Abstract

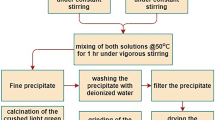

Recrystallization of the copper sulfide occurs during the thermal treatment of the samples and directly affects the size of the nanoparticles. Since particle size is one of the most important characteristics of copper sulfides, in determining the electrochemical and optical properties of nanostructured sulfides, the investigation of the thermal stability of copper sulfides is relevant. In this work, the mechanism of the thermal decomposition of synthetic covellite was investigated and proposed. According to the literature, thermal decomposition and oxidation presumably occur up to 600 °C, and therefore, the experiments were carried out in a temperature range of 25–600 °C. The thermal behavior and decomposition were investigated and characterized by XRD, DSC, and SEM–EDX analysis methods. It was determined that the duration of synthesis had an influence on the temperature of decomposition of synthetic covellite, because by prolonging the duration of synthesis from 0.5 to 4 h, the temperature range of the stability of covellite increased by 100 °C (from 300 to 400 °C). Furthermore, the application of different sulfurizing agents for hydrothermal synthesis insignificantly affected the mineral changes of the annealing products in the temperature range of 250–400 °C. It was established that minor reactions of covellite decomposition started in 300 °C, by forming Cu7S4 and Cu9S5. The majority of digenite formed at a temperature higher than 400 °C. It was determined that at a temperature higher than 450 °C, Cu1.81S and Cu2S formed and copper sulfide oxidation to copper sulfate occurred.

Similar content being viewed by others

References

Majumdar D. Recent progress in copper sulfide based nanomaterials for high energy supercapacitor applications. J Electroanal Chem. 2020. https://doi.org/10.1016/j.jelechem.2020.114825.

Sun S, Li P, Liang S, Yang Z. Diversified copper sulfide (Cu2–xS) micro-/nanostructures: a comprehensive review on synthesis, modifications and applications. Nanoscale Royal Soc Chem. 2017;9:11357–404.

Chen Y, Li J, Lei Z, Huo Y, Yang L, Zeng S, et al. Hollow CuS nanoboxes as Li-free cathode for high-rate and long-life lithium metal batteries. Adv Energy Mater. 2020. https://doi.org/10.1002/aenm.201903401.

Liu M, Liu Y, Gu B, Wei X, Xu G, Wang X, et al. Recent advances in copper sulphide-based nanoheterostructures. Chem Soc Rev Royal Soc Chem. 2019;48:4950–65.

Shaikh S, Rabinal MK. Rapid ambient growth of copper sulfide microstructures: binder free electrodes for supercapacitor. J Energy Storage. 2020;28:101288.

Zhao T, Yang W, Zhao X, Peng X, Hu J, Tang C, et al. Facile preparation of reduced graphene oxide/copper sulfide composite as electrode materials for supercapacitors with high energy density. Compos Part B Eng. 2018;150:60–7.

Zhou S, Gong L, Zhao X, Liang Q, Zhang W, Wang L, et al. Synthesis and photocatalytic performance of copper sulfide by a simple solvothermal method. Chem Phys Lett. 2020;759:138034.

Nabi G, Tanveer M, Bilal Tahir M, Kiran M, Rafique M, Khalid NR, et al. Mixed solvent based surface modification of CuS nanostructures for an excellent photocatalytic application. Inorg Chem Commun. 2020. https://doi.org/10.1016/j.inoche.2020.108205.

Iqbal S, Bahadur A, Anwer S, Ali S, Saeed A, Muhammad Irfan R, et al. Shape and phase-controlled synthesis of specially designed 2D morphologies of l-cysteine surface capped covellite (CuS) and chalcocite (Cu2S) with excellent photocatalytic properties in the visible spectrum. Appl Surf Sci. 2020. https://doi.org/10.1016/j.apsusc.2020.146691.

Tsiba Matondo J, Malouangou Maurice D, Chen Q, Bai L, Guli M. Inorganic copper-based hole transport materials for perovskite photovoltaics: challenges in normally structured cells, advances in photovoltaic performance and device stability. Sol Energy Mater Sol Cells. 2021. https://doi.org/10.1016/j.solmat.2021.111011.

Tirado J, Roldán-Carmona C, Muñoz-Guerrero FA, Bonilla-Arboleda G, Ralaiarisoa M, Grancini G, et al. Copper sulfide nanoparticles as hole-transporting-material in a fully-inorganic blocking layers n-i-p perovskite solar cells: Application and working insights. Appl Surf Sci. 2019. https://doi.org/10.1016/j.apsusc.2019.01.289.

Hu R, Zhang R, Ma Y, Liu W, Chu L, Mao W, et al. Enhanced hole transfer in hole-conductor-free perovskite solar cells via incorporating CuS into carbon electrodes. Appl Surf Sci. 2018;462:840–6.

Li M, Liu Y, Zhang Y, Han X, Zhang T, Zuo Y, et al. Effect of the annealing atmosphere on crystal phase and thermoelectric properties of copper sulfide. ACS Nano Am Chem Soc. 2021;15:4967–78.

Sadovnikov SI. Thermal stability and recrystallization of semiconductor nanostructured sulfides and sulfide solid solutions. J Alloys Compd. 2019;788:586–99.

Tang H, Sun F-H, Dong J-F, Zhuang H-L, Pan Y, et al. Graphene network in copper sulfide leading to enhanced thermoelectric properties and thermal stability. Nano Energy. 2018;49:267–73.

Mikhlin Y, Nasluzov V, Ivaneeva A, Vorobyev S, Likhatski M, Romanchenko A, Krylov A, Zharkov S, Meira DM. Formation, evolution and characteristics of copper sulfide nanoparticles in the reactions of aqueous cupric and sulfide ions. Mater Chem Phys. 2020;255:123600.

Dexter M, Gao Z, Bansal S, Chang C-H, Malhotra R. Temperature, crystalline phase and influence of substrate properties in intense pulsed light sintering of copper sulfide nanoparticle thin films. Sci Rep. 2018;8:1–14.

Nafees M, Ikram M, Ali S. Thermal behavior and decomposition of copper sulfide nanomaterial synthesized by aqueous sol method. Dig J Nanomater Biostruct. 2015;10:635–41.

Dunn J, Muzenda C. Thermal oxidation of covellite (CuS). Thermochim Acta. 2001. https://doi.org/10.1016/S0040-6031(00)00748-6.

Simonescu CM, Teodorescu VS, Carp O, Patron L, Capatina C. Thermal behaviour of CuS (covellite) obtained from copper–thiosulfate system. J Therm Anal Calorim. 2007. https://doi.org/10.1007/s10973-006-8079-z.

Botha NL, Ajibade PA. Effect of temperature on crystallite sizes of copper sulfide nanocrystals prepared from copper(II) dithiocarbamate single source precursor. Mater Sci Semicond Process. 2016. https://doi.org/10.1016/j.mssp.2015.12.006.

Mousavi-Kamazani M, Zarghami Z, Salavati-Niasari M. Facile and novel chemical synthesis, characterization, and formation mechanism of copper sulfide (Cu2S, Cu2S/CuS, CuS) nanostructures for increasing the efficiency of solar cells. J Phys Chem C. 2016. https://doi.org/10.1021/acs.jpcc.5b11566.

Abouserie A, El-Nagar GA, Heyne B, Günter C, Schilde U, Mayer MT, et al. Facile synthesis of hierarchical CuS and CuCo2S4 structures from an ionic liquid precursor for electrocatalysis applications. ACS Appl Mater Interfaces. 2020. https://doi.org/10.1021/acsami.0c13927.

Sarapajevaite G, Baltakys K. Purification of sulfur waste under hydrothermal conditions. Waste Biomass Valoriz. 2021. https://doi.org/10.1007/s12649-020-01206-y.

Funding

No funding was received for conducting this study.

Author information

Authors and Affiliations

Contributions

GS and KB contributed to conceptualization; KB was involved in methodology, writing—review and editing, and supervision; and GS contributed to formal analysis and investigation and writing.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Sarapajevaite, G., Baltakys, K. Thermal stability and decomposition mechanism of synthetic covellite samples. J Therm Anal Calorim 147, 10951–10963 (2022). https://doi.org/10.1007/s10973-022-11313-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-022-11313-8