Abstract

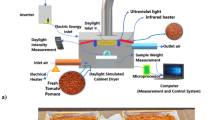

Olive pomace is generated during the production of olive oil. The disposal of olive pomace presents a serious environmental issue to the agricultural community in Morocco. Among all actions devoted to the reduction of olive pomace waste, their revaluation seems to be the most efficient and advantageous from both environmental and economic points of view. Due to its high moisture content, solar drying constitutes an important and promising solution for a possible bio-fuel conversion of olive pomace. For this purpose, a modified uneven-span greenhouse dryer was designed and installed at the faculty of sciences Semlalia, Marrakech, Morocco. An experimental study of solar drying kinetics of the olive pomace was conducted to test the performances of the modified greenhouse dryer under a hybrid (solar/hot air) forced convection mode. The hot-air blower was supplied by electricity from a PV array installed near the greenhouse. The mean temperatures of air within the greenhouse and of the olive waste during the drying hours reached, respectively, 63 °C and 55 °C (from August 3rd to August 5th). The duration of the drying operation of 300 kg of waste from a moisture content of 50 mass% to 19 mass% was 27 h, which was low compared to the open sun drying. Therefore, hybrid forced mode enabled a considerable reduction in drying time, being an aspect to take into account for its use during low solar radiation. The drying kinetics of thin layer two-phase olive pomace was also investigated. The Two-term Gaussian model was found to be the most suitable model to describe the thin layer drying behavior of the two-phase olive pomace dried under hybrid forced convection greenhouse drying mode. In addition, the Fourier series was used to solve the diffusivity equation inside the two-phase olive pomace. The effective diffusivity was found to be 2.0 10–09 m2 s−1 and 2.3 10–09 m2 s−1 using the linear fit and the slope from two successive points methods, respectively.

Similar content being viewed by others

Data availability

The datasets generated during and analyzed during the current study are not publicly available due to confidential issues but are available from the corresponding author on reasonable request.

Abbreviations

- η (%):

-

Drying efficiency

- Q f (W):

-

Power of the extraction fans

- m ev (kg):

-

Mass of water evaporated from the two-phase olive pomace

- m i (kg):

-

Initial mass of the two-phase olive pomace

- h L (kJ kg− 1):

-

Latent heat of evaporation of water

- M i :

-

Initial moisture content

- I (W m− 2):

-

Solar radiation

- M f :

-

Final moisture content

- τ :

-

Greenhouse cover transmission

- M wt :

-

Instantaneous moisture content on a wet basis

- A (m2):

-

Greenhouse floor area

- SEC (kWh kg− 1):

-

Specific energy consumption

- t (h):

-

Drying time

- SMER (kg kWh− 1):

-

Specific moisture extraction rate

- Q b(W):

-

Power of the hot air blower

- MR:

-

Moisture ratio, dimensionless value

References

Meziane S. Drying kinetics of olive pomace in a fluidized bed dryer. Energy Convers Manag. 2011;52(3):1644–9. https://doi.org/10.1016/j.enconman.2010.10.027.

Bouraoui C, Debenest G, Ben Nejma F. Numerical performance assessment of a solar greenhouse dryer for the drying of Olive Mill Wastewater. J Therm Anal Calorim. 2022;147(15):8381–95. https://doi.org/10.1007/S10973-021-11134-1/METRICS.

K. Apostolos and S. Fereidoon, 2017 Olives and olive oil as functional foods.

Guida MY, et al. Thermochemical treatment of olive mill solid waste and olive mill wastewater: pyrolysis kinetics. J Therm Anal Calorim. 2016;123(2):1657–66. https://doi.org/10.1007/S10973-015-5061-7/METRICS.

Khayer A, Bari M, Akratos CS, Vayenas DV, Pavlou S. International biodeterioration & biodegradation olive mill waste composting : a review. Int Biodeterior Biodegradation. 2013;85:108–19. https://doi.org/10.1016/j.ibiod.2013.06.019.

Muik B, Lendl B, Ayora-cañada LPMJ. Determination of oil and water content in olive pomace using near infrared and Raman spectrometry a comparative study. Anal Bioanal Chem. 2004;379(1):35–41. https://doi.org/10.1007/s00216-004-2493-5.

Montero I, Miranda MT, Sepúlveda FJ, Arranz JI, Rojas CV, Nogales S. Solar dryer application for olive oil mill wastes. Energies. 2015;8(12):14049–63. https://doi.org/10.3390/en81212415.

Papaioannou EH, Patsios SI, Karabelas AJ, Philippopoulos NA. Journal of environmental chemical engineering characterization of condensates from an indirect olive oil pomace drying process : the effect of drying temperature. Biochem Pharmacol. 2013;1(4):831–7. https://doi.org/10.1016/j.jece.2013.07.025.

Aboulkas A, El Harfi K. Co-pyrolysis of olive residue with poly(vinyl chloride) using thermogravimetric analysis. J Therm Anal Calorim. 2009;95(3):1007–13. https://doi.org/10.1007/S10973-008-9315-5/METRICS.

Aboulkas A, El Harfi K, Nadifiyine M, El Bouadili A. Thermogravimetric characteristics and kinetic of co-pyrolysis of olive residue with high density polyethylene. J Therm Anal Calorim. 2008;91(3):737–43. https://doi.org/10.1007/S10973-007-8661-Z/METRICS.

Asimakidou T, Chrissafis K. Thermal behavior and pyrolysis kinetics of olive stone residue. J Therm Anal Calorim. 2022;147(16):9045–54. https://doi.org/10.1007/S10973-021-11163-W/METRICS.

Manchanda H, Kumar M. Performance evaluation of a locally designed stepped solar distillation-cum-active drying unit. J Therm Anal Calorim. 2022;147(6):4383–95. https://doi.org/10.1007/s10973-021-10835-x.

Sunil V, Sharma N. Experimental investigation of the performance of an indirect-mode natural convection solar dryer for drying fenugreek leaves. J Therm Anal Calorim. 2014;118(1):523–31. https://doi.org/10.1007/s10973-014-3949-2.

Goel V, Bhattacharyya S, Kumar R, Pathak SK, Tyagi VV, Saini RP. Identification of barriers and drivers to implementation of solar drying technologies. J Therm Anal Calorim. 2022;164:1–24.

Prakash O, Kumar A. Solar greenhouse drying: a review. Renew Sustain Energy Rev. 2014;29:905–10. https://doi.org/10.1016/j.rser.2013.08.084.

Beigi M, Torki M, Khoshnam F, Tohidi M. Thermodynamic and environmental analyses for paddy drying in a semi-industrial dryer. J Therm Anal Calorim. 2021;146(1):393–401. https://doi.org/10.1007/S10973-020-09968-2/METRICS.

Baysan U, Koç M, Güngör A, Ertekin FK. Investigation of drying conditions to valorize 2-phase olive pomace in further processing. Dry Technol. 2020;40(1):65–76. https://doi.org/10.1080/07373937.2020.1770279.

Fudholi A, Sopian K, Alghoul MA, Ruslan MH, Othman MY. Performances and improvement potential of solar drying system for palm oil fronds. Renew Energy. 2015;78:561–5. https://doi.org/10.1016/j.renene.2015.01.050.

Maragkaki A, Markakis FGN, Tsompanidis GSC. Initial investigation of the solar drying method for the drying of olive oil by-products. Waste and Biomass Valorization. 2016. https://doi.org/10.1007/s12649-016-9505-5.

Gilago MC, Mugi VR, VP, C. Evaluating the performance of an indirect solar dryer and drying parameters of pineapple: comparing natural and forced convection. J Therm Anal Calorim. 2023;104:1–9. https://doi.org/10.1007/S10973-023-11955-2.

Mellalou A, Riad W, Hnawi SK, Tchenka A, Bacaoui A, Outzourhit A. Experimental and CFD investigation of a modified uneven-span greenhouse solar dryer in no-load conditions under natural convection mode. Int J Photoenergy. 2021;2021:1–12. https://doi.org/10.1155/2021/9918166.

Mellalou A, Riad W, Mouaky A, Bacaoui A, Outzourhit A. Optimum design and orientation of a greenhouse for seasonal winter drying in Morocco under constant volume constraint. Sol Energy. 2021;230(August):321–32. https://doi.org/10.1016/j.solener.2021.10.050.

Forson FK, Nazha MAA, Akuffo FO, Rajakaruna H. Design of mixed-mode natural convection solar crop dryers : application of principles and rules of thumb. Renewable Energy. 2007;32:2306–19. https://doi.org/10.1016/j.renene.2006.12.003.

ELkhadraoui A, Kooli S, Hamdi I, Farhat A. Experimental investigation and economic evaluation of a new mixed-mode solar greenhouse dryer for drying of red pepper and grape. Renew Energy. 2015;77:1–8. https://doi.org/10.1016/j.renene.2014.11.090.

Erick César LV, Ana Lilia CM, Octavio GV, Isaac PF, Rogelio BO. Thermal performance of a passive, mixed-type solar dryer for tomato slices (Solanum lycopersicum). Renew Energy. 2020;147:845–55. https://doi.org/10.1016/j.renene.2019.09.018.

Mellalou A, Mouaky A, Bacaoui A, Outzourhit A. A comparative study of greenhouse shapes and orientations under the climatic conditions of Marrakech, Morocco. Int J Environ Sci Technol. 2021. https://doi.org/10.1007/s13762-021-03556-z.

Kiburi FG, Kanali CL, Kituu GM, Ajwang PO, Ronoh EK. Performance evaluation and economic feasibility of a solar-biomass hybrid greenhouse dryer for drying banana slices. Renew Energy Focus. 2020. https://doi.org/10.1016/j.ref.2020.06.009.

Xu B, Wang D, Li Z, Chen Z. Drying and dynamic performance of well-adapted solar assisted heat pump drying system. Renew Energy. 2020;164:1209–305. https://doi.org/10.1016/j.renene.2020.10.104.

Deeto S, Thepa S, Monyakul V, Songprakorp R. The experimental new hybrid solar dryer and hot water storage system of thin layer coffee bean dehumidification. Renew Energy. 2017. https://doi.org/10.1016/j.renene.2017.09.009.

Ortiz-Rodríguez NM, García-Valladares O, Pilatowsky-Figueroa I, Menchaca-Valdez AC. Solar-LP gas hybrid plant for dehydration of food. Appl Therm Eng. 2020;177:115496. https://doi.org/10.1016/j.applthermaleng.2020.115496.

Sethi VP, Dhiman M. Design, space optimization and modelling of solar-cum-biomass hybrid greenhouse crop dryer using fl ue gas heat transfer pipe network. Sol Energy. 2020;206:120–35. https://doi.org/10.1016/j.solener.2020.06.006.

Taskin O, Polat A, Etemoglu AB, Izli N. Energy and exergy analysis, drying kinetics, modeling, microstructure and thermal properties of convective-dried banana slices. J Therm Anal Calorim. 2022;147(3):2343–51. https://doi.org/10.1007/s10973-021-10639-z.

Mondal IH, Rangan L, Uppaluri RVS. Symphony of kinetics and statistical design approaches for response analysis during tray drying of Lagenaria siceraria leaves. J Therm Anal Calorim. 2021;145(5):2389–403. https://doi.org/10.1007/s10973-020-09782-w.

Kesavan S, Arjunan TV, Vijayan S. Thermodynamic analysis of a triple-pass solar dryer for drying potato slices. J Therm Anal Calorim. 2019;136(1):159–71. https://doi.org/10.1007/s10973-018-7747-0.

Vijayan S, Arjunan TV, Kumar A. Exergo-environmental analysis of an indirect forced convection solar dryer for drying bitter gourd slices. Renew Energy. 2020;146:2210–23. https://doi.org/10.1016/j.renene.2019.08.066.

Malakar S, Arora VK, Nema PK. Design and performance evaluation of an evacuated tube solar dryer for drying garlic clove. Renew Energy. 2021;168:568–80. https://doi.org/10.1016/j.renene.2020.12.068.

Dutta P, Dutta PP, Kalita P. Thermal performance studies for drying of Garcinia pedunculata in a free convection corrugated type of solar dryer. Renew Energy. 2021;163:599–612. https://doi.org/10.1016/j.renene.2020.08.118.

Nourhène B, Mohammed K, Nabil K. Experimental and mathematical investigations of convective solar drying of four varieties of olive leaves. Food Bioprod Process. 2008;86(3):176–84. https://doi.org/10.1016/j.fbp.2007.10.001.

Akgun NA, Doymaz I. Modelling of olive cake thin-layer drying process. J Food Eng. 2005;68(4):455–61. https://doi.org/10.1016/j.jfoodeng.2004.06.023.

Celma AR, Rojas S, López F, Montero I, Miranda T. Thin-layer drying behaviour of sludge of olive oil extraction. J Food Eng. 2007;80(4):1261–71. https://doi.org/10.1016/j.jfoodeng.2006.09.020.

Ortiz-Rodríguez NM, Marín-Camacho JF, González AL, García-Valladares O. Drying kinetics of natural rubber sheets under two solar thermal drying systems. Renew Energy. 2021;165:438–54. https://doi.org/10.1016/j.renene.2020.11.035.

Murali S, Amulya PR, Alfiya PV, Delfiya DSA, Samuel MP. Design and Performance Evaluation of Solar - LPG Hybrid Dryer for Drying of Shrimps. Renew Energy. 2019. https://doi.org/10.1016/j.renene.2019.10.002.

Vengsungnle P, Jongpluempiti J, Srichat A, Wiriyasart S, Naphon P. Thermal performance of the photovoltaic-ventilated mixed mode greenhouse solar dryer with automatic closed loop control for Ganoderma drying. Case Stud Therm Eng. 2020;21:100659. https://doi.org/10.1016/j.csite.2020.100659.

Tripathy PP, Kumar S. Modeling of heat transfer and energy analysis of potato slices and cylinders during solar drying. Appl Therm Eng. 2009;29(5–6):884–91. https://doi.org/10.1016/j.applthermaleng.2008.04.018.

Crank J. The mathematics of diffusion. Oxford: Clarendon Press; 1975.

Nukulwar MR, Tungikar VB. Drying kinetics and thermal analysis of turmeric blanching and drying using solar thermal system. Sustain Energy Technol Assessments. 2021;45:101120. https://doi.org/10.1016/j.seta.2021.101120.

Patil RC, Gawande RR. Mathematical modeling of solar drying systems. Solar Drying Technol. 2017. https://doi.org/10.1007/978-981-10-3833-4_9.

Fudholi A, Bakhtyar B, Saleh H, Ruslan MH, Othman MY, Sopian K. Drying of salted silver jewfish in a hybrid solar drying system and under open sun: modeling and performance analyses. Int J Green Energy. 2016;13(11):1135–44. https://doi.org/10.1080/15435075.2016.1175347.

Meziane S, Mesbahi N. Determination of moisture diffusivity and activation energy in thin layer drying of olive Pomace. Int J Food Eng. 2012. https://doi.org/10.1515/1556-3758.2648.

Rabha DK, Muthukumar P, Somayaji C. Energy and exergy analyses of the solar drying processes of ghost chilli pepper and ginger. Renew Energy. 2017;105:764–73. https://doi.org/10.1016/j.renene.2017.01.007.

Montero I, Miranda T, Arranz JI, Rojas CV. Thin layer drying kinetics of by-products from olive oil processing. Int J Mol Sci. 2011;12(11):7885–97. https://doi.org/10.3390/ijms12117885.

Acknowledgements

This work was performed in the framework of the Bioresol project. The authors are grateful to IRESEN for the financial support.

Funding

The authors declare that no funds, grants, or other support were received during the preparation of this manuscript.

Author information

Authors and Affiliations

Contributions

MA: Writing, Methodology, Data acquisition, Original draft preparation, Experience processing RW: Data acquisition, Experience processing BA: Visualization, Investigation OA: Writing, Reviewing, Editing, Investigation and Supervision.

Corresponding author

Ethics declarations

Conflict of interest

The authors have no relevant financial or non-financial interests to disclose.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Mellalou, A., Riad, W., Bacaoui, A. et al. Experimental investigations on drying kinetics and modeling of two-phase olive pomace dried in a hybrid solar greenhouse dryer. J Therm Anal Calorim 148, 5471–5483 (2023). https://doi.org/10.1007/s10973-023-12063-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-023-12063-x