Abstract

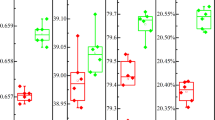

One of the major factors in reducing a cost of commercial solar cells is the lifetime of the photovoltaic material. In this work, a deterioration of Si generated by solvent metal gathering method (SMG) and Si removed from damaged solar cells is analyzed and compared with electronic grade Si. The differences in heating and cooling cycles on the DTA curves of different solar grade Si and Cu–Si mixtures are compared. A nonequilibrium exothermic reaction in Si generated by SMG method is recorded in samples aged in room atmosphere for 1 year. The outcomes of the cooling cycles after the DTA analyses for various solar grades Si were not significantly differentiated from the referred electronic grade Si indicating that recrystallization of aged Si diminishes the problem related to agglomeration of Cu and oxygen on the surface of Si solar grade particles. The DTA tests showed that recrystallized Si from the deteriorated solar cells can be recycled as feedstock materials for solar cells applications while Si generated by SMG method can be used for blending in order to achieve a long lifetime of Si solar cells.

Similar content being viewed by others

References

Jester T. Crystalline silicon manufacturing progress. Prog Photovolt. 2002;10:99–106.

Genieva S, Turmanova S, Dimitrova A, Vlaev L. Thermal degradation of rice husks and characterization of the products. J Therm Anal Calorim. 2008;93:387–96.

Gu J, Fahrenkrug E, Maldonado S. Direct electrodeposition of crystalline silicon at low temperatures. J Am Chem Soc. 2013;135:1684–87.

Mitrašinović A. Photo-catalytic properties of silicon and its future in photovoltaic applications. Renew Sustain Energy Rev. 2011;15:3603–7.

Abdyukhanov I, Abdyukhanov M, Kuz’min Y, Merkushkin V. Production of metallurgical silicon of enhanced quality for land-based solar cells. Met Sci Heat Treat. 2000;42:246–9.

Arkhipov M, Dubovskiy A, Reu A, Mukhanov V, Smirnova S. Carbothermic synthesis of silicon in 150 kW DC arc furnace for solar applications. Silicon for the Chem and Sol Ind. IX, Oslo, Norway, 2008.

Yoshikawa T, Morita K. Refining of silicon during its solidification from a Si–Al melt. J Cryst Growth. 2009;311:776–9.

Gumaste J, Mohanty B, Galgali R, Syamaprasad U, Nayak B, Singh S, Jena P. Solvent refining of metallurgical grade silicon. Sol Energy Mater. 1987;16:289–96.

Olesinski R, Abbaschian G. The copper–silicon system. Bull of Alloy Phase Diagr. 1986;7:170–8.

Buonassisi T, Marcus M, Istratov A, Heuer M, Ciszek T, Lai B, Cai Z, Weber E. Analysis of copper-rich precipitates in silicon: chemical state, gettering, and impact on multicrystalline silicon solar cell material. J Appl Phys. 2005;97:063503.

Mitrašinović A, Utigard T. Trace elements distribution in Cu–Si alloys. Chem Phys Lett. 2011;515:72–7.

Mitrašinović A, Utigard T. Copper removal from hypereutectic Cu–si alloys by heavy liquid media separation. Metall Mater Trans B. 2012;43:379–87.

Bronsveld P, Naber R, Geerligs L, Pozigun S, Syvertsen M, Knopf C, Kvande R. p and n-type mono and mc-Si solar cells using blended upgraded metallurgical grade silicon. 24th European Photovoltaic Solar Energy Conference and Exhibition 2009 21–25 September, Hamburg, Germany.

Pavone A. Polysilicon for solar wafers. SRI Consulting, Process Econ Progr. PEP Report No.272, December 2009.

Mitrašinović A, D’Souza R, Utigard T. Impurity removal and overall rate constant during low pressure treatment of liquid silicon. J Mater Process Technol. 2012;212:78–82.

Grmela L, Škarvada P, Tománek P, Macků R, Smith S. Local investigation of thermal dependence of light emission from reverse-biased monocrystalline silicon solar cells. Sol Energy Mater & Sol Cells. 2012;96:108–11.

Miller T. Use of TG/FT-IR in material characterization. J Therm Anal Calorim. 2011;106:249–54.

Ould-Abbas A, Bouchaour M, Trari D, Chabane Sari N. The impact of drying phenomena and heat treatment on the structure of porous silicon. J Therm Anal Calorim. 2012;109:1347–51.

Madarász J, Nagygyörgy V, Stathatos E, Pokol G. Ageing and thermal stability studies on quasi-solid composite electrolytes for Gra¨tzel-type solar cells. J Therm Anal Calorim. 2013;. doi:10.1007/s10973-012-2904-3.

Boettinger W, Kattner U, Moon K, Perepezko DTA and Heat-flux DSC Measurements of Alloy Melting and Freezing. J Natl Inst Stand Technol. 2006 Special Publication 960-15, U.S. Department of Commerce.

Sułowska J, Wacławska I, Szumera M. Effect of copper addition on glass transition of silicate–phosphate glasses. J Therm Anal Calorim. 2012;109:705–10.

DeWolf I. Micro-Raman spectroscopy to study local mechanical stress in silicon integrated circuits. Semicond Sci Tech. 1996;11:139–54.

Robles Hernandez F, De Cruz Rivera. Micro-Raman analysis of the Si particles present in Al–Si hypereutectic alloys in liquid and semi-solid states. J Adv Eng Mater. 2007;9:46–51.

Schade M, Varlamova O, Reif J, Blumtritt H, Erfurth W, Leipner H. High-resolution investigations of ripple structures formed by femtosecond laser irradiation of silicon. Anal Bioanal Chem. 2010;396:1905–11.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mitrašinović, A.M., Robles Hernández, F.C. Comparison of solar silicon feedstock. J Therm Anal Calorim 115, 177–183 (2014). https://doi.org/10.1007/s10973-013-3245-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-013-3245-6