Abstract

In this study, the stability, thermal conductivity and viscosity of carbide-derived carbon antifreeze thermal fluids were explored. The study also compares the results between antifreeze suspensions prepared using oxidized CDC and emulsified CDC using gum arabic. At first, the raw CDC was oxidized with oxygen by acid treatment and the Fourier transform infrared spectroscopy and X-ray photoelectron spectroscopy results revealed an increase in the oxygen content and oxygen functional groups in oxidized CDC. The two-step method was utilized for CDC thermal fluids preparation. Sedimentation visualization and zeta potential testing were employed to investigate stability of nanofluids with time. The stability results revealed that the oxidized CDC has better stability and higher zeta potential values than the emulsified CDCs; however, both mixtures demonstrated stable suspensions for three months. Viscosity measurements showed that the gum arabic CDC suspensions have a higher viscosity than the oxidized CDC; the viscosity was growing with CDC and gum arabic loadings and decreased with temperature. The thermal conductivity analysis was carried out using a lambda analyzer in a temperature range of 288–338 K with a CDC mass loading range of 0.05–0.3 mass%. The experimental outcomes demonstrated that oxidized CDC suspension has better thermal conductivity than gum arabic emulsified CDC. The highest improvement in thermal conductivity was 25.6% using 0.3 mass% of oxidized CDC at 338 K. Moreover, raising the gum arabic mass loading was found to reduce the thermal conductivity enhancement. Therefore, according to the results, the oxidized CDC antifreeze suspensions can perform better than the emulsified CDC.

Graphical abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The harmony between technological developments in materials science and energy saving in cooling systems and heat exchanger applications undoubtedly leads to improved energy sustainability. For energy savings, researchers are interested to improve the performance of all of the heating/cooling system components such as changing the cooling/heating system design and improving the properties of the metals used in equipment design. In the last two decades, the research on changing the heating or antifreeze liquids properties gained a lot of concern. Antifreeze is usually a mixture of glycols and water, such as propylene glycol (PG) or ethylene glycol (EG) [1]. Glycols are added to water to reduce the freezing temperature and increase the boiling point for the purpose of increasing the use of liquid water in applications or conditions where the temperature is less than zero Celsius [2]. Although some of the challenges have been reduced by adding glycol, the thermal properties of water, especially the thermal conductivity (k), have been reduced. Nanofluids or thermal fluids formed by adding solid particles of nano- to micro-scale dimensions to conventional coolants such as antifreeze have maintained high k values [3].

Research progress in nano/thermal fluids is continuously increasing [4, 5]. The research began with investigating the effect of adding one type of solid particulates on the k and viscosity of traditional heating fluids. Over the years, the stability of nanoparticles has posed a significant challenge to scientists, which has been improved in several ways, most notably the use of surfactants, chemical modification, pH adjustment and ultrahigh sonication [6]. Many other factors have also attracted researchers’ attention, such as studying the effect of nanoparticle mass loading, temperature, and sonication time on the amount of increase in viscosity and the k enhancement [7, 8]. In the last decade, research in this field have intensified to study the effect of two types of additives on physical and thermal characteristics of the base fluids (i.e., hybrid nanofluids) [9]. Some researchers have proven that by adding two types of nanoparticles, the amount of improvement in k is more than using one type [10]. For example, Pourrajab et. al [11] obtained a 33.45% enhancement in overall heat transfer using 0.023 mass% of silica/Cu composite in water-based hybrid nanofluid. Moreover, the same research group obtained a 24.24% enhancement in k using 0.075 mass% at 323 K using the same hybrid nanofluid [12]. Furthermore, using 0.064 mass% of Cu/silica nanocomposite achieved 22.46% enhancement in the k of EG-based hybrid nanofluid [13]. Additionally, the k of water has improved by 47.3% using a hybrid nanofluid containing (0.05 vol% of silver nanoparticles and 0.16 oxidized multi wall carbon nanotubes-MWCNTs) [14]. Despite this, the biggest concern of nano/thermal fluids is the stability of suspended particles [15].

Several types of particles (metals, metal oxides, carbides, carbon-based materials and polymeric materials) were utilized to enhance the thermophysical characteristics of base fluids [16]. Among these particles, carbonaceous materials were of significant interest in the area of nano/thermal fluids because of their high k [17, 18]. It has been stated that the k of carbonaceous materials between 2000 and 2500 W m-1 K-1 [19]. There are many carbon-based materials used in this field, such as graphene, graphene oxide, graphene nanopellets, graphite, nanodiamond, MWCNTs, double-walled, few walled and single walled (DWCNTs, FWCNTs and SWCNTs). Table 1 lists the stability, k and viscosity of antifreeze nanofluids containing carbon-based materials. The size of CNTs and graphene comes in nanodimensions, which have higher stability than microparticles due to their mass and size. However, larger particles (up to micrometers) such as graphite have also been shown to improve k. Ma et al. [20] reached a 25% improvement in k of water utilizing 0.4 vol% of graphite flakes. Shaikh et al. [19] concluded that utilizing 1 vol% of exfoliated graphite in polyalphaolefin oil, the k increased by 130%. Both studies concluded that larger particles can form bigger clusters and percolation networks, improving the bulk’s k. In order to have a good and applicable thermal/nanofluids, the nanofluid should have high k enhancement, long-term stability as well as low viscosity. Viscosity is cross-linked to the pumping power, and hence the energy savings by improving the k must be corresponding to little increase in viscosity.

Owing to the robust van der Waals forces among carbon molecules, the carbonaceous particles have a tendency to aggregate and sediment. As such, efforts were made to enhance the durability of carbonaceous particulates in base fluids to produce long-term stable suspensions. The use of surfactants and surface functionalization were widely used for the stability enhancement of carbon-based materials. Both methods aim to increase the surface charge (zeta potential) of the particles, which leads to an increase in their stability. Several surfactants including polyvinylpyrrolidone (PVP), gum arabic (GA), sodium dodecylbenzene sulfonate (SDBS), and sodium dodecylbenzene (SDS) were used for stabilizations. The addition of surfactants was found to inhibit the k enhancement of nanofluids. In a comparison study, Almanassra et al. [28] found that GA was better than SDS and polyethylene glycol (PEG) for CNTs suspended nanofluids. GA not only has the best stability (up to 6 months for MWCNTs), but it has the lowest viscosity increase and the lowest negative effect on k enhancement [28]. Surface functionalization by acid treatment (sulfuric acid, phosphoric acid and nitric acid) was also found to significantly improve the stability of MWCNTs, SWCNTs and graphene nanopellets in water. Through acid treatment, several oxygen functional groups such as carboxylic, alcohols, carbonyls and carboxyl’s are created on the surface of carbon atoms, which improve the particle charge and hydrophilicity properties of the carbon material in the aqueous solution that in turn enhance their stability [29].

Carbide-derived carbon (CDC) is a carbon originated material synthesized through thermal and chemical treatment of several carbides such as titanium carbide and silicon carbide [30]. The CDC has attracted noteworthy attention in different applications due to its tunable structure, high surface area and can be produced in different sized and pore diameters [30]. As such, the CDC has proven its effectiveness in many applications, including water treatment (adsorption and membranes) [31, 32], capacitors [33], thermal fluids [34] and fuel cells [35]. According to the literature review, there were no experimental reports on the stability, thermal and physical characteristics of CDC/antifreeze suspensions.

The main goals of the current study are: (i) oxidize the surface of CDC, (ii) characterize the surface of raw and oxidized CDC, (iii) preparing CDC/antifreeze thermal fluids with oxidized CDC and emulsified CDC with GA, (iv) investigates the stability, thermal and physical characteristics of oxidized and emulsified CDC antifreeze thermal fluids and (v) proposing the best CDC thermal fluid (or nanofluid) in terms of the highest k and lower viscosity.

Material and methods

Materials

The CDC particles (purity ~ 98%, Category: Nanopore U) were obtained from Carbon-Ukraine® (Ukraine). As defined by the producer, the CDC particles were made by the treatment of titanium carbide (TiC) fine particles. Concisely, the TiC was heated to 1,073 K under inert gas. Then, the TiC powder was treated with Cl2 gas at 1,073 K for 6.5 h followed by H2 gas treatment at 873 K for 2 h.

The following compounds/chemical were purchased: sulfuric acid (H2SO4, 94.5%) from VWR Chemicals® (Radnor, PA, USA); phosphoric acid (H3PO4, ≥ 85%) from Sigma-Aldrich® (Switzerland); hydrochloric acid (HCl, 37%) from Sigma-Aldrich® (St. Louis, MO, USA); potassium permanganate (KMnO4, ≥ 99%) from Honeywell Fluka® (Morris Plains, NJ, USA); hydrogen peroxide (H2O2, 30%) from VMR chemicals® (France); gum arabic (approximate molar mass of 250 kDa) from Sigma-Aldrich (USA); and ethylene glycol (C2H6O2, ≥ 99%) from Merck (Darmstadt, Germany). Deionized water (DW) was used for thermal fluids preparation and carboxylation process. All chemicals were utilized without further treatment or purification.

Oxidation/carboxylation of CDC

In a classic experiment, CDC powder (1 g) was added steadily in 100 cm3 of an acid mixture (40 cm3 of H3PO4 and 60 cm3 of H2SO4) in a 1,000 cm3 beaker surrounded by ice with continuous stirring. Next, 9 g of KMnO4 were gradually added while keeping the temperature under 278 K. The reaction vessel temperature was then raised to 318 ± 5 K for 2.5 h utilizing an oil path. The reaction was shifted again to the ice media, and 100 cm3 of DW was slowly added to the mixture while keeping the stirring and temperature at 288 ± 5 K. The reaction vessel was then maintained at 353 ± 5 K for 2 h with continuous stirring in the oil path. The reaction was taken to an end by the concurrent steady addition of 20 cm3 of ice-cold H2O2 and 150 cm3 chilled DW. A color change from brown to light green color can indicate the reaction completion. Subsequently, the resultant is mixed with 10 vol% diluted HCl solution using a volumetric share (50% of the diluted HCl and 50% of the reaction liquid). Then, the contents were centrifuged at 10,000 rpm for 20 min at 295 K. The wet precipitate product was then separated and washed with DW numerous times till getting neutral pH was achieved. Finally, the oxidized CDC was oven-dried over a night at 353 K.

Characterization of CDC

The morphological analysis of raw and carboxylated CDC was inspected by field emission scanning electron microscopy (type: FESEM, FEI Versa 3D dual beam, ThermoFisher Scientific, USA). The TEM (transmission electron microscope) imaging was carried out using HR-TEM, (FEI Talos F200X, ThermoFisher Scientific, Billerica, MA, USA) operating at 200 kV. Samples were sonicated in isopropyl alcohol for 10 min for proper spreading, then 0.02 cm3 of the solution was dropped onto a carbon-coated grid and allowed to dry at 295 K before imaging. The Fourier transform infrared spectroscopy (FTIR, manufacturer: ThermoFisher Scientific, Nicolet iS10, USA) analysis was conducted to investigate the surface functional groups. For FTIR analysis, samples were oven-dried for 24 h at 333 K followed by grinding, and then the spectra were recorded in a wavelength between 600 and 4000 cm-1. The dynamic light scattering measurements (DLS) is utilized for particle size distribution analysis, and the DLS analysis was studied by Zetasizer (type: Nano ZS 90, Malvern Instruments, UK). The chemical state exploration was conducted by X-ray photoelectron spectroscopy (XPS) technique (Escalab 250 Xi, ThermoFisher Scientific, UK). The k-alpha monochromated X-ray source energy is 1486.68 eV, and the pass energy is 20 eV for high-resolution scans and 100 eV for survey scans. The thermal gravimetric analysis (TGA) of the raw CDC was carried out using (TGA type Jupiter, model STA 449, F5, NETZSCH, Germany). Briefly, 30 mg of CDC powder placed in alumina crucible and then raise the temperature from 293 to 1,273 K using a heating rate of 20 K min-1 under the flowrate of oxygen 30 cm3 min-1.

Preparation of antifreeze thermal fluids

The antifreeze was prepared by a volumetric ratio of 40%:60% ethylene glycol to water. Gum arabic was used as a dispersant to enhance the CDC particles stability in the EG/water mixture. The two-step method was utilized for CDC thermal fluids preparation. The desired amounts of the raw or oxidized CDC and GA were weighed and dispersed in a desired volume of DW. Next, the liquid thermal fluid was sonicated for 1 h using a probe sonicator (Fisher scientific sonicator, USA) at a frequency of 20 kHz, pulse (4:2), amplitude 60% and power of 500 watts.

Three different mass loadings (0.05, 0.1 and 0.3 mass%) were prepared to investigate the CDC thermal fluids. The oxidized CDC thermal fluids were prepared without GA, while it was used for raw CDC thermal fluids. To investigate the effect of GA, the GA was added to raw CDC thermal fluids once at an equal concentration of CDC (i.e., ratio 1:1) and once at twice the concentration of the CDC (i.e., ratio 1:2).

Stability of thermal fluids

The stability of the thermal fluids was observed by computing the zeta potential of the suspended particles (oxidized and emulsified CDCs) with time using the Zetasizer (Nano ZS 90, Malvern Instruments, UK). This equipment is functioned with an inside laser of 0.4 mW. Zeta readings were carried out at pH 7 and 295 K; each reading repeated 3 times, and mean values were displayed. The suspended particles with zeta potential values of > 30 mV or < –30 mV are considered to have moderate stability. Table 2 elucidates the zeta potential values and their corresponding signs of stability.

The stability was also investigated by observing the signs of CDC particles agglomeration with time. Images were recorded for the samples at static conditions and room temperature at time zero and after 90 days.

Viscosity measurements

The discovery hybrid rheometer, DHR (category HR-2, TA Instruments, USA), was used for the viscosity measurements of the thermal fluids. Viscosity experiments were conducted by injecting a sample of the thermal fluid by syringe in a cavity between the moving cone and static plate. The viscosity is recorded based on the torque between the cone and the plate. Measurements were obtained by varying the temperature between 288 and 338 K using a 5 K min-1 as a heating rate. Each run was conducted 3 times, and mean numbers were displayed. The standard error was between 3 and 5%. The relative viscosity increase was calculated according to the following equation:

where \(\mu_{\text{TF}}\) (cp) is the dynamic viscosity of the thermal fluid, and \(\mu_{\text{BF}}\) (cp) represents the dynamic viscosity of the base fluid.

Thermal conductivity measurements

The LAMBDA thermal conductivity tester (manufacturer: PSL Systemtechnik, Germany) was used for the k measurements of the CDC antifreeze thermal fluids. The experiments were carried out over a temperature range of 288 to 338 K. Each run was repeated 20 times, and the average values were presented. Lambda instrument involves two major parts, the thermostat LM30190, which contains the measuring head and the sample cup. The second part is the screen and the temperature set point settings. The LAMBDA instrument works on the transient hot-wire principle. The k enhancement was obtained using the following equation:

where \(k_{\text{TF}}\) (W m−1 K−1) is the k of the thermal fluid, and \(k_{\text{BF}}\) (W m-1 K−1) represents the k of the base fluid.

Experimental data accuracy analysis

For zeta potential measurements, the equipment was calibrated using a standard solution provided by Malvern company. The equipment was calibrated before conducting each set of experimental data. The experimental error for zeta measurements was between 3.9 and 4.5%. For viscosity and k measurements, the base fluid analysis was conducted at the beginning and compared with the theoretical values available in the literature. In viscosity analysis, each reading was repeated three times, and the maximum error was less than 5% in comparison with the theoretical measurements. For k analysis, the maximum error of the base fluid analysis was 2.2%. Moreover, in our analysis, each run was repeated 20 times in PSL Systemtechnik laboratories, Germany, and the percent error in the measurements was between 2.1 and 3.0%.

Results and discussions

CDC characterization

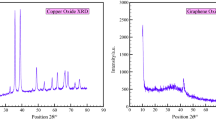

X-Ray photoelectron spectroscopy (XPS)

The XPS results of raw and oxidized CDC are shown in Fig. 1. The survey spectra reveal that the raw CDC (R-CDC) surface consists of approximately 97% at. of carbon, 2.5% at. of O and a small impurity of Cl around 0.5% at. This confirms the high quality of the R-CDC sample. On the other hand, the oxidized CDC (O-CDC) consists of approximately 85% at. of carbon, 11% at. of oxygen as well as the presence of impurities such as Si 1% at. mainly as SiO2, Cl 1.5% at. N 1% at. both elements are mainly forming bonds with carbon. This reveals that the CDC composition slightly changed toward a more oxidized state while incorporating some minor impurities.

The chemical state analysis for as-received and modified CDC samples were conducted using high-resolution spectra of C 1 s and O 1 s, which revealed the presence of the following chemical states: C–C/C = C/C–H, C–O, C = O and O–C = O for carbon and O–C = O, C = O, C–O–H, C–O–C and SiO2 (only for treated CDC) as given in Table 3.

O 1 s spectra reveal the presence of the following chemical states O-C = O, C = O, C–O–H, C–O–C for untreated and treated CDC samples, while SiO2 was only found in treated CDC sample. C 1 s spectrum for raw CDC reveals that the significant presence of sp2 along with sp3 which is mainly a mixture of C = C/C–C/C–H due to asymmetric peak shape and the satellite peak above 290 eV. The C 1 s spectrum of oxidized CDC shows a similar peak shape of raw CDC, confirming the significant presence of sp2 and sp3 (C = C/C–C/C–H). These observations are in line with FTIR results which will be discussed later. The other chemical states of carbon are C–O, C = O, O–C = O and C–Cl for both raw and oxidized CDC. In addition, oxidized CDC also has C–N chemical state. These findings suggest that the treatment of the CDC has increased the oxidation state by incorporating more functional groups at the surface, mainly C–O, C = O, O–C = O [36, 37].

SEM and TEM

The morphological properties of raw and oxidized CDC were investigated by SEM and the monographs are shown in Fig. 2. The shape of the oxidized looks similar to the raw CDC, indicating the preservation of the surface and shape throughout the oxidation process. Both CDCs demonstrated irregular shapes with homogenous and smooth surfaces. It can be noticed that the oxidation process increased the distribution of the CDC clusters, which is observed in Fig. 2b, as the sizes of the oxidized CDC blocks are relatively smaller than the raw CDC. It is worth mentioning that the oxidation process worked to loosen some CDC blocks and not break the general structure of the main form. The SEM images also show that the size of raw CDC particles is between 160 nm to more than 1 µm, while in the case of oxidized CDC, the sizes were relatively less but with an increase in the density of the smaller CDC particles; despite this, the large blocks still exist in the oxidized CDC.

Field emission scanning electron microscopy (FESEM) images for raw CDC a, oxidized CDC b [34]

The TEM photographs of raw and oxidized CDC (Fig. 3) comply with the SEM data. The CDC demonstrated shape preservation after oxidation with a slightly wider particle size distribution. The TEM images also show that the CDC has an amorphous surface with some dark spots at the center of the particles, representing the unconverted titanium carbide.

Fourier transform infrared spectroscopy (FTIR)

The FTIR analysis was studied to explore the functional groups of the raw CDC and the created functional group onto the CDC surface after oxidation. Figure 4 elucidates the FTIR spectra of as-received and oxidized CDC in a wavelength range of 500 to 4000 cm-1. As a result of oxidation, a new characteristic band has appeared on the oxidized CDC at the wavelength 1724 cm-1 which is ascribed to the C = O stretching vibration in carbonyls or carboxyls. The adsorptions at 1090 and 1250 cm-1 at the oxidized and raw CDCs represent the C–O stretching with a significant increase in the intensity of oxidized CDC. These observations confirm the successful oxidation of CDC by acid treatment. The peaks at 1624 and 1574 cm-1 are attributed to the aromatic C = C stretching vibration. The 2350 cm-1 peak in both curves assigned to the atmospheric carbon dioxide O = C = O. The adsorptions at 2860, 2930, 2940 cm-1 are credited to the aliphatic C–H stretching mode, while the strong, wide peaks at 3430 and 3450 cm-1 represent the H–O stretching vibration of the absorbed ambient atmospheric water.

Dynamic light scattering (DLS)

The DLS technique was used to investigate the particle size distribution, and the results are clarified in Fig. 5. As it can be seen, both CDCs have demonstrated two peaks of particle size, which indicate that the CDC particles are not uniform in size, but it is a mixture of particles size of about 100 nm up to 1 µm. Considering the effect of the oxidation process, the particle size of raw CDC ranges between 146 ± 40 nm and 568 ± 320 nm, while the oxidized CDC size ranges between 108 ± 21 nm and 488 ± 300 nm. These results confirm the TEM and SEM observations.

Thermal gravimetric analysis (TGA)

The TGA analysis was conducted to investigate the thermal stability of the raw CDC used in the current study. Figure 6 illustrates the mass loss and derivative mass loss of CDC oxidation under air as a function of temperature. The results demonstrated different oxidation states of raw CDC with temperature. The first material loss occurred at a temperature below 393 K which is attributed to the moisture content onto the CDC. Next, the main oxidation of the CDC started at 705 K with a maximum loss at 748 K and completely oxidized at 990 K. It can be noticed that within the main oxidation range (705–990 K), two different oxidation states occurred during the heating process; this is also confirmed from the derivative mass loss plot (see Fig. 6). These two regimes attributed to the amorphous and graphitic carbon structures [38]; the amorphous carbon could be more reactive structure than the graphitic carbon, and hence it is oxidized earlier (i.e., at a temperature between 705 and 780 K), in which the mass loss was 47%. The graphitic carbon demonstrated higher thermal stability and hence higher resistance to oxidation, and the graphitic carbon oxidation started at 780 K and ends at 990 K in which the mass loss was 27.3%. Similar observations were obtained for the CDC produced from TiC precursor at 1273 K [38].

CDC antifreeze thermal fluids stability

Zeta potential analysis has been commonly used to scrutinize the stability of suspended particles in liquid solutions. As such, zeta potential measurements were utilized to investigate the stability of oxidized and raw CDC antifreeze thermal fluids. As the zeta potential values deviate from zero mV, either in the negative or the positive direction suggests higher stability. Moreover, the visual observations of stationary samples were recorded over 90 days to explore the signs of CDC particles sedimentation with time. Figure 7 illustrated the absolute zeta potential measurements of O-CDC and emulsified GA R-CDC antifreeze thermal fluids over 90 days from the preparation time. The values of zeta potential were analyzed according to Table 1. As shown in Fig. 7, a relative reduction in the absolute values of zeta potential measurements of all thermal fluids with time was observed. This is explained by the disengagement between R-CDC particles and GA with time and the release of some oxygen groups from the surface of O-CDC with time. However, all thermal fluids have demonstrated a zeta potential of more than 32 mV after 90 days. It is worth mentioning that zeta potential values were not affected by increasing the concentration of O-CDC particles in the solution. Similarly, the zeta potential values were similar for the same surfactant ratio (i.e., the zeta potential is not a function of CDC particles concentration). For O-CDC thermal fluid, the absolute value of zeta potential was 46.7 mV demonstrating good stability with possible settling. After 90 days, the zeta potential value decreased to 42.5 mV, indicating a moderately stable suspension. For the emulsified GA R-CDC thermal fluids, the zeta potential value of the ratio 1:1 was 35.6 mV at the preparation time, further increasing the GA ratio to 1:2, the absolute value of zeta potential increased to 37.5 mV (at preparation time), indicating a moderately stable solution. The zeta potential values have decreased to 32.4 mV and 34.9 mV after 90 days of preparation for the ratio 1:1 and 1:2, respectively, demonstrating moderately stable suspensions. According to the zeta potential results, both emulsification and chemical oxidation methods disclose homogeneous suspensions and good stability of CDC particles in water/EG mixture. The chemical oxidation has increased the quantity of oxygen-related functional groups onto the surface of CDC, which in turn has improved the hydrophilicity properties of CDC. At the same time, GA emulsification has changed the wetting and adhesion behavior of CDC particles which also has resulted in improved stability.

Figures 8 and 9 present the digital photographs of oxidized and emulsified CDC thermal fluids at the preparation time and after 90 days in a static mode. It can be seen that well-dispersed and homogenized CDC antifreeze thermal fluids were observed at time zero (Fig. 8). This is attributed to chemical (oxidation) and physical (emulsification) modifications of CDC particles. After 90 days of preparation, minor sedimentation of CDC particles was observed as shown in Fig. 9. As depicted in this figure, the amount of CDC sedimentation varies according to the modification method, CDC particles concentration and GA ratio. First, the bottom accumulation of CDC particles in the test samples has occurred in increasing order of 0.05 mass%, 0.1 mass% and 0.3 mass%. A higher concentration of CDC thermal fluids contains a higher amount of large CDC particles and increases the number of sedimented particles due to their mass and gravity. Besides that, CDC particles easily form clusters, and when the volume of clusters increases, their mass also increases and thus falls due to their mass. Moreover, a low concentration of CDC particles implies a weaker tendency to agglomerate than at higher concentration, implying better distribution of CDC particles by minimizing particles sedimentation. Second, the oxidized CDC thermal fluids demonstrated lower amounts of sedimentation than the emulsified suspensions. This is consistent with the zeta potential results, which indicates that the oxidized particles have higher net stability than the emulsified particles. Finally, the sedimented CDC amount was reduced by increasing the GA ratio, which is also explained by increasing the absolute value of zeta potential using higher amounts of GA, which means better stability of the suspended particles.

Viscosity of CDC antifreeze thermal fluids

Figure 10 illustrates the viscosity measurements of oxidized and raw CDC thermal fluids at different temperatures and CDC loading. This figure also displays the effect of modification methods and GA ratio on viscosity measurements. As shown in Fig. 10, at constant CDC loading, the viscosity measurements for all thermal fluids decreased with temperature. For example, using CDC loading of 0.05 mass%, the viscosity decreased from 3.12, 3.20 and 3.35 mPa s to 0.94, 0.96 and 0.99 mPa s by increasing the temperature between 288 and 338 K for O-CDC, R-CDC GA ratio 1:1 and R-CDC GA ratio 1:2 thermal fluids, respectively. This is because raising the temperature will weaken the intermolecular forces and increase the distances between the CDC particles, and hence decrease the resistance to flow and, therefore, viscosity decreases [39]. Moreover, increasing the temperature will enhance the kinetic energy of the mixture molecules; this leads to an increase in the collisions between CDC particles; thus, the resistance to flow declined and the viscosity reduced.

As shown in Fig. 10a, b, and c, the viscosity measurements increased with CDC loading. For example, at a temperature of 318 K, the viscosity increased from 1.48 mPa.s to 1.66 mPa.s by increasing the O-CDC loading from 0.05 mass% to 0.3 mass%. It can also be noticed that the viscosity is increasing with the surfactant ratio. For example, at temperature 318 K and R-CDC loading 0.3 mass%, the viscosity increased from 1.83 mPa.s to 2.04 mPa.s by increasing the GA ratio from 1:1 to 1:2. The viscosity improvement with CDC loading and surfactant concentration can be attributed to several reasons; first, introducing higher quantities of CDC particles and GA surfactant into the base fluid will promote the resistance to flow and therefore, the viscosity increased. Second, increasing the concentration of CDC particles will lead to create bigger clusters because of the van der Waals forces among the CDC bundles; those clusters will obstruct the movement of the mixture and, therefore, the viscosity increase. Third, higher amounts of CDC/GA particles will promote the internal shear stress, and accordingly, the viscosity increase.

The relative dynamic viscosity (viscosity of thermal fluid divide by the viscosity of the base fluid) as a function of temperature is shown in Fig. 11. As can be seen, at a constant mass concentration of CDC particles, the O-CDC thermal fluids demonstrated the lowest viscosity among the emulsified CDC suspensions. This is attributed to the effect of introducing the surfactant into the R-CDC thermal fluids. Moreover, the highest increase in viscosity measurements was for the emulsified R-CDC suspensions using the ratio 1:2. The maximum increase in viscosity measurements was 16.2, 27.2 and 42.8% at 288 K and 0.3 mass% of O-CDC, R-CDC GA ratio 1:1 and R-CDC GA ratio 1:2, respectively. According to the stability results, the oxidized CDC particles demonstrated the highest stability and, in this part, demonstrated the lowest increase in the viscosity measurements.

Thermal conductivity of CDC antifreeze thermal fluids

The effects of oxidized CDC loading (0.05–0.3 mass%) and temperature variation (288–338 K) on the k of water–EG antifreeze are shown in Fig. 12. It can be noticed that the k is positively influenced by increasing the O-CDC loading and temperature. As depicted by the graph, the relationship between temperature and k is almost linear. The k measurements were found between 0.490 and 0.632 W m-1 K-1 over the investigated conditions. The maximum improvement in k was 25.6% using 0.3 mass% of O-CDC at 338 K. The k results of emulsified raw CDC suspensions are shown in Fig. 13. This figure elucidates the effect of temperature, R-CDC loading and GA ratio on antifreeze k. Similar to O-CDC suspensions, the k was enhanced with R-CDC loading and temperature, while the improvement of k was declined by increasing the surfactant ratio. Thermal conductivity measurements were found between 0.476 and 0.618 W m-1 K-1 for the GA ratio 1:1, while it is decreased to the range 0.457–0.602 W m-1 K-1 for the GA ratio 1:2 at R-CDC loading 0.05–0.3 mass% and temperature range 288–338 K.

Figure 14 provides a comparison of k enhancement between oxidized and raw CDC suspensions at different CDC loading and 308 K. As seen, the O-CDC thermal fluids have the highest k enhancement, and then the enhancement was decreasing with increasing the GA ratio. The maximum enhancement at 308 K was 25.51, 22.46 and 19.24% for 0.3 mass% of O-CDC, R-CDC GA ratio 1:1 and R-CDC GA ratio 1:2, respectively. The observed linear relationship in the k with increasing temperature indicates that the temperature did not affect the amount of k improvement. For example, the k enhancement was 25 ± 0.5%, 22 ± 0.3% and 19 ± 0.6% within the temperature range 288–338 K for 0.3 mass% of O-CDC, R-CDC GA ratio 1:1 and R-CDC GA ratio 1:2, respectively. These results are consistent with what was previously published in the improvement of k using particles size ranging from several hundreds of nanometers to micrometers, such as graphite antifreeze and water suspensions [19, 20]. These results also point out that the Brownian motion of CDC particles was not the primary mechanism of k improvement. It is believed that particle clustering was behind the k improvement of CDC antifreeze thermal fluids. Because of the van der Waals forces among carbon atoms, the stabilized CDC particles tend to form clusters or percolation networks in the base fluid, forming a high rich zone of highly conductive materials (CDC) that increases the bulk k [40].

The reason behind increasing the k with CDC loading is explained two phenomena. First, suspending highly conductive material (CDC) in a fluid that has lower k will consequently improve the overall k and hence increasing the mass loading of the CDC will improve the bulk k. Second, increasing the CDC loading will increase the chains of CDC particles, which increase the size of the clusters (percolation networks), clusters in their role weakens the interfacial resistance among CDC particles and water/EG particles and hence improve the k.

The stability of suspended particles has a primary role in k enhancement [41, 42]. As shown in Fig. 9, the higher the stability of thermal fluid, the higher the improvement in k. The higher stability of dispersed particles allows them to be suspended in the base fluid, forming the clusters responsible for k improvement. Lower stability will result in particle sedimentation and decrease the surface area to volume ratio, decreasing the k enhancement. However, it is not the case of using surfactants; increasing the GA ratio has increased the stability of CDC particles and decreased the enhancement in k. This can be explained by increasing the GA concentration that has led to increased interfacial resistance among the CDC particles surface and the water/EG molecules. Therefore, the k improvement has declined. As such, preparing emulsified thermal fluids should be prepared in a way that stability and other thermophysical properties are considered and optimized.

Advantages of CDC antifreeze thermal fluids

As stated earlier, the CDC is a carbon-based material with a particles size between nano- and micrometers. In this study and for the first time, the CDC was utilized for the enhancement of the k of anti-freeze solutions. The advantage of CDC among other carbon-based nanomaterials is attributed to its varied particle sizes which, allow them to form bigger clusters that can help in improving the k. The improved k of CDC antifreeze is due to the synergetic effect of having nano- and microparticles. The nanoparticles encourage the formation of a homogeneous solution, while microparticles encourage the formulation of bigger percolation networks (clusters) resulting in improved k[19]. Based on the results of this study, the oxidized CDC demonstrated a 25.6% enhancement in k using 0.3 mass% of O-CDC. The R-CDC demonstrated 22.7% enhancement in k using 0.3 mass% of R-CDC and GA ratio of 1:1. These results are considered good in comparison with the antifreeze k enhancement using other carbon-based materials (see Table 1).

Conclusions

In this study, a new antifreeze-based thermal fluid containing oxidized and emulsified CDC particles was utilized for the k enhancement of water/ethylene glycol mixtures. The stability, viscosity and thermal conductivity of the CDC/antifreeze thermal fluids were experimentally investigated. The oxidation of CDC was carried out by acid treatment process while the emulsification of CDC was achieved by a GA surfactant. Raw and oxidized CDC were characterized by SEM, TEM, FTIR, DLS and XPS techniques. The results illustrated the successful oxidation of CDC by increasing oxygen related functional groups onto the CDC as revealed by FTIR and XPS analysis. The results also revealed that the oxygen content has increased from 2.5% to 11% throughout oxidation, as detailed in the XPS analysis.

Zeta potential analysis and visual photographs were used to study the stability of the suspensions. The results demonstrated that the oxidized CDC suspensions have better stability than the GA emulsified CDC. These observations were confirmed by the digital photographs of the suspensions with time. It was also observed that increasing the GA loading has improved the absolute value of the zeta potential of CDC particles. The viscosity values of the emulsified CDC suspensions were higher than the oxidized CDC. It was noticed that the viscosity was increasing with CDC loading and GA ratio while decreasing with temperature. The maximum increase in the viscosity was 42.8% using 0.3 mass% of R-CDC to GA ratio of 1:2. The k improvement was increasing with CDC loading, while the amount of enhancement in k was stable with temperature. Increasing the GA ratio found to inhibit the k enhancement. Furthermore, the k improvement of O-CDC suspensions was higher than the emulsified CDC. The maximum increase in k was 25.6% using 0.3 mass% of oxidized CDC at 338 K. The relative advantages of using oxidized CDC particles are: (i) high k of CDC have resulted in enhanced k of the base fluid, (ii) stability of CDC particles has improved with oxidation more than with the use of GA and hence better enhancement in k, and (iii) the relative increase in viscosity was lower for oxidized CDC, which in turn requires less pumping power if applied in heat transfer applications.

References

Vallejo JP, Żyła G, Ansia L, Fal J, Traciak J, Lugo L. Thermophysical, rheological and electrical properties of mono and hybrid TiB2/B4C nanofluids based on a propylene glycol:water mixture. Powder Technol. 2022;395:391–9. https://doi.org/10.1016/j.powtec.2021.09.074.

Zhu Y, Zamani M, Xu G, Toghraie D, Hashemian M, Alizadeh A. A comprehensive experimental investigation of dynamic viscosity of MWCNT-WO3/water-ethylene glycol antifreeze hybrid nanofluid. J Mol Liq. 2021;333:115986. https://doi.org/10.1016/j.molliq.2021.115986.

Kumar LH, Kazi SH, Masjukiab HH, Zubir MNM. A review of recent advances in green nanofluids and their application in thermal systems. Chem Eng J. 2022;429:132321. https://doi.org/10.1016/j.cej.2021.132321.

Mahian O, Bellos E, Markides CN, Taylor RA, Alagumalai A, Yang L, Qin C, Lee BJ, Ahmadi G, Safaei MR, Wongwises S. Recent advances in using nanofluids in renewable energy systems and the environmental implications of their uptake. Nano Energy. 2021;86:106069. https://doi.org/10.1016/j.nanoen.2021.106069.

Tembhare SP, Barai DP, Bhanvase BA. Performance evaluation of nanofluids in solar thermal and solar photovoltaic systems: a comprehensive review. Renew Sustain Energy Rev. 2022;153:111738. https://doi.org/10.1016/j.rser.2021.111738.

Chakraborty S, Panigrahi PK. Stability of nanofluid: a review. Appl Therm Eng. 2020;174:115259. https://doi.org/10.1016/j.applthermaleng.2020.115259.

Huq T, Ong HC, Leong KY, Kazi SN. Review on aqueous graphene nanoplatelet nanofluids: preparation stability thermophysical properties and applications in heat exchangers and solar thermal collectors. Appl Therm Eng. 2022;210:118342. https://doi.org/10.1016/j.applthermaleng.2022.118342.

Arora N, Gupta M. An experimental analysis of CTAB surfactant on thermo-physical properties and stability of MWCNT/water nanofluids. Appl Nanosci. 2022. https://doi.org/10.1007/s13204-022-02458-x.

Eshgarf H, Kalbasi R, Maleki A, Shadloo MS, Karimipour A. A review on the properties, preparation, models and stability of hybrid nanofluids to optimize energy consumption. J Therm Anal Calorim. 2021;144:1959–83. https://doi.org/10.1007/s10973-020-09998-w.

Sajid MU, Ali HM. Thermal conductivity of hybrid nanofluids: a critical review. Int J Heat Mass Transf. 2018;126:211–34. https://doi.org/10.1016/j.ijheatmasstransfer.2018.05.021.

Pourrajab R, Noghrehabadi A, Behbahani M. Thermo-hydraulic performance of mesoporous silica with Cu nanoparticles in helically grooved tube. Appl Therm Eng. 2021;185:116436. https://doi.org/10.1016/j.applthermaleng.2020.116436.

Pourrajab R, Noghrehabadi A, Hajidavalloo E, Behbahani M. Investigation of thermal conductivity of a new hybrid nanofluids based on mesoporous silica modified with copper nanoparticles: synthesis, characterization and experimental study. J Mol Liq. 2020;300:112337. https://doi.org/10.1016/j.molliq.2019.112337.

Pourrajab R, Noghrehabadi A, Behbahani M. Development of Cu/mesoporous SBA-15 nanocomposite in ethylene glycol for thermal conductivity enhancement: heat transfer applications. Int Commun Heat Mass Transf. 2020;119:104931. https://doi.org/10.1016/j.icheatmasstransfer.2020.104931.

Pourrajab R, Noghrehabadi A, Behbahani M, Hajidavalloo E. An efficient enhancement in thermal conductivity of water-based hybrid nanofluid containing MWCNTs-COOH and Ag nanoparticles: experimental study. J Therm Anal Calorim. 2021;143:3331–43. https://doi.org/10.1007/s10973-020-09300-y.

Lenin R, Joy PA, Bera C. A review of the recent progress on thermal conductivity of nanofluid. J Mol Liq. 2021;338:116929. https://doi.org/10.1016/j.molliq.2021.116929.

Ali ARI, Salam B. A review on nanofluid: preparation, stability, thermophysical properties, heat transfer characteristics and application. SN Appl Sci. 2020;2:1636. https://doi.org/10.1007/s42452-020-03427-1.

Borode A, Ahmed N, Olubambi P. A review of solar collectors using carbon-based nanofluids. J Clean Prod. 2019;241:118311. https://doi.org/10.1016/j.jclepro.2019.118311.

Ali N, Bahman AM, Aljuwayhel NF, Ebrahim SA, Mukherjee S, Alsayegh A. Carbon-based nanofluids and their advances towards heat transfer applications—a review. Nanomaterials. 2021;11:1628. https://doi.org/10.3390/nano11061628.

Shaikh S, Lafdi K, Ponnappan R. Thermal conductivity improvement in carbon nanoparticle doped PAO oil: an experimental study. J Appl Phys. 2007;101:064302. https://doi.org/10.1063/1.2710337.

Ma L, Wang J, Marconnet AM, Barbati AC, McKinley GH, Liu W, Chen G. Viscosity and thermal conductivity of stable graphite suspensions near percolation. Nano Lett. 2015;15:127–33. https://doi.org/10.1021/nl503181w.

Dehkordi RA, Esfe MH, Afrand M. Effects of functionalized single walled carbon nanotubes on thermal performance of antifreeze: an experimental study on thermal conductivity. Appl Therm Eng. 2017;120:358–66. https://doi.org/10.1016/j.applthermaleng.2017.04.009.

Vallejo JP, Żyła G, Fernández-Seara J, Lugo L. Rheological behaviour of functionalized graphene nanoplatelet nanofluids based on water and propylene glycol:water mixtures. Int Commun Heat Mass Transf. 2018;99:43–53. https://doi.org/10.1016/j.icheatmasstransfer.2018.10.001.

Kumaresan V, Khader SMA, Karthikeyan S, Velraj R. Convective heat transfer characteristics of CNT nanofluids in a tubular heat exchanger of various lengths for energy efficient cooling/heating system. Int J Heat Mass Transf. 2013;60:413–21. https://doi.org/10.1016/j.ijheatmasstransfer.2013.01.021.

Soltanimehr M, Afrand M. Thermal conductivity enhancement of COOH-functionalized MWCNTs/ethylene glycol–water nanofluid for application in heating and cooling systems. Appl Therm Eng. 2015;105:716–23. https://doi.org/10.1016/j.applthermaleng.2016.03.089.

Dalkilic AS, Küçükyıldırım BO, Eker AA, Çebi A, Tapan S, Jumpholkul C, Wongwises S. Experimental investigation on the viscosity of water-CNT and Antifreeze-CNT nanofluids. Int Commun Heat Mass Transf. 2017;80:47–59. https://doi.org/10.1016/j.icheatmasstransfer.2016.11.011.

Gao Y, Wang H, Sasmito AP, Mujumdar AS. Measurement and modeling of thermal conductivity of graphene nanoplatelet water and ethylene glycol base nanofluids. Int J Heat Mass Transf. 2018;123:97–109. https://doi.org/10.1016/j.ijheatmasstransfer.2018.02.089.

Izadi F, Ranjbarzadeh R, Kalbasi R, Afrand M. A new experimental correlation for non-Newtonian behavior of COOH-DWCNTs/antifreeze nanofluid. Phys E Low-Dimensional Syst Nanostructures. 2018;98:83–9. https://doi.org/10.1016/j.physe.2017.12.031.

Almanassra IW, Manasrah AD, Al-Mubaiyedh UA, Al-Ansari T, Malaibari ZO, Atieh MA. An experimental study on stability and thermal conductivity of water/CNTs nanofluids using different surfactants: A comparison study. J Mol Liq. 2020;304:111025. https://doi.org/10.1016/j.molliq.2019.111025.

Yarmand H, Gharehkhani S, Shirazi SFS, Goodarzi M, Amiri A, Sarsam WS, Alehashem MS, Dahari M, Kazi SN. Study of synthesis, stability and thermo-physical properties of graphene nanoplatelet/platinum hybrid nanofluid. Int Commun Heat Mass Transf. 2016;77:15–21. https://doi.org/10.1016/j.icheatmasstransfer.2016.07.010.

Almanassra IW, Kochkodan V, Mckay G, Atieh MA, Al-Ansari T. Kinetic and thermodynamic investigations of surfactants adsorption from water by carbide-derived carbon. J Environ Sci Heal Part A. 2021;56:1206–20.

Najimu MO, Aljundi IH. Separation performance of CO2 by hybrid membrane comprising nanoporous carbide derived carbon. J Nat Gas Sci Eng. 2018;59:9–20. https://doi.org/10.1016/j.jngse.2018.08.007.

Awad A, Aljundi IH. Layer-by-layer assembly of carbide derived carbon-polyamide membrane for CO2 separation from natural gas. Energy. 2018;157:188–99. https://doi.org/10.1016/j.energy.2018.05.136.

Malmberg S, Arulepp M, Savest N, Tarasova E, Vassiljeva V, Krasnou I, Käärik M, Mikli V, Krumme A. Directly electrospun electrodes for electrical double-layer capacitors from carbide-derived carbon. J Electrostat. 2020;103:103396. https://doi.org/10.1016/j.elstat.2019.103396.

Almanassra IW, Okonkwo EC, Alhassan O, Atieh MA, Kochkodan V, Al-Ansari T. Stability and thermophysical properties test of carbide-derived carbon thermal fluid; a comparison between functionalized and emulsified suspensions. Powder Technol. 2021;377:415–28. https://doi.org/10.1016/j.powtec.2020.09.012.

Lilloja J, Kibena-Põldsepp E, Sarapuu A, Douglin JC, Käärik M, Kozlova J, Paiste P, Kikas A, Aruväli J, Leis J, Sammelselg V, Dekel DR, Tammeveski K. Transition-metal- and nitrogen-doped carbide-derived carbon/carbon nanotube composites as cathode catalysts for anion-exchange membrane fuel cells. ACS Catal. 2021;11:1920–31. https://doi.org/10.1021/acscatal.0c03511.

Al-Gaashani R, Najjar A, Zakaria Y, Mansour S, Atieh MA. XPS and structural studies of high quality graphene oxide and reduced graphene oxide prepared by different chemical oxidation methods. Ceram Int. 2019;45:14439–48. https://doi.org/10.1016/j.ceramint.2019.04.165.

Zinovev AV, Elam JW, Moore JF, Hryn JN, Auciello O, Carlisle JA, Pellin MJ. Coating of SiC surface by thin carbon films using the carbide-derived carbon process. Thin Solid Films. 2004;469–470:135–41. https://doi.org/10.1016/j.tsf.2004.08.165.

Osswald S, Portet C, Gogotsi Y, Laudisio G, Singer JP, Fischer JE, Sokolov VV, Kukushkina JA, Kravchik AE. Porosity control in nanoporous carbide-derived carbon by oxidation in air and carbon dioxide. J Solid State Chem. 2009;182:1733–41. https://doi.org/10.1016/j.jssc.2009.04.017.

Molana M, Ghasemiasl R, Armaghani T. A different look at the effect of temperature on the nanofluids thermal conductivity: focus on the experimental-based models. J Therm Anal Calorim. 2021. https://doi.org/10.1007/s10973-021-10836-w.

Soltani F, Toghraie D, Karimipour A. Experimental measurements of thermal conductivity of engine oil-based hybrid and mono nanofluids with tungsten oxide (WO3) and MWCNTs inclusions. Powder Technol. 2020;371:37–44. https://doi.org/10.1016/j.powtec.2020.05.059.

Manasrah AD, Al-Mubaiyedh UA, Laui L, Ben-Mansour R, Al-Marri MJ, Almanassra IW, Abdala A, Atieh MA. Heat transfer enhancement of nanofluids using iron nanoparticles decorated carbon nanotubes. Appl Therm Eng. 2016;107:1008–18. https://doi.org/10.1016/j.applthermaleng.2016.07.026.

Okonkwo EC, Wole-Osho I, Almanassra IW, Abdullatif YM, Al-Ansari T. An updated review of nanofluids in various heat transfer devices. J Therm Anal Calorim. 2021;145:2817–72. https://doi.org/10.1007/s10973-020-09760-2.

Acknowledgements

The authors would like to acknowledge the Core lab staff in Qatar Environmental and Energy Research Institute (QEERI), Hamad Bin Khalifa University; namely Dr. Said Mansour, Dr. Ayman Samara and Mr. Omar Alhassan for the assistance in material characterization and viscosity analysis. The authors are also wanting to thank QEERI for funding the thermal conductivity measurements. Open Access funding provided by the Qatar National Library.

Funding

Open Access funding provided by the Qatar National Library. Thermal conductivity analysis funded by Qatar Environmental and Energy Research Institute (QEERI), Hamad Bin Khalifa University.

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Material preparation, data collection and analysis were performed by IWA, YZ, VK, KM, AZ, MAA and TA-A. The first draft of the manuscript was written by IWA, and all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript. Writing–Original draft, conceptualization, formal analysis, investigation and methodology were done by IA. Investigation, formal analysis, writing–review and editing were done by YZ. Conceptualization and visualization were done by VK. Formal analysis and investigation were done by AZ. Formal analysis and investigation were done by KM. Conceptualization and resources were done by MAA. Conceptualization, project administration, resources, supervision, writing–review and editing were done by TAl-A.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that there is no conflict of interests regarding the publication of this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Almanassra, I.W., Zakaria, Y., Kochkodan, V. et al. XPS and material properties of raw and oxidized carbide-derived carbon and their application in antifreeze thermal fluids/nanofluids. J Therm Anal Calorim 147, 11787–11803 (2022). https://doi.org/10.1007/s10973-022-11419-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-022-11419-z