Abstract

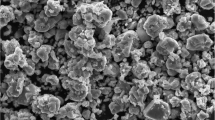

Today, biodiesel fuel is a suitable alternative to diesel fuel due to its less pollution and renewable nature. Waste and non-edible oils and heterogeneous catalysts can be used to produce biodiesel at a low cost. In this study, waste oil from restaurants is produced using the ester exchange method (transesterification) in the presence of a nano-catalyst prepared from stone-cutting factory sludge nano-powder. The produced nano-catalyst is identified by the mechanical method using a ball mill by nitrogen adsorption–desorption, scanning electron microscope, and transmission electron microscopy technique. Then, the important characteristics of the produced biodiesel have been matched with the standard test methods (ASTM D). After ensuring the proper characteristics of the produced biodiesel fuel, is investigated the performance change of the single-cylinder engine of 1.8 M at speeds of 1300–2000 rpm by 20% (B20), 50% (B50), and 100% (B100) combinations of biodiesel and diesel fuel. The results of the test showed with adding 20% volume of biodiesel in the fuel mixture, the power and torque of the engine increase due to complete combustion. Due to the improvement of combustion quality, the emission of CO and UHC pollutants is reduced by approximately 73% compared to diesel fuel, but the NOX pollutant increases by 32% compared to diesel fuel due to the high pressure and temperature of the combustion chamber. In general, it can be concluded that the use of 20% volume (B20) of biodiesel in the fuel composition, not only does not result in loss of power, but also reduces the special fuel consumption of braking, which is very important from an economic point of view.

Similar content being viewed by others

Data availability

The authors confirm that the data supporting the finding of this study are available within the article and its supplementary material.

Abbreviations

- SCFS-NP:

-

Stone-cutting factory sludge nano-powder

- ASTM:

-

American standard test method

- SEM:

-

Scanning electron microscope

- TEM:

-

Transmission electron microscopy

- ROH:

-

Alcohol hydroxide

- IUPAC:

-

International union of pure and applied chemistry

- BTE:

-

Brake thermal efficiency

- BJH:

-

Barrett–Joyner–Halenda

- FTIR:

-

Fourier-transform infrared spectroscopy

- CO:

-

Carbon monoxide emission

- CO2 :

-

Carbon dioxide emissions

- NOx :

-

Oxides of nitrogen emissions

- UHC:

-

Unburned hydrocarbon

- HFRR:

-

High-frequency reciprocating rig

- WSD:

-

Wear scar diameter

References

Kassahun BM, Balcha M, Damtew Z, BIsrat D, Asaminew G, Tadese S, Philipos M, Guteta N, Nurhusain H, Haile F, Abate S, Mekonnen B. Fatty acid and biodiesel characteristics Ethiopian Jatropha (Jatropha Curcas L.) provenances. Int J Adv Biol Biomed Res. 2016;4(1):15–31. https://doi.org/10.18869/IJABBR.2016.15.

Talha M, Sohail M, Tariq R, Ahmad MT. Impact of oil prices, energy consumption and economic growth on the inflation rate in Malaysia. Cuad de Econ. 2021;44(124):26–32. https://doi.org/10.32826/cude.v1i124.501.

Ninduangdee P, Paphan S, Chupava C. Torrefaction of oil palm frond using dry flue gas. Int J Sustain Energy Environ Res (IJSEER). 2022;11(1):57–66. https://doi.org/10.18488/13.v11i1.3060.

Asif MA. A theoretical study of the size effect of carbon nanotubes on the removal of water chemical contaminants. J Res Sci Eng Technol (JRSET). 2018;6(4):21–7. https://doi.org/10.24200/jrset.vol6iss04pp21-27.

Gad MS, Panchal H, Ağbulut Ü. Waste to energy: an experimental comparison of burning the waste-derived bio-oils produced by transesterification and pyrolysis methods. Energy. 2022;242:122945. https://doi.org/10.1016/j.energy.2021.122945.

More GV, Koli SR, Rao YVH, Prasad PI, Rao BN. Effect of compression ratio on compression ignition engine with RUCO biodiesel/diethyl ether/diesel fuel blends. Energy Sources A Recov Util Environ Eff. 2020. https://doi.org/10.1080/15567036.2020.1785593.

More GV, Rao YVH, Prasad PI, Rao BN. Experimental investigation on the effect of compression ratio over emission and performance characteristics of the diesel engine using ternary blends. Int J Green Energy. 2021;18(3):231–42. https://doi.org/10.1080/15435075.2020.1854263.

Elkelawy M, El Shenawy EA, Almonem SA, Nasef MH, Panchal H, Bastawissi HAE, Sadasivuni KK, Choudhary AK, Sharma D, Khalid M. Experimental study on combustion, performance, and emission behaviours of diesel/WCO biodiesel/Cyclohexane blends in DI-CI engine. Process Saf Environ Prot. 2021;149:684–97. https://doi.org/10.1016/j.psep.2021.03.028.

Zerafati ME, Bozorgi-Amiri A, Golmohammadi AM, Jolai F. A multi-objective mixed integer linear programming model proposed to optimize a supply chain network for microalgae-based biofuels and co-products: a case study in Iran. Environ Sci Pollution Res. 2022. https://doi.org/10.1007/s11356-022-19465-8.

More GV, Rao YVH. Thermogravimetric study and combustion characteristics of biodiesel blends produced from repurpose used cooking oil. Int J Environ Sci Technol. 2022;19:6847–62. https://doi.org/10.1007/s13762-021-03474-0.

Elkelawy M, Etaiw SEH, Bastawissi HAE, Marie H, Radwan AM, Dawood MM, Panchal H. WCO biodiesel production by heterogeneous catalyst and using cadmium (II)-based supramolecular coordination polymer additives to improve diesel/biodiesel fueled engine performance and emissions. J Therm Anal Calorim. 2022;147:6375–91. https://doi.org/10.1007/s10973-021-10920-1.

Bohlouli A, Mahdavian L. Catalysts used in biodiesel production: review. Biofuels-UK. 2021;12(8):885–98. https://doi.org/10.1080/17597269.2018.1558836.

Najafian A, Mahdavian L. Investigation of properties of biodiesel produced from sheep fatty wastes by eggshell. Energy Environ Focus. 2017;6(2):125–31. https://doi.org/10.1166/eef.2017.1255.

Dalvand P, Mahdavian L. Calculation of the properties of biodiesel produced from castor seed by eggshell catalyst. Biofuels-UK. 2019;9(6):705–10. https://doi.org/10.1080/17597269.2017.1302668.

Pinzi S, Leiva-Candia D, Lopez-Garcia I, Redel-Macias MD, Dorado MP. Latest trends in feedstocks for biodiesel production. Biofuel Bioprod Biorefn. 2014;8:126–43. https://doi.org/10.1002/bbb.1435.

Mahlia TMI, Syazmi ZAHS, Mofijur M, PgAbas AE, Bilad MR, Ong HC, Silitonga AS. Patent landscape review on biodiesel production: technology updates. Renew Sustain Energy Rev. 2020;118:109526. https://doi.org/10.1016/j.rser.2019.109526.

Putra ABW. Computer technology simulation towards power generation potential from coproduced fluids in South Lokichar oil fields. Int J Commun Comput technol. 2020;8(2):9–12. https://doi.org/10.31838/ijccts/08.02.03.

More GV, Rao YVH, Kedar SA, Gawande SH. Biodiesel production from DK oils using Taguchi L9 techniques: characterization and thermogravimetric study of combustion characteristics. J Therm Anal Calorim. 2022;147:7043–62. https://doi.org/10.1007/s10973-021-11020-w.

Albuquerque AR, Maul J, Vasconcelos AFF, Filho JRC, Santos IMG, Souza AG. The first step of biodiesel autoxidation by differential scanning calorimetry and DFT calculations. J Therm Anal Calorim. 2014;117:799–806. https://doi.org/10.1007/s10973-014-3835-y.

Jeyakumar N, Narayanasamy B. Effect of Basil antioxidant additive on the performance, combustion and emission characteristics of used cooking oil biodiesel in CI engine. J Therm Anal Calorim. 2020;140:457–73. https://doi.org/10.1007/s10973-019-08699-3.

Feyzi M, Hassankhani A, Rafiee HR. Preparation and characterization of Cs/Al/Fe3O4 nanocatalysts for biodiesel production. Energy Convers Manag. 2013;71:62–8. https://doi.org/10.1016/j.enconman.2013.03.022.

Ma A, Ji J, Khayatnezhad M. Risk-constrained non-probabilistic scheduling of coordinated power-to-gas conversion facility and natural gas storage in power and gas-based energy systems. Sustain Energy Grids Netw. 2021;26:100478. https://doi.org/10.1016/j.segan.2021.100478.

Osorio-González CS, Gómez-Falcon N, Sandoval-Salas F, Saini R, Brar SK, Ramírez AA. Production of biodiesel from castor oil: a review. Energies. 2020;13:2467. https://doi.org/10.3390/en13102467.

Brown P, Mazumder P. Current progress in mechanically durable water-repellent surfaces: a critical review. Rev Adhes Adhes. 2021;9(1):123–52. https://doi.org/10.7569/RAA.2021.097301.

Athiyaman A, Magapa T. Market intelligence from the internet: an illustration using the biomass heating industry. Int J Econ Financ Stud. 2019;11(1):1–16. https://doi.org/10.34109/ijefs.201911101.

Hanif M, Bhatti LA, Shahzad K, Hanif MA. Biodiesel production from waste plant oil over a novel nano-catalyst of Li-TiO2/Feldspar. Catalysts. 2023;13:310. https://doi.org/10.3390/catal13020310.

Elumalai PV, Parthasarathy M, Hariharan V, Jayakar J, Iqbal SM. Evaluation of water emulsion in biodiesel for engine performance and emission characteristics. J Therm Anal Calorim. 2022;147:4285–301. https://doi.org/10.1007/s10973-021-10825-z.

Moorthi M, Murugesan A, Alagumalai A. Effect of nanoparticles on DI-CI engine characteristics fueled with biodiesel–diesel blends—a critical review. J Therm Anal Calorim. 2022;147:9163–79. https://doi.org/10.1007/s10973-022-11234-6.

Baramaleki S, Mahdavian L. Investigation of mechano–chemical properties of the effects of nanoparticles in artificial stone produced. SILICON. 2019;11:1071–82. https://doi.org/10.1007/s12633-018-9909-x.

Mashaly AO, Shalaby BN, El-Hefnawi MA. Characterization of the marble sludge of the Shaq El Thoaban industrial zone, egypt and its compatibility for various recycling applications. Aust J Basic Appl Sci. 2012;6(3):153–61.

Bakhshkandi R, Ghoranneviss M. Investigating the synthesis and growth of titanium dioxide nanoparticles on a cobalt catalyst. J Res Sci Eng Technol. 2019;7(4):1–3. https://doi.org/10.24200/jrset.vol7iss4pp1-3.

Aburas H, Bafail A, Demirbas A. The pyrolizing of waste lubricating oil (WLO) into diesel fuel over a supported calcium oxideadditive. Pet Sci Technol. 2015;33:226–36. https://doi.org/10.1080/10916466.2014.973604.

Netam AK, Bhargava VP, Singh R, Sharma P. Physico-chemical characterization of ayurvedic swarna bhasma by using SEM, EDAX, XRD and PSA. J Complement Med Res. 2021;12(2):204–9. https://doi.org/10.5455/jcmr.2021.12.02.23.

Chen TC, Yu SY, Wang CM, Xie S, Barazandeh H. Investigation and calibration of thermal and salinity layering in surface water resources using Ce-Qual-W2 model. J Water Land Dev. 2021;51:117–23. https://doi.org/10.24425/jwld.2021.139021.

Makovetskii AA, Zamyatin AA, Ivanov GA. Technique for estimating the viscosity of molten silica glass on the kinetics of the collapse of the glass capillary. Glass Phys Chem. 2014;40:526–30. https://doi.org/10.1134/S1087659614050083.

Patel A, Patel B, Patel B, Kulshreshtha N. Thermodynamic properties of lubricating oil. Int J Eng Trends Technol. 2019;67(4):42–3. https://doi.org/10.14445/22315381/IJETT-V67I4P210.

Ojovan MI, Travis KP, Hand RJ. Thermodynamic parameters of bonds in glassy materials from viscosity-temperature relationships. J Phys Condens Matter. 2007;19(41):415107. https://doi.org/10.1088/0953-8984/19/41/415107.

ASTM D975–20c. Standard specification for diesel fuel. ASTM International. 2020.

Hurtado B, Posadillo A, Luna D, Bautista FM. Synthesis, performance and emission quality assessment of ecodiesel from castor oil in diesel/biofuel/alcohol triple blends in a diesel engine. Catalysts. 2019;9(1):40. https://doi.org/10.3390/catal9010040.

ASTM D-6751–03a. Standard specification for biodiesel fuel blend stock (B100) for middle distillate fuels. ASTM International. 2003.

ASTM D6079. Standard Test Method for Evaluating Lubricity of Diesel Fuels by the High-Frequency Reciprocating Rig (HFRR). 2005.

Funding

The authors have no affiliation with any organization with a direct or indirect financial interest in the subject matter discussed in the manuscript.

Author information

Authors and Affiliations

Contributions

Study concept and design were contributed by GW, AB, OV, and LM. Analysis and in the perpetration of data were contributed by GW, AB, OV, and LM. Drafting of the manuscript was contributed by LM and AB. Critical revision of the manuscript for important intellectual content was contributed by LM. Statistical analysis was contributed by GW, AB, OV, and LM. Administrative, technical, or material support and supervision were contributed by GW, AB, OV, and LM.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Ethical approval

The study is done through computational methods of chemistry, which are not related to human and animal studies.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Widjaja, G., Bohlouli, A., Voronkova, O. et al. Investigation of thermodynamic parameters, combustion, and emissions of produced biodiesel fuel (from waste oil by heterogeneous nano-catalyst of stone cutting factory sludge) and its combination with diesel fuel. J Therm Anal Calorim 148, 7781–7793 (2023). https://doi.org/10.1007/s10973-023-12270-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-023-12270-6