Abstract

The tomato pomace (TP), which is a by-product of the production of tomato paste, was dried in a novel custom-designed daylight simulated photovoltaic assisted dryer (DPVD). The different light applications (daylight, UV light, daylight + UV light, and without light), different air velocities (1.5 and 2 m/s), and different heating source modes (hot air and infrared) were applied to dry TP having a moisture content of 80.60 ± 0.73% to the moisture content of 7.66 ± 1.72%. The average water activity values of all dried samples were measured as 0.52 ± 0.08. Analysis was conducted to compare sun drying with the effects of process conditions on the quality (color properties, lycopene, β-carotene, and total mesophilic aerobic bacteria count) and performance (energy efficiency, exergy efficiency, specific moisture evaporation rate, and improvement potential) characteristics of TP. The effects of process conditions for each heating source mode were determined separately, and the improvement of the system performance for each mode was investigated. The effect of the process conditions on total aerobic mesophilic bacteria (TAMB) count was similar in general. In the infrared heating mode, the loss in lycopene and β-carotene contents was 59.55 ± 2.22 and 57.87 ± 2.51 minimum for 1.5 m/s air velocity without light application and for 2 m/s with ultraviolet + daylight application. In general, the performance of the system decreased in case of using ultraviolet light. The retention in the lycopene and β-carotene contents was higher in the infrared mode with light applications compared to hot air mode without light. The optimum drying conditions were air velocity of 2 m/s with “daylight” assistance in the hot air heating mode and with “ultraviolet + daylight” assistance in the infrared heating mode. All the energy and the daylight source used in drying applications were obtained from the sun, a renewable energy source, thanks to the photovoltaic panel and the solar tube units in the novel custom-designed drying system.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The absence of storage facilities and incorrect handling of perishables account for almost a third of the global production of foodstuffs consumed by humans, about 1.3 billion tons annually (FAO, 2016). In this case, it increases in developing countries where products are wasted. Drying is a highly recommendable practice as a simple and widely used technique to tackle this worrisome food waste problem in processing. Hot air or convective drying is the easiest and oldest method of drying food. However, drying is one of the applications that require the most energy (Kovacı & Dikmen, 2018). Most of the drying processes in developing countries are carried out either under the sun or using hot air (Kovacı & Dikmen, 2018; Sonmete et al., 2017). Environment variables such as relative humidity, temperature, air movement, and hygiene cannot be kept under control during sun drying. Foreign substances such as dust, soil, and heavy metals can mix with the products (Demiray & Tülek, 2012; Mustayen et al., 2014; Yıldız et al., 2016), and the microbiological load may increase, especially in products dried under adverse weather conditions (Bourdoux et al., 2016). At the same time, drying time with sun drying takes much longer than in artificial systems. With all these aspects, sun drying poses a risk for food products and may adversely affect product quality.

Although the methods used as an alternative to the sun drying method provide positive effects in shortening the drying time, they have disadvantages in terms of energy use and product quality. There are many studies in the literature comparing various drying methods such as hot air drying, freeze drying, infrared drying, and microwave drying with sun drying (Cao et al., 2016; Hay et al., 2022). Today, the rapid depletion of energy resources, increasing consumer demand for quality products, and increasing competition with globalization encourage innovations in the drying process. Therefore, improving the performance of existing drying technologies and developing new drying approaches have gained importance to ensure the sustainability of the food industry (Sabarez, 2015). Since drying is a very intensive basic process in terms of energy consumption and energy efficiency needs to be increased (Erbay and Hepbaşli, 2013), solar panels are used to benefit from solar energy, which is a renewable energy type (Weiss & Buchinger, 2012). The application area of solar energy to foods is common in drying processes. There are several studies on the use of solar energy as a renewable energy source as drying energy rather than the effect of sunlight in drying systems (Chinenye et al., 2022; Marinoni et al., 2022; Pasifico et al., 2022). Tubular daylight transfer systems for conveying daylight have been implemented since 1982 and have been refined over time (Malet-Damour et al., Bigot and Boyer, 2020). By taking advantage of the sun’s renewable energy, these systems can help to reduce electricity consumption (Goharian and Mahdayinejad, 2020; Balabel et al., 2022).

Tomato pomace (TP) is important because of the high production and consumption in our country and because it is a by-product of tomato, which has rich nutritional content. According to FAO, 2019 data, Turkey ranks third in world tomato production with 12.84 million tons, after China and India (FAOSTAT, 2019). At the same time, our country ranks fifth in the world export share of tomatoes with approximately 530 thousand tons (TEPGE, 2020). In addition to being the most common commercially produced vegetable in the world and consumed fresh, tomato is processed into various products such as tomato paste, sauce, ketchup, tomato juice, tomato puree, canned tomatoes, and dried tomatoes in the food industry (Løvdal et al., 2019). Processing wastes generated during the production of tomato paste are called secondary raw materials (Navarro-González et al., 2011). TP, which is a by-product of tomato processing, can be dried and used in both human food and animal feed, in Turkey. TP contains high levels of polysaccharides such as fiber and pectin. TP contains the skin, broken seeds, and fruit flesh that remains after the tomato juice has been taken. Dried and ground pomace, depending on the type of tomato harvested, consists of protein, lipid, ash, and fiber (Savadkoohi et al., 2014). According to the quality of the tomatoes produced, 1 kg of tomato paste is obtained from 6–7 kg of tomatoes, and large amounts of waste products are formed after processing. This waste product is important in terms of converting it into valuable and completely herbal additives by making use of dietary fiber, pectin, lycopene, and various bioactive components in its composition.

In the studies carried out to obtain valuable components from tomato processing wastes, the main aim was generally to find the most efficient method. Thus, hot air drying (Alazb et al., 2021; Allison et al., 2016), drum drying (Milczarek et al., 2017), microwave drying (A-Harahsheh, Ala’a and Magee, 2009), freeze-drying (Nemli et al., 2021), sun drying (Badaoui et al., 2019), and sun-traditional drying applications have been investigated. In all these studies, it was aimed to obtain the valuable component, especially lycopene, at the highest rate from tomato processing wastes or TP.

A study has been carried out to develop a new combination drying technology with temperature and humidity control followed by radio frequency hot air drying techniques, in order to overcome the problems of severe cracking and odor loss resulting from hot air drying for Amomi fructus. As a result, it has been reported that the combined use of hot air and radio frequency application in the developed system reduces drying time by 55.5% and energy consumption by 47.80% compared to the use of hot air alone. As a result, it has been revealed that the combined use of radio frequency and hot air applications is a promising drying approach that ensures efficient energy use while preserving product quality during drying (Ai et al., 2023). In the study where significant color changes were observed in the experiments where tomato slices were dried at different infrared powers and different air speeds, the temperature inside the cabin where the drying trials were carried out was not given, but the air temperature entering the drying cabin was given as 35 °C ± 1 (Kocabiyik et al., 2015). Unlike the aforementioned study, in this study, in which daylight was simulated with a new approach, ultraviolet light (A-B) and visible light were also included in the drying cabinet. Additionally, temperature measurements were taken from three different points in the cabin during drying (60 °C). In another study, it was reported that fluidized bed hot air drying combined with halogen lamp drying was an innovative hybrid drying technique for the production of parboiled rice that was more effective than traditional parboiled rice production. Traditionally, parboiled rice production requires the use of steam. As an alternative to the steaming process, which is a complex process in addition to its high energy consumption, it has been shown that the combined application of fluidized bed hot air drying with a halogen lamp can also provide a better quality product than steamed parboiled rice (Srisang et al., 2021). In the study presented by our team, hot air and infrared lamps were included in different trial groups and their effects on the quality and performance characteristics of tomato pomace were evaluated individually. Therefore, unlike the studies in the literature, convection and radiation mechanisms of heat transfer during drying of tomato pulp in an environment where traditionally carried out drying practices were simulated in a closed drying cabinet were examined in separate experimental groups.

One of the important sources of energy for plant development is the use of light, which plays an important role in the synthesis of certain compounds. Exposure with wavelengths of light from UV to infrared is believed to influence phytochemical synthesis and plant development at different stages of growth, elongation, flowering, or fruiting (Artés-Hernández et al., 2022). Consequently, through the use of LEDs stimulated with photoreceptors and genes activated by abiotic stress, physical stimulation resulting from visible light can be controlled so that plant secondary mutating machinery is activated to counter incoming light (Santin et al., 2021). Several authors have established that the stress caused by lighting is associated with an increase in synthesis and accumulation of nutraceuticals. For example, low doses of UV-B and UV-C have been shown to be good precursors of glucosinolates and isothiocyanates in broccoli (Moreira-Rodríguez et al., 2017a, 2017b) and radish, as well as the biosynthesis of carotenoids and flavonoids in bell peppers (Castillejo et al., 2021), sprouts (Castillejo et al., 2022), and cabbage sprouts (Martínez-Zamora et al., 2021) and phenolic compounds in carrots (Artés-Hernández et al., 2022). Furthermore, it has been shown that bioactive compounds, due to high energy UV light that can cause cellular damage, are favorably affected by other less energetic electromagnetic spectrum regions, with no potential impact on fruits and vegetables (Artés-Hernández et al., 2022). There are studies showing that tomatoes are exposed to ultraviolet light (C) during storage after harvest, which increases their lycopene content (Baenas et al., 2021; Jagadeesh et al., 2011; Liu et al., 2009; Urban et al., 2016). This study contributes to conducted by exposing the A and B regions of ultraviolet light during drying. In that respect, in order to improve the quality of young plants at an early developmental stage by improving their phytochemical compounds, use of different spectrum lighting techniques and green technology with low energy costs is important. In this study, it was aimed to provide valuable component recovery from a product having no production cost by reducing the energy consumption cost. In this context, it was aimed to dry TP samples in two different heating source modes (hot air and infrared) with the assistance of the daylight from the sun via solar panels and its combinations with UV light by providing electrical energy from photovoltaic panels. The effect of processing conditions on changes in certain quality characteristics (total dry matter, color properties, lycopene and β-carotene contents, total aerobic mesophilic bacteria count) of dried TP was determined and compared with the effects of drying under the sun. In addition, the performance characteristics (energy and exergy efficiency, specific moisture loss rate, improvement potential) in the custom-designed DPVD under different operating conditions were compared. The improvements in the performance characteristics for both heating source modes were examined for different energy supply cases.

Materials and Methods

Materials

The TP has been obtained from an agricultural processing plant. The pomace samples were mixed homogeneously in smaller Ziplock bags (20 × 25 cm, Korozo Ambalaj, Turkey) and then cooled to − 30 °C (BK 3288, Beko, Turkey) and stored (for a period of 3 months). In cold ambient conditions for 24 h, the sample has been defrosted (+ 4 °C, stagnant air) (5231 NFY, Arçelik, Turkey). The method described in Bayana and İçier (2022) has been used for the sample preparation step (Bayana & İçier, 2022).

Methods

Daylight Simulated Photovoltaic-Assisted Drying (DPVD) System

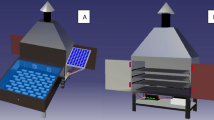

The details of the daylight simulated photovoltaic-assisted drying, which was a custom-made design, had been given in the previous paper of our team (Bayana & İçier, 2022). The system comprises of a dryer unit, PV panel unit, light units (daylight, infrared, ultraviolet, and LED), measurement units, weight measurement unit, and control unit (Fig. 1a; Bayana & İçier, 2022). There was a process control system for the properties of air (velocity, temperature, and humidity), the weight of the product, and the energy consumption (fan, the electrical heater, infrared light, ultraviolet light). A humidity and temperature probe was used to measure the humidity and temperature of the ambient conditions outside the cabin (0420.0023, Testo, Germany). The PV panel unit comprises of four photovoltaic panels (PV), (Lexron, Korea) (installation capacity per hour, 1 kWh) to use as renewable energy the full amount of electricity required by the system. A full sine power inverter with a capacity of 3 kW and four gel batteries has been placed beside the dryer for storage of electrical energy produced by PVs. The electrical power values which were supplied to the dryers from PV systems and orators of electricity main supply have been recorded as a result of the custom microprocessor integrated into the system.

a Schematic illustration of daylight simulated cabinet dryer (Bayana & İçier, 2022). b Drying under the sun

The method described in Bayana and İçier (2022) has been used to measure air velocity in the cabin (Bayana & İçier, 2022). During the drying process, two different air velocities have been adjusted between 1.5 and 2 m/s.

There were two different heating source modes: hot air and infrared. In hot air mode, the cabin’s air temperature was continuously maintained at 60 °C by heating the inside air controlled via the on–off of an electric heater (2 kW, Ohmik Energy, Turkey) within the DPVD cabinet. In infrared mode, the infrared source consisting of four different infrared lamps (quartz tube, 30 cm, 0.5 kW, Stick IR Lamp, China), which were placed on the edges of the inside top surface of the dryer, was used to heat the sample and the air inside the dryer. The on–off control of the infrared source kept the inside air temperature constant at 60 °C.

There were four different light applications for each heating source mode: daylight, UV light, daylight + UV light, and no light. The use of a tubular UV-blocked daylight system (Solatube, Brighten Up-160 DS, Solatube International, Inc., California, USA) enables the system to take advantage of daylight. Therefore, the light emitter blocked the daylight from the outside environment and transferred it to the drying cabinet by means of reflective tubes (Fig. 1a; Bayana & İçier, 2022). Almost anything below 375 nm and more than 775 nm is blocked by the light emitting system. Thus, it transferred all UV-B and the majority of UV-A but not UV-C and infrared (American Research and Testing Inc., 1994). The most appropriate daylight condition (7500 lx), which has been reported in our previous paper of our team (Bayana & İçier, 2022), was used as the “daylight” application mode. In order to adjust the amount of light (7500 lx) entering the system, a dimmer has been installed between the tube connections in the drying chamber. The daylight intensity was measured with a photometer (Lutron Electronic Enterprise Co., Ltd., LX-105, Taipei, Taiwan) in “lux” during the drying process, for a period of 30 min. The “UV light” was also applied as another light application by using a total of four UV light lamps in 100 W by placing them on the corners of the top surface of the dryer cabinet. The combination of the daylight with the UV light (“daylight + UV light”) was applied as another daylight application mode. Furthermore, there was also “no light” application without light.

The TP samples (352.82 ± 1.09) were laid as thin layers of 1 cm homogeneously on a tray with side height of 2 cm and diameter of 34 cm from the DPVD cabinet (Bayana & İçier, 2022). The sample was taken at every 30 min intervals and then mixed throughout the process. The change in the weight of the sample using a weighing instrument installed inside DPVD with an 0.1 g sensitivity has been quantified and documented (EHB-3000 + , Desis, Turkey).

In this study, the 16 different process conditions consisted of the combination of different heating source modes (hot air and infrared), different air velocities (1.5 and 2 m/s), and four different light applications (no light, daylight, UV light, and daylight + UV light) were applied in triplicate.

Drying Under the Sun

Drying under the sun was used as a control drying process. The wooden crates filled with soil were used, and portable covers in white color were laid on the soil. In order to prevent the sample loss due to the wind effect, the covers were laid out on the flat surfaces that fit into the wooden crates. In this way, it was ensured that the TP samples remained slightly below the height of the wooden case. The drying experiments were carried out under the sun by mixing at 30-min intervals (Fig. 1b). Weighing was carried out for sampling plate of 40 × 40 cm to determine the weight change in TP during drying. The drying process was carried out on the terrace of Ege University Food Engineering Department Pilot Facility Building (Bornova, İzmir, Turkey).

The humidity and temperature changes of the ambient, the air velocity, light intensities, and the weight change were determined. TP samples were dried until they reached the target total dry matter (TDM) content (94.11 ± 1.09%) and were stored at 4 °C, packed with Ziplock bags, aluminum foil, and the stretch cover to prevent moisture absorption until analysis. The sun drying process was conducted in two parallel with three replicates on consecutive days.

Analyses

All analyses were conducted in three parallel.

Total Dry Matter Content and Drying Time

The rapid moisture analyzer (Radwag, MA 210R, Poland) at 90 °C has established the total dry matter (TDM) in TP (kg water/kg dry matter) (American Research and Testing Inc., 1994).

The time required for drying TP having a moisture content of 80.63% ± 1.16 to reach the total dry matter (TDM) content of 94.11% ± 1.09 was defined as “the drying time.”

Water Activity

The water activity of TP prior to and during drying has been measured by a water activity measuring device (AB-0028-K, Testo 400, Germany). The samples have been substituted into the closed chamber of the device. As soon as the relative humidity (ERH%) stabilized in the room, water activity values were taken into account in this ratio (Stekelenburg & Labots, 1991).

Color Analysis

For the drying process, a colorimeter (Konica Minolta CR-400 Chroma Meter, Tokyo, Japan) has been used to measure the color properties of TP. In the first place, the device was calibrated with a white standard plate, and then, the color properties of the samples (L*, a*, and b*) were measured. For each three replications of each drying condition, the color values were measured from three different regions of each three random parallel. Use of color values from the sample before drying has been used to calculate the ΔE, ΔC, and hue angle (Eqs. 1–3, Baysal et al., 2003).

where i is the raw TP (before drying) and d is the dehydrated TP (after drying).

Lycopene and β-Carotene Contents

The modification of the methods of Sadler et al. (1990) and Fish et al. (2002) to determine the lycopene and β-carotene contents of TP before and after drying has been given in Bayana and Icier (2022) in detail. A spectrophotometer (Rayleigh, VIS-723G, China) was used to measure the lycopene and carotene content of the samples, and readings were made against hexane at 503 (lycopene) and 451 nm (β-carotene). For each three replications of each drying condition, the % decrease in lycopene and β-carotene contents was determined by the equations given in Bayana and Icier (2022).

Total Aerobic Mesophilic Bacteria (TAMB) Count

Total aerobic mesophilic bacteria count of fresh and dried TP samples was determined by applying FDA’s Bacteriological Analytical Manual (BAM) reference method (BAM, 2001) in the Tempo device (Biomerieux, France). The dilution of the sample taken from the tomatoes into stomacher bags was prepared using 0.1% buffered peptone water (BPW) and kept in the stomacher (Stomacher Lab-Blender 400, Seward Medical, London, UK) for 3 min and homogenized. 10−2 and 10−3 dilutions of the obtained food homogenate were prepared and 10−4 and 10−6 dilutions were prepared for the special cards of the Tempo device (Biomerieux, France) using the special filling unit of the device (Biomerieux, France), and the cards were hermetically sealed in the filling unit. The filled cartridges were closed and incubated at 30 °C for 40–48 h (American Research and Testing Inc., 1994). At the end of the incubation, the cards were read in the reading unit of the Tempo device in cfu/g. For each three replications of each drying condition, the TAMB count was determined in three parallel (Table 1, 2, 3, 4, 5, 6).

Performance Analyses

The energy effectiveness, exergy efficiency, the potential to improve evaporation and specific moisture SMER values are used for determining the performance of a drying process. First, the system boundary was selected as control volume, and then, the mass, energy, entropy, and finally exergy governing equations were solved, respectively.

Since the related equations have been given in our previous study (Bayana & İçier, 2022) in detail, only specific expressions were mentioned below. In the related equations, the subscript “i” referred to “f,” “ain,” “about,” ew, and “d” were mentioned for fresh TP, inlet air, outlet air, water vapor evaporated from the sample, and dried TP, respectively.

Mass Balances

The moisture left the product and was transported to the air on the system’s boundary while it dried. Therefore, this moisture was absorbed by the air that entered the system and then left it as moist air. It was assumed that the flow rates of the dry air entering and leaving the system would be the same. The sum of the dried TP and its evaporated water mew content at initial (min) was then expressed as a mass (mout) (Eq. 4).

Energy Analysis

The process control unit within the DPVD system assessed the energy consumption of drying processes. The TP’s initial energy, the air entering the system, the air leaving the system, and the dried TP’s energy Ef, Ea in, Ea out, Ed, respectively (Eq. 5).

The total energy required to evaporate the moisture from the TP was Eew. The total energy loss from the control volume was Qloss. “Esystem” consisted of the sum of the energies of the fan system, and the electrical heater (Esystem, heat) or the infrared source, in addition to UV light source in case of UV light mode. The energies of air, the pomace at the initial and the end of the drying, and the evaporated moisture were predicted by using Eqs. 6–8. ∆Ti was predicted by subtracting the dead state temperature (10 °C) from the related temperature (Ti). For the air and tomato sample, the “cpi” (J/kgK) values and densities for any moisture content at any temperature were determined from the equations given in the literature (ASHRAE, 2006).

The energy efficiency (ƞenergy) of the process was determined by using Eq. 10.

By dividing the amount of water vapor leaving the system (Esystem) by the amount of energy entering the system, the SMER (g/kJ) was predicted (Eq. 11) (Hepbasli et al., 2010).

Entropy Balance

Since the disturbance caused by evaporating water during drying should be included in the entropy balance, the irregularities resulting from the energy entering the control volume have been defined as the entropy entering the system (Sin) (Eqs. 12 and 13). The mean temperature (Tmean) (K) is defined as an average of the associated and dead state temperatures. The entropy leaving the system (Sout) was predicted from the sum of the entropies due to the energy heat loss (SQloss) (Eq. 13) and the evaporated moisture vapor (Sew) (kJ/K) (Eq. 15) (Hepbasli et al., 2010; Çengel et al., 2002; Hancioglu et al., 2010).

The difference in entropy of the system (ΔS) was the sum of differences between entropies of both the TP and air at the initial (subscript 1) and the end (subscript 2) of the drying [Eqs. 16 and 17] (Bayana & İçier, 2022).

The “Sgeneration” value determined from Eq. 12 was used in the exergy balance.

Exergy Analysis

Unlike energy, exergy takes into consideration the manufacture of entropy in the system, which is incontrovertible and proportional to waste. Hence, exergy is the combination of the 1st and 2nd Laws of Thermodynamics (Çengel & Boles, 2015). Exergy analysis can cover the determination of irreversibility in the system, the minimization of the energy losses, and the evaluation of the waste energy. The calculation of exergy destruction (Exdestroyed) was the primary aim, taking into account expected exergy values at the water intake and outlet as well as changes in exergy within the system boundary (Eq. 18) (Hepbasli et al., 2010; Çengel et al., 2002; Erbay and İçier, 2010);

Exa,in, Exf, Exa,out, Exd, and Exew were the exergies of the inlet air, the raw (undried) TP at the initial, the outlet air, the dried TP at the end of drying, and from the TP water vaporizes, respectively (Eq. 19). The Exsystem has been estimated by calculating the exergy of the heat inputs (Exsystem,heat) (Eq. 20) and the exergies of the mechanical and light energies entering the system.

In comparison with checking the suitability of exergy analysis for drying process, exergy destruction (Exdestroyed) was predicted between Eqs. 19 and 21 (Hepbasli et al., 2010; Erbay and İçier, 2010).

The exergy efficiency \(\left({\eta }_{{\text{exergy}}}\right)\) of the drying process was calculated by Eq. 22.

It was predicted that a term “improvement potential (IP)” would define the potential of improvement in this process (Eq. 23) (Hammond & Stapleton, 2001).

Assumptions: It was estimated that the dead state pressure would be one atm. Assuming that at 60 °C, the water would evaporate. There was a lack of attention to the effects of potential and kinetic energies.

Statistical Evaluation

The experimental data were evaluated based on the “General Factorial Approach to Face Centering” design for the three replications through the Design Expert Ver. 7.0.0 package program (Stat-Ease, 2005). Factors were the air velocity and the type of the light application (Fig. 2). The heating source mode was taken as the separate blocks.

Using both the ANOVA and post hoc tests conducted with SPSS 22.0 (IBM, 2013), the effects of factors on some quality characteristics and system performance properties were determined. For each heating source mode, the polynomial equations for the response values (lycopene loss, β-carotene loss, ΔE, energy and exergy efficiencies, IP or SMER) were formed depending on the factors. The variance analysis of these chosen responses, such as model regression coefficient (R2), corrected regression coefficient (Adj-R2), estimated error sum for squares (PRESS), estimation multiple regression coefficients (Pre-R2), and adequate precision (i2 > 0.95; Adj-R2–Pre-R2 < 0.2; max.PRESS; Pre-R2 > 0.7; Adeq.Precision > 4), has been evaluated using statistics criteria (Myers & Montgomery, 2002). The confidence interval was taken as 95%.

Uncertainty Analysis

After a series of measurements were made, assuming that the uncertainty in each measurement was specified with the same probabilities, these measurements were then used to calculate some desired results of the experiments. The result R is a function of the independent variables x1, x2, x3,…,xn. Assuming that wR is the uncertainty of the outcome and w1, w2, w3,…,wn are the uncertainties of the independent variables, if the uncertainties in the independent variables are specified with the same probabilities, the outcome uncertainty with these probabilities can be calculated with Eq. 24 (Kline & McClintock, 1953). Uncertainty analysis for this system is presented in Table 6.

Results and Discussion

The average final moisture content of the dried TP samples, which was similar for all drying conditions, was obtained as 7.66 ± 1.72%. In addition, the average water activity values of all dried samples were measured as 0.52 ± 0.08. The effects of process conditions consisting of the combinations of different heating source modes (hot air and infrared), different light applications (daylight, UV, daylight + UV light, and without light), and different air speeds (1.5 and 2 m/s) on some quality characteristics and system performance characteristics were determined (Tables 4 and 5). The situation of providing the energy of system elements through photovoltaic panels was examined.

The average drying times for the hot air group at 1.5 and 2 m/s air velocities were 16,062 ± 338 s and 13,581 ± 896 s, respectively, while they were 16,064 ± 344 and 13,589 ± 911 s, respectively, for the infrared group. The drying time at 2 m/s air speed was shorter compared to 1.5 m/s air speed (p < 0.05). Although the drying times were similar for both heating source modes at same velocities, in the DPVD cabinet, the drying under the sun was longer (7 h) compared to all conditions in the DPVD cabinet. Similarly, Badaoui et al. (2019) have determined that the drying temperature of the TP was dried within 5 h in a greenhouse type dryer with a temperature varying between 40 and 58 °C (Badaoui et al., 2019). Ibrahim et al. (2017) dried TP in different drying systems (60, 80, 100 °C) and at different air speeds (1, 1.5, and 2 m/s) (Ibrahim et al., 2017). They reported that the drying process performed at 60 °C in an electric oven dryer takes approximately 120 min. However, the drying times of the TP were 240 and 200 min in the dryer with mechanical mixing at 60 °C and 1.5–2 m/s air velocity, respectively. Similarly, the drying times of TP in the present study were compatible to the reported values for various agricultural products and by-products in the literature (Alam et al., 2013; Ibrahim et al., 2017; Sharma & Yadav, 2017).

The Change in Color Properties

The effects on the changing color properties (L*, a*, b*, ∆E, ∆C, and hue angle) of TP by different DPVD processing conditions have been investigated (Tables 1, 2, and 5) and compared with under the sun drying. L*, a*, and b* color values of raw TP were 45.99 ± 1.21, 17.32 ± 1.71, and 36.56 ± 6.67 (Table 1), respectively (Bayana & İçier, 2022). Similarly, Silva et al. (2019) reported the color values of the fresh TP collected from an industrial processing plant in Brazil for six different days, as follows: L* values were between 44.95 ± 1.27 and 48.84 ± 0.57, a* values were between 16.95 ± 0.95 and 18.99 ± 0.83, and b* values were between 16.78 ± 1.35 and 20.20 ± 0.68 (Silva et al., 2019). Bayana and İçier (2019) carried out the drying processes of TP by applying different infrared powers. They obtained fresh TP as raw material without any heat treatment under laboratory conditions. L*, a*, and b* values of TP were 42.05, 23.38, and 25.3, respectively (Bayana & İçier, 2019). On the other hand, it is known that the heat treatment increases the extractability of β-carotene, and different components in the pomace mixture could change the color properties. A high b* value indicates that the TP sample has stronger color intensity (Lavelli & Torresani, 2011). Similarly, Lavelli and Torresani (2011) reported higher color values (L*, a, b*) for heat-treated TP as 59.3 ± 0.5, 23.8 ± 0.5, and 30.9 ± 0.4, respectively. They discussed that the moisture content of the raw material varied between 66 and 93% since the raw material was variable (Lavelli & Torresani, 2011). In this study, TP was taken as the by-product of the double heat-treated tomato paste production in the industrial factory. Thus, its b* value was significantly higher, which has stronger color intensity, than fresh TP reported in the literature.

The average values of color characteristics (L*, a*, and b*) of the TP were 54.59 ± 3.20, 18.82 ± 2.83, and 41.41 ± 2.62, respectively, after DPVD processes while 44.43 ± 0.90, 18.37 ± 0.37, and 33.14 ± 0.37, respectively, after under the sun drying. DPVD drying caused an increase in L* in general (p < 0.05). L* and b* values of TP dried in DPVD were higher than the sun-dried one. The effects of different process conditions on color characteristics were given in Tables 1, 2, and 5. Similarly, Alqahtani et al. (2020) reported the color characteristics (L*, a*, and b*) of dried TP powder as 54.33 ± 0.58, 16.17 ± 0.12, and 19.33 ± 0.15, respectively (Alqahtani et al., 2020). Lavelli and Torresani (2011) reported that the by-product from the processing of heat-treated tomatoes had a different color and higher b* value compared to that obtained from raw tomatoes (Lavelli & Torresani, 2011).

The effect of air velocity on the L* value was found to be significant only in the UV + daylight condition of the hot air mode (Table 5; p < 0.05). For 2 m/s air velocity, the highest L* value was determined for the daylight application in the hot air mode (Table 5; p < 0.05). The reduction in L* values during drying has been reported to be linked to degradation, Maillard reaction, carotenoids, and non-enzymatic reactions (Nisha et al., 2011). In addition, the L* value of tomato puree decreased significantly at the end of the heat treatment (Nisha et al., 2011). The change in the color after dehydration may be due to pigment degradation or the browning reaction or both (Lopez et al., 1997). In addition, the color substitutes absorb UV-A and UV-B less than UV-C (Koutchma, 2009). Similarly, in this study, the increase in L* value in the DPVD processes can be attributed to the interference light effects due to the assistance of infrared, UV (A and B bands), and visible lights during drying.

The interaction effects of air velocity, heating source mode, and the type of light application had a significant effect on a* value (p < 0.05) (Table 5; p > 0.05). For example, for the UV + daylight application, a* value was lower at 1.5 m/s air velocity compared to 2 m/s in the hot air mode while it was higher at the 1.5 m/s air velocity in the infrared mode (p < 0.05). In general, a* value was found to be lower in the applications including daylight (p < 0.05). Santos-Sanchez et al. (2012) reported that a* value of tomato slices increased from 18.18 to 29.05 ± 0.20 after drying at 60 °C at 1.2 m/s. They explained this increase by Maillard reactions occurring with the effect of temperature (Santos-Sánchez et al., 2012) similar to the findings in other studies (Kerkhofs et al., 2005) which have reported that the redness value due to Maillard reactions increased as the temperature increased.

In the present study, the individual effects of air velocities and the heating source on the b* value were not significant (Table 5; p > 0.05). On the other hand, the application of daylight-assisted conditions increased the b* value (p < 0.05). Santos-Sanchez et al. (2012) reported that Maillard reactions that occurred due to thermal effects increased the b* value of tomato slices from 15.37 to 20.49 ± 0.61, similar to the case of a* value (Santos-Sánchez et al., 2012). In addition, the b* value of TP dried under the sun was found to be significantly lower than dried pomaces in the DPVD system (p < 0.05). Since the drying time under the sun took longer than the drying in the DPVD system, the samples were exposed to heat, light, and oxygen for a longer time. It is known that exposure to temperature, light, and oxygen adversely affects color pigments (Özkan & Bilek-Ersus, 2015) The decrease in the b* value in the experiments performed under the sun can also be explained in this way.

Hue angle is a color circle and red-violet colors take an angle value between 0 and 360°, while red color takes 0°, yellow 90°, green 180°, and blue 270° (Eleroğlu & Taşdemir, 2020; Pavlidis et al., 2006). The hue angle of raw TP was 56.48 ± 1.82 while it was 60.99 ± 0.76 for the sun-dried one. In addition, the hue angle values of TP dried in different conditions in the DPVD system referred to the color in the middle of red and yellow (Table 5). The hue angle values of dried TP were similar for both drying methods (p > 0.05). The effect of air velocity on the hue angle was significant for the light applications of hot air mode (Table 5; p < 0.05) but it was not effective for infrared mode (p > 0.05). For both air velocities, the light applications including daylight resulted in higher hue angle values (p < 0.05).

When the general color changes of the TP dried in the DPVD cabinet were evaluated compared to before drying, the ΔE and ΔC values were found to be significantly higher in the conditions where sunlight was used in general (p < 0.05). It was observed that daylight had a significant effect on the color change of dried TP compared to the fresh TP. It was thought that the decrease in the redness (a*) value through the decomposition of carotenoids was reflected in the color characteristics as the increase in the yellowness (b*) value. However, it was determined that there was no correlation between the effect of processing conditions on lycopene and β-carotene reduction values and their effects on the change in color properties. The ΔE values were higher in ultraviolet + daylight conditions compared to other conditions (p < 0.05; Table 5). Similarly, the effect of air speed on the chromatic color change (ΔC value) of daylight application mode and light intensity was not significant (p > 0.05; Table 5).

Lycopene and β-Carotene Loss

Lycopene and β-carotene contents of raw TP samples were determined as 0.37 ± 0.16 and 0.41 ± 0.14 mg/g dry matter, respectively. Baysal et al. (2000) have reported similar initial total lycopene contents (0.3096 ± 0.0015 mg/g dry matter) but lower β-carotene contents of TP as 0.0296 ± 0.003 mg/g dry matter (Baysal et al., 2000). It might be due to the different ratios of the raw materials used in the pomace mixture (the presence of the skin, seeds, pomace, and components other than these, for example, the stem of the tomato fruit and the leaves of the tomato plant). Górecka et al. (2020) have determined the lycopene contents of different tomato products (fresh and dried tomatoes, tomato paste, fresh and dried pomace) as 0.2045 mg/g dry matter for fresh and 0.2511 mg/g dry matter for dried forms. They also concluded that lycopene contents depended on the type of tomato crop and harvest time (Górecka et al., 2020).

The percentage (%) decrease in the carotenoid contents (on a dry basis) depending on the process conditions (heating source, light application, and air velocity) of drying in DPVD is given in Table 4. It was determined that the % decrease in lycopene and β-carotene during DPVD was 66.42 ± 3.56% and 64.16 ± 3.28% on average, respectively, while they were 69.48 ± 5.62 and 69.32 ± 4.89 for the drying under the sun, respectively. In other words, the DPVD process caused similar lycopene and β-carotene reductions with drying under the sun, in general (p > 0.05). Specifically, the lycopene and β-carotene decrease (%) obtained in the infrared drying conditions without light application was found to be lower than the values under the sun.

Smith et al. (2018) reported that the β-carotene contents of tomato and mango fruits dried in a greenhouse-type cabinet dryer decreased by 79.3% compared to the raw material (Smith et al., 2018). Similar studies examining the degradation of β-carotene in fruits after drying under the sun have emphasized that there was a tendency to show a correlation between degradation rates and drying time (Ndawula et al., 2004; Gao et al., 2012; Türkyılmaz et al., 2014). Gao et al. (2012) found that β-carotene in jujube decreased by 100% after drying in the sun for 3 weeks (Gao et al., 2012). It was reported that the β-carotene content of apricots dried in the sun for 6 days decreased to 21% of the initial value (Türkyılmaz et al., 2014) while the β-carotene content of mangoes decreased significantly (94.2%) after sun drying (Ndawula, Kabasa & Byaruhanga, 2004). In a recent study, Tilahun-Dufera et al. (2021) reported that the total phenolic matter, lycopene, and β-carotene content of tomato slices decreased significantly after drying under the sun (Tilahun-Dufera et al., 2021). On the other hand, Tahmasebi and Emam-Djomeh (2021) discussed that the lycopene content of tomato slices was better preserved under sun drying compared to other drying treatments (microwave and vacuum-assisted hot air only) (Tahmasebi & Emam-Djomeh, 2021). However, they also reported that prolonged (26 and 30 h) exposure to light and oxygen during sun drying caused a significant increase in the degradation rate of lycopene compared to raw material. Hence, the lycopene loss may increase more at low temperatures and for long periods (Shi et al., 2008). Thus, in this study, high carotenoid losses under sun drying compared to some light application modes in the DPVD system could also be related to longer drying times under the sun.

The effect of air velocity on the reduction of lycopene and β-carotene for the same light application in the hot air mode was insignificant (p > 0.05). However, for the infrared mode, the ultraviolet + daylight application at 2 m/s and the without light application at 1.5 m/s resulted in lower lycopene and β-carotene losses (Table 4, p < 0.05). For 2 m/s air velocity, all light treatments reduced (or had at least similar) carotenoid loss (p < 0.05) compared to hot air without light mode (Table 4). The use of light assistance during drying had the potential to reduce the rate of change of lycopene and β-carotene amounts in TP compared to raw material. Since infrared has similar optical properties to visible light such as reflection, refraction, and creating interference patterns (Zibordi, Donlon and Parr, 2014), the light applications in infrared mode could have created an interference effect. Thus, it could have limited the negative effect of light on carotenoids that are normally damaged by light. These carotenoids are susceptible to oxidation, isomerization, and degradation due to a highly unsaturated structure which may result from the presence of heat, sunlight, oxygen, catalysts, etc. in both model systems and food matrices as well as other factors with very complex properties (Xiao et al., 2018). In addition to this, it is explained that heating increases the release of bound compounds, and a higher content can be achieved compared to fresh produce (Leong & Oey, 2012). Similarly, Ihns et al. (2011) discussed that the decrease in β-carotene content was less at higher temperatures (Ihns et al., 2011). Garcia-Martínez et al. (2013) found significant increases in the vitamin A content of apricots dried by hot air at 40 and 60 °C (García-Martínez et al., 2013). Similarly, Rashidi et al. (2021), in the drying processes of tablets produced from tomato powders at five different temperatures (40, 50, 60, 70, and 80 °C), four different air velocities, and four different infrared powers, the lycopene content of the compressed tablet produced from tomato powder increased with the increase in drying air temperature, indicating that it was better preserved. The highest lycopene value (22.05 mg/g dry matter) was obtained at the highest drying temperature (80 °C), air velocity of 1.5 m/s, and 1000 W infrared power. The lowest lycopene value (6.66 mg/g km) was obtained at the lowest drying temperature (40 °C) (Rashidi et al., 2021). These increases were thought to be a result of the increase in the extractability of carotenoids in response to heat (Kamiloglu et al., 2016). This can be explained by the fact that heat treatment of lycopene-rich fruits and vegetables results in higher lycopene availability in a fresh product so that higher temperature treatments stabilize or somewhat reduce the lycopene content of the fruit. Lycopene bioavailability has been enhanced when the tomato matrix is broken by mechanical homogenization or heat treatment (Das Purkayastha et al., 2013).

Fresh tomato lycopene can be converted to cis-lycopene due to heat treatment or colorless decomposition. In tomatoes, the heat treatment has caused a very strong increase in lycopene content. Increase in the release of phytochemicals from the matrix which made them more suitable for extraction has been primarily considered to be a reason for this increase in bioaccessible lycopene (Ekow et al., 2013).

The effects of daylight use mode on certain quality properties and system performance parameters for TP have been determined by a study carried out by our team (Bayana & İçier, 2022). Drying experiments involving a combination of three different daylight application modes (UV-blocked daylight via solar tube-DLST, DLST + LED, and LED) and three different daylight intensities (2500, 7500, and 10,000 lx) with constant air temperature (60 °C) and air velocity (2 m/s) for 240 min. Similarly, the lycopene and β-carotene losses in TP after drying have been reported as 68.36 ± 4.32% and 65.66 ± 4.33%, respectively. The DLST mode (only UV-blocked daylight) at 7500 lx (desirability 0.728) has been reported to be the optimum condition, meeting the criteria for better quality and higher performance. Thus, the UV-blocked daylight without LED mode was used in all daylight conditions in the present study.

The Change in Total Aerobic Mesophilic Bacteria (TAMB) Counts

The effects of the processing conditions comprise of a combination of different heating sources, different air velocities, and different light applications on the total aerobic mesophilic bacteria (TAMB) counts of TP were investigated (Table 4) and compared with the effects of sun drying. The difference between the TAMB counts (log cfu/g) of the wet TP and the TAMB counts (log cfu/g) of TP dried in the DPVD cabinet under different conditions is given in Table 4.

The batch of raw material has been obtained from the tomato paste production factory where the same type of tomato variety (Rio Grande) was used and then frozen immediately, and all samples were thawed under the same conditions before drying. The total aerobic mesophilic bacteria count value of the raw TP sample was 4.03 log cfu/g (Table 1). Similarly, Peralta-Ruiz et al. (2020) reported the TAMB count of tomatoes was 3.14 ± 0.15 and 6.96 ± 0.44 log cfu/g for day 0 and day 12, respectively (Peralta-Ruiz et al., 2020). On the other hand, in some studies, it was determined that TP was included as an ingredient, and TAMB count in a new product developed was examined.

It was determined that the individual and interactive effects of different heating sources and light applications on TAMB count were not statistically significant in drying processes at 2 m/s air velocity (p > 0.05; Table 4). Specifically, the ultraviolet + daylight application in the infrared mode provided less TAMB reduction at both air velocities (p < 0.05). The individual effect of air velocity was insignificant in general (p > 0.05). However, the application of infrared heating alone resulted in a higher TAMB count reduction at 1.5 m/s air velocity compared to 2 m/s air velocity (p < 0.05). It is thought that thanks to the long processing time especially due to the lower air velocity caused higher exposure to infrared light and thus may have increased the microbial inactivation. It was also noteworthy that the decrease in TAMB count was high in applications containing UV in general. It is thought that the interference effect of infrared, UV, and daylight may affect the inactivation.

The effects of DPVD processes and drying under the sun on the log reduction in TAMB count of TP samples were also compared. A decrease of 4.01 ± 0.01 log cfu/g was obtained in TAMB count in the drying under the sun. Kolawole et al. (2010) reported that the sunlight reflected from the covers of different colors has different effects on the dried end products. The lowest colony count (4.9 × 104 cfu/g) was found on the white cover compared to the other colors. It is interpreted that different frequency regions of daylight may also play a role in reducing the microbial load (Kolawole et al., 2010). However, in this study, there was a statistically similar decrease in the TAMB count of TP dried in DPVD and under the sun (p > 0.05). This may be attributed to the controlled conditions set under the sun-drying experiments and relatively short drying times compared to other sun-dried food products. On the other hand, since DPVD processes were significantly shorter than the sun drying process, it has been revealed that it can be an alternative drying system where similar microbial inactivation to under-the-sun drying can be achieved.

Performance Evaluation

The changes in the performance of DPVD processes depending on the heating source mode, type of light application, and the air velocity were determined (Fig. 3a, b and Tables 2, 3, and 4). Although the TP was dried to similar final dry matter contents (7.50 ± 2.23%) at a similar temperature (60 ± 3 °C) under all processing conditions, the differences in energy consumption and loss energy losses in the system depending on the processing conditions affected the performance characteristics of the system (energy efficiency, exergy efficiency, improvement potential, specific moisture evaporation rate).

The energy efficiencies for DPVD processes were in the range of 59.81–87.89% for hot air and 22.78–41.34% for infrared heating group, respectively. The exergy efficiencies for DPVD processes were in the range of 15.08–36.77% for hot air and 10.29–15.74% for infrared heating group, respectively. Fudholi and Sopian (2019) presented their work on the performance analysis of solar air heaters, which was the most important component of solar drying systems. They reported that the energy efficiency of solar air heater dryers varied between 30 and 79% and exergy efficiencies of 8–61% (Fudholi & Sopian, 2019). It could be said that the performance of the DPVD system investigated in this study had similar energy and exergy efficiency ranges to the solar air heater reported.

In general, the energy and exergy efficiencies were found to be statistically higher in the hot air mode compared to the infrared mode (p > 0.05) (Fig. 3a, b). It was attributed to the existence of higher energy losses in the infrared source converting electrical energy to heat energy. In addition, the additional use of UV light caused a decrease in exergy efficiency (p < 0.05). However, especially in the infrared mode, the UV light did not decrease the energy efficiency of the process (p > 0.05). It can be explained by additional heat effects transferring from the UV light into the drying cabinet. It contributed to the stabilization of the temperature inside the cabinet and thus the infrared unit was activated less frequently to provide the desired temperature. However, since the conversion rate to heat energy could not be measured, this contribution could not be taken into account in the exergy calculations. But the total effect of the use of UV light on system performance was reflected in the exergy efficiency values. In addition, the additional use of daylight did not affect the energy and exergy efficiencies (p > 0.05) since there was no additional energy consumption in daylight treatment and it did not change the drying time as well.

For higher air velocity, the exergy efficiency of UV + daylight application was higher for both heating source modes. In addition, the exergy efficiency of hot air without light mode was higher at higher air velocity (p > 0.05). Similarly, this condition had the highest energy and exergy efficiencies among other conditions (p < 0.05). It was thought that the increase in the fan energy used had less effect than the decrease in the drying time. Due to the increased air velocity (2 m/s), the drying time was shortened, and thus, the energy consumption of the system elements (ultraviolet + fan + hot air or infrared heating system) decreased. Consequently, the efficiency of the process increased. Doymaz (2019) reported the highest energy efficiency (12.75%) for 230 W power application compared to other infrared heater powers (104, 146, 188, and 230 W) for the drying of the black carrot pulp since the drying time was shortest at high power application (Doymaz, 2019). In a recent study (Dolgun et al., 2020), the grape pomace has been dried in an infrared film dryer at different temperatures (40, 45, and 50 °C) under natural convection and forced convection conditions. In terms of energy and exergy yields, it was reported that the most suitable temperature for drying the grape pomace with infrared was the highest temperature (50 °C). In terms of energy use, efficiency, and time to dry, it was concluded that an organic convection state has been more effective than a forced circulating condition. The average energy efficiency was between 8.68 and 21.82% and the exergy efficiency was between 32.85 and 35.91%. They have discussed that the energy efficiency of natural convection groups has been estimated to be approximately 10% higher because of continuous operation of the fan. In this study, it was found that there is so much difference in energy consumption of the fan at different air velocities. Drying time therefore plays a major role in exergy efficiency.

In another recent study, the infrared dryer and the carbon fiber-assisted cabinet dryer were compared in terms of energy-exergy efficiencies during licorice drying (Icier et al., 2021). The energy efficiencies for the carbon fiber-assisted drying and the infrared drying were 40.2% and 10.39% while exergy efficiencies were determined as 31.87% and 9.99%, respectively. Although infrared drying had shorter drying times, they suggested the use of the carbon fiber-assisted cabinet dryer for licorice drying due to its higher energy-exergy efficiencies. Moreover, Tezcan et al. (2021) performed energy and exergy analyses for drying dill leaves under three different infrared radiation power densities. They reported that as the infrared power density increased the drying time decreased. The energy efficiencies of 54%, 57%, and 63% and exergy efficiencies of 49%, 52%, and 59%, respectively, were determined in drying carried out at low, medium, and high-power densities. Thus, the highest power density provided the most efficient process in terms of performance. However, they concluded that the color properties were negatively affected at high infrared power density although the drying time was shortest and the energy and exergy efficiency were highest for this condition. They recommended the use of medium power density (1970 W/m2) for drying dill leaves (Tezcan et al., 2021).

From the viewpoint of improvement potential (IP), the performance of the system was higher at low air velocity conditions for the same light application and heating source mode (p < 0.05) since the decrease in IP meant an increase in the performance of the process. The assistance of any light during drying increased the necessity for improvement in the performance of the system (p < 0.05). The IP values were predicted in the range of 65.77–476.66 kJ (Table 4). In general, infrared mode had higher IP values than hot air mode for the same velocity (p < 0.05). The condition that needs the most performance improvement was “UV + daylight application at 1.5 m/s air velocity in the infrared mode.” Nwakuba et al. (2020) evaluated the performance of the drying of tomato slices. They revealed that the improvement potential of the system decreased as the drying time decreased, and air velocity did not affect the IP (Nwakuba et al., 2020). Castro et al. (2018) performed the exergy analysis of convection drying of onions. They reported the exergy efficiencies in the range of 0.099 and 0.289 kJ/s and discussed that IP increased as the air velocity increased (Castro et al., 2018).

The SMER values during DPVD processes were obtained in the range of 0.10–0.40 g/kJ (Table 4). The infrared mode decreased the SMER values for the same light application (p < 0.05). The increase in the air velocity did not affect SMER values (p > 0.05), except for UV + daylight application. The highest SMER value was obtained for hot air without light mode at 2 m/s (p < 0.05), and hence, the use of light assistance in hot air mode decreased the SMER values (p < 0.05). Karabacak and Atalay (2010) investigated the effects of types of drying systems (heat pump, solar assisted system, and sun drying) on drying time, geometry, energy consumption, and physical conditions of the tomatoes. The average air velocity was 2 m/s similar to this study, but tomatoes were in the shape of half and quarter geometries. While the highest specific moisture loss rate of 4.37 × 10−4 (g/J) was obtained for quarter tomato slices in the solar-assisted dryer, the lowest specific moisture loss rate of 0.22 × 10−4 (g/J) was for half tomatoes dried in a heat pump dryer. They reported that the shape of the tomatoes affected the SMER values as expected, probably due to the change in the surface area (Karabacak & Atalay, 2010).

In summary, the hot air alone (no light) and the UV light assistance in infrared mode conditions had higher energy and exergy efficiencies and less development need among all conditions, in general (Table 4).

The Improvement of System Performance

Drying is an energy-intensive process that provides the opportunity to preserve food in a stable and safe condition, as it reduces water activity, slows down the activity of enzymes and microorganisms, and extends shelf life compared to fresh fruits and vegetables (Faisal et al., 2013; Wambugu, 2020). In parallel with the increase in the world population, energy demand is also increasing. All over the world, there is a tendency to limit the use of fossil fuel resources by using energy more efficiently and increasing the use of renewable energy resources.

The sun is an important renewable energy source used in the production of heat and electricity (Şevik et al., 2019). Applications in which solar energy is included in the drying system to increase energy efficiency in drying applications that require intense energy consumption are frequently encountered in the literature (Kavak-Akpinar, 2019; Singh et al., 2020; Rani & Tripathy, 2021). However, the studies mostly cover drying applications made in dryers where the sun is used to obtain heat energy and is included in the system. On the other hand, in recent studies, it has been observed that the photovoltaic effects of the sun are also included in the drying system and its use to obtain electrical energy tends to increase (Mirzaei et al., 2021; Veeramanipriya & Sundari, 2021; Vengsungnle et al., 2020).

In this study, to provide some or all of the total energy needed by the system elements from the sun, a photovoltaic panel, inverter, and battery system, which can convert the energy from sun to the electrical energy, have been integrated into the DPVD system. It has been determined how the performance of the system changed depending on the differences in the use of the energy produced by the photovoltaic panel of the dryer cabinet system elements.

It was predicted that the panels could have provided and stored an average of 4.33 kWh energy transfer rate. This means that, during the four hour drying period, four PV panels could generate 13,104 kJ of energy. However, in case of the existence of any malfunctions in the installed system, firstly the case of fewer system elements getting their energy from the panel has been examined. And then, more and more system elements were added in subsequent improvement cases. The improvements were investigated for the optimum conditions of both heating source modes. The change in the energy efficiency (%), exergy efficiency (%), improvement potential (kJ), and SMER (g/kJ) depending on the improvement cases was determined.

-

Improvement case 1: meeting the energy needs of only the fan and condenser system elements from the photovoltaic panel system.

-

Improvement case 2: meeting the energy needs of UV source, fan, and condenser system elements from the photovoltaic panel system.

-

Improvement case 3: the energy consumption of all system elements, including the electric heater and infrared light unit, was met by the photovoltaic panel system.

For improvement case 1, since the only system element providing energy from the mains electricity in the daylight application condition of the hot air heating source was the electrical heater (the energy of the fan and condenser system was supplied from photovoltaic panels), the drying process was performed with high energy efficiency (100%) than before improvement (77.95%). However, due to the high amount of energy consumption of infrared lamps in the infrared heating source group, the energy efficiency values were still low even if the energies of the fan and compressor were supplied from the panels. Similarly, the energy efficiencies of both modes increased compared to the situation where the energy was completely supplied from the mains’ electricity.

For improvement case 2, the energies of the fan and condenser, as well as the UV source used in the infrared mode, were taken from the panel system. In this case, only infrared light units were connected to the main supply. In particular, the IP value increased significantly (118.52 ± 13.03 kJ) compared to improvement case 1 (288.66 ± 25.85). However, in the experiments carried out in different weather conditions (between July and September) during the summer period, the difference in the temperature of the air entering the system caused high differences between the operating times of the infrared unit in different repetitions of the same condition. This situation caused the variation in the energy consumption of the infrared, and thus, the standard deviation values of the energy and exergy efficiencies were high. However, when compared with the application of drying under the sun in the study; similarly, it has been determined that it needs more improvement in order to transform it into a self-sufficient drying system in terms of energy.

In the last stage of the improvement studies (improvement case 3), the energy consumption of all system elements, including the electric heater and infrared source, was met from the photovoltaic panel system. It has been determined that the photovoltaic panel system installed in support of the DPVD cabinet could have met the entire energy consumption needed during the process to dry the TP samples up to the target total dry matter content. The highest energy requirement in the system was determined as 0.59 ± 0.10 kWh in the application of the infrared heating source group, and the average amount of energy provided from the photovoltaic panels during the drying process was 4.33 ± 0.35 kWh. As a result, it has been concluded that the energy used in all drying applications could have been obtained from the sun, a renewable energy source, thanks to the panel system included in the system. In other words, without the need to use energy from the mains supply, the developed photovoltaic supported simulated daylight drying system could have performed the drying process with similar performance to drying under the sun.

Conclusion

Tomato pomace samples were dried in a novel custom designed dryer consisting of two different heating modes (hot air and infrared) and different light application units (daylight and ultraviolet combinations) at two different air velocities (1.5 and 2 m/s). The effects of process conditions on the quality changes (total dry matter content, aW, color characteristics, total aerobic mesophilic bacteria count, lycopene and β-carotene contents) and the performance characteristics were determined. The average TDM content of TP samples dried in DPVD drying cabinet and under the sun at the end of the process was similar. Drying under the sun and DPVD cabinet showed similar lycopene and β-carotene losses (p > 0.05). The use of light in both heating source modes had the potential to reduce the lycopene and β-carotene losses. For the infrared heating source, the TP dried at 1.5 m/s air velocity had significantly more log cfu/g reduction than those dried at 2 m/s air velocity (p < 0.05). There was a similar decrease in TAMB count during drying under the sun and in the DPVD cabinet (p > 0.05). Total color difference (ΔE) was higher in ultraviolet + daylight condition compared to other conditions for both air velocities (p < 0.05). In general, the energy and exergy efficiencies were statistically higher in the hot air source compared to infrared source (p > 0.05). The use of ultraviolet light source caused a decrease in exergy efficiency in both heating sources (p < 0.05).

In order to improve the energy and exergy efficiency of the drying processes and thus the system performance, modifications have been made to utilize solar energy. For this purpose, the photovoltaic panel system enabling the system elements to get some of their energy from solar energy as renewable energy was integrated into the drying system and its effect on the performance characteristics of the system was investigated. The variation in the system performance was determined when the photovoltaic panel system was on/off.

On the basis of solar power, which is a renewable energy resource, and through photovoltaic panels similar to drying applications by sunlight, DPVD system has been custom designed and assembled. The quality characteristics similar to sun-dried TP quality can be obtained in DPVD drying process, while valuable dried waste by-product can be obtained with high energy efficiency. In order to provide the best possible quality and safety of various food products, as well as energy efficiency, which is also very desirable, a developed DPVD drying system may be an alternative method for conventional dry processes.

Data Availability

All data supporting the findings of this study are available within the paper and its Supplementary Information (especially “Figures” and “Tables” files). More detailed information will be shared by the authors if requested.

References

Ai, Z., Zhu, G., Zheng, Z., Xiao, H., Mowafy, S., & Liu, Y. (2023). Successive two-stage hot air-drying with humidity control combined radio frequency drying improving drying efficiency and nutritional quality of Amomi fructus. Food and Bioprocess Technology, 16(1), 149–166. https://doi.org/10.1007/s11947-022-02928-8

Alam, M. S., Gupta, K., Khaira, H., & Javed, M. (2013). Quality of dried carrot pomace powder as affected by pretreatments and methods of drying. Agricultural Engineering International: CIGR Journal, 15(4), 236–243.

Alazb, B. R., El-Sahy, K. M., Sulieman, A. E. R. M., & Youssif, M. R. (2021). Physicochemical and organoleptic characteristics of cakes supplemented with tomato pomace, mango seeds kernel and pomegranate peels powders. Plant Archives, 21(1), 432–439.

Al-Harahsheh, M., & Ala’a, H. and Magee, T. R. A. (2009). Microwave drying kinetics of tomato pomace: Effect of osmotic dehydration. Chemical Engineering and Processing: Process Intensification, 48(1), 524–531. https://doi.org/10.1016/j.cep.2008.06.010

Allison, B. J., Cádiz, J. C., Karuna, N., Jeoh, T., & Simmons, C. W. (2016). The effect of ionic liquid pretreatment on the bioconversion of tomato processing waste to fermentable sugars and biogas. Applied Biochemistry and Biotechnology, 179(7), 1227–1247. https://doi.org/10.1007/s12010-016-2061-4

Alqahtani, N., Helal, A.M., Alnemr, T.M. and Márquez, Ó.R. (2020). Influence of tomato pomace inclusion on the chemical, physical and microbiological properties of stirred yoghurt. International Journal of Dairy Science.

American Research and Testing Inc. (1994). Number 94018. https://www.gunisigiaydinlatma.com/Doc/UV%20Testing%20Results.pdf

American Society of Heating, Refrigerating and Air-Conditioning Engineers. (2006). Ashrae Handbook: Refrigeration. Atlanta: ASHRAE.

Artés-Hernández, F., Castillejo, N., & Martínez-Zamora, L. (2022). UV and visible spectrum led lighting as abiotic elicitors of bioactive compounds in sprouts, microgreens, and baby leaves—a comprehensive review including their mode of action. Foods, 11(3), 265. https://doi.org/10.3390/foods11030265

Badaoui, O., Hanini, S., Djebli, A., Haddad, B., & Benhamou, A. (2019). Experimental and modelling study of tomato pomace waste drying in a new solar greenhouse: Evaluation of new drying models. Renewable Energy, 133, 144–155. https://doi.org/10.1016/j.renene.2018.10.020

Baenas, N., Iniesta, C., González-Barrio, R., Nuñez-Gómez, V., Periago, M. J., & García-Alonso, F. J. (2021). Post-harvest use of ultraviolet light (UV) and light emitting diode (LED) to enhance bioactive compounds in refrigerated tomatoes. Molecules, 26(7), 1847. https://doi.org/10.3390/molecules26071847

Balabel, A., Alwetaishi, M., Abdelhafiz, A., Issa, U., Sharaky, I. A., Shamseldin, A. K., & Al-Harthi, M. (2022). Potential of Solatube technology as passive daylight systems for sustainable buildings in Saudi Arabia. Alexandria Engineering Journal, 61(1), 339–353. https://doi.org/10.1016/j.aej.2021.06.001

BAM (Bacteriological Analytical Manual), (2001). Chapter 3, Aerobic plate count. https://www.fda.gov/food/foodscienceresearch/laboratorymethods/ucm063346.htm. Accessed 10 Mar, 2023.

Bayana, D. and İçier, F. (2019). Drying of tomato pomace at different infrared powers, 4th international anatolian agriculture, food, environment and biology congress, Afyonkarahisar, Turkey, Nisan 2019, In Congress Book (p. 85).

Bayana, D., & İçier, F. (2022). Drying of tomato pomace in daylight simulated photovoltaic-assisted drying system: Effects of daylight intensity and application mode. Journal of Food Process Engineering, 45(3), e13990. https://doi.org/10.1111/jfpe.13990

Baysal, T., Ersus, S., & Starmans, D. A. J. (2000). Supercritical CO2 extraction of β-carotene and lycopene from tomato paste waste. Journal of Agricultural and Food Chemistry, 48(11), 5507–5511.

Baysal, T., Icier, F., Ersus, S., & Yıldız, H. (2003). Effects of microwave and infrared drying on the quality of carrot and garlic. European Food Research and Technology, 218, 68–73. https://doi.org/10.1007/s00217-003-0791-3

Bourdoux, S., Li, D., Rajkovic, A., Devlieghere, F., & Uyttendaele, M. (2016). Performance of drying technologies to ensure microbial safety of dried fruits and vegetables. Comprehensive Reviews in Food Science and Food Safety, 15(6), 1056–1066. https://doi.org/10.1111/1541-4337.12224

Cao, Z., Zhou, L., Bi, J., Yi, J. C., Wu, X., & Li, S. (2016). Effect of different drying technologies on drying characteristics and quality of red pepper (Capsicum frutescens L.): a comparative study. Journal of The Science of Food and Agriculture, 96(10), 3596–3603. https://doi.org/10.1002/jsfa.7549

Castillejo, N., Martínez-Zamora, L., & Artés-Hernández, F. (2021). Periodical UV-B radiation hormesis in biosynthesis of kale sprouts nutraceuticals. Plant Physiology and Biochemistry, 165, 274–285. https://doi.org/10.1016/j.plaphy.2021.05.022

Castillejo, N., Martínez-Zamora, L., & Artés-Hernández, F. (2022). Postharvest UV radiation enhanced biosynthesis of flavonoids and carotenes in bell peppers. Postharvest Biology and Technology, 184, 111774. https://doi.org/10.1016/j.postharvbio.2021.111774

Castro, M., Román, C., Echegaray, M., Mazza, G., & Rodriguez, R. (2018). Exergy analyses of onion drying by convection: Influence of dryer parameters on performance. Entropy, 20(5), 310. https://doi.org/10.3390/e20050310

Çengel, Y., & Boles, M. (2015). Thermodynamics: An Engineering Approach, 8th Edition.

Çengel, Y. A., Wood, B., & Dincer, I. (2002). Is bigger thermodynamically better? Exergy, an International Journal, 2(2), 62–68. https://doi.org/10.1016/S1164-0235(02)00061-4

Chinenye, N. M., Onyenwigwe, D. I., Abam, F., Lamrani, B., Simo-Tagne, M., Bekkioui, N., Bennamoun, L., & Said, Z. (2022). Influence of hot water blanching and saline immersion period on the thermal effusivity and the drying kinetics of hybrid solar drying of sweet potato chips. Solar Energy, 240, 176–192. https://doi.org/10.1016/j.solener.2022.05.026

Das Purkayastha, M., Nath, A., Deka, B. C., & Mahanta, C. L. (2013). Thin layer drying of tomato slices. Journal of Food Science and Technology, 50(4), 642–653. https://doi.org/10.1007/s13197-011-0397-x

Demiray, E., & Tulek, Y. (2012). Thin-layer drying of tomato (Lycopersicum esculentum Mill. cv. Rio Grande) slices in a convective hot air dryer. Heat and Mass Transfer, 48, 841–847. https://doi.org/10.1007/s00231-011-0942-1

Dolgun, E. C., Karaca, G., & Aktaş, M. (2020). Performance analysis of infrared film drying of grape pomace using energy and exergy methodology. International Communications in Heat and Mass Transfer, 118, 104827. https://doi.org/10.1016/j.icheatmasstransfer.2020.104827

Doymaz, İ. (2019). Drying of black carrot pomace in an infrared dryer: Kinetics, modelling and energy efficiency. Sigma Journal of Engineering and Natural Sciences, 37(1), 71–84.

Ekow, A. E., Haile, M. A., John, O. W. U. S. U., & Narku, E. F. (2013). Microwave-vacuum drying effect on drying kinetics, lycopene and ascorbic acid content of tomato slices. Journal of Stored Product and Postharvest, 4, 11–22.

Eleroğlu, H., & Taşdemir, A. N. (2020). Effect of laying time and age-related change on egg characteristics ın brown layer pure lines. Turkish Journal of Agriculture-Food Science and Technology, 8(11), 2498–2506. https://doi.org/10.24925/turjaf.v8i11.2498-2506.4110

Erbay, Z., & Icier, F. (2010). Energy and exergy analyses on drying of olive leaves (Olea europaea L) in tray drier. Journal of Food Process Engineering, 34(6), 2105–2123. https://doi.org/10.1111/j.1745-4530.2009.00505.x

Erbay, Z., & Hepbasli, A. (2013). Advanced exergy analysis of a heat pump drying system used in food drying. Drying Technology, 31(7), 802–810. https://doi.org/10.1080/07373937.2012.763044

Faisal, S., Tabassum, R., & Kumar, V. (2013). Performance evaluation and process optimization of potato drying using hot air oven. Journal of Food Processing and Technology, 4(10), 2–9.

FAOSTAT. (2019). Available at: https://www.fao.org/faostat/en/#search/tomato. Accessed 16 July, 2022.

Fish, W. W., Perkins-Veazie, P., & Collins, J. K. (2002). A quantitative assay for lycopene that utilizes reduced volumes of organic solvents. Journal of Food Composition and Analysis, 15(3), 309–317.

Food and Agriculture Organization (FAO). (2016). Save food: Global initiative on food loss and waste reduction. FAO.

Fudholi, A., & Sopian, K. (2019). A review of solar air flat plate collector for drying application. Renewable and Sustainable Energy Reviews, 102, 333–345.

Gao, Q. H., Wu, C. S., Wang, M., Xu, B. N., & Du, L. J. (2012). Effect of drying of jujubes (Ziziphus jujuba Mill.) on the contents of sugars, organic acids, α-tocopherol, β-carotene, and phenolic compounds. Journal of Agricultural and Food Chemistry, 60(38), 9642–9648.

García-Martínez, E., Igual, M., Martín-Esparza, M. E., & Martínez-Navarrete, N. (2013). Assessment of the bioactive compounds, color, and mechanical properties of apricots as affected by drying treatment. Food and Bioprocess Technology, 6(11), 3247–3255. https://doi.org/10.1007/s11947-012-0988-1

Goharian, A., & Mahdavinejad, M. (2020). A novel approach to multi-apertures and multi-aspects ratio light pipe. Journal of Daylighting, 7(2), 186–200. https://doi.org/10.15627/jd.2020.17

Górecka, D., Wawrzyniak, A., Jędrusek-Golińska, A., Dziedzic, K., Hamułka, J., Kowalczewski, P. Ł, & Walkowiak, J. (2020). Lycopene in tomatoes and tomato products. Open Chemistry, 18(1), 752–756. https://doi.org/10.1515/chem-2020-0050

Hammond, G. P., & Stapleton, A. J. (2001). Exergy analysis of the United Kingdom energy system. Proceedings of the Institution of Mechanical Engineers, Part a: Journal of Power and Energy, 215(2), 141–162.

Hancioglu, E., Hepbasli, A., Icier, F., Erbay, Z., & Colak, N. (2010). Performance investigation of the drying of parsley in a tray dryer system. International Journal of Exergy, 7(2), 193–210.

Hay, N., Quang Huy, L., & Van Kien, P. (2022). A review of drying methods assisted by ınfrared radiation, microwave and radio frequency. IntechOpen. https://doi.org/10.5772/intechopen.108650

Hepbasli, A., Colak, N., Hancioglu, E., Icier, F., & Erbay, Z. (2010). Exergoeconomic analysis of plum drying in a heat pump conveyor dryer. Drying Technology, 28(12), 1385–1395. https://doi.org/10.1080/07373937.2010.482843

IBM (2013) SPSS Statistics 22, IBM Corp. Released 2013. IBM SPSS Statistics for Windows, Version 22.0. Armonk, NY: IBM Corp., IBM SPSS Statistics 22, Document number: 313621.

Ibrahim, A., El-Iraqi, M., Osman, T., & Hendawey, Y. (2017). Bio-engineering studies for tomato pomace powder production as a nutritional valuable material. Journal of Soil Sciences and Agricultural Engineering, 8(12), 671–680. https://doi.org/10.21608/jssae.2017.38212

Icier, F., Ozmen, D., Cevik, M., & Cokgezme, O. F. (2021). Drying of licorice root by novel radiative methods. Journal of Food Processing and Preservation, 45(3), e15214. https://doi.org/10.1111/jfpp.15214