Abstract

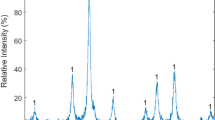

The reduction kinetics of zinc ferrite in CO was investigated under isothermal conditions at different CO concentration and roasting temperature with the help of the thermogravimetric analysis (TGA). The reduction of zinc ferrite was a step-wise mechanism. As the model fitting results suggest, the first stage was controlled by the rate of first-order (when CO = 4%) or the second-order (when CO = 6%, 8%) reaction, with the Ea in 4%, 6%, and 8% of CO being 91.45 kJ mol−1, 73.08 kJ mol−1, and 73.49 kJ mol−1, correspondingly. Also, the diffusion of reactant proves to constitute the rate-determining step in the second stage, and the reaction model is R2 (contracting cylinder), wherein the Ea in 4%, 6%, and 8% of CO is 80.81 kJ mol−1, 59.11 kJ mol−1, and 59.19 kJ mol−1, correspondingly. The generation of magnetite and zinc oxide is the chemical reaction control, and the generation of ferrous oxide, metal iron was the diffusion control. The increase in the CO concentration from 4% to 6% or 8% could decrease the Ea and increase the reaction order, consequently, the reductive roasting was accelerated.

Similar content being viewed by others

References

Peng B, Peng N, Liu H, Xue K, Lin D-h. Comprehensive recovery of Fe, Zn, Ag and In from high iron-bearing zinc calcine. J. Cent. South. Univ. 2017;24(5):1082–9.

Gargul K, Boryczko B. Removal of zinc from dusts and sludges from basic oxygen furnaces in the process of ammoniacal leaching. Arch. Civ. Mech. Eng. 2015;15(1):179–87.

Li K, An X, Park KH, Khraisheh M, Tang J. A critical review of CO2 photoconversion: catalysts and reactors. Catal Today. 2014;224:3–12.

Nordhei C, Mathisen K, Safonova O, van Beek W, Nicholson DG. Decomposition of carbon dioxide at 500 °C over reduced iron, cobalt, nickel, and zinc ferrites: a combined xanes − xrd study. J Phys Chem C. 2009;113(45):19568–77.

Tabata M, Nishida Y, Kodama T, Mimori K, Yoshida T, Tamaura Y. CO2 decomposition with oxygen-deficient Mn(II) ferrite. J Mater Sci. 1993;28(4):971–4.

Liang Y, Min X, Chai L, Wang M, Liyang W, Pan Q, et al. Stabilization of arsenic sludge with mechanochemically modified zero valent iron. Chemosphere. 2017;168:1142–51.

Nasiri Y, Panjepour M, Ahmadian M. The kinetics of hematite reduction and cementite formation with CH4-H2-Ar gas mixture. Int J Miner Process. 2016;153:17–28.

Kang HW, Chung WS, Murayama T. Effect of iron ore size on kinetics of gaseous reduction. ISIJ Int. 1998;38(2):109–15.

Khedr MH. Isothermal reduction kinetics at 900–1100 °C of NiFe2O4 sintered at 1000–1200 °C. J. Anal. Appl. Pyrolysis. 2005;73(1):123–9.

Davies M, Simnad M, Birchenall C. On the mechanism and kinetics of the scaling of iron. JOM. 1951;3(10):889–96.

Li J, Li B, Han J, Cao Z, Wang J. A Comparative study on the reduction mechanism of Fe 2 O 3 under different heating methods. JOM. 2014;66(8):1529–36.

Mac Rae DR. Kinetics and mechanism of the reduction of solid iron oxides in iron-carbon melts from 1200 to 1500 C. JOM. 1965;17(12):1391–5.

Drakshayani DN, Mallya RM. Reactivity with hydrogen of pure iron oxide and of iron oxides doped with oxides of Mn, Co, Ni and Cu. J. Therm. Anal. 1991;37(5):891–906.

Lee JJ, Lin CI, Chen HK. Carbothermal reduction of zinc ferrite. Metall Mater Trans B-Proc Metall Mater Proc Sci. 2001;32(6):1033–40.

Tong LF, Hayes P. Mechanisms of the reduction of zinc Ferrites in H2/N2 gas mixtures. Miner Process Extr Metall Rev. 2006;28(2):127–57.

Tong LF. Reduction mechanisms and behaviour of zinc ferrite - Part 2: znFe2O4 solid solutions. Trans Inst Min Metall Sect C-Miner Process Extr Metall. 2001;110:C123–32.

Tong LF. Reduction mechanisms and behaviour of zinc ferrite - Part 1: pure ZnFe2O4. Trans Inst Min Metall Sect C-Miner Process Extr Metall. 2001;110:C14–24.

Wang Z, Liang Y, Peng N, Peng B. The non-isothermal kinetics of zinc ferrite reduction with carbon monoxide. J Therm Anal Calorim. 2019;136(5):2157–64.

Zhang L, Mo J, Li X, Pan L, Liang X, Wei G. A kinetic study of indium leaching from indium-bearing zinc ferrite under microwave heating. Metall Trans B. 2013;44(6):1329–36.

Vyazovkin S. Kinetic concepts of thermally stimulated reactions in solids: a view from a historical perspective. Int Rev Phys Chem. 2000;19(1):45–60.

Opfermann J. Kinetic analysis using multivariate non-linear regression. I. Basic concepts. J. Therm. Anal. Calorim. 2000;60(2):641–58.

Junca E, Restivo TAG, de Oliveira JR, Espinosa DCR, Tenório JAS. Reduction of electric arc furnace dust pellets by simulated reformed natural gas. J Therm Anal Calorim. 2016;126(3):1889–97.

Vyazovkin S, Burnham AK, Criado JM, Pérez-Maqueda LA, Popescu C, Sbirrazzuoli N. ICTAC Kinetics Committee recommendations for performing kinetic computations on thermal analysis data. Thermochim Acta. 2011;520(1–2):1–19.

Galwey AK. What is meant by the term ‘variable activation energy’ when applied in the kinetic analyses of solid state decompositions (crystolysis reactions). Thermochim Acta. 2003;397(1):249–68.

Junca E, Grillo FF, Restivo TAG, de Oliveira JR, Espinosa DCR, Tenório JAS. Kinetic investigation of synthetic zinc ferrite reduction by hydrogen. J Therm Anal Calorim. 2017;129(2):1215–23.

Acknowledgements

The authors would like to thank National Key R&D Program of China (2018YFC1900300), National Science Fund for Distinguished Young Scholars (51825403), and National Natural Science Foundation of China (51574295) for financial support for this study.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wang, G., Min, X., Peng, N. et al. The isothermal kinetics of zinc ferrite reduction with carbon monoxide. J Therm Anal Calorim 146, 2253–2260 (2021). https://doi.org/10.1007/s10973-020-10542-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-020-10542-z