Abstract

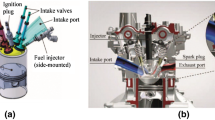

Usage of natural gas in an internal combustion engine that has different combustion technologies is considered a possible solution to reduce engine outlet emissions and lower fuel consumption. A single-cylinder IDI engine, a variable compression ratio engine equipped with a mechanical pumping diesel fuel that can change the timing of starting a fuel injection from 0° to 45° before TDC, for the empirical study of combustion and pollutants is tested. Computational fluid dynamics simulation with detailed chemical kinetic mechanisms is compared with experimental results. Experimental results are evaluated in two different engines loads of 25%, 60%, and 1100 rpm. Four cases are tested with different natural gas ratio and the same start of diesel fuel injection. Increasing the formation and release of HC and CO pollutant occurs with an increase in premix natural gas due to incomplete combustion. Furthermore, by increasing the percentage of natural gas from case 1 to 4, the reduction of NOx in the engine output occurs by increasing the natural gas ratio and at the end, reducing HC and CO emissions happen by increasing engine loading and combustion improvement. Also, in-cylinder pressure at the compression stage decreases with an increase in natural gas ratio because with the increase in the mixing of natural gas fuel with air, the special heat capacity of the mixture increases.

Similar content being viewed by others

Abbreviations

- IDI:

-

Indirect injection

- LTC:

-

Low-temperature combustion

- PPC:

-

Partially premixed combustion

- RCCI:

-

Reactivity controlled compression ignition

- NG:

-

Natural gas

- PRR:

-

Pressure rise rate

- EGR:

-

Exhaust gas recirculation

- TDC:

-

Top dead center

- CA:

-

Crank angle

- aBDC:

-

After bottom dead center

- bBDC:

-

Before bottom dead center

- bTDC:

-

Before top dead center

- CFD:

-

Computational fluid dynamic

- KH:

-

Kelvin–Helmholtz

- RT:

-

Rayleigh–Taylor

- HRR:

-

Heat release rate

- IVC:

-

Intake valve closing

- EVO:

-

Exhaust valve opening

- NOx:

-

Oxides of nitrogen

- CO:

-

Carbon monoxide

- HC:

-

Unburned hydrocarbon

References

Garvin A. One giant leap, Interview of armstrong, engine technology international, Issue 3/2002, 2002.

Doosje E, Willems F, Baert R. Experimental demonstration of RCCI in heavy-duty engines using diesel and natural gas. SAE Technical Paper 2014-01-1318, 2014.

Khatamnejad H, Khalilarya S, Jafarmadar S, Mirsalim M et al. Influence of blend ratio and injection parameters on combustion and emissions characteristics of natural gas-diesel RCCI engine. SAE Technical Paper 2017-24-0083, 2017.

Mikulski M, Bekdemir C, Willems F. Experimental validation of a combustion kinetics based multi-zone model for natural gas-diesel RCCI engines. In: Symposium for combustion control Aachen, 2016.

Hanson R, Kokjohn S, Splitter D, Reitz R. An experimental investigation of fuel reactivity controlled PCCI combustion in a heavy-duty engine. SAE Int J Engines. 2010;3(1):700–16.

Ebrahimi M, Najafi M, Jazayeri SA, Mohammadzadeh AR. A detail simulation of reactivity controlled compression ignition combustion strategy in a heavy-duty diesel engine run on natural gas/diesel fuel. Int J Engine Res. 2017;19:774–89.

Paykani A, Kakaee AH, Rahnama P, Reitz RD. Effects of diesel injection strategy on natural gas/diesel reactivity controlled compression ignition combustion. Energy. 2015;90:814–26.

Ghadikolaei MA, Cheung CS, Yung K-F. Study of combustion, performance, and emissions of a diesel engine fueled with ternary fuel in blended and fumigation modes. Fuel. 2019;235:288–300.

An Y, Raman V, Tang Q, Shi H, Sim J, Chang J, Magnotti G, Johansson B. Combustion stability study of partially premixed combustion with low-octane fuel at low engine load conditions. Appl Energy. 2019;235:56–67.

Gharehghani A. Load limits of an HCCI engine fueled with natural gas, ethanol, and methanol. Fuel. 2019;239:1001–14.

Polat S. An experimental study on combustion, engine performance and exhaust emissions in a HCCI engine fuelled with diethyl ether–ethanol fuel blends. Fuel Process Technol. 2016;143:40–150.

Tong L, Wang H, Zheng Z, Reitz R, Yao M. Experimental study of RCCI combustion and load extension in a compression ignition engine fueled with gasoline and PODE. Fuel. 2016;181:878–86.

Yousefi A, Birouk M, Guo H. An experimental and numerical study of the effect of diesel injection timing on natural gas/diesel dual-fuel combustion at low load. Fuel. 2017;203:642–57.

Yousefi A, Birouk M. Investigation of natural gas energy fraction and injection timing on the performance and emissions of a dual-fuel engine with pre-combustion chamber under low engine load. Appl Energy. 2017;189:492–505.

Abd Alla GH, Soliman HA, Badr OA, Abd Rabbo MF. Effect of injection timing on the performance of a dual fuel engine. Energy Convers Manag. 2002;43:269–77.

Abagnale C, Cameretti MC, De Simio L, Gambino M, Iannaccone S, Tuccillo R. Numerical simulation and experimental test of dual fuel operated diesel engines. Appl Therm Eng. 2014;65:403–17.

Mittal M, Donahue R, Winnie P, Gillette A. Exhaust emissions characteristics of a multicylinder 18.1-L diesel engine converted to fueled with natural gas and diesel pilot. J Energy Inst. 2014;88:275–83.

Mbarawa M, Milton BE, Casey RT. Experiments and modelling of natural gas combustion ignited by a pilot diesel fuel spray. Int J Therm Sci. 2001;40:927–36.

Jafarmadar S, Zehni A. Modeling the effect of EGR on combustion and pollution of dual fuel engines with flow field model. Int J Energy Environ Eng. 2010;1:19–26.

Hockett AG, Hampson G, Marchese AJ. Natural gas/diesel RCCI CFD simulations using multi-component fuel surrogates. Int J Powertrains. 2017;6(1):76–108.

Santoso H, Matthews J, Cheng W. Managing SI/HCCI dual-mode engine operation. SAE Technical Paper 2005-01-0162, 2005.

Han Z, Reitz RD. Turbulence modeling of internal combustion engines using RNG κ-ε models. Combust Sci Technol. 1995;106(4–6):267–95.

Beale JC, Reitz RD. Modeling spray atomization with the Kelvin–Helmholtz/Rayleigh–Taylor hybrid model. At Sprays. 1999;9:623–50.

Smith GP, Golden DM, Frenklach M, Moriarty NW, Eiteneer B, Goldenberg M, Bowman CT, Hanson RK, Song S, Gardiner WC, Jr., Lissianski VV, Qin Z. http://www.me.berkeley.edu/gri_mech/;2006.

Nieman DE, Dempsey AB, Reitz RD. Heavy-duty RCCI operation using natural gas and diesel. SAE Int J Eng. 2012;5:270–85.

Wissink ML, Curran SJ, Roberts G, Musculus MP, Mounaïm-Rousselle C. Isolating the effects of reactivity stratification in reactivity-controlled compression ignition with iso-octane and n-heptane on a light-duty multi-cylinder engine. Int J Engine Res. 2017;19(9):907–26.

Ladommatos N, Zhao H. Engine combustion instrumentation and diagnostics. Warrendale: SAE International; 2001.

Plee S, Ahmad T, Myers J. Flame temperature correlation for the effects of exhaust gas recirculation on diesel particulate and NOx emissions, SAE Technical Paper 811195, 1981.

Wei L, Geng P. A review on natural gas/diesel dual fuel combustion, emissions and performance. Fuel Process Technol. 2016;142:264–78.

Raihan MS, Guerry ES, Dwivedi U, Srinivasan KK, Krishnan SR. Experimental analysis of diesel-ignited methane dual-fuel low-temperature combustion in a singlecylinder diesel engine. J Energy Eng. 2015;141:C4014007.

Shoemaker NT, Gibson CM, Polk AC, Krishnan SR, Srinivasan KK. Performance and emissions characteristics of bio-diesel (B100)-ignited methane and propane combustion in a four cylinder turbocharged compression ignition engine. J Eng Gas Turbines Power Trans ASME. 2012;134:082803.

Polk AC, Gibson CM, Shoemaker NT, Srinivasan KK, Krishnan SR. Detailed characterization of diesel-ignited propane and methane dual-fuel combustion in a turbocharged direct-injection diesel engine. Proc Inst Mech Eng D J Automob Eng. 2013;227:1255–72.

Wang X, Deng K, He F, Zhou Z. A thermodynamics model for the compression and expansion process during the engine’s motoring and a new method for the determination of TDC with simulation technique. Appl Therm Eng. 2007;27:2003–10.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Khatamnejad, H., Khalilarya, S., Jafarmadar, S. et al. Experimental investigation on the effect of natural gas premixed ratio on combustion and emissions in an IDI engine. J Therm Anal Calorim 138, 3977–3986 (2019). https://doi.org/10.1007/s10973-019-08726-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-019-08726-3