Abstract

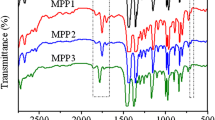

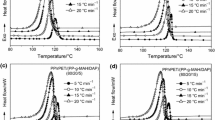

Polypropylene/Polyethylene (PP/PE) incompatibility is the key factor that restricts the use of PE to further improve the performance of Polypropylene Random (PPR). Although there are many studies on PP/PE blends have been compatibilized by adding Maleic Anhydride (MAH) as a solubilizer, how MAH affects the crystal structure of PPR/PE blends has not been systematically investigated. This study compares the thermodynamic and crystallization behavior that adding of PPR and PPR blended with MAH-grafted PP and High-density polyethylene (HDPE). The addition of a small amount of (EP1:1)-MAH (MAH grafted PP/HDPE 1:1 blend) considerably enhanced the crystallization temperature of the system. Small-Angle X-ray Scattering (SAXS) confirmed that (EP1:1)-MAH has reduced the order of the lamellae structure of the PPR blend system compared with the addition of EP1:1 (ungrafted PP/PE 1:1 blend). MAH-grafted PE (PE-g-MAH) and MAH-grafted PP (PP-g-MAH) are compatible with PPR, thus allowing easy entry of PE into the phase region of PP and vice versa. By clarifying the crystal structure modification of PE/PPR blends, this study highlights the application potential of modifying PPR with the MAH-grafted polymer.

Similar content being viewed by others

References

Ren Q, Fan J, Zhang Q et al (2016) Toughened polypropylene random copolymer with olefin block copolymer. Mater Des 107:295–301. https://doi.org/10.1016/j.matdes.2016.06.052

Benarab A, Blázquez-Blázquez E, Krache R et al (2011) Composites of a Polypropylene Random Copolymer and Date Stone Flour: Crystalline Details and Mechanical Response. Polymers (17). https://doi.org/10.3390/POLYM13172957

Pereira J, Bernardes GP, Silva J et al (2020) Structure-property correlation of an impact- modified random polypropylene copolymer. J Elastom Plastics (225). https://doi.org/10.1177/009524432094776

Hua G (2010) Maleic anhydride grafted PP/PE blend and their composites with wood fiber. 46(1):107–111. https://doi.org/10.11707/j.1001-7488.20100117

Gorre RC, Tumolva TP (2020) Solvent and non-solvent selection for the chemical recycling of waste Polyethylene (PE) and Polypropylene (PP) metallized film packaging materials. IOP Conf Ser Earth Environ Sci 463(1). https://doi.org/10.1088/1755-1315/463/1/012070

Xu X, Ding XJ et al (2019) Preparation of amidoxime-based PE/PP fibers for extraction of uranium from aqueous solution. (2):39–51. https://doi.org/10.1007/s41365-019-0543-0

Ouyang Y, Mauri M, Pourrahimi AM et al (2020) Recyclable Polyethylene Insulation via Reactive Compounding with a Maleic Anhydride-Grafted Polypropylene. ACS Applied Polymer Materials 2(6):2389–2396. https://doi.org/10.1021/acsapm.0c00320

Karimi MH, Mortazavi S, Ahmadjo S et al (2022) Improvement in the thermal and mechanical properties of PP/Clay nanocomposite using novel ethoxylated oxidized PE wax as a compatibilizer. Polym Compos 43(1):389–398. https://doi.org/10.1002/pc.26383

ARS, AKW, APZ et al (2007) Shear-induced epitaxial crystallization in injection-molded bars of high-density polyethylene/isotactic polypropylene blends - ScienceDirect[J]. Polymer 48( 15):4529–4536. https://doi.org/10.1016/j.polymer.2007.06.001

Zhang HC, Kang BH, Chen LS et al (2020) Enhancing toughness of poly (lactic acid)/Thermoplastic polyurethane blends via increasing interface compatibility by polyurethane elastomer prepolymer and its toughening mechanism. Polym Test 87. https://doi.org/10.1016/j.polymertesting.2020.106521

Yi S, Xu S, Li Y et al (2019) Synergistic Synergistic toughening effects of grafting modification and elastomer-olefin block copolymer addition on the fracture resistance of wood particle/polypropylene/elastomer composites. Mater Des 181:1–9. https://doi.org/10.1016/j.matdes.2019.107918

Sun DX, Lei YZ, Lu Y et al (2020) Fabrication of super-toughened polypropylene-based nanocomposite with low elastomer content through tailoring the microscale damage mechanisms. Compos Sci Technol 193:108148. https://doi.org/10.1016/j.compscitech.2020.108148

Wang Y, Shi Y, Shao W et al (2020) Crystallization structures and properties of different polyolefins with similar grafting degree of maleic anhydride. Polymers 12(3):675. https://doi.org/10.3390/polym12030675

Shang M, Wu Y, Shentu B et al (2019) Toughening of PBT by POE/POE- g -GMA elastomer through regulating interfacial adhesion and toughening mechanism. Indus Eng Chem Res 58(28). https://doi.org/10.3390/polym12030675

Wu P, Yang Q, Zhao Z et al (2019) Realizing simultaneous toughening and reinforcement in polypropylene blends via solid die-drawing. Polymer 161:109–121. https://doi.org/10.1016/j.polymer.2018.12.011

Ghanbari A, Jalili NS, Haddadi SA et al (2020) Mechanical properties of extruded glass fiber reinforced thermoplastic polyolefin composites. Polym Compos. https://doi.org/10.1002/pc.25672

Kovács T, Simon-Stger L, Heller B et al (2021) Enhancing properties of PC/PA blends via compatibilization of olefin-maleic-anhydride copolymer-based additives in masterbatch form. J Polym Res 28(8). https://doi.org/10.1007/s10965-021-02656-1

Liu Y, Zhang X, Gao Q et al (2021) Structure and properties of polyoxymethylene/silver/maleic anhydride-grafted polyolefin elastomer ternary nanocomposites. Polymers 13(12):1954. https://doi.org/10.3390/polym13121954

Bujjibabu G, Das VC, Ramakrishna M et al (2021) Development of Banana/Coir Natural Fibers Reinforced Polypropylene Hybrid Composites: The Effect of MA-g-PP (Maleic Anhydride Grafted Polypropylene) on Mechanical Properties and Thermal Properties. Nano Hybrids and Composites 32:85–97. https://doi.org/10.4028/www.scientific.net/NHC.32.85

Andre JS, Li B, Chen X et al (2020) Interfacial reaction of a maleic anhydride grafted polyolefin with ethylene vinyl alcohol copolymer at the buried solid/solid interface. Polymer 212(9):123141. https://doi.org/10.1016/j.polymer.2020.123141

Rychl J, Matisová-Rychlá L, Novak I et al (2020) Thermooxidative stability of hot melt adhesives based on metallocene polyolefins grafted with polar acrylic acid moieties. Polymer Testing. In Press J Pre-Proof. Available online. https://doi.org/10.1016/j.polymertesting.2020.106422

Jaisingh A, Kapor GS, Nebhani L (2021) Tuning Melt Strength and Processability of Polyolefins by Addition of a Functionalized Additive Designed via the TEMPO-Driven Thiol-ene Reaction. Ind Eng Chem Res. https://doi.org/10.1021/acs.iecr.1c01190

Birch NP, Liu K, Mun SC et al (2019) Accelerating the coupling of maleated polyolefins with polyesters via tin compounds. Macromolecules 52(21). https://doi.org/10.1021/acs.macromol.9b01444

Mousavi-Fakhrabadi S H, Ahmadi S, Arabi H (2022) Mixing of hindered amine-grafted polyolefin elastomers with LDPE to enhance its long-term weathering and photo-stability. Polym Degrad Stability 198:109882-. https://doi.org/10.1016/j.polymdegradstab.2022.109882

Cui L, Wang S, Yong Z et al (2010) Morphology and nonisothermal crystallization behavior of PP/Novolac blends. J Appl Polym Sci 105(2):379–389. https://doi.org/10.1002/app.25948

Liu J, Liu J (2018) Characterization of maleic anhydride/styrene melt-grafted random copolypropylene and its impact on crystallization and mechanical properties of isotactic polypropylene. Polym Bullet 76(9). https://doi.org/10.1007/s00289-018-2609-2

Tariq A, Afzal A, Rashid IA et al (2020) Study of thermal, morphological, barrier and viscoelastic properties of PP grafted with maleic anhydride (PP-g-MAH) and PET blends. J Polym Res 27(10):309. https://doi.org/10.1007/s10965-020-02291-2

Liu HP, Li PY, Gu Z et al (2020) Charaterization and Preparation of PA6/EPDM-g-MAH/OMMT Polymer Alloys Nanocomposites. Key Eng Mater 852:80–88. https://doi.org/10.4028/www.scientific.net/KEM.852.80

Liu B, Shangguan Y, Song Y et al (2013) Influences of compatibilizers on rheology and mechanical properties of propylene random copolymer/styrene-ethylene-butylene-styrene block copolymer/organic-montmorillonite nanocomposites. J Appl Polym Sci 129(3):973–982. https://doi.org/10.1002/app.38637

Zhou YG, Su B et al (2017) Effect of Cold-Drawn Fibers on the Self-Reinforcement of PP/LDPE Composites. J Mater Eng Perform 26(8):4072–4082. https://doi.org/10.1007/s11665-017-2823-3

Dikovsky D, Marom G, Avila-Orta CA et al (2005) Shear-induced crystallization in isotactic polypropylene containing ultra-high molecular weight polyethylene-oriented precursor domains. Polymer 46(9):3096–3104. https://doi.org/10.1016/j.polymer.2005.01.086

Avila-Orta CA, Burger C, Somani R et al (2005) Shear-induced crystallization of isotactic polypropylene within the oriented scaffold of noncrystalline ultrahigh molecular weight polyethylene. Polymer 46(20):8859–8871. https://doi.org/10.1016/j.polymer.2005.05.136

Acknowledgements

This work is supported by a Liaoning climbing scholar program. In this work, the Beijing Synchrotron Radiation Facility (BSRF) 1W2A line station was used for synchrotron radiation characterization. We sincerely thank the scientists of BSRF line station, especially Dr. Moguang for their help.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflicts of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Shao, W., Liu, L., Wang, Y. et al. Crystallization, structure, and properties of polypropylene random copolymer (PPR) / high-density polyethylene/polypropylene grafted maleic anhydride((HDPE/PP)-g-MAH) blends. J Polym Res 29, 354 (2022). https://doi.org/10.1007/s10965-022-03211-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-022-03211-2