Abstract

Nanostructurization-driven responses in calorimetric heat-transfer phenomena are compared for glassy arsenoselenides at different levels of their molecular network organization, namely in high-polymerized g-As5Se95 and low-polymerized g-As55Se45, employing multifrequency temperature-modulated DSC-TOPEM® method complemented with Raman scattering microspectroscopy. It is shown that high-polymerized network composed of AsSe3 pyramids interlinked by Se chains with small number of Se8 molecular units decoupled from this network prevails in melt-quenched and nanomilling-derived g-As5Se95. Transition to more polymerized network due to incorporation of destroyed Se8 molecules into glass backbone occurs in this glass under nanostructurization. As a result, nanostructurization-driven calorimetric response in g-As5Se95 dominates by size-induced glass-transition temperature depression. The low-polymerized structure of g-As55Se45 is built of As–Se network enriched with tetra-arsenic selenide molecular units decoupled from this network. Molecular-to-network transition owing to nanomilling-driven destruction of these cage molecules and their incorporation into newly polymerized glass-forming backbone occurs in g-As55Se45 resulting in strong increase in calorimetric glass-transition temperature.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Background

Nanostructured materials are distinguished by great variety of size-dependent phenomena which play a pivotal role in the majority of their practical applications [1]. Thus, being transferred to a nanoscale level evolving agglomerates of atoms and/or atomic groups composing nanoparticles, these nanoscopic materials demonstrate strong propensity to multiphase occurrence, modifying essentially calorimetric responses from conventional heat-transfer phenomena [1,2,3]. As a rule, clear reduction trend dominates in characteristic interphase transition temperatures in nanostructured crystalline materials below some critical nanosizes, when one of the metastable phases becomes thermodynamically more favorable over others [3,4,5,6,7].

The similar trend is character for amorphous polymeric substances, which typically reveal notable depression trend in glass-transition temperature Tg when being prepared as thin and ultra-thin (having a few nm in thickness) films [8,9,10,11,12].

However, in some amorphous materials belonging to molecular network chalcogenide glass-formers [13, 14] such as melt-quenched glassy arsenoselenides g-As-Se possessing structural conformations with different degrees of polymerization [15, 16], the calorimetric response on transferring to nanoscale is expected to be more complicated because of possible effect from nanostructurization-driven molecular-to-network transitions (as was also in the case of isotypical glassy arsenosulphides g-As–S [17, 18]). Stable low-polymerized (preferentially molecular-type) and high-polymerized (preferentially network-type) atomistic structures in g-As–Se subjected to nanostructurization through high-energy mechanical milling were refined with a help of X-ray powder diffraction (XRPD) analysis [19]. It was shown that cage-like molecular entities stabilized initially in melt-quenched g-As–Se were merely destroyed under high-energy mechanical milling-driven nanostructurization facilitating formation of more polymerized chain-like network structures, this process being referred to as re-amorphization [20]. The objective of the current research is to compare most plausible nanostructurization-driven responses in the glass-transition region of these arsenoselenide glasses revealed at principally different levels of their molecular network arrangement, namely in high-polymerized g-As5Se95 and low-polymerized g-As55Se45 specimens, employing the multifrequency temperature-modulated DSC-TOPEM® method complemented with microstructural characterization using the Raman scattering (RS) microspectroscopy.

Materials and methods

The bulk samples of glassy g-As5S95 and g-As55S45 were prepared from high-purity elemental precursors (As and Se of 5 N purity) employing conventional melt quenching technological route, that is rapid cooling of the glass from melt-liquid state [13]. The melt-rocking operation was used to prepare homogeneous alloys (as was justified by Lucas et al. [21]), avoiding necessity of extra-long homogenization stabilizing these glasses from very unfavorable vertical position in the furnace [22]. The sealed ampoules with elemental precursors taken in the ratio corresponding to As5S95 and As55S45 compositions were heated in a rocking furnace up to 650 °C in 6 h and then homogenized at this temperature for 10 h. At the finishing stage, the ampoule was cooled down to 500 °C and finally quenched in a water. To eliminate mechanical strains appeared in bulky material after rapid cooling, the just-synthesized glasses were annealed at 120 °C for 1 h. The ingots extracted from ampoules were amorphous, as it followed from the XRPD analysis, conch-like fracture and IR transparency of freshly prepared cut sections. The room temperature densities of g-As5S95 and g-As55S45 samples determined by the Archimedes displacement in ethanol using the Mettler Toledo balances were (4.310 ± 0.005) g cm−3 and (4.447 ± 0.005) g cm−3, respectively, in full agreement with the known atomic densities of compositionally similar glassy counterparts from binary As-Se system [15, 16].

The melt-quenched bulk chalcogenide glasses of the above chemical compositions (hereafter referred to as unmilled samples) were subjected to nanostructurization by high-energy mechanical milling (nanomilling) in a dry mode using Pulverisette 6 mill operated at protective Ar atmosphere and 500 min−1 rotational speed. This procedure was performed for 60 min in 250 mL tungsten carbide chamber loaded with 50 balls (each having 10 mm in diameter), using ~ 3 g of coarse-grained glass sieved under 200 μm. The amorphous state of the samples was not changed under nanomilling, as it follows from diffuse peak-halos in their XRPD patterns [19, 20]. The fine-grained powdered substance was finally compressed in stainless steel die (under ~ 0.7 GPa) to produce the disc-like pellets (having ~ 6 mm in diameter and ~ 1 mm in thickness) most suitable for further microstructural characterization research.

Calorimetric thermo-analytical measurements were performed employing multifrequency temperature-modulated DSC-TOPEM® with DSC-1 calorimeter (Mettler Toledo, Switzerland), as described in more details elsewhere [17, 18]. In this method, stochastic temperature modulations are superimposed on underlying rate of DSC scans, resulting in frequency dependent and independent phenomena [23]. This provides more information on thermodynamic stability of the revealed phases. The DSC-TOPEM® instrument was equipped with FRS5 + sensor and HT100 (Huber, Germany) intracooler, the STARe ver. 13a software being used to control experimental conditions and process the data. The calorimeter was multi-point calibrated using In and Zn standard probes. The tested samples (ca. 10–15.0) were encapsulated in sealed 20 μL Al pans kept in protective N2 atmosphere, and scanned at the rate of 1.0 K min−1 stochastically modulated in pulses between 15 and 40 s, the pulse height being 1 K. The evaluations were adjusted using sapphire reference curve, the width and shift of calculation window being 60 s and 1 s, respectively.

The detected calorimetric events were parameterized using the DSC-TOPEM® profiles presenting temperature variations of non-reversing (HFnrev) and reversing (HFrev) heat flow in the heating run, each measuring protocol being averaged in triplicate. The reversing thermal effects, resulted from second-order phase transitions such as glass transition [24], were parameterized by heat capacity step-like jump (ΔCp) allowing characteristic glass-transition temperatures determination in onset (T onsetg ) and mid-point (T midg ) presentation [24, 25]. The non-reversing thermal effects, connected with enthalpy relaxation in the glass-transition region during heating run, were parameterized by specific enthalpies difference ΔH [17, 25].

Microstructural nature of nanostructurization-driven transformations in the glass was identified with micro-Raman spectroscopy using the Horiba Xplora spectrometer equipped by CCD detector operated at room temperature. The CW 785 nm laser of 90 mW output power was employed for excitation, the 10% power option being used to avoid photostructural effects. Other measurement options applied were as follows: × 100 objective, 1800 1 mm−1 grating, 500 μm hole, and 50 μm slit. The spectral resolution was maintained at around 2 cm−1 and spatial resolution was near 2 μm. A number of scans were chosen in dependence on the surface of pelletized glass samples. Numerous scans on the entire surface were performed to be sure that RS spectra processed with the Horiba LabSpec software were reasonably identical. The milled and unmilled samples were compared through normalization by matching spectral areas in the region of interest. The detected RS bands were identified using the known data for numerous glassy analogs [26, 27].

Results and discussion

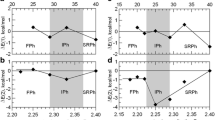

Thermodynamic heat-transfer responses were detected in the pellets of arsenoselenide glasses by multifrequency DSC-TOPEM® method. The temperature-modulated DSC-TOPEM profiles showing variation of reversing (HFrev) and non-reversing (HFnrev) heat flow in the bulky melt-quenched (unmilled) and nanostructurized (milled, viz. subjected to high-energy mechanical milling) g-As5Se95 and g-As55Se45 samples are depicted on Figs. 1, 2, respectively, the calorimetric parameters derived from these curves being gathered in Table 1.

Under heating run, the principal endothermic thermal alteration event in the studied substance represents glass transition. In modulated DSC-TOPEM profiles of unmilled g-As5Se95 sample depicted on Fig. 1a, the characteristic step-like jump supplemented by small peak is revealed in the temperature behavior of reversing (HFrev) heat flow near the glass-transition region with heat capacity variation ΔCp approaching ~ 0.14 J g−1 K−1, while distinct peak with specific enthalpies difference of ΔH ~ 3.32 J g−1 is observed in non-reversing (HFnrev) heat flow dependence shown on Fig. 1b. The similar calorimetric thermal alteration responses are character for other families of chalcogenide glasses undergoing physical aging [28, 29].

An evident depression in the glass-transition temperature Tg is observed in modulated DSC-TOPEM profiles of this g-As5Se95 sample after nanomilling, and this trend being accompanied by increase in the DSC-TOPEM peak amplitude. As it follows from Table 1, the T onsetg value is reduced in milled g-As5Se95 on 2.6 °C (from 69.3 to 66.7 °C), while specific enthalpies difference ΔH derived from temperature variation of non-reversing (HFnrev) heat flow is enriched on more than 16% (reaching as high as 3.86 J g−1). Noteworthy, the glass-transition width defined from temperature dependence of reversing (HFrev) heat flow on Fig. 1a for g-As5Se95 samples nanostructurized by high-energy mechanical milling does not change essentially.

Thus, milling-driven nanostructurization of chalcogenide glasses possessing highly polymerized network (such as under-stoichiometeric g-As5Se95) prevails by the known effect of size-induced glass-transition temperature Tg depression, which has been extensively studied from the mid 1990s [8,9,10,11,12]. However, this calorimetric heat-transfer phenomenon is cardinally changed in case of glasses having more irregular molecular-like structure (such as over-stoichiometric g-As55Se45). The bulk glass of this composition derived by melt quenching shows similar responses (albeit more reduced ones in modulated DSC-TOPEM profiles) within the glass-transition region, particularly, the characteristic step-like jump without accompanied peak in reversing (HFrev) heat flow on Fig. 2a with ΔCp ~ 0.11 J g−1 K−1 (Table 1) and distinct endothermic peak in non-reversing (HFnrev) heat flow on Fig. 2b with ΔH ~ 5.57 J g−1. The value of T onsetg temperature for this unmilled glass (g-As55Se45) defined from reversing curve occurs to be 134.6 °C (Table 1), and this value being in an excellent agreement with reduced glass-transition temperatures in the As-rich arsenoselenide glasses ascribed to variance of different molecular tetra-arsenic selenide species (such as As4Se4, As4Se3, As4) [16].

Under transition to more polymerized structure of g-As55Se45 samples undergoing nanomilling, the bulk glass-transition temperature notably increases approaching T onsetg ~ 170.0 °C (see Table 1), the value character for unmilled melt-quenched samples of stoichiometric arsenic triselenide glass g-As2Se3 [15, 16]. At the same time, the glass-transition temperature width in nanomilled g-As55Se45 defined from reversing heat flow curve on Fig. 2a is narrowed by a factor at least 2.

The principal calorimetric response originated from non-reversing (HFnrev) heat flow variation is changed drastically in nanostructurized g-As55Se45 due to thermal relaxation of strong inner strength generated in this glass under high-energy mechanical milling. As a result, the pronounced exothermic event (depicted on Fig. 2b) with specific enthalpies difference ΔH approaching as high as -29.70 J g−1 (see Table 1) prevails in this glassy sample (nanomilled g-As55Se45).

To shed light on the nature of nanomilling-driven microstructural transformations in the studied glasses, the micro-RS spectra were collected and compared for g-As5Se95 and g-As55Se45 samples in both unmilled (melt-quenched) and milled (nanostructurized) states (Fig. 3, 4).

In the micro-RS-spectrum of melt-quenched g-As5Se95 (Fig. 3, black curve) only a few bands are resolved, these being weak and relatively narrow band near ~ 107 cm−1 and ~ 132 cm−1, weak but evidently broader band positioned near ~ 490 cm−1 and very strong band near ~ 248 cm−1. The latter is due to overlapping of bond-stretching vibrational modes assigned to trigonal AsSe3 pyramids at 227 cm−1 [30], and modes at ~ 230–270 cm−1 assigned to multiatomic Se fragments incorporated in various local environment [31], in part, strongly correlated chains disposed in trigonal t-Se conformations at 234 cm−1, dissolved multi-Se chains at 250 cm−1 and molecular-type Se8 species at ~ 260 cm−1. The band at 107 cm−1 is probably connected with Se8 rings contributing through A1 mode at 112 cm−1 [32], while 132 cm−1 band is due to Se polymeric chains having RS-active E mode positioned at 138 cm−1 [32]. The broad RS-active band at 490 cm−1 is related to second-order Raman scattering from homonuclear Se-Se bonds [33]. Thus, the structure of unmilled g-As5Se95 represents highly polymerized network built of AsSe3 pyramids interlinked by Se chains with very small number of molecular units (such as Se8) decoupled from this network.

Only slight changes occur in the RS spectrum of this glass subjected to nanostructurization through milling (also shown on Fig. 3). The RS band at ~ 132 cm−1 ascribed to E mode of Se chains is increased in nanomilled g-As5Se95. Strong band at ~ 248 cm−1 does not change its position after nanomilling, while being slightly depressed, especially from the high-frequency side corresponding to spectral domain of preferential location of intramolecular bond-stretching modes ascribed to Se8 molecules [31, 32]. Due to incorporation of atomic remainders of destroyed molecular units into glass network, the milled specimen becomes more polymerized, and this effect being associated with slight increase in the respective glass-transition parameters on this glass (see Table 1).

In the collected micro-RS-spectrum of melt-quenched g-As55Se45 depicted on Fig. 4, several low-frequency bands (at 109, 130, 143, 154, 168 and 190 cm−1) and high-frequency bands (at 203, 218, 235, 253 and 278 cm−1) are resolved. The high-frequency bands are ascribed to overlapped (preferentially strong) bond-stretching vibrational modes of AsSe3 pyramidal units at 227 cm−1 [30], and some fingerprints of cage-like arsenoselenide molecules, such as As4Se4 at 248 and 190 cm−1 [34]; As4Se3 at 196, 242, 256, 266 and 280 cm−1 [35], as well as As4 at ~ 200 cm−1 [33]. The low-frequency peaks (preferentially weak and medium) can be ascribed to bond-bending vibrational modes of these molecular cages, in part, As4Se3 at 140 and 166 cm−1 [26] and As4Se4 at 106, 136, 144, 190 and 207 cm−1 [34].

In the milled g-As55Se45 samples, all the above features observed in the micro-RS spectra are essentially broadened and depressed (see Fig. 1, red curve), testifying in favor of nanostructurization-driven destruction of respective tetra-arsenic selenide molecular units and their incorporation in newly polymerized arsenoselenide glass-forming network. Thus, the structure of this nanostructurized chalcogenide glass becomes notably stressed (as compared with iso-compositional unmilled sample), being affected by a variety of structural defects generated under high-energy mechanical milling. Atomic remainders of destroyed molecules are reincorporated into a glassy network, completely changing calorimetric response from the glass-transition event.

Conclusions

Nanostructurization-driven thermodynamic responses in calorimetric heat-transfer phenomena are compared for glassy arsenoselenides at principally different levels of their molecular network organization, namely in high-polymerized under-stoichiometric (preferentially network-type) g-As5Se95 and low-polymerized over-stoichiometric (preferentially molecular-type) g-As55Se45, using multifrequency temperature-modulated DSC-TOPEM® complemented with microstructure research based on Raman scattering (RS) microspectroscopy.

It is shown that high-polymerized network composed of AsSe3 pyramidal fragments interlinked by long Se chains with small number of Se8 molecular units (decoupled from this network under melt quenching) prevails in both melt-quenched and nanomilling-derived g-As5Se95 samples. Transition to more polymerized network occurs in this glass under nanostructurization by nanomilling, being caused by incorporation of destroyed Se8 molecules into the glass backbone. As a result, nanostructurization-driven calorimetric response in this glass dominates with the known effect of size-induced glass-transition temperature depression.

The low polymerized preferentially molecular-type structure of g-As55Se45 is built of arsenoselenide network enriched with tetra-arsenic selenide molecules decoupled from this network under melt quenching. Molecular-to-network transition owing to nanomilling-driven destruction of the above molecular units and their incorporation into newly polymerized glass-forming backbone occurs in this glass undergoing nanostructurization, thus resulting in strong increase in calorimetric glass-transition temperature.

References

Roduner E. Nanoscopic materials. Size-dependent phenomena. Cambridge: RSC Publication; 2006.

Naterer GF. Heat transfer in single and multiphase systems. Boca Raton, London, New York, Washington: CRC Press LLC; 2003.

Roduner E. Size matters: why nanomaterials are different. Chem Soc Rev. 2006;35:583–92. https://doi.org/10.1039/B502142C.

Qadri SB, Skelton EF, Hsu D, Dinsmore AD, Yang J, Gray HF, Ratna BR. Size-induced transition-temperature reduction in nanoparticles of ZnS. Phys Rev B. 1999;60:9191–3. https://doi.org/10.1103/PhysRevB.60.9191.

Tomaszewski PE. Phase transitions in extremely small crystals. Ferroelectrics. 2008;375:74–91. https://doi.org/10.1080/00150190802437910.

Gilbert B, Zhang H, Feng H, Finnegan MP, Waychunas GA, Banfield JF. Special phase transformation and crystal growth pathways observed in nanoparticles. Geochem Trans. 2003;4:20–7. https://doi.org/10.1039/b309073f.

Prabhu D, Narayanasamy A, Shinoda K, Jeyadeven B, Greneche J-M, Chattopadhyay K. Grain size effect on the phase transformation temperature of nanostructured CuFe2O4. J Appl Phys. 2011;109:013532-1–6. https://doi.org/10.1063/1.3493244.

Reiter G. Mobility of polymers in films thinner than their unperturbed size. Eur Lett. 1993;23:579–84. https://doi.org/10.1209/0295-5075/23/8/007.

Keddie JL, Jones RA, Cory RA. Size-dependent depression of the glass transition temperature in polymer films. Eur Lett. 1994;27:59–64. https://doi.org/10.1209/0295-5075/27/1/011.

Keddie JL, Jones RAL, Cory RA. Interface and surface effects on the glass-transition temperature in thin polymer films. Faeaday Discuss. 1994;98:219–30. https://doi.org/10.1039/FD9949800219.

Keddie JL, Jones RA. Glass transition behavior in ultra-thin polystyrene films. Isr J Chem. 1995;35:21–6. https://doi.org/10.1002/ijch.199500005.

Cangialosi D, Alegria A, Colmenero J. Effect of nanostructure on the thermal glass transition and physical aging in polymer materials. Progr Polym Sci. 2016;54–55:128–47. https://doi.org/10.1016/j.progpolymsci.2015.10.005.

Feltz A. Amorphous inorganic materials and glasses. Weinheim: VCH; 1993.

Tanaka K, Shimakawa K. Amorphous chalcogenide semiconductors and related materials. New York, Dordrecht, Heidelberg, London: Springer; 2011.

Feltz A, Aust H, Blayer A. Glass formation and properties of chalcogenide systems XXVI: permittivity and the structure of glasses AsxSe1-x and GexSe1-x. J Non-Cryst Solids. 1983;55:179–90. https://doi.org/10.1016/0022-3093(83)90667-1.

Yang G, Bureau B, Rouxel T, Gueguen Y, Gulbiten O, Roiland C, Soignard E, Yarger JL, Troles J, Sangleboeuf J-CH, Lucas P. Correlation between structure and physical properties of chalcogenide glasses in the AsxSe1−x system. Phys Rev B. 2010;82:195206-1–8. https://doi.org/10.1103/PhysRevB.82.195206.

Shpotyuk O, Kozdras A, Baláz P, Bujnáková Z, Shpotyuk Y. Thermal-alteration interphase transformations in natural and synthetic arsenic sulfide polymorphs. J Chem Thermodyn. 2019;128:110–8. https://doi.org/10.1016/j.jct.2018.08.019.

Shpotyuk O, Kozdras A, Balaz P, Bujnakova Z, Shpotyuk Y. DSC TOPEM study of high-energy mechanical milling-driven amorphization in β-As4S4-based arsenicals. J Therm Anal Calorim. 2019;135:2935–41. https://doi.org/10.1007/s10973-018-7613-0.

Shpotyuk Y, Demchenko P, Bujňáková Z, Baláž P, Boussard-Pledel C, Bureau B, Shpotyuk O. Effect of high-energy mechanical milling on the medium-range ordering in glassy As-Se. J Am Ceram Soc. 2020;103:1631–46. https://doi.org/10.1111/jace.16877.

Shpotyuk Y, Demchenko P, Shpotyuk O, Balitska V, Boussard-Pledel C, Bureau B, Lukáčová Bujňáková Z, Baláž P. High-energy mechanical milling-driven reamorphization in glassy arsenic monoselenide g-AsSe: on the path tailoring special molecular-network glasses. Materials. 2021;14:44781-1–4. https://doi.org/10.3390/ma14164478.

Lucas P, Coleman GJ, Sen S, Gui S, Guimond Y, Calvez L, Boussard-Pledel C, Bureau B, Troles J. Structural and chemical homogeneity of chalcogenide glass prepared by melt-rocking. J Chem Phys. 2019;150:014505-1–9. https://doi.org/10.1063/1.5054704.

Ravindren S, Gunasekera K, Tucker Z, Diebold A, Boolchand P, Micoulaut M. Crucial effect of melt homogenization on the fragility of non-stoichiometric chalcogenides. J Chem Phys. 2014;140:134501-1–9. https://doi.org/10.1063/1.4869107.

Fraga I, Montserrat S, Hutchinson J. TOPEM, a new temperature modulated DSC technique. Application to the glass transition of polymers. J Therm Anal Calorim. 2007;87:119–24. https://doi.org/10.1007/s10973-006-7969-4.

Pielichowska K, Krol P, Krol B, Pagacz J. TOPEM DSC study of glass transition region of polyurethane cationomers. Thermochim Acta. 2012;545:187–93. https://doi.org/10.1016/j.tca.2012.06.029.

Gabbott P. Chapter 1: a practical introduction to differential scanning calorimetry. In: Paul G, editor. Principles and applications of thermal analysis. Oxford, Ames, Carltoon: Blackwell Publ. Ltd; 2008. p. 1–50. https://doi.org/10.1002/9780470697702.

Kovanda V, Vlcek M, Jain H. Structure of As-Se and As-P-Se glasses studied by Raman spectroscopy. J Non-Cryst Solids. 2003;326&327:88–92. https://doi.org/10.1016/S0022-3093(03)00383-1.

Golovchak R, Oelgoetz J, Vlcek M, Esposito A, Saiter A, Saiter J-M, Jain H. Complex structural rearrangements in As-Se glasses. J Chem Phys. 2014;140:054505-1–8. https://doi.org/10.1063/1.4863561.

Saiter JM. Physical ageing in chalcogenide glasses. J Optoelectron Adv Mater. 2001;3:685–94.

Shpotyuk O, Golovchak R, Kozdras A. Physical ageing of chalcogenide glasses. In: Chalcogenide glasses: preparation, properties and applications. Philadelphia, New Delhi: Woodhead Publ.; 2014. p. 209–64. https://doi.org/10.1533/9780857093561.1.209.

Lucovsky G. Optic modes in amorphous As2S3 and As2Se3. Phys Rev B. 1972;6:1480–9. https://doi.org/10.1103/PhysRevB.6.1480.

Yannopoulos SN, Andrikopoulos KS. Raman scattering study on structural and dynamical features of noncrystalline selenium. J Chem Phys. 2004;121:4747–58. https://doi.org/10.1063/1.1780151.

Lucovsky G, Mooradian A, Taylor W, Wright GB, Keezer RC. Identification of the fundamental vibrational modes of trigonal, α-monoclinic and amorphous selenium. Solid State Commun. 1967;5:113–7. https://doi.org/10.1016/0038-1098(67)90006-3.

Lannin JS. Raman scattering properties of amorphous As and Sb. Phys Rev B. 1977;15:3863–71. https://doi.org/10.1103/PhysRevB.15.3863.

Ystenes M, Menzel F, Brockner W. Ab initio quantum mechanical calculations of energy, geometry, vibrational frequencies and IR intensities of tetraphosphorus tetrasulphide, α-P4S4 (D2d), and vibrational analysis of As4S4 and As4Se4. Spectrochim Acta. 1994;50A:225–31. https://doi.org/10.1016/0584-8539(94)80050-2.

Ystenes M, Brockner W, Menzel F. Scaled quantum mechanical (SQM) calculations and vibrational analyses of the cage-like molecules P4S3, As4Se3, P4Se3, As4S3, and PAs3S3. Vib Spectrosc. 1993;5:195–204. https://doi.org/10.1016/0924-2031(93)87068-5.

Acknowledgements

The paper is a part of scientific research within the project No 0122U001806, the subject of Scientific Program funded by Ministry of Education and Science of Ukraine for years 2022–2024.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all co-authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Kozdras, A., Shpotyuk, O., Mahlovanyi, B. et al. Thermodynamic heat-transfer phenomena in nanostructured glassy substances: a comparative study on g-As5Se95 and g-As55Se45. J Therm Anal Calorim 148, 2265–2271 (2023). https://doi.org/10.1007/s10973-022-11913-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-022-11913-4