Abstract

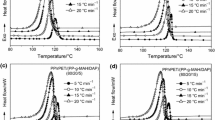

The influence of organic additives on crystallization of polyolefins has not been paid enough attention due to the low dosage, but it may have a significant impact on the properties of polyolefins. In the paper, the organic amphiphilic molecules were introduced into high-density polyethylene (HDPE) through melt blending, and compared with neat HDPE. It is mainly discussed for the following aspects including analysis of crystal structure and morphology using wide-angle X-ray diffraction (WAXD) and polarized optical microscopy (POM), respectively; analysis of crystallinity, crystal rate, crystal growth and crystallization enthalpy, using the differential scanning calorimetry (DSC). The research indicates that the organic amphiphilic molecules may act as an internal lubricant. On the one hand, HDPE molecular chains are easy to fall off from crystal lattices, resulting in lagging crystallization peak, simultaneously reducing the interaction between HDPE molecules should induce the lower activation energy (ΔEm) to increase the crystallinity of HDPE. On the other hand, the amphiphilic molecules should be exclude from HDPE crystal to the amorphous area due to poor compatibility; thus, the HDPE/amphiphilic molecules blends, similar to neat HDPE, conduct homogeneous nucleation, and the growth of monocrystal performs the tendency of the zero-dimension to the two-dimension with increase in temperature of isothermal crystallization and decreasing cooling rate of non-isothermal crystallization. It is hoped that through these studies, people will pay more attention to the impact of organic additives on the performance of HDPE.

Graphic abstract

Similar content being viewed by others

References

Shehzad F, Thomas SP, Al-Harthi MA. Non-isothermal crystallization kinetics of high density polyethylene/graphene nanocomposites prepared by in-situ polymerization. Thermochim Acta. 2014;589:226–34. https://doi.org/10.1016/j.tca.2014.05.039.

Khanam PN, Almaadeed MAA. Processing and characterization of polyethylene-based composites. Adv Manuf Polym Compos Sci. 2015;1:63–79. https://doi.org/10.1179/2055035915Y.0000000002.

Zhang R, He XR, Yang DB, Lai Z. Non-isothermal crystallization kinetics and segmental dynamics of high density polyethylene/butyl rubber blends. Polym Int. 2015;64:1252–61. https://doi.org/10.1002/pi.4910.

Nomura K, Terwilliger P. Self-dual Leonard pairs. Spec Matrices. 2019;7:1–19. https://doi.org/10.1515/spma-2019-0001.

Li JX, Zhou C, Xu SY, Shen LG. Investigation of hindered phenol antioxidant effects on the aging performance of cross-linked LDPE in the presence of copper. Sci Rep-UK. 2020;10:10189. https://doi.org/10.1038/s41598-020-67131-1.

Romani VP, Martins VG, Goddard JM. Radical scavenging polyethylene films as antioxidant active packaging materials. Food Control. 2020;109:106946. https://doi.org/10.1016/j.foodcont.2019;106946.

Kourtidou D, Tarani E, Chrysafi I, Menyhard A, Bikiaris DN, Chrissafis K. Non-isothermal crystallization kinetics of graphite-reinforced crosslinked high-density polyethylene composites. J Therm Anal Calorim. 2020;142:1849–61. https://doi.org/10.1007/s10973-020-10085-3.

Wu ZX, Zhang ZS, Mai KC. Non-isothermal crystallization kinetics of UHMWPE composites filled by oligomer-modified CaCO3. J Therm Anal Calorim. 2020;139:1111–20. https://doi.org/10.1007/s10973-019-08428-w.

Layachi A, Makhlouf A, Frihi D, Satha H, Belaadi A, Seguela R. Non-isothermal crystallization kinetics and nucleation behavior of isotactic polypropylene composites with micro-talc. J Therm Anal Calorim. 2019;138:1081–95. https://doi.org/10.1007/s10973-019-08262-0.

Bourque AJ, Locker CR, Tsou AH, Vadlamudi M. Nucleation and mechanical enhancements in polyethylene-graphene nanoplate composites. Polymer (Guilford). 2016;99:263–72. https://doi.org/10.1016/j.polymer.2016.07.025.

Wang SC, Zhang J. Non-isothermal crystallization kinetics of high density polyethylene/titanium dioxide composites via melt blending. J Therm Anal Calorim. 2014;115:63–71. https://doi.org/10.1007/s10973-013-3241-x.

He LH, Xu Q, Song R, Hua CG. Thermal and morphological characterization of composites prepared by solution crystallization method of high-density polyethylene on carbon nanotubes. Polym Compos. 2010;31:913–20. https://doi.org/10.1002/pc.20875.

Schlotter NE, Furlan PY. A review of small molecule diffusion in polyolefins. Polymer. 1992;33:3323–42. https://doi.org/10.1016/0032-3861(92)91089-K.

Datla V, Shim E, Pourdeyhimi B. Surface modifications of polypropylene with nonylphenol ethoxylates melt additives. Polym Eng Sci. 2012;52:1920–7. https://doi.org/10.1002/pen.23153.

Zhu S, Hirt DE. Hydrophilization of polypropylene films by using migratory additives. J Vinyl Addit Technol. 2007;13:57–64. https://doi.org/10.1002/vnl.20102.

Datla VM, Shim E, Pourdeyhimi B. Polypropylene surface modification with stearyl alcohol ethoxylates to enhance wettability. J Appl Polym Sci. 2011;121:1335–47. https://doi.org/10.1002/app.31051.

Lavoie JH, Rojas OJ, Khan SA, Shim E. Migration effects of fluorochemical melt additives for alcohol repellency in polypropylene nonwoven materials. ACS Appl Mater Interfaces. 2020;12:36787–98. https://doi.org/10.1021/acsami.0c10144.

Trujillo M, Arnal ML, Müller AJ, Laredo E, Bredeau S, Bonduel D, et al. Thermal and morphological characterization of nanocomposites prepared by in-situ polymerization of high-density polyethylene on carbon nanotubes. Macromolecules. 2007;40:6268–76. https://doi.org/10.1021/ma071025m.

Jayasree TK, Predeep P. Non-isothermal crystallization behavior of Styrene butadiene rubber/high density polyethylene binary blends. J Therm Anal Calorim. 2012;108:1151–60. https://doi.org/10.1007/s10973-012-2257-y.

Seven KM, Cogen JM, Gilchrist JF. Nucleating agents for high-density polyethylene-a review. Polym Eng Sci. 2016;56:541–54. https://doi.org/10.1002/pen.24278.

Zou P, Tang SW, Fu ZZ, Xiong HG. Isothermal and non-isothermal crystallization kinetics of modified rape straw flour/high-density polyethylene composites. Int J Therm Sci. 2009;48:837–46. https://doi.org/10.1016/j.ijthermalsci.2008.06.010.

Shehzad F, Daud M, Al-Harthi MA. Synthesis, characterization and crystallization kinetics of nanocomposites prepared by in situ polymerization of ethylene and graphene. J Therm Anal Calorim. 2016;123:1501–11. https://doi.org/10.1007/s10973-015-5087-x.

Cestari SP, Mendes LC, Altstädt V, Mano EB, Da Silva DF, Keller J. Crystallization kinetics of recycled high density polyethylene and coffee dregs composites. Polym Polym Compos. 2014;22:541–50. https://doi.org/10.1177/096739111402200606.

Liua M, Zhaoa Q, Wang Y. Melting behaviors, isothermal and non-isothermal crystallization kinetics of nylon 1212. Polymer. 2003;44:2537–45. https://doi.org/10.1016/S0032-3861(03)00101-0.

Gholami F, Pircheraghi G, Rashedi R, Sepahi A. Correlation between isothermal crystallization properties and slow crack growth resistance of polyethylene pipe materials. Polym Test. 2019;80:106128. https://doi.org/10.1016/j.polymertesting.2019.106128.

Vilanova PC, Ribas SM, Guzman GM. Isothermal crystallization of poly(ethylene-terephthalate) of low molecular weight by differential scanning calorimetry: 1. Crystallization kinetics. Polymer. 1985;26:423–8. https://doi.org/10.1016/0032-3861(85)90205-8.

Samthong C, Deetuam C, Yamaguchi M, Praserthdam P, Somwangthanaroj A. Effects of size and shape of dispersed poly(butylene terephthalate) on isothermal crystallization kinetics and morphology of poly(lactic acid) blends. Polym Eng Sci. 2016;56:258–68. https://doi.org/10.1002/pen.24246.

Bai H, Zhang Y, Zhang Y, Zhang X, Zhou W. Crystallization kinetics of toughed poly(butylene terephthalate)/polycarbonate blends. J Appl Polym Sci. 2006;101:1295–308. https://doi.org/10.1002/app.22669.

Li X, Qiu Z. Crystallization kinetics, morphology, and mechanical properties of novel poly(ethylene succinate-co-octamethylene succinate). Polym Test. 2015;48:125–32. https://doi.org/10.1016/j.polymertesting.2015.10.002.

Dulal N, Shanks R, Chalmers D, Adhikari B, Gill H. Migration and performance of erucamide slip additive in high-density polyethylene bottle caps. J Appl Polym Sci. 2018;135:46822. https://doi.org/10.1002/APP.46822.

Llop C, Manrique A, Navarro R, Mijangos C, Reinecke H. Control of the migration behavior of slip agents in polyolefin-based films. Polym Eng Sci. 2011;51:1763–9. https://doi.org/10.1002/pen.21963.

Treviño Quintanilla CD, Krishnamoorti R, Bonilla Ríos J. Flash DSC crystallization study of blown film grade bimodal high density polyethylene (HDPE) resins. Part 2. Non-isothermal kinetics. J Polym Sci B Polym Phys. 2017;55:1822–7. https://doi.org/10.1002/polb.24431.

Mohtaramzadeh Z, Hemmati F, Kasbi SF, Goodarzi V, Arnhold K, Khonakdar HA. Structure-properties correlations in poly(ε-caprolactone)/poly(styrene-co-acrylonitrile)/nanosilica mixtures: interrelationship among phase behavior, morphology and non-isothermal crystallization kinetics. Polym Test. 2020;89:106593. https://doi.org/10.1016/j.polymertesting.2020.106593.

de Melo CCN, Beatrice CAG, Pessan LA, de Oliveira AD, Machado FM. Analysis of nonisothermal crystallization kinetics of graphene oxide-reinforced polyamide 6 nanocomposites. Thermochim Acta. 2018;667:111–21. https://doi.org/10.1016/j.tca.2018.07.014.

Jeziorny A. Parameters characterizing the kinetics of the non-isothermal crystallization of poly(ethylene terephthalate) determined by d.s.c. Polymer. 1978;19:1142–4. https://doi.org/10.1016/0032-3861(78)90060-5.

Somsunan R, Mainoiy N. Isothermal and non-isothermal crystallization kinetics of PLA/PBS blends with talc as nucleating agent. J Therm Anal Calorim. 2020;139:1941–8. https://doi.org/10.1007/s10973-019-08631-9.

Zhang J, Chen SJ, Su J, Shi XM, Jin J, Wang XL. Non-isothermal crystallization kinetics and melting behavior of EAA with different acrylic acid content. J Therm Anal Calorim. 2009;97:959–67. https://doi.org/10.1007/s10973-009-0014-7.

Chen L, Dou Q. Influence of the combination of nucleating agent and plasticizer on the non-isothermal crystallization kinetics and activation energies of poly(lactic acid). J Therm Anal Calorim. 2020;139:1069–90. https://doi.org/10.1007/s10973-019-08507-y.

Friedman HL. Kinetics of thermal degradation of char-forming plastics from thermogravimetry. Application to a phenolic plastic. J Polym Sci C Polym Symp. 1964;6:183–95. https://doi.org/10.1002/polc.5070060121.

Li X, Guo W, Zhou Q, Xu S, Wu C. Non-isothermal crystallization kinetics of poly (ethylene terephthalate)/grafted carbon black composite. Polym Bull. 2007;59:685–97. https://doi.org/10.1007/s00289-007-0798-1.

Kashani Rahimi S, Otaigbe JU. The role of particle surface functionality and microstructure development in isothermal and non-isothermal crystallization behavior of polyamide 6/cellulose nanocrystals nanocomposites. Polymer. 2016;107:316–31. https://doi.org/10.1016/j.polymer.2016.11.023.

Acknowledgements

This research is financially supported by Advantage Discipline Construction Foundation of Jiangsu, the Priority Academic Program Development of Jiangsu Higher Education Institutions (PAPD).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhu, C., Zhang, Y., Zhou, X. et al. Influence of the amphiphilic molecule on high-density polyethylene crystallization. J Therm Anal Calorim 147, 4151–4164 (2022). https://doi.org/10.1007/s10973-021-10794-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-021-10794-3