavashi M, Raeni AQ, Blunt MJ. Pore-scale simulation of nanoparticle transport and deposition in a microchannel using a Lagrangian approach. J Mol Liq. 2022;355: 118948. https://doi.org/10.1016/j.molliq.2022.118948.

Soumya DO, Gireesha BJ, Venkatesh P. Tangent-hyperbolic nanoliquid flow in a microchannel, thermal and irreversibility rate analysis. Waves Random Complex Media. 2022. https://doi.org/10.1080/17455030.2022.2108157.

Izadi A, Siavashi M, Rasam H, Xiong Q. MHD enhanced nanofluid mediated heat transfer in porous metal for CPU cooling. Appl Therm Eng. 2020;168: 114843. https://doi.org/10.1016/j.applthermaleng.2019.114843.

Qasemian A, Moradi F, Karamati A, Keshavarz A, Shakeri A. Hydraulic and thermal analysis of automatic transmission fluid in the presence of nano-particles and twisted tape: an experimental and numerical study. J Central South Univ. 2021;28:3404–17. https://doi.org/10.1007/s11771-021-4864-x.

Khoshtarash H, Siavashi M, Ramezanpour M, Blunt MJ. Pore-scale analysis of two-phase nanofluid flow and heat transfer in open-cell metal foams considering Brownian motion. Appl Therm Eng. 2023;221: 119847. https://doi.org/10.1016/j.applthermaleng.2022.119847.

Ghachem K, Kolsi L, Larguech S, Alnemer G. Heat and mass transfer enhancement in triangular pyramid solar still using CNT-water nanofluid. J Central South Univ. 2021;28:3434–48. https://doi.org/10.1007/s11771-021-4866-8.

Albaqawy G, Mesloub A, Kolsi L. CFD investigation of effect of nanofluid filled Trombe wall on 3D convective heat transfer. J Central South Univ. 2021;28:3569–79. https://doi.org/10.1007/s11771-021-4876-6.

Aouinet H, Dhahri M, Safaei MR, Sammouda H, Anqi AE. Turbulent boundary layers and hydrodynamic flow analysis of nanofluids over a plate. J Central South Univ. 2021;28:3340–53. https://doi.org/10.1007/s11771-021-4859-7.

Afshari F, Sözen A, Khanlari A, Tuncer AD. Heat transfer enhancement of finned shell and tube heat exchanger using Fe2O3/water nanofluid. J Central South Univ. 2021;28:3297–309. https://doi.org/10.1007/s11771-021-4856-x.

Jalil E, Molaeimanesh GR. Effects of turbulator shape, inclined magnetic field, and mixed convection nanofluid flow on thermal performance of micro-scale inclined forward-facing step. J Central South Univ. 2021;28:3310–26. https://doi.org/10.1007/s11771-021-4857-9.

Sindhu S, Gireesha BJ. Scrutinization of unsteady non-Newtonian fluid flow considering buoyancy effect and thermal radiation: tangent hyperbolic model. Int Commun Heat Mass Transf. 2022;135:106062. https://doi.org/10.1016/j.icheatmasstransfer.2022.106062.

Felicita A, Berrehal H, Venkatesh P, Gireesha BJ, Sowmya G. Slip flow of Walter’s B liquid through the channel possessing stretched walls by employing optimal homotopy asymptotic method (OHAM). J Mol Liq. 2022;353:118731. https://doi.org/10.1016/j.molliq.2022.118731.

Ho CJ, Chen MW, Li ZW. Numerical simulation of natural convection of nanofluid in a square enclosure: effects due to uncertainties of viscosity and thermal conductivity. Int J Heat Mass Transf. 2008;51:4506–16. https://doi.org/10.1016/j.ijheatmasstransfer.2007.12.019.

Mansour RB, Galanis N, Nguyen CT. Effect of uncertainties in physical properties on forced convection heat transfer with nanofluids. Appl Therm Eng. 2007;27:240–9. https://doi.org/10.1016/j.applthermaleng.2006.04.011.

Arefmanesh A, Mahmoodi M. Effects of uncertainties of viscosity models for Al2O3–water nanofluid on mixed convection numerical simulations. Int J Therm Sci. 2011;50:1706–19. https://doi.org/10.1016/j.ijthermalsci.2011.04.007.

Mahdy A, ElShehabey HM. Uncertainties in physical property effects on viscous flow and heat transfer over a nonlinearly stretching sheet with nanofluids. Int Commun Heat Mass Transf. 2012;39:713–9. https://doi.org/10.1016/j.icheatmasstransfer.2012.03.019.

Minea AA. Uncertainties in modeling thermal conductivity of laminar forced convection heat transfer with water alumina nanofluids. Int J Heat Mass Transf. 2014;68:78–84. https://doi.org/10.1016/j.ijheatmasstransfer.2013.09.018.

Selvakumar RD, Dhinakaran S. Nanofluid flow and heat transfer around a circular cylinder: a study on effects of uncertainties in effective properties. J Mol Liq. 2016;223:572–88. https://doi.org/10.1016/j.molliq.2016.08.047.

Fazeli H, Pourrajabian A, Nikooei E. Simultaneous optimization of geometric and nanofluids parameters in a rectangular microchannel heat sink. Heat Transf Eng. 2022;43:1820–37. https://doi.org/10.1080/01457632.2021.2016138.

López A, Ibáñez G, Pantoja J, Moreira J, Lastres O. Entropy generation analysis of MHD nanofluid flow in a porous vertical microchannel with nonlinear thermal radiation, slip flow and convective-radiative boundary conditions. Int J Heat Mass Transf. 2017;107:982–94. https://doi.org/10.1016/j.ijheatmasstransfer.2016.10.126.

Jamshed W, Mohd Nasir NAA, Qureshi MA, Shahzad F, Banerjee R, Mohamed R. Dynamical irreversible processes analysis of Poiseuille magneto-hybrid nanofluid flow in microchannel: a novel case study. Waves Random Complex Media. 2021. https://doi.org/10.1080/17455030.2021.1985185.

Ibáñez G, López A, Pantoja J, Moreira J. Entropy generation analysis of a nanofluid flow in MHD porous microchannel with hydrodynamic slip and thermal radiation. Int J Heat Mass Transf. 2016;100:89–97. https://doi.org/10.1016/j.ijheatmasstransfer.2016.04.089.

Mondal P, Dilip KM, Shit GC, Ibañez G. Heat transfer and entropy generation in a MHD Couette-Poiseuille flow through a microchannel with slip, suction–injection and radiation. J Therm Anal Calorim. 2022;147:4253–73. https://doi.org/10.1007/s10973-021-10731-4.

Gómez I, Ibáñez G, López A, Lastres O, Reyes J. Entropy generation minimization and nonlinear heat transport in MHD flow of a couple stress nanofluid through an inclined permeable channel with a porous medium, thermal radiation and slip. Heat Transf. 2020;49:4878–906. https://doi.org/10.1002/htj.21858.

Ibáñez G, Cuevas S, De Haro ML. Minimization of entropy generation by asymmetric convective cooling. Int J Heat Mass Transf. 2003;46:1321–8. https://doi.org/10.1016/S0017-9310(02)00420-9.

Mahian O, Mahmud S, Zeinali SH. Effect of uncertainties in physical properties on entropy generation between two rotating cylinders with nanofluids. J Heat Transf. 2012;134:101704. https://doi.org/10.1115/1.4006662.

Ibáñez G, López A, López I, Pantoja J, Moreira J, Lastres O. Optimization of MHD nanofluid flow in a vertical microchannel with a porous medium, nonlinear radiation heat flux, slip flow and convective–radiative boundary conditions. J Therm Anal Calorim. 2019;135:3401–20. https://doi.org/10.1007/s10973-018-7558-3.

Aaiza G, Khan I, Shafie S. Energy transfer in mixed convection MHD flow of nanofluid containing different shapes of nanoparticles in a channel filled with saturated porous medium. Nanoscale Res Lett. 2015;10:1–14. https://doi.org/10.1186/s11671-015-1144-4.

Sheikholeslami M, Sajjadi H, Amiri A. Magnetic force and radiation influences on nanofluid transportation through a permeable media considering Al2O3 nanoparticles. J Therm Anal Calorim. 2019;136:2477–85. https://doi.org/10.1007/s10973-018-7901-8.

Benkhedda M, Boufendi T, Tayebi T. Convective heat transfer performance of hybrid nanofluid in a horizontal pipe considering nanoparticles shapes effect. J Therm Anal Calorim. 2020;140:411–25. https://doi.org/10.1007/s10973-019-08836-y.

Saleem S, Qasim M, Alderremy A, Noreen S. Heat transfer enhancement using different shapes of Cu nanoparticles in the flow of water based nanofluid. Phys Scr. 2020;95: 055209. https://doi.org/10.1088/1402-4896/ab4ffd.

Ghadikolaei SS, Yassari M, Sadeghi H, Hosseinzadeh K, Ganji DD. Investigation on thermophysical properties of TiO2–Cu/H2O hybrid nanofluid transport dependent on shape factor in MHD stagnation point flow. Powder Technol. 2017;322:428–38. https://doi.org/10.1016/j.powtec.2017.09.006.

Sindhu S, Gireesha BJ, Sowmya G, Makinde OD. Hybrid nanoliquid flow through a microchannel with particle shape factor, slip and convective regime. Int J Numer Methods Heat Fluid Flow. 2022;32:3388–410. https://doi.org/10.1108/HFF-11-2021-0733.

Kumar A, Ray RK. Shape effect of nanoparticles and entropy generation analysis for magnetohydrodynamic flow of (Al2O3−Cu/H2O) hybrid nanomaterial under the influence of Hall current. Indian J Phys. 2022;96:3817–30. https://doi.org/10.1007/s12648-022-02300-8.

Ellahi R, Hassan M, Zeeshan A. Shape effects of nanosize particles in Cu–H2O nanofluid on entropy generation. Int J Heat Mass Transf. 2015;81:449–56. https://doi.org/10.1016/j.ijheatmasstransfer.2014.10.041.

Zeeshan A, Hassan M, Ellahi R. Shape effect of nanosize particles in unsteady mixed convection flow of nanofluid over disk with entropy generation. Proc Inst Mech Eng Part E: J Process Mech Eng. 2017;231:871–9. https://doi.org/10.1177/0954408916646139.

Seyyedi SM, Dogonchi AS, Ganji DD. Entropy generation in a nanofluid-filled semi-annulus cavity by considering the shape of nanoparticles. J Therm Anal Calorim. 2019;138:1607–21. https://doi.org/10.1007/s10973-019-08130-x.

Zhang C, Zheng L, Zhang X, Chen G. MHD flow and radiation heat transfer of nanofluids in porous media with variable surface heat flux and chemical reaction. Appl Math Model. 2015;39:165–81. https://doi.org/10.1016/j.apm.2014.05.023.

Makinde OD. Second law analysis for variable viscosity hydromagnetic boundary layer flow with thermal radiation and Newtonian heating. Entropy. 2011;13:1446–64. https://doi.org/10.3390/e13081446.

Bejan A. Entropy generation minimization: the method of thermodynamic optimization of finite-size systems and finite-time processes. Boca Raton: CRC Press; 2013. https://doi.org/10.1201/9781482239171.

Gupta M, Singh V, Kumar R, Said Z. A review on thermophysical properties of nanofluids and heat transfer applications. Renew Sustain Energy Rev. 2017;74:638–70. https://doi.org/10.1016/j.rser.2017.02.073.

Minea AA. A review on the thermophysical properties of water-based nanofluids and their hybrids. Ann als of “Dunarea de Jos” University of Galati Fascicle IX. Ann “Dunarea de Jos” Univ Galati: Fascicle IX, Metallurgy and Materials Science. 2016;39:35–47.

Saqib M, Khan I, Shafie S. Recent advancement in thermophysical properties of nanofluids and hybrid nanofluids: an overview. Int J Comput Anal. 2019;1:16–25. https://doi.org/10.33959/cuijca.v3i2.27.

Mahian O, Kianifar A, Kleinstreuer C, Al-Nimr MA, Pop I, Sahin AZ, Wongwises S. A review of entropy generation in nanofluid flow. Int J Heat Mass Transf. 2013;65:514–32. https://doi.org/10.1016/j.ijheatmasstransfer.2013.06.010.

Buongiorno J. Convective transport in nanofluids. ASME J Heat Transf. 2006;128:240–50. https://doi.org/10.1115/1.2150834.

Chandrasekar M, Suresh S, Chandra A. Experimental investigations and theoretical determination of thermal conductivity and viscosity of Al2O3/water nanofluid. Exp Thermal Fluid Sci. 2010;34:210–6. https://doi.org/10.1016/j.expthermflusci.2009.10.022.

Huminic G, Huminic A. Entropy generation of nanofluid and hybrid nanofluid flow in thermal systems: a review. J Mol Liq. 2020;302:112533. https://doi.org/10.1016/j.molliq.2020.112533.

Timofeeva EV, Gavrilov AN, McCloskey JM. Thermal conductivity and particle agglomeration in alumina nanofluids: experiment and theory. Phys Rev E. 2007;76:061203. https://doi.org/10.1103/PhysRevE.76.061203.

Pak BC, Cho YI. Hydrodynamic and heat transfer study of dispersed fluids with submicron metallic oxide particles. Exp Heat Transf Int J. 1990;11:151–70. https://doi.org/10.1080/08916159808946559.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Estrada, R., Ibáñez, G., López, A. et al. Analytical analysis of impacts of nanoparticle shapes and uncertainty in thermophysical properties on optimum operating conditions of MHD nanofluid flow in a microchannel filled with porous medium. J Therm Anal Calorim 149, 265–298 (2024). https://doi.org/10.1007/s10973-023-12678-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-023-12678-0