Abstract

The aim of paper was to determine the activation, deactivation energies and optimum temperatures for recombinant endo-inulinases of various origins, including also recombinant endo-inulinases from Aspergillus niger, Escherichia coli, Saccharomyces cerevisiae and Yarrowia lipolytica. The activity recombinant endo-inulinases of various origins vs. temperature curves were analyzed. A mathematical model describing the effect of temperature on recombinant endo-inulinase activity was used. Based on the analysis, values of the activation energies E were in the range from \({22.08 \pm 13.94}\) kJ mol\(^{-1}\) to \({62.62 \pm 17.24}\) kJ mol\(^{-1}\) and in the range from \({29.80 \pm 8.83}\) kJ mol\(^{-1}\) to \({92.69 \pm 15.31}\) kJ mol\(^{-1}\) for recombinant endo-inulinase A. niger and various origins, respectively. The deactivation energies \({E_{\mathrm{D}}}\) were from the range from \({146.80 \pm 20.31}\) kJ mol\(^{-1}\) to \({301.95 \pm 95.81}\) kJ mol\(^{-1}\) and in the range from \({159.96 \pm 14.80}\) kJ mol\(^{-1}\) to \({289.43 \pm 21.18}\) kJ mol\(^{-1}\) for recombinant endo-inulinase A. niger and various origins, respectively. The optimum temperatures \({T_{\mathrm{opt}}}\) were obtained in the range from \({328.67 \pm 1.32}\) K to \({335.94 \pm 1.22}\) K and in the range from \({319.41 \pm 0.85}\) K to \({338.53 \pm 0.45}\) K for recombinant endo-inulinase A. niger and various origins, respectively.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The activity of the enzyme changes with temperature. In the first stage, the activity of the enzyme increases with increasing temperature. At a certain temperature, referred to as \({T_{\mathrm{opt}}}\), the activity of the enzyme is maximal. When the \({T_{\mathrm{opt}}}\) is exceeded, the activity of the enzyme decreases. The knowledge of the optimum temperature \({T_{\mathrm{opt}}}\) and the activation energy E and deactivation energy \({E_{\mathrm{D}}}\) of the enzyme enables the bioprocess optimization with the reduction of its costs at the same time. The \({T_{\mathrm{opt}}}\) value is mostly determined experimentally. The values of the activation energies E and \({E_{\mathrm{D}}}\) can be determined from the curves Arrhenius of the dependence of the logarithm of the reaction rate (lnv) on the reciprocal of temperature (\(T^{-1}\)) [1]. It has been shown that the determined values of E and \({E_{\mathrm{D}}}\) by application of the Arrhenius relationship is burdened with an error [2, 3].

Inulin consists of linear chains of 2,1-\(\beta\)-D-fructofuranose molecules terminated with a glucose residue at the reducing end. Inulin is a reserve carbohydrate \({\left( 0.5-22\%\right) }\) in many plant tubers, roots or leaves [4,5,6]. Inulin can be used for the production of many bio-based products, such as high-fructose syrups, bioethanol, fructose and glucose inulo-oligosaccharides [5, 7, 8].

Inulinases (2,1-\(\beta\)-D-fructan fructanohydrolase) are hydrolysed, catalyzing the inulin hydrolysis of about \({90-95\%}\) converse of inulin [9]. Inulinases can be classified into endo-inulinases (EC 3.2.1.153) and exo-inulinases (EC 3.2.1.80). Exo-inulinases remove terminal fructose residues from the non-reducing end of inulin, and endo-inulinases act on the internal bonds of the inulin molecule to produce inulotrioses, inulotetraoses and fructo-oligosaccharides [7, 10, 11]. Inulinases occur inter alia in plants, fungi Penicillium sp., Aspergillus niger and bacteria Pseudomonas mucidolens, Arthrobacter sp. S37 can to produce endo-inulinase [12,13,14,15,16,17,18,19,20,21].

Endo-inulinases obtained from them are characterized by high activity and high thermostability [12]. The optimum temperatures for endo-inulinases are around \(40\,^{\circ }\)C [2, 3]. They are higher for commercial endo-inulinases [14, 21] even above \(60\,^{\circ }\)C [15, 17] and \(65\,^{\circ }\)C [16, 20] for recombinant endo-inulinases.

Formation of the recombinant endo-inulinases associated with their industrial use. Commercial of preparations endo-inulinase should have economic and technical advantages including low price, high activity and stability under industrial reaction conditions [16].

There have been many publications in the literature on A. niger recombinant endo-inulinase [13,14,15,16,17] used for high-performance engineered endo-inulinanse for fructooligosaccharides production from inulin. There are also publications on recombinant endo-inulinase of various microbial origins, including Pseudomonas mucidolens into Saccharomyces cerevisiae EBY 100 [19], endo Arthrobacter sp. S37 in Yarrowia lipolytica Po1h [18] and Penicillium restrictum A191 in Escherichia coli [20]. However, processes involving recombinant endo-inulinase of various origins purposes can not be designed and optimized without knowing the values of the activation energy E and deactivation energy \({E_{\mathrm{D}}}\) and optimum temperature \({T_{\mathrm{opt}}}\). Additionally, the parameters E, \({E_{\mathrm{D}}}\) and \({T_{\mathrm{opt}}}\) for recombinant endo-inulinases A. niger [13,14,15,16,17] were determined.

Determination the parameters E, \({E_{\mathrm{{\bf D}}}}\), \({T_{\mathrm{{\bf opt}}}}\) for recombinant endo-inulinase activity

The activity of recombinant endo-inulinase in the inulin hydrolysis reaction changes with temperature. At temperatures below the optimum temperature \({T_{\mathrm{opt}}}\), the endo-inulinase activity increases with increasing temperature. After exceeding the optimum temperature \({T_{\mathrm{opt}}}\), the enzyme activity decreases with increasing temperature. Both recombinant endo-inulinase activity increase or decrease are described by the first-order equations due to the enzyme concentration, like in recombinant exo-inulinase [23, 24].

In particular studying recombinant endo-inulinase activity during the inulin hydrolysis, it is assumed that the change in substrate concentration \(C_{\mathrm{S}}\) during reaction time t describes by the first-order equations

where k is the kinetic constant of the enzymatic reaction (min\(^{-1}\)) and \({C_{\mathrm{E}}}\) is the concentration of the active enzyme (M).

Next, the change in recombinant endo-inulinase dimensionless activity A it is also assumed that by the first-order kinetics [23,24,25] with the following equation

where \(k_{\mathrm{D}}\) is the deactivation process kinetic constants (min-1). Dimensionless activity of enzyme A is expressed by the equation

where \(C_{\mathrm{E}0}\) is initial concentration of the active enzyme (M).

The kinetic constants k and also, the deactivation constants \(k_{\mathrm{D}}\) depend on temperature T according the equation Arrhenius. The initial assumptions described by equations Eqs. 1, 2 and 3 allow to present the final form of the solution Eq. (4), which was presented in greater detail in the earlier work [26]. The Eq.(4) describes the change in the absolute activity of the enzyme A vs. temperature T

where \({T_{\mathrm{opt}}}\) is the optimum temperature at which recombinant endo-inulinase activity shows maximum activity (K), T is temperature (K), R is gas constant (8.314 J mol\(^{-1}\) K\(^{-1}\)), \({E_{\mathrm{D}}}\) is the activation energy of the deactivation process (J mol\(^{-1}\)) and dimensionless parameter B is determined from the relationship

where t is an inulin hydrolysis time of recombinant endo-inulinases (min) and \({k_{\mathrm{D}0}}\) is a pre-exponential factor the kinetic constant of the deactivation process of recombinant endo-inulinase (min\(^{-1}\)).

When the value of the deactivation energy \({E_{\mathrm{D}}}\) and the parameter B were known, the activation energy E is calculated from the equation

Based on equations Eq. (4) and Eq. (6), the values of deactivation energy \({E_{\mathrm{D}}}\), optimum temperatures \({T_{\mathrm{opt}}}\) and parameter B were determined in SigmaPlot 14.5 by using a method of nonlinear estimation [24, 26,27,28,29,30,31] in which the residual sum of squares RSS (Eq. (7)) was minimized

where A - recombinant endo-inulinase of various origins activity determined experimentally, \(A_{\mathrm{cal}}\left( E_{\mathrm{D}},B,T_{\mathrm{opt}}\right)\) - recombinant endo-inulinase of various origins activity calculated from Eq. (4).

Equations from Eq. (4) to Eq. (6) are used to determine the parameters E, \({E_{\mathrm{D}}}\) and \({T_{\mathrm{opt}}}\) of inulin hydrolysis by endo-inulinase Aspergillus niger [24], by exo-inulinases A. niger [27] and by recombinanat exo-inulinases A. niger [28], olive oil hydrolysis by lipase [3] and hydrolysis of starch by α-amylase Bacillus spp. [26] and porcine pancreas [29].

Results and discussion

The previously study presented the values optimum temperatures \({T_{\mathrm{opt}}}\), the activation energies E and deactivation energies \({E_{\mathrm{D}}}\) for inulin hydrolysis by endo-inulinases A. niger [24]. The main aim of this study was to determine the parameters \({T_{\mathrm{opt}}},\ {E}\), \({E_{\mathrm{D}}}\) for inulin hydrolysis by recombinant endo-inulinases A. niger [13,14,15,16,17]. Additionally, these parameters were analyzed for recombinant endo-inulinases of various origins [18,19,20]. Table 1 shows the conditions for measuring recombinant endo-inulinases activity, such as concentration of inulin, pH buffer and type, and time measurement. Measurements of endo-inulinase activity were determined using the Nelson-Somogyi method at 610 nm [13, 16] and dinitrosalicylic acid at 540 nm [15, 17,18,19,20].

Volkov et al. [13] analyzed the recombinant endo-inulinase obtained from gene A. niger strain into Penicillium canescens A3. Used strains have been obtained from the Laboratory of Enzyme Biotechnology in Bach Institute of Biochemistry in Russian Academy of Sciences.

Endo-inulinase gene from A. niger sp. F4 was loned and expressed in Yarrowia lipolytica Po1h by Liu et al. [15]. Used strains has been obtained from the Ocean University of China. Recombinant endo-inulinases A. niger degraded inulin with a high degree of polymerization.

High-yield endo-inulinase for fructooligosaccharides production from inulin was constructed by Mao et al. [16]. Used strains have been obtained also from the Ocean University of China. An inulin binding module (IBM) from a cycloinulinooligosaccharide fructanotransferase of Bacillus macerans CFC1 was fused into either N-(IBM-Endo) or C-(Endo-IBM) terminal of an endo-inulinase A. niger was fused.

Gen endo-inulinase from A. niger CICIM F0620 has been cloned and expressed in Pichia pastoris by He et al. [17]. Used strains have been obtained from the State Key Laboratory of Food Science and Technology at Jiangnan University in China. The recombinant endo-inulinase activity was 4.18 times that observed using the native gene.

Endo-inulinase gene from Arthrobacter sp. S37 was cloned and expressed in Yarrowia lipolytica Po1h by Li et al. [18]. Endo Arthrobacter sp. S37 strain (collection number 2E001892) and Y. lipolytica Po1h strain (collection number 2E0189) were used from the Marine Microorganisms Culture Collection of China (MCCC). The endo-inulinase activity produced by the recombinant Y. lipolytica was very high. The optimum pH of the recombinant endo-inulinase Y. lipolytica was 4 while, the native endo-inulinase Arthrobacter sp. was optimum in pH at 7.

Endo-inulinase gen from Pseudomonas mucidolens was cloned and expressed into S. cerevisiae EBY 100 by Hyun-Chul et al. [19]. Used strains have been obtained from own the Laboratory of Department of Biotechnology and Bioengineering, Dong-Eui University, Korea. The recombinant endo-inulinase S. cerevisiae was achieved the highest yield 71.2 of oligosaccharides from inulin after 30 h of reaction.

Endo-inulinase gene from Penicillium restrictum A191 was cloned and expressed in E. coli by Puratos [20]. Used strains by Puratos [20] has been obtained from the BCCM/MUCL Agro-food and Environmental Fungal Collection, Université Catholique de Louvain, Belgium, the number MUCL 42612. The optimum temperature of the recombinant endo-inulinase E. coli was \(65\,^{\circ }\)C.

The effect of temperature on the recombinant endo-inulinases activity

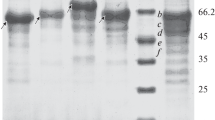

Based on experimental data on the change in the activity of recombinant endo-inulinase from A. niger [13,14,15,16,17] and of recombinant endo-inulinase of various origins [18,19,20] values of deactivation energy \({E_{\mathrm{D}}}\), B parameter and optimum temperature \({T_{\mathrm{opt}}}\) are determined from Eq. (4) and listed in Table 2. Figures 1–9 show the experimental data on the activity of recombinant endo-inulinases.

Knowing the deactivation energy \({E_{\mathrm{D}}}\) and the parameter B values, the activation energy E is calculated from Eq. (6). The obtained results \({T_{\mathrm{opt}}}\), \({E_{\mathrm{D}}}\), B and E for recombinant endo-inulinases A. niger and different origins activity were shown and presented according to the increasing values \({T_{\mathrm{opt}}}\) in Table 2.

Table 3 shows the statistical data calculated for obtained the parameters \({E_{\mathrm{D}}}\), \({T_{\mathrm{opt}}}\) and B of recombinant endo-inulinases.

The residual sum of squares RSS were obtained below 0.153, the high regression coefficients \(R^2\) were above 0.95 for recombinant endo-inulinase A. niger. F-Fisher test values were in the range from 53.92 to 932.77 with a low probability value P were below 0.0013.

For recombinant endo-inulinase of various origins the residual sum of squares RSS were obtained below 0.088, the high regression coefficients \(R^2\) were above 0.97. The statistical data in Table 3 confirmed that it was appropriate to apply Eq.(4) when determining the parameters \({E_{\mathrm{D}}}\), \({T_{\mathrm{opt}}}\) and B. F-Fisher test values were in the range from 72.07 to 349.48 with a low probability value P below 0.0007.

Also, Figs. 1-9 present standard deviation errors for experimental points, with the 95% confidence bands for the obtained curves.

The values of activation energy E

The valeues of activation energies E were obtained in the range from \({22.08 \pm 13.94}\) kJ mol\(^{-1}\) to \({62.62 \pm 17.24}\) kJ mol\(^{-1}\) and in the range from \({27.21 \pm 6.95}\) kJ mol\(^{-1}\) to \({92.69 \pm 15.31}\) kJ mol\(^{-1}\) for recombinant endo-inulinase A. niger and various origins, respectively.

Table 2 shows, that the values E estimated for recombinant endo-inulinases from A. niger F4 (Endo-IBM) - Fig. 5, was lowest about 60% than recombinant endo-inulinases from A. niger F4 (IBM-Endo) - Fig. 4 [16].

For the commercial endo-inulinases A. niger in previous work [24], it was found that E is in the range from \({23.53 \pm 3.20}\) kJ mol\(^{-1}\) to \({50.66 \pm 3.61}\) kJ mol\(^{-1}\).

The endo-inulinase Arthrobacter sp. S37 in Yarrowia lipolytica Po1h [18] is characterized by the highest the value E of among analyzed cases.

The values of deactivation energy \({E_{\mathrm{D}}}\)

The values of deactivation energies \({E_{\mathrm{D}}}\) of recombinant endo-inulinase A. niger were obtained in the range from \({143.24 \pm 9.87}\) kJ mol\(^{-1}\) to \({301.95 \pm 95.81}\) kJ mol\(^{-1}\) (Table 2). These values \({E_{\mathrm{D}}}\) are higher than the values obtained for non-recombinant endo-inulinases A. niger shown in previous work [24] which the values \({E_{\mathrm{D}}}\) were in the range from \({88.42 \pm 5.03}\) kJ mol\(^{-1}\) to \({142.87 \pm 2.75}\) kJ mol\(^{-1}\).

The values \({E_{\mathrm{D}}}\) of recombinant endo-inulinases from A. niger were higher about 40% (IBM-Endo) and 100% (Endo-IBM) [16] than the values \({E_{\mathrm{D}}}\) obtained for non-recombinant endo-inulinase A. niger equals \({150.89 \pm 40.72}\) kJ mol\(^{-1}\) calculated from Eq. (4).

The deactivation energy \({E_{\mathrm{D}}}\) of the commercial inulinase of Aspergillus niger (Fructozyme LTM, Novozymes, Denmark) for marked \({k_{\mathrm{D}}}\) Ricca et al. [22] was calculated from the Arrhenius equation as equal to 313.47 kJ mol\(^{-1}\).

The values of deactivation energies \({E_{\mathrm{D}}}\) for recombinant endo-inulinases of various origins were obtained ine the range from \({168.58 \pm 7.78}\) kJ mol\(^{-1}\) to \({295.80 \pm 18.78}\) kJ mol\(^{-1}\) (Table 2).

In most of analyzed cases, the recombinant endo-inulinases A. niger have higher values of \({E_{\mathrm{D}}}\), so they are more thermally stable than, that no-recombinant endo-inulinases A. niger [24].

When the \({E_{\mathrm{D}}}/{E}\) relationship is known for an A. niger and of various origins recombinant endo-inulinases, one can choose the enzyme with the highest thermal stability. The higher the \({E_{\mathrm{D}}}/{E}\) value of a given recombinant endo-inulinases, the more stable the enzyme is. The better activity, thermostability was obtained for the C-terminal fusion (Endo-IBM) recombinant endo-inulinase A. niger [16]. In this work, the value of the \({E_{\mathrm{D}}}/{E}\) is equal to 13.67 but also this value is almost 2.5 yields higher than form for the N-terminal fusion (IBM-Endo) recombinant endo-inulinase A. niger [16]. Among recombinant endo-inulinase of various origins, the most stable is Pseudomonas mucidolens into S. cerevisiae [19] with the value \({E_{\mathrm{D}}}/{E}\) equals 10.87, but with low value \({T_{\mathrm{opt}}}\) equals \({319.57 \pm 0.57}\) K.

The values of optimum temperature \({T_{\mathrm{opt}}}\)

The values of optimum temperature \({T_{\mathrm{opt}}}\) for recombinant endo-inulinase from A. niger were determined in the range from \({328.67 \pm 1.32}\) K to \({335.94 \pm 1.22}\) K [13,14,15,16,17]. This values \({T_{\mathrm{opt}}}\) are higher even \(18\,^{\circ }\)C than determined for no-recombinant endo-inulinases from A. niger [24]. The estimated values of the optimum temperatures \({T_{\mathrm{opt}}}\) for recombinant endo-inulinase of various origins [18,19,20] were found to be in the range from \({319.41 \pm 0.85}\) K to \({338.53 \pm 0.45}\) K.

Based on the analyses, it was observed that recombinant endo-inulinase A. niger at Fig. 1, Fig. 3, Fig. 4 and recombinant endo-inulinase E. coli at Fig. 9, are characterized by the determined optimal temperature values \({T_{\mathrm{opt}}}\), correspond to the optimum temperature determined experimentally. Additionally, the statistical parameters (F–Fisher test values and probability value P) for these measurements are the highest. Whereas for recombinant endo-inulinase Aspergillus niger (Endo-IBM) at Fig. 5, recombinant endo-inulinase Yarrowia lipolytica at Fig. 7 and recombinant endo-inulinase S. cerevisiae at Fig. 8, estimated optimum temperatures \({T_{\mathrm{opt}}}\) are about \(3.5\,^{\circ }\)C lower than the values determined experimentally. In the applied method of determining the parameters \({E_{\mathrm{D}}}\), \({T_{\mathrm{opt}}}\), B with Eq. (4) all measuring points that contribute to the final \({T_{\mathrm{opt}}}\) result are included.

The highest optimum temperature \({T_{\mathrm{opt}}}\) has been determined for the recombinant endo-inulinase Penicillium restrictum A191 in E. coli by measurements Puratos [20]. That value \({T_{\mathrm{opt}}}\) is most highest than those described in the available literature. Higher values \({T_{\mathrm{opt}}}\) obtained for recombinant endo-inulinases Aspergillus niger. The maximal activities of recombinant endo-inulinase A. niger F4 by expressed Bacillus macerans CFC1 [16] and A. niger CICIM F0620 in Pichia pastoris [17] are at temperatures \({335.94 \pm 1.22}\) K and \({334.81 \pm 1.08}\) K, respectively.

Conclusions

The values of parameters the activation energies E and the deactivation energies \({E_{\mathrm{D}}}\) and the optimum temperatures \({T_{\mathrm{opt}}}\) of inulin hydrolysis by recombinant endo-inulinases from Aspergillus niger and from various origins were determined. The differences in the estimated values of the activation energy E are equal to about 40 kJ mol\(^{-1}\) and about 70 kJ mol\(^{-1}\) for recombinant endo-inulinases from A. niger and from various origins, respectively. The differences in the estimated values of deactivation energy \({E_{\mathrm{D}}}\) are equal to about 160 kJ mol\(^{-1}\) and about 130 kJ mol\(^{-1}\) for recombinant endo-inulinase A. niger and from various origins. For the optimum temperatures \({T_{\mathrm{opt}}}\), the difference between the obtained values is about \(7.5\,^{\circ }\)C and about \(19\,^{\circ }\)C for recombinant endo-inulinases from A. niger and from various origins. The recombinant endo-inulinases A. niger were characterized by the higher values of optimum temperature \({T_{\mathrm{opt}}}\) as well as higher values of energy \({E_{\mathrm{D}}}\) compare to the values of recombinant endo-inulinases from various origins and also no-recombinant endo-inulinases A. niger. Knowledge of parameters E, \({E_{\mathrm{D}}}\), \({T_{\mathrm{opt}}}\) for recombinant endo-inulinase from a various origin of yeast and bacteria strains will allow design, modeling and optimization of inulin hydrolysis.

Change history

06 May 2024

A Correction to this paper has been published: https://doi.org/10.1007/s10973-024-13212-6

References

Ghaderi F, Nemati M, Siahi-Shadbad MR, Valizadeh H, Monajjemzadeh F. Evaluation of activation energy conformity derived from modelfree non-isothermal predictions and Arrhenius isothermal results. J Therm Anal Calorim. 2017;130:1417–27.

S̆imon P, Dubaj T, Cibulková Z. Equivalence of the Arrhenius and non-Arrhenian temperature functions in the temperature range of measurement. J Therm Anal Calorim. 2015;120:231–8.

Miłek J. The activation energies and optimum temperatures of olive oil hydrolysis by lipase porcine pancreas. Ecol Chem Eng S. 2021;28(3):389–98.

Espinosa-Andrews H, Rodríguez-Rodríguez R. Water state diagram and thermal properties of fructans powders. J Therm Anal Calorim. 2018;132:197–204.

Chi ZM, Zhang T, Cao TS, Liu XY, Cui W, Zhao CH. Biotechnological potential of inulin for bioprocesses. Bioresour Technol. 2011;102:4295–303.

Xu Y, Zheng Z, Xu Q, Yong Q, Ouyang J. Efficient conversion of inulin to inulooligosaccharides through endoinulinase from Aspergillus niger. J Agric Food Chem. 2016;64:2612–8.

Singh P, Gill PK. Production of inulinases: recent advances. Food Technol Biotechnol. 2006;44:151–62.

Chi Z, Chi Z, Zhang T, Liu G, Yue L. Inulinase-expressing microorganisms and applications of inulinases. Appl Microbiol Biotechnol. 2009;82:211–20.

Pankiewicz U, Jamroz J. Accumulation of selenium and changes in the activity of inulinase and catalase in the cells of Kluyveromyces marxianus on pulsed electric field treatment. J Microbiol Biotechnol. 2010;20:1101–6.

Fernandes P. Marine enzymes and food industry: insight on existing and potential interactions. Front Mar Sci. 2014;46(1):1–18.

Han Y-Z, Zhou C-C, Xu Y-Y, Yao J-X, Chi Z, Chi Z-M, Liu G-L. High-efficient production of fructo-oligosaccharides from inulin by a two-stage bioprocess using an engineered Yarrowia lipolytica strain. Carbohydr Polym. 2017;173:592–9.

Singh RS, Chauhan K. Production, purification, characterization and applications of fungal inulinases. Current Biotechnol. 2018;7:242–60.

Volkov PV, Sinitsyna OA, Fedorova EA, Rojkova AM, Satrutdinov AD, Zorov IN, Okunev ON, Gusakov AV, Sinitsyn AP. Isolation and properties of recombinant inulinases from Aspergillus sp. Biochemistry. 2012;77:492–501.

Megazyme, Endo inulinase Aspergillus niger. (technical information) www.megazyme.com/documents/Booklet/E-ENDOIAN DATA.pdf. Accessed 2021;Feb:12.

Liu Y, Zhou S-H, Cheng Y-R, Chi Z, Chi Z-M, Liu G-L. Synergistic effect between the recombinant exo-inulinase and endo-inulinase on inulin hydrolysis. J Mol Catal B: Enzym. 2016;128:27–38.

Mao W, Han Y, Wang X, Zhao X, Chi Z, Chi Z, Liu G. A new engineered endo-inulinase with improved activity and thermostability: Application in the production of prebiotic fructooligosaccharides from inulin. Food Chem. 2019;294:293–301.

He M, Wu D, Wu J, Chen J. Enhanced expression of endoinulinase from Aspergillus niger by codon optimization in Pichia pastoris and its application in inulooligosaccharide production. J Ind Microbiol Biotechnol. 2014;41:105–14.

Li Y, Liu G-L, Wang K, Chi Z-M, Madzak C. Overexpression of the endo-inulinase gene from Arthrobacter sp. S37 in Yarrowia lipolytica and characterization of the recombinant endo-inulinase. J Mol Catal B: Enzymatic. 2012;74:109–15.

Hyun-Chul K, Kim H-J, Choi W-B, Nam S-W. Inulooligosaccharide production from inulin by Saccharomyces cerevisiae strain displaying cell-surface endoinulinase. J Microbiol Biotechnol. 2006;16(3):360–7.

Puratos NV, 2007. Enzyme or cell preparation with inulinase activity. EP 1 205 554 B1. https://patents.google.com/patent/EP1205554B1/en. Accessed 2021;Feb:12.

Nguyen QD, Rezessy-Szabo JM, Czukor B, Hoschke A. Continuous production of oligofructose syrup from Jerusalem artichoke juice by immobilized endo-inulinase. Process Biochem. 2011;46:298–303.

Ricca E, Calabrŏ V, Curcio S, Iorio G. Optimization of inulin hydrolysis by inulinase accounting for enzyme time- and temperature-dependent deactivation. Biochem Eng J. 2009;48:81–6.

Karimi M, Chaudhury I, Jianjun C, Safari M, Sadeghi R, Habibi-Rezaei M, Kokini J. Immobilization of endo-inulinase on non-porous aminofunctionalized silica nanoparticles. J Mol Catal B: Enzymatic. 2014;104:48–55.

Miłek J. Determination the optimum temperatures and activation energies of inulin hydrolysis by endo-inulinase Aspergillus niger. Chem Proc Eng. 2020;41:229–36.

Torabizadeh H, Mahmoudi A. Inulin hydrolysis by inulinase immobilized covalently on magnetic nanoparticles prepared with wheat gluten hydrolysates. Biotechnol Rep. 2018;17:97–103.

Miłek J, Lamkiewicz J. The starch hydrolysis by \(\alpha\)-amylase Bacillus spp.: an estimation of the optimum temperatures, the activation and deactivation energies. J Therm Anal Calorim. 2022. https://doi.org/10.1007/s10973-xxx-xxxxx-x.

Miłek J. Application of the new method to determine of the kinetic parameters of inulin hydrolysis by exo-inulinase Aspergillus niger. J Therm Anal Calorim. 2022;147:1374–7. https://doi.org/10.1007/s10973-020-10495-3.

Miłek J. The inulin hydrolysis by recombinant exo-inulinases - determining the optimum temperatures and activation energies. J Therm Anal Calorim. 2022;147:8061–7. https://doi.org/10.1007/s10973-021-11086-6.

Miłek J. Determination of activation energies and the optimum temperatures of starch hydrolysis by \(\alpha\)-amylase from porcine pancreas. Molecules. 2021;26(4117):1–9.

Maleki A, Haghighi A, Shahrestani MI, Abdelmalek Z. Applying different types of artificial neural network for modeling thermal conductivity of nanofluids containing silica particles. J Therm Anal Calorim. 2020. https://doi.org/10.1007/s10973-020-09541-x.

Kayran S, Doymaz I. Determination of drying kinetics and physicochemical characterization of apricot pomace in hot-air dryer. J Therm Anal Calorim. 2017;130:1163–70.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The author declares that she has no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Miłek, J. Recombinant endo-inulinases: determination the activation and deactivation energies and optimum temperatures in inulin hydrolysis. J Therm Anal Calorim 148, 859–866 (2023). https://doi.org/10.1007/s10973-022-11809-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-022-11809-3