Abstract

A series of Zr-based glasses has been obtained by rapid melt quenching and their thermal characteristics (Tg, Tx, Tl) were determined by DSC/DTA. Some of the most recognized glass forming ability (GFA) criteria were applied to predict the glass forming ability of the alloys and to study its dependence on the alloy composition. As a result, the best glass forming compositions among the studied alloys could be selected. It was found that as a general trend an increase of the Zr content results in Tx and ΔTx (= Tx − Tg) decrease. The determined liquidus temperatures of chosen compositions with substantially different ΔTx were found to vary relatively little. Therefore, it was concluded that the variation in the GFA of the studied alloys is mainly due to difficulties in the crystallization process, rather than to different stability of the melts.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Zr-based alloys are among the intensively studied multicomponent metallic glasses [1,2,3]. The reasons for this interest are their good mechanical properties included high tensile strength, high bending strength, high fracture toughness, high hardness and fatigue strength, high impact fracture energy, good castability and cutting machinability [3,4,5] as well as high corrosion stability [6,7,8]. They are also known as easy glass formers and appropriate alloys to be prepared in a bulk amorphous form [9]. Thus, having the size in the centimeter-scale, bulk metallic glasses (BMG) allow being developed as good structural and functional materials [3, 10,11,12,13].

The first Pd-based BMG, which belongs to such a group, was prepared at the beginning of 1980s by Turnbull. Later large number of BMG on the base of La, Mg, and Zr were developed at the end of the decade by the group of Inoue [14,15,16] and Johnson [2]. Zr-Al-TM system was also studied, showing a large supercooled liquid region. The multicomponent alloys offer significantly larger glass forming ability due to their relatively lower critical cooling rate and bigger critical glass formation size in comparison to the binary systems investigated. The additional elements improve both, stabilize the liquid phase and prevent the crystallization process. The improvement of GFA in Zr-Al-Ni alloys could be related to an optimum atomic configuration achieved with the dissolution of Al and increased short-range packing density of the amorphous phase [17,18,19].

The glass forming ability is usually expressed by the maximum obtainable diameter of a fully amorphous ingot, called critical diameter [20]. However, the methods for the critical diameter determination are time and materials exhausting. Therefore, many papers were devoted to attempts to correlate the GFA with the thermal characteristics of the alloys and already accepted criteria, such as temperature interval of supercooled liquid region ΔTx = Tx − Tg [1], reduced glass transition temperature Trg = Tg/Tl [21], α = Tx/Tl [22], γm = (2Tx − Tg)/Tl [23], γ = Tx/(Tl + Tg]) [24], K = (Tx − Tg)/(Tl − Tx) [25], δ = Tx/(Tl − Tg) [26], and ω = (Tg/Tx − 2Tg)/(Tg + Tl) [27]. Some of these criteria take into account the difficulties in the crystallization process of the glasses and others the stability (thermodynamic and rheological properties) of their melts [28,29,30,31,32,33].

Some of the amorphous alloys included in the present work have already been the subject of our previous studies, which mainly traced their crystallization behavior, crystalline products (quasicrystalline and equilibrium crystalline phases) at different annealing conditions [34]. For the purpose of the present work a large series of similar in composition Zr-based amorphous alloys has been selected, all obtained under well-controlled and uniform quenching conditions, and on the base of determined thermal characteristics Tg, Tx, Tl using known criteria their GFA has been predicted. Dependence of GFA on the composition of the glasses was sought, as well as the specific heat change ΔCp at glass transition temperature was determined for the whole series of zirconium glasses studied.

Experimental part

The alloy ingots were prepared by arc-melting the mixture of Zr (99.5%), Cu (99.9%), Ni (99.9%), Al (99.99%) and Ag (99.95%) in a pure argon atmosphere approx. 1.2 bar on a water-cooled copper substrate. Homogeneous alloys composition was achieved by 3 times remelting the master alloys. The alloys were then rapidly solidified by melt spinning in a He atmosphere of 300 mbar to obtain ribbons with a thickness of 40 µm and width of 3 mm. The temperature of the melt was between 1100 and 1200 °C. Since oxygen contamination significantly affects the thermal stability [34], special care was taken to ensure comparable conditions for all ribbons produced.

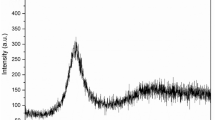

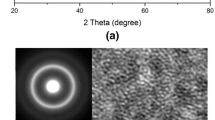

The microstructure of the as-cast samples was characterized by X-ray diffraction (XRD) with Cu-Kα radiation (diffractometer Siemens D 500, at a step of 0.05Θ and counting time 2 s/step). Thermal analysis was carried out by differential scanning calorimetry (Perkin-Elmer DSC7) and differential thermal analysis (Perkin-Elmer DTA). Scanning rate of 10 K.min−1, sample mass of 15–20 mg and purified nitrogen purging gas were used for all thermal experiments.

Results and discussion

X-ray diffraction analysis reveals the amorphous character of all studied Zr-based alloys. The diffraction patterns of the amorphous alloys, shown in Fig. 1, are ordered according to their composition. Figure 1c shows XRD patterns of Zr alloys containing Ag and Au in their composition. For all studied alloys two clearly observed diffraction halloes with little difference in the position of their maximums could be detected. The differences in the positions of the diffraction maxima are minor due to the small differences in the overall glasses’ composition. Therefore, it can be concluded that the most frequently observed interatomic distances in the studied glasses are comparable (2.45 ± 0.04 Å). Nevertheless, some minor differences in the interatomic distance could be detected, e.g., Zr70Cu12Ni10.5Al7.5 glass is characterized with the smallest mean interatomic distance (2.41 Å), whereas Zr63.5Cu16Ni13Al7.5 with the largest one (2.48 Å). The observed minor variations can be explained with the difference in the alloy compositions and with the atomic radii of the metals constituting the alloys.

The DSC scans of the Zr-based amorphous alloys are presented in Fig. 2, as the glasses were again grouped in the same order as in Fig. 1. It is noteworthy that despite the relatively similar compositions of the glasses, there are significant differences in their thermal behavior. However, on all thermal curves, the glass transition is clearly detected, as well as the temperature range of the supercooled liquid (Tx ÷ Tg) is well determined. The last observation allowed relatively accurate definition of the region of supercooled liquid, as well as of the specific heat difference due to the glass transition, ΔCp. The enthalpies of crystallization were also reliably determined. All the above thermal characteristics of the glasses are presented in Table 1.

Comparing the thermal characteristics of the studied Zr-based glasses and applying the simplest GFA criterion (ΔTx = Tx − Tg) [1, 35, 36] some important conclusions could be formulated.

In the first place, the general trend shows crystallization temperature, Tx, increase with the decrease in the Zr content of the glasses (with all the conditionality that the concentration of other metals also slightly changes), Fig. 3. Depending on the alloy composition the glass transition temperature, Tg, varies within a range of only about 30 °C (360–390 °C), while Tx differs significantly more (from 390 to 465 °C). Therefore, the different temperature range of the supercooled liquid (ΔTx = Tx − Tg) of the glasses is mainly due to their different crystallization temperatures, and to lesser extend to variations in their glass transition temperatures.

Another notable compositional dependence is related to the Zr glasses containing silver/gold. These amorphous alloys generally show higher Tg and lower Tx, i.e., smaller ΔTx, compared to the glasses without noble metal, Table 1. Figure 4 reveals the dependence of Tg and Tx on the Ag/Au content of the studied glasses. While Tg does not vary with the Ag concentration, the crystallization temperature of the glasses decreases visibly with increasing the silver content. The last leads to the conclusion that the GFA of the studied Zr-based glasses deteriorates when the silver concentration is increased. The only glass with Au in its composition also reveals lower ΔTx, compared to the Zr glasses that do not contain precious metals. Thus, it can be summarized that the presence of precious metals in the Zr–Cu–Ni–Al glasses results in a GFA decrease. The comparison between the two glasses with the same composition (Zr68.5Cu11Ag2Ni11Al7.5) but vitrified by different melt temperatures (1000 and 1100 °C) is also interesting. The melt, cooled from a higher temperature, leads to a glass with higher Tg and Tx compared to that vitrified from a lower temperature, the difference in Tx being greater. This reasonably results in a larger ΔTx for the glass obtained from the melt annealed at 1100 °C, which result can be explained by a better homogenization of the melt at the higher temperature and hence to a impeded nucleation of the crystalline phase(s).

Other dependence that can also be established form the thermal behavior of the studied Zr glasses (without Ag/Au) is related to alloys with the same or very similar Zr and Al content, but with varying Ni and Cu content. These glasses showed similar Tg and Tx values, and therefore comparable ΔTx value, Table 1.

Although the glass transition is a kinetic phenomenon strongly dependent on the heating rate, and ΔCp is a value at a particular temperature (Tg) it is worth noting the observation that glasses with large ΔTx are generally characterized with larger ΔCp (> 0.35–0.50 J g−1 K−1) and the opposite, glasses with smaller ΔTx show also reduced ΔCp (< 0.3 J g−1 K−1). To confirm and clarify this fact, a separate systematic measurement of the absolute value of the specific heat at different temperatures, both in the alloys’ glassy state and as supercooled liquid, is necessary.

DTA analysis to higher temperatures of Zr-based amorphous alloys, showing very different ΔTx, was also carried out, Fig. 5. Besides, two glasses with the same composition (Zr68.5Cu11Ag2Ni11Al7.5) but solidified from different temperature of the melt were also analyzed. This study revealed the liquidus temperature of the alloys, Tl (Table 1), and thus allowed the GFA criteria ΔTx/Tl or (2Tx − Tg)/Tl, Tg/Tl, Tx/(Tg + Tl) related to the overall liquid phase stability (both at undercooled state and at the equilibrium), to be also applied [23, 37]. There is an agreement between the result of the applied GFA criteria: glasses with a larger ΔTx follow a larger ΔTx/Tl, (2Tx − Tg)/Tl and Tx/(Tg + Tl), as well (Table 1). Some exception is observed only when we apply the Tg/Tl criterion for glasses with similar Tg and Tl, but with a significant difference in Tx. Thus, Zr69.5Cu8Ag4Ni11Al7.5 alloy shows a better GFA compared to Zr68.5Cu11Ag2Ni11Al7.5 (Tm = 1000 °C), although ΔTx is significantly larger for the latter alloy.

Based on the thermal characteristics of the studied Zr-based glasses, it can be concluded that the evaluated higher GFA of certain alloy compositions should be attributed mainly to their higher crystallization temperatures Tx, reflecting the crystallization resistance of the glass, than to the increased liquid phase stability.

Conclusions

The thermal characteristics (Tg, Tx, Tl) of a series of Zr-based amorphous alloys, obtained by rapid quenching (melt spinning), were determined. The specific heat change at glass transition ΔCp was also determined. The alloys were obtained under the same well-controlled conditions of quenching (temperature of the melt, quenching disk size and velocity, He atmosphere), which fact allowed to search for a relationship between the compositional variations and thermal behavior of the glasses. From the obtained thermal parameters and using well accepted glass forming ability (GFA) criteria the compositions with the higher GFA were determined. An answer was also given to the question of what determines the high GFA for these glasses: the difficulties in crystallization or the stability of the melt.

References

Inoue A. High strength bulk amorphous alloys with low critical cooling rates. Mater Trans JIM. 1995;36:866–75. https://doi.org/10.2320/matertrans1989.36.866.

Peker A, Johnson WL. A highly processable metallic glass: Zr41.2Ti13.8Cu12.5Ni10.0Be22.5. Appl Phys Lett. 1993;63:2342. https://doi.org/10.1063/1.110520.

Inoue A. Stabilization of metallic supercooled liquid and bulk amorphous alloys. Acta Mater. 2000;48:279–306. https://doi.org/10.1016/S1359-6454(99)00300-6.

Johnson WL. Bulk amorphous metal - an emerging engineering material. JOM. 2002;54:40–3. https://doi.org/10.1007/bf02822619.

Schuh CA, Hufnagel TC, Ramamurty U. Mechanical behavior of amorphous alloys. Acta Mater. 2007;55:4067–109. https://doi.org/10.1016/j.actamat.2007.01.052.

Gebert A, Mummert K, Eckert J, Schultz L, Inoue A. Electrochemical investigations on the bulk glass forming Zr55Cu30Al10Ni5 alloy. Mater Corr. 1997;48:293–7. https://doi.org/10.1002/maco.19970480504.

Gebert A, Buchholz K, Leonhard AK, Mummert K, Eckert J, Schultz L. Investigations on the electrochemical behaviour of Zr-based bulk metallic glasses. Mater Sci Eng A. 1999;267:294–300. https://doi.org/10.1016/S0921-5093(99)00105-7.

Zander D, Köster U. Corrosion of amorphous and nanocrystalline Zr-based alloys. Mater Sci Eng A. 2004;375–7:53–9. https://doi.org/10.1016/j.msea.2003.10.230.

Inoue A, Zhang T, Nishiyama N, Ohba K, Masumoto T. Preparation of 16 mm diameter rod of amorphous Zr65Al7.5Ni10Cu17.5 Alloy. Mater Trans JIM. 1993;34:1234–7. https://doi.org/10.2320/matertrans1989.34.1234.

Chen N, Martin L, Luzguine-Luzgin DV, Inoue A. Role of alloying additions in glass formation and properties of bulk metallic glasses. Materials. 2010;3:5320–39. https://doi.org/10.3390/ma3125320.

Greer AL. Metallic glasses. Science. 1995;267:1947–53. https://doi.org/10.1126/science.267.5206.1947.

Johnson WL. Bulk glass-forming metallic alloys: science and technology. MRS Bull. 1999;24:42–56. https://doi.org/10.1557/S0883769400053252.

Wang WH, Dong C, Shek CH. Bulk metallic glasses. Mater Sci Eng R. 2004;44:45–89. https://doi.org/10.1016/j.mser.2004.03.001.

Inoue A, Kita K, Zhang T, Masumoto T. An amorphous La55Al25Ni20 alloy prepared by water quenching. Mater Trans JIM. 1989;30:722–5. https://doi.org/10.2320/matertrans1989.30.722.

Inoue A, Zhang T, Masumoto T. Zr-Al-Ni amorphous-alloys with high glass transition temperature and significant supercooled liquid region. Mater Trans JIM. 1990;31:177–83. https://doi.org/10.2320/matertrans1989.31.177.

Inoue A, Nakamura T, Nishiyama N, Masumoto T. Mg-Cu-Y bulk amorphous alloys with high tensile strength produced by a high-pressure die-casting method. Mater Trans JIM. 1992;33:937–45. https://doi.org/10.2320/matertrans1989.33.937.

Chen W, Wang Y, Qiang J, Dong C. Bulk metallic glasses in the Zr-Al-Ni-Cu system. Acta Mater. 2003;51:1899–907. https://doi.org/10.1016/s1359-6454(02)00596-7.

Zhang T, Inoue A, Masumoto T. Amorphous Zr-Al-TM (TM=Co, Ni, Cu) alloys with significant supercooled liquid region of over 100 K. Mater Trans JIM. 1991;32:1005–10. https://doi.org/10.2320/matertrans1989.32.1005.

Takeuchi A, Inoue A. Classification of bulk metallic glasses by atomic size difference, heat of mixing and period of constituent elements and its application to characterization of the main alloying element. Maters Trans. 2005;46:2817–29. Special Issue on Materials Science of Bulk Metallic Glasses. Doi: https://doi.org/10.2320/matertrans.46.2817

Blyskun P, Maj P, Kowalcsyk M, Latuch J, Kulik T. Relation of various GFA indicators to the critical diameter of Zr-based BMGs. J Alloys Compd. 2015;625:13–7. https://doi.org/10.1016/jallcom.2014.11.112.

Turnbull D. Under what conditions can a glass be formed? Contemp Phys. 1969;10:473–88. https://doi.org/10.1080/00107516908204405.

Mondal K, Murty BS. On the parameters to assess the glass forming ability of liquids. J Non-Cryst Solids. 2005;351:1366–71. https://doi.org/10.1016/j.jnoncrysol.2005.03.006.

Du XH, Huang JC, Liu CT, Lu ZP. New criterion of glass forming ability for bulk metallic glasses. J Appl Phys. 2007;101:086108. https://doi.org/10.1063/1.2718286.

Lu ZP, Liu CT. A new glass-forming ability criterion for bulk metallic glasses. Acta Mater. 2002;50:3501–12. https://doi.org/10.1016/S1359-6454(02)00166-0.

Hruby A. Evaluation of glass-forming tendency by means of DTA. Czech J Phys B. 1972;22:1187–93. https://doi.org/10.1007/BF01690134.

Chen QJ, Shen J, Zhang D, Fan HB, Sun JF, McCartney DG. A new criterion for evaluating the glass-forming ability of bulk metallic glasses. Mater Sci Eng A. 2006;433:155–60. https://doi.org/10.1016/j.msea.2006.06.053.

Long ZL, Wei HQ, Ding YH, Zhang P, Xie GQ, Inoue A. A new criterion for predicting the glass-forming ability of bulk metallic glasses. J Alloys Compd. 2009;475:207–19. https://doi.org/10.1016/j.jallcom.2008.07.087.

Takeuchi A, Inoue A. Calculations of amorphous-forming composition range for ternary alloy systems and analyses of stabilization of amorphous phase and amorphous-forming ability. Mater Trans. 2001;42:1435–44. https://doi.org/10.2320/matertrans.42.1435.

Zhang K, Smith W, Wang M, Liu Y, Schroers J, Shattuck M, Ohern C. Connection between the packing efficiency of binary hard spheres and the glass-forming ability of bulk metallic glasses. Phys Rev E. 2014;90:032311. https://doi.org/10.1103/PhysRevE.90.032311.

Uhlmann DR. A kinetic treatment of glass formation. J Non-Cryst Solids. 1972;7:337–48. https://doi.org/10.1016/0022-3093(72)90269-4.

Cohen MH, Grest GS. Liquid-glass transition, a free-volume approach. Phys Rev B. 1979;20:1077–98. https://doi.org/10.1103/PhysRevB.20.1077.

Louzguine-Luzgin DV, Inoue A. An extended criterion for estimation of glass-forming ability of metals. J Mater Res. 2007;22:1378–83. https://doi.org/10.1557/JMR.2007.0167.

Chang YC, Hung TH, Chen HM, Huang JC, Nieh TG, Lee CJ. Viscous flow behavior and thermal properties of bulk amorphous Mg58Cu31Y11 alloy. Intermetallics. 2007;15:1303–8. https://doi.org/10.1016/j.intermet.2007.03.012.

Zander D, Janlewing R, Rüdiger A, Köster U. Nucleation of quasicrystals in bulk glass forming Zr-Cu-Ni-Al alloys. Mater Sci Forum. 1999;307:25–30. https://doi.org/10.4028/www.scientific.net/MSF.307.25.

Inoue A, Zhang T, Masumoto T. Glass-forming ability of alloys. J Non Cryst Solids. 1993;156–158:473–80. https://doi.org/10.1016/0022-3093(93)90003-G.

Li Y, Ng SC, Ong CK, Hng HH, Goh TT. Glass forming ability of bulk glass forming alloys. Scripta Mater. 1997;36:783–7. https://doi.org/10.1016/S1359-6462(96)00448-4.

Liu X, Wang X, Han F. Glass-forming ability and thermal properties of Al70Fe12.5V12.5X5 (X=Zr, Nb, Ni) amorphous alloys via minor alloying additions. Nanomaterials. 2021;11:488. https://doi.org/10.3390/nano11020488.

Acknowledgements

This work was supported by the European Regional Development Fund within the Operational Programme “Science and Education for Smart Growth 2014–2020” under the Project CoE “National Center of Mechatronics and Clean Technologies” (BG05M2OP001-1.001-0008). Research equipment of the Distributed Research Infrastructure INFRAMAT D01-306/20.12.2021, part of the Bulgarian National Roadmap for Research Infrastructures, supported by the Bulgarian Ministry of Education and Science was used in this investigation.

Author information

Authors and Affiliations

Contributions

Tony Spassov: Conceptualization, Methodology, Investigation, Writing—original draft, Writing—review & editing. Lyudmila Lyubenova: Investigation, Sample preparation and characterization, Data curation. Vesselina Rangelova: Sample preparation and characterization, Data curation. Maya Spassova: Investigation, Characterization.

Corresponding author

Ethics declarations

Conflict of interest

The authors have no competing interests to declare that are relevant to the content of this article.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

The article is dedicated to Prof. Uwe Koester (Technical University Dortmund), with whom all the authors of this study were closely related.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Lyubenova, L., Rangelova, V., Spassova, M. et al. Glass forming ability of Zr-based Zr–Cu–Ni–Al–(Ag) alloys. J Therm Anal Calorim 148, 3975–3980 (2023). https://doi.org/10.1007/s10973-023-12044-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-023-12044-0