Abstract

The reduced performance of a diesel engine with biodiesel can be overcome by inclusion of nanoparticles. This study uses a novel binary mixture of Prosopis juliflora biodiesel (PJB) and 200 ppm of metal-based nanoparticles [cerium oxide (CeO2), manganese dioxide (MnO2), and titanium dioxide (TiO2)], to operate and examine the behaviour of a four-stroke, one-cylinder, naturally aspirated, water-cooled diesel engine. The work comprises a new comparison of energy, exergy, and sustainability performance through energy distribution and utilisation inside the engine using first and second laws of thermodynamics for the fuel samples PJB0, PJB100, PJB100Ce, PJB100Mn, and PJB100Ti. The boundary conditions for the analysis are set to a compression ratio of 17.5, an engine speed of 1500 rpm, and injection timing of 23° crank angle bTDC. The addition of various nanoparticles into the pure PJB fuel increased the energy and exergy efficiency by 6.1–7.3%, the exergy performance coefficient by 9.9–14.6%, and the sustainability index by 3.6–6.8% and reduced the exergy destruction by 3.5–6.4% at full engine load. Among the various blends analysed, PJB100Ti performed superiorly as compared to others. From the detailed analysis, energy, exergy, and sustainability provide insightful information about the engine’s operation and its impact on the engine system. The adoption of nanoparticle-enhanced biodiesel is not only a promising alternative in the search for cleaner but also more effective energy sources. This study suggests more investigation and development in the areas of alternative fuels, engine optimization, and the development of sustainable energy solutions.

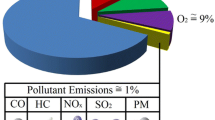

Graphical abstract

Similar content being viewed by others

Data availability

This paper was published with all the data that is generated or analysed during this investigation.

Abbreviations

- ASTM:

-

American Standard Testing Method

- bTDC:

-

Before top dead centre

- BTE:

-

Brake thermal efficiency

- CA:

-

Crank angle

- CeO2 :

-

Cerium oxide

- CI:

-

Compression ignition

- CN:

-

Cetane number

- CO:

-

Carbon monoxide

- CO2 :

-

Carbon dioxide

- CR:

-

Compression ratio

- DI:

-

Direct injection

- MnO2 :

-

Manganese dioxide

- PJB0:

-

Pure diesel

- PJB100:

-

100% Of Prosopis juliflora biodiesel

- PJB100Ce:

-

100% Of Prosopis juliflora biodiesel + 200 ppm CeO2 nanoparticles

- PJB100Mn:

-

100% Of Prosopis juliflora biodiesel + 200 ppm MnO2 nanoparticles

- PJB100Ti:

-

100% Of Prosopis juliflora biodiesel + 200 ppm TiO2 nanoparticles

- ppm:

-

Parts Per Million

- SI:

-

Sustainability index

- TiO2 :

-

Titanium dioxide

- Ta :

-

Ambient air temperature

- T1 :

-

Cooling water temperature at inlet

- T2 :

-

Cooling water temperature at outlet

- T5 :

-

Exhaust gas temperature at outlet

References

Sundar Rajan P, Gopinath KP, Greetham D, Antonysamy AJ. A review on cleaner production of biofuel feedstock from integrated CO2 sequestration and wastewater treatment system. J Clean Prod. 2019;210:445–58.

Rajpoot AS, Choudhary T, Chelladurai H, Mishra S, Shende V. Performance analysis of a CI engine powered by different generations of biodiesel; Palm oil, Jatropha, and microalgae. Materials Today: Proceedings. 2023.

Devi DS, Kumar R, Rajak U. Plastic waste as a biofuel feedstock—a conceptual study. IOP Conf Ser Mater Sci Eng. 2021;1116:012029.

Faisal A, Javed F, Hassan M, Gorji M, Akram S, Rashid N, et al. Experimental and mathematical nonlinear rheological characterization of chicken fat oil—a sustainable feedstock for biodiesel. Biomass Convers Biorefinery. 2021;13(8):7043–50.

Chinni G, Alarifi IM, Rahimi-Gorji M, Asmatulu R. Investigating the effects of process parameters on microalgae growth, lipid extraction, and stable nanoemulsion productions. J Mol Liq. 2019;291:111308.

Mujtaba M, Kalam MA, Masjuki H, Razzaq L, Khan HM, Soudagar MEM, et al. Development of empirical correlations for density and viscosity estimation of ternary biodiesel blends. Renew Energy. 2021;179:1447–57.

Tayari S, Abedi R, Rahi AJRE. Comparative assessment of engine performance and emissions fueled with three different biodiesel generations. Renew Energy. 2020;147:1058–69.

Ong HC, Masjuki H, Mahlia TI, Silitonga A, Chong W, Yusaf TJE. Engine performance and emissions using Jatropha curcas. Ceiba pentandra and Calophyllum inophyllum biodiesel in a CI diesel engine. 2014;69:427–45.

Devi DS, Kumar R, Rajak U. Experimental investigation of performance, emission and combustion characteristics of a CI engine fuelled by blends of waste plastic oil with diesel. Energy Sources Part A Recovery Utili Environ Eff. 2022;44(3):7693–708.

Elkelawy M, Bastawissi HAE, El Shenawy EA, Taha M, Panchal H, Sadasivuni KK. Study of performance, combustion, and emissions parameters of DI-diesel engine fueled with algae biodiesel/diesel/n-pentane blends. Energy Convers Manag X. 2021;10:100058.

Nouri M, Isfahani AHM, Shirneshan A. Effects of Fe2O3 and Al2O3 nanoparticle-diesel fuel blends on the combustion, performance and emission characteristics of a diesel engine. Clean Technol Environ Policy. 2021;23(8):2265–84.

Hoang AT, Balasubramanian D, Venugopal IP, Rajendran V, Nguyen DT, Lawrence KR, et al. A feasible and promising approach for diesel engine fuelled with a blend of biodiesel and low-viscosity Cinnamon oil: a comprehensive analysis of performance, combustion, and exergy. J Clean Prod. 2023;401:136682.

Rajpoot AS, Saini G, Chelladurai HM, Shukla A, Choudhary T. Comparative combustion, emission, and performance analysis of a diesel engine using Carbon Nanotube (CNT) blended with three different generations of biodiesel. Environ Sci Pollut Res. 2023.

Kumar KG, Hani EHB, Assad MEH, Rahimi-Gorji M, Nadeem S. A novel approach for investigation of heat transfer enhancement with ferromagnetic hybrid nanofluid by considering solar radiation. Microsyst Technol. 2021;27:97–104.

Manigandan S, Sarweswaran R, Devi PB, Sohret Y, Kondratiev A, Venkatesh S, et al. Comparative study of nanoadditives TiO2, CNT, Al2O3, CuO and CeO2 on reduction of diesel engine emission operating on hydrogen fuel blends. Fuel. 2020;262:116336.

Rajpoot AS, Choudhary T, Chelladurai H, Rajak U, Sahu MK. Comparison of the effect of CeO2 and CuO2 nanoparticles on performance and emission of a diesel engine fueled with Neochloris oleoabundans algae biodiesel. Materials Today: Proceedings. 2023.

Soudagar MEM, Nik-Ghazali N-N, Kalam MA, Badruddin I, Banapurmath N, Akram N. The effect of nano-additives in diesel-biodiesel fuel blends: a comprehensive review on stability, engine performance and emission characteristics. Energy Convers Manag. 2018;178:146–77.

Rajpoot AS, Choudhary T, Chelladurai H, Patel NK. Effect of graphene nanoparticles on the behavior of a CI engine fueled with Jatropha biodiesel. Materials Today: Proceedings. 2023.

Kumar KG, Reddy MG, Aldalbahi A, Rahimi-Gorji M, Rahaman M. Application of different hybrid nanofluids in convective heat transport of Carreau fluid. Chaos Solitons Fractals. 2020;141:110350.

Saxena V, Kumar N, Saxena VK. A comprehensive review on combustion and stability aspects of metal nanoparticles and its additive effect on diesel and biodiesel fuelled CI engine. Renew Sustain Energy Rev. 2017;70:563–88.

Asokan M, Prabu SS, Bade PKK, Nekkanti VM, Gutta SSGJE. Performance, combustion and emission characteristics of juliflora biodiesel fuelled DI diesel engine. Energy. 2019;173:883–92.

Rajamohan S, Gopal AH, Muralidharan KR, Huang Z, Paramasivam B, Ayyasamy T, et al. Evaluation of oxidation stability and engine behaviors operated by Prosopis juliflora biodiesel/diesel fuel blends with presence of synthetic antioxidant. Sustain Energy Technol Assess. 2022;52:102086.

Gavhane R, Kate A, Soudagar MEM, Wakchaure V, Balgude S, Rizwanul Fattah I, et al. Influence of silica nano-additives on performance and emission characteristics of Soybean biodiesel fuelled diesel engine. Energies. 2021;14(5):1489.

Hosseinzadeh-Bandbafha H, Panahi HKS, Dehhaghi M, Orooji Y, Shahbeik H, Mahian O, et al. Applications of nanotechnology in biodiesel combustion and post-combustion stages. Renew Sustain Energy Rev. 2023;182:113414.

Mahian O, Mirzaie MR, Kasaeian A, Mousavi SH. Exergy analysis in combined heat and power systems: a review. Energy Convers Manag. 2020;226:113467.

Venugopal IP, Balasubramanian D, Rajarajan A, Suresh K. Quantification of φ-operating range with impact of exhaust gas recirculation under low-temperature combustion mode with polyoxymethylene dimethyl ether: a perspective study. J Clean Prod. 2023;411:137298.

Razmara M, Bidarvatan M, Shahbakhti M. Optimal exergy-based control of internal combustion engines. Appl Energy. 2016;183:1389–403.

Sayin Kul B, Kahraman AJE. Energy and exergy analyses of a diesel engine fuelled with biodiesel–diesel blends containing 5% bioethanol. Entropy. 2016;18(11):387.

Bora BJ, Saha UK. Estimating the theoretical performance limits of a biogas powered dual fuel diesel engine using emulsified rice bran biodiesel as pilot fuel. J Energy Resour Technol. 2016;138(2).

Paul A, Panua R, Debroy DJE. An experimental study of combustion, performance, exergy and emission characteristics of a CI engine fueled by diesel–ethanol–biodiesel blends. Energy. 2017;141:839–52.

Krishnamoorthi M, Malayalamurthi RJRE. Availability analysis, performance, combustion and emission behavior of bael oil–diesel–diethyl ether blends in a variable compression ratio diesel engine. Renew Energy. 2018;119:235–52.

Verma S, Das LM, Kaushik SC, Tyagi SK. An experimental investigation of exergetic performance and emission characteristics of hydrogen supplemented biogas–diesel dual fuel engine. Int J Hydrog Energy. 2018;43(4):2452–68.

Wang X, Sun BG, Luo QH. Energy and exergy analysis of a turbocharged hydrogen internal combustion engine. Int J Hydrog Energy. 2019;44(11):5551–63.

Mahabadipour H, Srinivasan KK, Krishnan SR. An exergy analysis methodology for internal combustion engines using a multi-zone simulation of dual fuel low temperature combustion. Appl Energy. 2019;256:113952.

Bhatti SS, Verma S, Tyagi SK. Energy and exergy based performance evaluation of variable compression ratio spark ignition engine based on experimental work. Therm Sci Eng Prog. 2019;9:332–9.

Dhyani V, Subramanian KA. Experimental based comparative exergy analysis of a multi-cylinder spark ignition engine fuelled with different gaseous (CNG, HCNG, and hydrogen) fuels. Int J Hydrog Energy. 2019;44(36):20440–51.

Sarkar A, Saha UK. Energetic and exergetic analyses of a dual-fuel diesel engine run on preheated intake biogas–air mixture and oxygenated pilot fuels. J Energy Eng. 2020;146(5):04020046.

Krishnamoorthi M, Sreedhara S, Duvvuri PP. Experimental, numerical and exergy analyses of a dual fuel combustion engine fuelled with syngas and biodiesel/diesel blends. Appl Energy. 2020;263:114643.

Chaudhary V, Gakkhar RP. Exergy analysis of small DI diesel engine fueled with waste cooking oil biodiesel. Energy Sour Part A Recovery Util Environ Eff. 2021;43(2):201–15.

Jafarmadar S, Amini Niaki SR. Experimental exergy analyses in a DI diesel engine fuelled with a mixture of diesel fuel and TiO2 nano-particle. Environ Prog Sustain Energy. 2022;41(1):e13703.

Raja E, Premjeyakumar M. Potent effect of Prosopis juliflora (biodiesel + isopropanol + diesel) fueled with diesel engine and egr alteration. Clean Eng Technol. 2021;4:100205.

Oni BA, Sanni SE, Orodu DO, Ogunkunle TF. Comparing the effects of juliflora biodiesel doped with nano-additives on the performance of a compression ignition (CI) engine: Part A. Energy. 2022;244:122635.

Rajak U, Ağbulut Ü, Veza I, Dasore A, Sarıdemir S, Verma TN. Numerical and experimental investigation of CI engine behaviours supported by zinc oxide nanomaterial along with diesel fuel. Energy. 2022;239:122424.

Doğan B, Erol D. The investigation of energy and exergy analyses in compression ignition engines using diesel/biodiesel fuel blends—a review. J Therm Anal Calorim. 2023;148(5):1765–82.

Karagoz M, Uysal C, Agbulut U, Saridemir S. Energy, exergy, economic and sustainability assessments of a compression ignition diesel engine fueled with tire pyrolytic oil–diesel blends. J Clean Prod. 2020;264:121724.

Rajpoot AS, Choudhary T, Chelladurai H, Verma TN, Pugazhendhi A. Sustainability analysis of spirulina biodiesel and their bends on a diesel engine with energy, exergy and emission (3E’s) parameters. Fuel. 2023;349:128637.

Uysal C, Ağbulut Ü, Elibol E, Demirci T, Karagoz M, Saridemir S. Exergetic, exergoeconomic, and sustainability analyses of diesel–biodiesel fuel blends including synthesized graphene oxide nanoparticles. Fuel. 2022;327:125167.

Krishnan MG, Rajkumar S. Effects of dual fuel combustion on performance, emission and energy–exergy characteristics of diesel engine fuelled with diesel–isobutanol and biodiesel–isobutanol. Energy. 2022;252:124022.

Ma B, Yao A, Yao C, Wu T, Wang B, Gao J, et al. Exergy loss analysis on diesel methanol dual fuel engine under different operating parameters. Appl Energy. 2020;261:114483.

Godiganur VS, Nayaka S, Kumar G. Thermal barrier coating for diesel engine application–a review. Mater Today Proc. 2021;45:133–7.

Özcan H. Energy and exergy analyses of Al2O3–diesel–biodiesel blends in a diesel engine. Int J Exergy. 2019;28(1):29–45.

Rath MK, Mohanta DK. Exergy and energy analysis of compression ignition engine using diesel and karanja oil blends under varying compression ratio and engine load. Biofuels. 2023;14(2):173–82.

Kavitha K, Jayaprabakar J, Prabhu A. Exergy and energy analyses on biodiesel–diesel–ethanol blends in a diesel engine. Int J Ambient Energy. 2022;43(1):778–82.

Rai RK, Sahoo RR. Engine performance, emission, and sustainability analysis with diesel fuel-based Shorea robusta methyl ester biodiesel blends. Fuel. 2021;292:120234.

Ge S, Brindhadevi K, Xia C, Khalifa AS, Elfasakhany A, Unpaprom Y, et al. Enhancement of the combustion, performance and emission characteristics of spirulina microalgae biodiesel blends using nanoparticles. Fuel. 2022;308:121822.

Gad M, Aziz MMA, Kayed H. Impact of different nano additives on performance, combustion, emissions and exergetic analysis of a diesel engine using waste cooking oil biodiesel. Propuls Power Res. 2022;11(2):209–23.

Acknowledgements

This work is supported by PDPM Indian Institute of Information Technology Design and Manufacturing, Jabalpur (M.P.)

Funding

The authors received no funding (institutional, private and/or corporate financial support) for the work reported in their manuscript.

Author information

Authors and Affiliations

Contributions

ASR was involved in conceptualisation, investigation, writing—reviewing and editing, writing—original draft, formal analysis, TC contributed to supervision, conceptualisation, formal analysis, writing—reviewing and editing, HC was involved in visualisation, conceptualisation, writing—reviewing and editing, and GD: contributed to visualisation, validation, editing.

Corresponding author

Ethics declarations

Competing interests

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Ethical approval and consent to participate

The methods used in this investigation were all carried out in compliance with institutional and/or national research and ethical standards.

Consent to publish

The authors grant the publisher the sole and exclusive license of the full copyright of this contribution.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Rajpoot, A.S., Choudhary, T., Chelladurai, H.M. et al. A novel comprehensive energy, exergy and sustainability analysis of a diesel engine powered by binary blends of juliflora biodiesel and nanoparticles. J Therm Anal Calorim 148, 11981–11997 (2023). https://doi.org/10.1007/s10973-023-12473-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-023-12473-x