Abstract

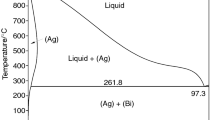

The knowledge of specific heat for Ag–Si–Ge alloys in a broad temperature range would facilitate their practical applications in various branches of engineering. In this work, differential scanning calorimetry measurements were executed to determine specific heat of Ag–Si–Ge alloys from 123 K to high temperatures. For binary alloys, distinct troughs of specific heat are observed at eutectic Ag89Si11 and Ag75Ge25, when temperatures are larger than 500 K. Furthermore, specific heat of ternary Ag–Si–Ge alloys was predicted by four candidate principles based on the binary alloy’s data. Accordingly, the specific heat of 15 compositions of ternary Ag–Si–Ge alloys was determined to evaluate the predicted value. It is found that specific heat increases linearly with the rising Ag and Ge content in Si-rich alloys at low temperatures. Besides, alloys around Si–Ag75Ge25 pseudobinary line in Ag-rich area exhibit much lower specific heat at high temperatures. According to the comparison between measured and predicted specific heat of ternary alloys, the interpolation which employs data of pure elements, hypo-/hypereutectic alloys and the eutectic points, provides highest accuracy, especially at high temperatures. This rule may be applied to other eutectic systems.

Similar content being viewed by others

References

Li S, Zheng QY, Lv YC, Liu XY, Wang XQ, Huang P, Cahill DG, Lv B. High thermal conductivity in cubic boron arsenide crystals. Science. 2018;361:579.

Waldrop MM. The chips are down for Moore’s law. Nat News. 2016;530:144.

Xiong SY, Saaskilahti K, Kosevich YA, Han HX, Donadio D, Volz S. Blocking phonon transport by structural resonances in alloy-based nanophononic metamaterials leads to ultralow thermal conductivity. Phys Rev Lett. 2016;117:025503.

Shon W, Rhyee JS, Jin YS, Kim SJ. Magnetic polaron and unconventional magnetotransport properties of the single-crystalline compound EuBiTe3. Phys Rev B. 2019;100:024443.

Drebushchak VA. Model-free temperature scaling for heat capacity. J Therm Anal Calorim. 2017;130:5.

Liu Z, Xu J, Wang Y, Jian Z, Liu J. Calorimetric study on Ge23Se67Sb10–0.5CsCl glass. J Therm Anal Calorim. 2018;132:103.

Wang Q, Wang HP, Geng DL, Li MX, Wei B. A calorimetric study assisted with first principle calculations of specific heat for Si-Ge alloys within a broad temperature range. Chin Phys Lett. 2018;35:126501.

Polman A, Knight M, Garnett EC, Ehrler B, Sinke WC. Photovoltaic materials: present efficiencies and future challenges. Science. 2016;352:AAD4424.

Yu ZW, Zhang XW, Zhang H, Huang YY, Li Y, Zhang X, Gan ZX. Improved power conversion efficiency in radial junction thin film solar cells based on amorphous silicon germanium alloys. J Alloy Compd. 2019;803:260.

Mitrasinovic AM, Hernandez FCR. Comparison of solar silicon feedstock. J Therm Anal Calorim. 2014;115:177.

Morozova NV, Korobeinikov IV, Ovsyannikov SV. Strategies and challenges of high-pressure methods applied to thermoelectric materials. J Appl Phys. 2019;125:220901.

Ozdamar B, Ozbal G, Cinar MN, Sevim K, Kurt G, Kaya B, Sevincli H. Structural, vibrational, and electronic properties of single-layer hexagonal crystals of group IV and V elements. Phys Rev B. 2018;98:045431.

Juntunen T, Vanska O, Tittonen I. Anderson localization quenches thermal transport in aperiodic superlattices. Phys Rev Lett. 2019;122:105901.

Talreja S, Sharma K, Ahuja BL. Feasibility of crystalline isostructural X2Sb2Te5 (X = Ge, Si) phase change materials in memory storage devices: first principles calculations. Comput Mater Sci. 2016;121:113.

Singh P, Kaur R, Sharma P, Sharma V, Mishra M, Gupta G, Thakur A. Optical band gap tuning of Ag doped Ge2Sb2Te5 thin films. J Mater Sci Mater Electron. 2017;28:11300.

Kumar KRS, Kalaiselvam S. Experimental investigations on the thermophysical properties of CuO-palmitic acid phase change material for heating applications. J Therm Anal Calorim. 2017;129:1647.

Goto M, Xu YB, Zhan TZ, Sasaki M, Nishimura C, Kinoshita Y, Ishikiriyama M. Ultra-low thermal conductivity of high-interface density Si/Ge amorphous multilayers. Appl Phys Express. 2018;11:045202.

Jung SC, Kim HJ, Kang YJ, Han YK. Advantages of Ge anode for Na-ion batteries: Ge vs. Si and Sn. J Alloy Compd. 2016;688:158.

Ehteshami H, Korzhavyi PA. Thermophysical properties of paramagnetic Fe from first principles. Phys Rev B. 2017;96:224406.

Ji PF, Zhang YW, Yang M. Structural, dynamic, and vibrational properties during heat transfer in Si/Ge superlattices: a Car–Parrinello molecular dynamics study. J Appl Phys. 2013;114:234905.

Lü P, Wang HP. Direct formation of peritectic phase but no primary phase appearance within Ni 83.25 Zr 16.75 peritectic alloy during free fall. Sci Rep. 2016;6:22641.

Wang HP, Zhao JF, Liu W, Wei B. An anomalous thermal expansion phenomenon induced by phase transition of Fe-Co-Ni alloys. J Appl Phys. 2018;124:215107.

Bochtler B, Gross O, Gallino I, Busch R. Thermo-physical characterization of the Fe67Mo6Ni3.5Cr3.5P12C5.5B2.5 bulk metallic glass forming alloy. Acta Mater. 2016;118:129.

Zou PF, Wang HP, Yang SJ, Hu L, Wei B. Anomalous temperature dependence of liquid state density for Ni50Ti50 alloy investigated under electrostatic levitation state. Chem Phys Lett. 2017;681:101.

Wang Q, Chang J, Wang HP. Thermophysical properties and atomic structure of liquid Si–Ge alloys. Mater Chem Phys. 2019;221:224.

Haynes WM. Handbook of chemistry and physics. 97th ed. Boca Raton: CRC Press; 2016.

Acknowledgements

This work is financially supported by National Natural Science Foundation of China (Grant Nos. 51734008, 51522102 and 51327901). We thank the director of LMSS, Prof. B. Wei, for his consistent support. The authors are grateful to J.F. Zhao and C.H. Zheng for their helpful discussions.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix

Rights and permissions

About this article

Cite this article

Wang, Q., Chen, H.M., Li, M.X. et al. Specific heat of ternary Ag–Si–Ge alloys from 123 K to high temperatures: experiment and prediction. J Therm Anal Calorim 145, 2287–2294 (2021). https://doi.org/10.1007/s10973-020-09839-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-020-09839-w