Abstract

Excipients in pharmaceutical formulations are inactive ingredient from the biological point of view, but they have a key role in the preparation, and they can alter the stability of the active principle. In this work, we prepared acetaminophen tablets with different amounts of talc as excipient and the thermal stability was deeply investigated by thermogravimetric studies. Isoconversional analysis by Kissinger–Akahira–Sunose method and “Master plot” analysis have been successfully employed to describe the kinetics of degradation under inert atmosphere, and the shelf lives have been calculated as a function of the talc content. The shelf-life values as well as the activation energy, which is the dominant factor, evidenced that the inorganic filler enhances the drug degradation to a certain extend and that the composition dependence has a peculiar trend reflecting the particle cluster formation at a critical concentration value. An effort of physico-chemical explanation for this behaviour is put forward by a simple geometrical model from the microparticle-size analysis to predict the critical talc concentration.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Drug formulations are carefully designed as mixtures of the active compound and excipients [1]. Typically, the nature and composition of excipients change between companies that produce a given drug formulation. Although the excipients should not alter the biological activity of the drug, they have a role in the production process (workability of the mixture) as well as in the stability of the active ingredients that is responsible for the shelf life of the final product [2,3,4,5].

Thermoanalytical methods are relevant in the characterization of pharmaceutics providing a straightforward approach to the degradation kinetics of composites under several controlled environmental conditions such as inert and oxidative gases [6,7,8,9]. Thermogravimetry was employed for the characterization of hybrid composite materials, and the inorganic fillers can have a key influence on the thermal behaviour as catalytic or stabilizing agents in the degradation process [10,11,12,13,14,15].

It is reported that excipients could lead to instabilities in the formulations with a significant reduction in the shelf life [16, 17]. The literature reports that iron oxide nanostructures or black TiO2 has a catalytic action towards acetaminophen degradation, and therefore, their uses as excipients should be considered with particular care; notwithstanding, these inorganic particles can be considered for the drug degradation in environmental remediation [18] [19]. Talc is a promising filler in polymer-based composites [20,21,22], adsorbent [23] and excipient in pharmaceutical formulations [24].

In this study, the thermal degradation of acetaminophen/talc formulations with different compositions was investigated by thermogravimetry at variable heating rate and isoconversional methods. The mechanism of degradation and the effect of the inorganic filler will be interpreted to the light of the particle dispersion into the composites.

Experimental

Materials

Acetaminophen (> 99.0%, Mw = 151.16 g mol−1) and talc (3MgO∙4SiO2∙H2O, Mw = 379.27 g mol−1, 325 mesh) were Sigma products.

Sample preparation

The tablets of acetaminophen and talc were obtained by mixing the powders in an agate mortar to obtain homogeneous samples for ten minutes. Afterwards, the tablets were obtained by processing ca. 250 mg of each sample under 10 tons for 20 min by means of a Manual Hydraulic Press 15 T (Specac). The talc mass per cent (Ct) was systematically varied from 0 to 13%.

Methods

Thermogravimetric experiments were performed by using a Q550 apparatus (Discovery series—TA Instruments) under N2 flow. The mass of each sample was ca. 10 mg. The heating rates (β) were selected at 2, 5, 10, 15 and 20 °C min−1 from room temperature to 400 °C. KAS was used for the isoconversional kinetic analysis of the thermogravimetric data. Finally, the Master plot analysis was used to define the kinetics model and the determination of the formulation shelf life.

Digital optical microscope (Digitus, DA–70351) was used for talc particle-size analysis. ImageJ software was used for the determination of particle-size distribution.

Results and discussion

Thermal degradation under nitrogen atmosphere

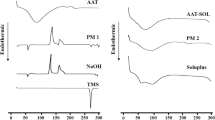

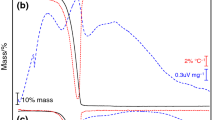

Figure 1 shows some examples of TG results on different samples. We detected that the mass loss up to 150 °C is insignificant for all tablets with variable amount of talc, highlighting that the water content is negligible. Mostly, the mass loss occurs between 160 and 350 °C due to the acetaminophen degradation. The talc addition generates an increase in the residual mass after the degradation step, and it slightly promotes the sample volatilization at lower temperature. It should be noted that filling organic materials with inorganic microsize particles can have both a stabilization and even a catalytic effect on the thermal degradation [25,26,27,28].

The thermogravimetric curves collected at variable talc content have been compared quantitatively at a given heating ramp by means of the following parameters: (1) residual mass at 400 °C and (2) decomposition temperature (Tmax) taken at the maximum of the first-order derivative curves of mass loss to temperature. The Tmax value shows a decrease up to 4% of talc content being constant for larger concentrations of the inorganic filler (Fig. 2), whilst the residual mass shows a linear trend as it is typically reported for other organic–inorganic composites [29]. Similar observations were reported for levothyroxine formulations [30]. It should be noted that the obtained findings are confirmed at each investigated heating ramp.

The analysis of single heating ramp TG results cannot provide a comprehensive point of view on the thermal stability of the formulations and in particular to the talc content effect. To this purpose, a complete kinetic investigation through non-isothermal isoconversional methods is more appropriate.

Isoconversional methods and kinetic parameters

Thermogravimetry and isoconversional methods represent powerful tools to estimate the stability of materials like vegetable oils [31, 32] and polymers [33,34,35] in various technological applications as well as in pharmaceutics [36,37,38]. Figure 3 shows an example of the thermogravimetric curves at variable heating rate. As expected, a single step of mass loss is observed within the temperature range between 160 and 350 °C. This is confirmed by the DTG curves (Fig. S1 in Supplementary Information), which evidenced the presence of a single peak.

The isoconversional methods (KAS) have been used to determine the activation energy as a function of the conversion degree (α) [39] and it turned out that the obtained values are consistent and constant with the conversion degree for all the samples. The averaged activation energies from KAS are presented in Fig. 4 as functions of the talc content. The addition of talc to acetaminophen generates a decrease in the activation energy value; nevertheless, the trend evidenced a minimum when the talc content is ca 7%. These results likely indicate that a catalytic effect at the talc surface enhances the drug degradation, and this effect is attenuated when the filler concentration overcomes a certain value.

It should be noted that the activation energy values reflect the thermal stability of the acetaminophen, but the evaluation of the pre-exponential factor and reaction mechanism have to be considered for a proper evaluation. Therefore, the Master plot method [40] was used to determine the reaction mechanism. Namely, the function z(α) was calculated (Eq. 1) as a function of α and compared to the theoretical curves [39]

where dα/dt is the first derivative of α respect to time and Tα is the temperature at a given α value. As Fig. 5 shows, the experimental z(α) function has a maximum at α ≈ 0.75 that together with the shape analysis indicates that the degradation mechanism follows a contracted cylindrical geometry (R2 mechanism), and therefore, the f(α) can be expressed as

The same conclusion can be drawn for all the investigated samples at variable talc content, highlighting that talc does not alter the degradation path of acetaminophen. This result is also consistent with the findings for several commercial formulations based on acetaminophen with a wide range of excipients [4].

As soon as the mechanism is identified, the pre-exponential factor (A) of the decomposition can be determined by fitting the experimental data with the following equation:

where Ea represents the averaged activation energies from the isoconversional analysis. The obtained A values are in Supplementary Information. The accuracy of the kinetic results was verified by comparing the experimental conversion curves with those obtained by simulation. Figure 6 shows some examples of the conversion curves as a function of temperature.

The presented curves (Fig. 6) are related to the sample of acetaminophen and acetaminophen with talc content of 9 and 13% at a heating rate of 10 °C min−1. The simulations were carried out by employing Eq. 4 [41]:

The obtained results demonstrate that both Friedman and KAS models accurately simulate the overall evolution of the conversion degree as a function of temperature, regardless of the specific sample under investigation. In general, the simulations generated by both models exhibit a good agreement with the experimental data, thereby confirming the reliability and consistency of the implemented modelling procedure.

The full description of the kinetic parameters, namely the activation energy, the pre-exponential factor and the reaction mechanism, endows to the estimation of the shelf life under inert storage atmosphere. Accordingly, the shelf life of drug formulations is typically calculated as the time (t10%) that correspond to 10% of degradation, namely at α = 0.1 [42, 43].

For a contracted cylindrical geometry (R2 mechanism), tα can be can be calculated as [39]

Figure 4 reports the shelf-life values calculated at 25 °C as functions of the talc content. The obtained trends agree with the activation energy findings, demonstrating that this is the dominant factor in the investigated systems.

Microscopic interpretation

The thermal properties of composites filled with inorganic particles are typically enhanced compared to the organic material. The influence of inorganic nanofillers is discussed in terms of barrier effects towards both mass and heat transports or catalytic effects [25, 44,45,46]. In general, the resistance to thermal stabilization is mainly due to a barrier effect towards the mass transport of the volatile products. In the investigated system, the talc addition has a destabilization effect on the acetaminophen thermal degradation. That observation may reflect the catalytic effect of the talc surface; this hypothesis can be verified through the effect generated by the increase in the concentration, considering that above the concentration that represents the contact distance between the particles, the further increase in the talc content does not increase the available surface, but actually, it generates a reduction in the free surface provided that particles clusters are obtained.

To determine a critical volume fraction of the particle, the particle size has to be determined. Therefore, the talc particles have been imaged by optical microscopy and the distribution function of the particle diameter was fitted to a Gaussian distribution that evidenced an average value of 38 µm (Fig. 7).

By assuming a simple cubic model of spherical particles of radius R at a given volume fraction (ϕ), the distance between particles (L) can be calculated as [47]

By considering the density values of talc (2.82 g cm−3) and acetaminophen (1.26 g cm−3), the dependence of L with talc content is provided in Fig. 8.

The contact distance, corresponding to the average particle diameter, is approached at a talc concentration of ca. 8%. This finding highlights that the minimum in the thermal stability evidenced by the activation energy vs talc content trend is nearly coincident with the critical composition required for a contact between particles. Therefore, the catalytic degradation of acetaminophen at the talc surface is enhanced up to a concentration that allows particle dispersion, whilst further addition generates a decrease in the available surface due to contact between particles, and therefore, the catalytic degradation is less pronounced.

Conclusions

Thermogravimetric experiments have been carried out in acetaminophen filled with variable amounts of talc as excipient. The degradation temperature shows a decrease up to a critical talc content, whilst the residual mass after the degradation shows a linear trend that correlates with the content of inorganic particles into the formulations.

Kinetic studies by non-isothermal thermogravimetry evidenced that the shelf lives of acetaminophen/talc formulations are dependent on the composition with a non-monotonic behaviour that is dominated by the activation energy contribute. The degradation mechanism of acetaminophen is not influenced by the talc content, but an enhanced degradation is attributed to the surface interaction. The key role of the interface is further highlighted by the calculated particles contact distance that evidences the possibility of talc-cluster formation at the excipient concentration corresponding to the minimum of the thermal stability.

It should be noted that shelf life corresponds to the time after which the formulation cannot perform its function efficiently, and therefore, additional factors including oxidation and microbial damage can play a role that is differently influenced by the excipient content, and therefore, further studies should be devoted to this direction.

References

Sengupta P, Chatterjee B, Tekade RK. Current regulatory requirements and practical approaches for stability analysis of pharmaceutical products: a comprehensive review. Int J Pharm. 2018;543:328–44.

Fisher AC, Lee SL, Harris DP, Buhse L, Kozlowski S, Yu L, et al. Advancing pharmaceutical quality: an overview of science and research in the U.S. FDA’s office of pharmaceutical quality. Int J Pharm. 2016;515:390–402.

Yu LX, Kopcha M. The future of pharmaceutical quality and the path to get there. Int J Pharm. 2017;528:354–9.

Calvino MM, Lisuzzo L, Cavallaro G, Lazzara G, Milioto S. Non-isothermal thermogravimetry as an accelerated tool for the shelf-life prediction of paracetamol formulations. Thermochim Acta. 2021;700: 178940.

Agafonov M, Garibyan A, Terekhova I. Improving pharmacologically relevant properties of sulfasalazine loaded in γ-cyclodextrin-based metal organic framework. J Ind Eng Chem. 2022;106:189–97.

Juhász M, Kitahara Y, Takahashi S, Fujii T. Thermal stability of vitamin C: thermogravimetric analysis and use of total ion monitoring chromatograms. J Pharm Biomed Anal. 2012;59:190–3.

Vlase G, Budiul M, Vlase T, Albu P, Ledeţi A. Thermally induced interactions between adamantan-2-one and some pharmaceutical excipients. J Therm Anal Calorim. 2018;131:201–13.

Vlase G, Blajovan R, Albu P, Vlase T. Study of thermally induced interaction between hydroxyethylcellulose and carboxymethylcellulose with different excipients. J Therm Anal Calorim. 2017;130:397–402.

Schiraldi A, Fessas D. Calorimetry and thermal analysis in food science: an updated review. J Therm Anal Calorim. 2019;138:2721–32.

Lisuzzo L, Cavallaro G, Milioto S, Lazzara G. Halloysite nanotubes coated by chitosan for the controlled release of khellin. Polymers. 2020;12:1766.

Lisuzzo L, Cavallaro G, Pasbakhsh P, Milioto S, Lazzara G. Why does vacuum drive to the loading of halloysite nanotubes? The key role of water confinement. J Colloid Interface Sci. 2019;547:361–9.

Panchal A, Fakhrullina G, Fakhrullin R, Lvov Y. Self-assembly of clay nanotubes on hair surface for medical and cosmetic formulations. Nanoscale. 2018;10:18205–16.

Stavitskaya A, Batasheva S, Vinokurov V, Fakhrullina G, Sangarov V, Lvov Y, et al. Antimicrobial applications of clay nanotube-based composites. Nanomaterials. 2019;9:708.

Taroni T, Cauteruccio S, Vago R, Franchi S, Barbero N, Licandro E, et al. Thiahelicene-grafted halloysite nanotubes: characterization, biological studies and pH triggered release. Appl Surf Sci. 2020;520: 146351.

Yendluri R, Otto DP, Villiers MMD, Vinokurov V, Lvov YM. Application of halloysite clay nanotubes as a pharmaceutical excipient. Int J Pharm. 2017;521:267–73.

Darji MA, Lalge RM, Marathe SP, Mulay TD, Fatima T, Alshammari A, et al. Excipient stability in oral solid dosage forms: a review. AAPS PharmSciTech. 2018;19:12–26. https://doi.org/10.1208/s12249-017-0864-4.

Zarmpi P, Flanagan T, Meehan E, Mann J, Østergaard J, Fotaki N. Biopharmaceutical implications of excipient variability on drug dissolution from immediate release products. Eur J Pharm Biopharm. 2020;154:195–209.

Bianca L-G, Rita S-T, Ramon F-D, Jose G-A. A pH study for the degradation of acetaminophen with iron oxide nanostructures. Chem Eng Trans. 2019;73:139–44. https://doi.org/10.3303/CET1973024.

Katal R, Salehi M, Davood Abadi Farahani MH, Masudy-Panah S, Ong SL, Hu J. Preparation of a new type of black TiO2 under a vacuum atmosphere for sunlight photocatalysis. ACS Appl Mater Interfaces. 2018;10:35316–26. https://doi.org/10.1021/acsami.8b14680.

Xu P, Tian H, Han L, Yang H, Bian J, Pan H, et al. Improved heat resistance in poly (lactic acid)/ethylene butyl methacrylate glycidyl methacrylate terpolymer blends by controlling highly filled talc particles. J Therm Anal Calorim. 2022;147:5719–32.

Layachi A, Makhlouf A, Frihi D, Satha H, Belaadi A, Seguela R. Non-isothermal crystallization kinetics and nucleation behavior of isotactic polypropylene composites with micro-talc. J Therm Anal Calorim. 2019;138:1081–95.

Várdai R, Schäffer Á, Ferdinánd M, Lummerstorfer T, Jerabek M, Gahleitner M, et al. Crystalline structure and reinforcement in hybrid PP composites. J Therm Anal Calorim. 2022;147:145–54.

Wal K, Rutkowski P, Stawiński W. Application of clay minerals and their derivatives in adsorption from gaseous phase. Appl Clay Sci. 2021;215: 106323.

Delgado R, Fernández-González MV, Gzouly M, Molinero-García A, Cervera-Mata A, Sánchez-Marañón M, et al. The quality of Spanish cosmetic-pharmaceutical talcum powders. Appl Clay Sci. 2020;193: 105691.

Cavallaro G, Lisi R, Lazzara G, Milioto S. Polyethylene glycol/clay nanotubes composites. J Therm Anal Calorim. 2013;112:383–9.

Lisuzzo L, Cavallaro G, Milioto S, Lazzara G. Halloysite nanotubes filled with MgO for paper reinforcement and deacidification. Appl Clay Sci. 2021;213: 106231.

Blanco I, Abate L, Bottino FA, Bottino P. Thermal behaviour of a series of novel aliphatic bridged polyhedral oligomeric silsesquioxanes (POSSs)/polystyrene (PS) nanocomposites: the influence of the bridge length on the resistance to thermal degradation. Polym Degrad Stab. 2014;102:132–7.

Blanco I, Cicala G, Latteri A, Mamo A, Recca A. Thermal and thermo-oxidative degradations of poly (2,6-dimethyl-1,4-phenylene oxide) (PPO)/copoly (aryl ether sulfone) P(ESES-co-EES) block copolymers: a kinetic study. J Therm Anal Calorim. 2013;112:375–81.

Cavallaro G, Lazzara G, Milioto S, Parisi F, Sparacino V. Thermal and dynamic mechanical properties of beeswax-halloysite nanocomposites for consolidating waterlogged archaeological woods. Polym Degrad Stab. 2015;120:220–5.

Ledeți I, Romanescu M, Cîrcioban D, Ledeți A, Vlase G, Vlase T, et al. Stability and compatibility studies of levothyroxine sodium in solid binary systems—instrumental screening. Pharmaceutics. 2020;12:58.

Li J, Liu J, Sun X, Liu Y. The mathematical prediction model for the oxidative stability of vegetable oils by the main fatty acids composition and thermogravimetric analysis. LWT. 2018;96:51–7.

Duce C, Vecchio Ciprioti S, Spepi A, Bernazzani L, Tinè MR. Vaporization kinetic study of lavender and sage essential oils. J Therm Anal Calorim. 2017;130:595–604.

Blanco I. Lifetime prediction of polymers: to bet, or not to bet—is this the question? Materials. 2018;11:1383.

de Jesus Silva AJ, Contreras MM, Nascimento CR, da Costa MF. Kinetics of thermal degradation and lifetime study of poly(vinylidene fluoride) (PVDF) subjected to bioethanol fuel accelerated aging. Heliyon. 2020;6: e04573.

Plota A, Masek A. Lifetime prediction methods for degradable polymeric materials—a short review. Materials. 2020;13:4507.

Ben Osman Y, Liavitskaya T, Vyazovkin S. Polyvinylpyrrolidone affects thermal stability of drugs in solid dispersions. Int J Pharm. 2018;551:111–20.

Circioban D, Ledeţi I, Vlase T, Rusu G, Ledeţi A, Vlase G. Stability evaluation and kinetic study for the atypical antidepressant opipramol. J Therm Anal Calorim. 2023. https://doi.org/10.1007/s10973-023-12249-3.

Pătruţescu C, Vlase G, Turcuş V, Ardelean D, Vlase T, Albu P. TG/DTG/DTA data used for determining the kinetic parameters of the thermal degradation process of an immunosuppressive agent: mycophenolate mofetil. J Therm Anal Calorim. 2015;121:983–8.

Vyazovkin S, Burnham AK, Criado JM, Pérez-Maqueda LA, Popescu C, Sbirrazzuoli N. ICTAC Kinetics Committee recommendations for performing kinetic computations on thermal analysis data. Thermochim Acta. 2011;520:1–19.

Criado JM, Málek J, Ortega A. Applicability of the master plots in kinetic analysis of non-isothermal data. Thermochim Acta. 1989;147:377–85.

Wang W, Lemaire R, Bensakhria A, Luart D. Thermogravimetric analysis and kinetic modeling of the AAEM-catalyzed pyrolysis of woody biomass. Molecules. 2022;27:7662.

Raghuvanshi D, Nkepang G, Hussain A, Yari H, Awasthi V. Stability study on an anti-cancer drug 4-(3,5-bis(2-chlorobenzylidene)-4-oxo-piperidine-1-yl)-4-oxo-2-butenoic acid (CLEFMA) using a stability-indicating HPLC method. J Pharm Anal. 2017;7:1–9.

Zhu W, Chen X, Yuan L, Wu J, Yao J. Degradation kinetics and shelf life of N-acetylneuraminic acid at different pH values. Molecules. 2020;25:5141.

Kremer I, Tomić T, Katančić Z, Erceg M, Papuga S, Parlov Vuković J, et al. Catalytic pyrolysis and kinetic study of real-world waste plastics: multi-layered and mixed resin types of plastics. Clean Technol Environ Policy. 2022;24:677–93.

Bertolino V, Cavallaro G, Milioto S, Lazzara G. Polysaccharides/halloysite nanotubes for smart bionanocomposite materials. Carbohyd Polym. 2020;245: 116502.

Blanco I, Cicala G, Tosto C, Bottino FA. Kinetic study of the thermal and thermo-oxidative degradations of polystyrene reinforced with multiple-cages POSS. Polymers. 2020;12:2742.

Bansal PP, Ardell AJ. Average nearest-neighbor distances between uniformly distributed finite particles. Metallography. 1972;5:97–111.

Acknowledgements

The work was financially supported by FFR 2023 project and University of Palermo.

Funding

Open access funding provided by Università degli Studi di Palermo within the CRUI-CARE Agreement.

Author information

Authors and Affiliations

Contributions

MMC was involved in investigation, data curation and writing—original draft preparation. GC was responsible for writing—reviewing and editing and validation. GL took part in conceptualization and supervision. SM contributed to funding acquisition and resources.

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Calvino, M.M., Cavallaro, G., Lazzara, G. et al. Talc concentration effect on shelf life of acetaminophen tablets. J Therm Anal Calorim 148, 13133–13139 (2023). https://doi.org/10.1007/s10973-023-12389-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-023-12389-6