Abstract

The heat transfer characteristics of a thin porous copper-coated wickless heat pipe using R134a as a working fluid is investigated and is compared for its performance with uncoated wickless heat pipe using the same working fluid. An electroplating process was utilised to form a porous structure of copper over the inner surface of the wickless heat pipe. The experiments were carried out in the heat input range between 50 and 250 W. The thermal resistance of heat pipe at three different inclination angles such as 0°, 45° and 90° with horizontal are investigated. The results showed that 45° inclination has the lowest resistance with significant improvement in heat transfer characteristics. The coated wickless heat pipe exhibited a low thermal resistance when compared to uncoated wickless heat pipe. The condenser and evaporator heat transfer coefficients of a coated wickless heat pipe were found to be higher by about 11% and 25%, respectively, when compared to uncoated heat pipe for a heat flux of 10 kW m−2 and inclination of 45°. The magnitudes of dimensionless numbers (such as, Bo, We, Ku and Co) on coated and uncoated wickless heat pipes are also found.

Similar content being viewed by others

Abbreviations

- A :

-

Area (m2)

- Bo :

-

Bond number

- Co :

-

Condensation number

- D :

-

Diameter (m)

- g :

-

Acceleration due to gravity (m s−2)

- h :

-

Heat transfer coefficient (W m−2 K−1)

- h fg :

-

Heat of vaporization (J kg−1 K−1)

- k :

-

Thermal conductivity (W m−1 K−1)

- Ku :

-

Kutateladze number

- L :

-

Length (m)

- Q :

-

Heat input (W)

- q :

-

Heat flux (W m−2)

- R t :

-

Total thermal resistance (°C W−1)

- r :

-

Radius (m)

- T :

-

Temperature (°C)

- We :

-

Webber number

- c:

-

Condenser

- e:

-

Evaporator

- v:

-

Vapour

- l:

-

Liquid

- Δx :

-

Change in any parameter “x”

- µ :

-

Viscosity (N s m−2)

- ρ :

-

Density (kg m−3)

- σ :

-

Surface tension (N m−1)

References

Faghri A. Heat pipes: review, opportunities and challenges. Front Heat Pipes. 2014;5:1–48.

Mahfoud M, Emadi D. Application of heat pipe technology in thermal analysis of metals. J Therm Anal Calorim. 2005;81:161–7.

Zohuri B. Heat pipe design and technology modern applications for practical thermal management. 2nd ed. Berlin: Springer; 2016.

Bertoldo Junior J, Vlassov VV, Cândido PA, Genaro G, Kiseev VM. Axially grooved heat pipes. Reston: American Institute of Aeronautics and Astronautics; 1976.

Qu J, Ying WH, Cheng P. Thermal performance of an oscillating heat pipe with Al2O3-water nanofluids. Int Commun Heat Mass Transf. 2010;37:111–5.

Shukla KN, Solomon AB, Pillai BC, Ibrahim M. Thermal performance of cylindrical heat pipe using nanofluids. J Thermophys Heat Transf. 2010;24:796–802.

Platzer B, Polt A, Maurer G. Thermophysical properties of refrigerants, vol. 1. Heidelberg: Springer; 1990.

Jouhara H, Ezzuddin H. Thermal performance characteristics of a wraparound loop heat pipe (WLHP) charged with R134A. Energy. 2013;61:128–38.

Solomon AB, Ram Kumar AM, Ramachandran K, Pillai BC, Senthil Kumar C, Sharifpur M. Characterisation of a grooved heat pipe with an anodised surface. Heat Mass Transf. 2017. https://doi.org/10.1007/s00231-016-1856-8.

Alammar AA, Al-Dadah RK, Mahmoud SM. Numerical investigation of effect of fill ratio and inclination angle on a thermosyphon heat pipe thermal performance. Appl Therm Eng. 2016;108:1055–65.

Akbari A, Saidi MH. Experimental investigation of nanofluid stability on thermal performance and flow regimes in pulsating heat pipe. J Therm Anal Calorim. 2018;3:1–13.

Mohanraj M, Jayaraj S, Muraleedharan C. Environment friendly alternatives to halogenated refrigerants—a review. Int J Greenh Gas Control. 2009;3:108–19.

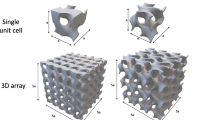

Solomon BA, Arul Daniel V, Ramachandran K, Pillai BC, Renjith Singh R, Sharifpur M, Meyer JP. Performance enhancement of a two-phase closed thermosiphon with a thin porous copper coating. Int Commun Heat Mass Transf. 2017;82:9–19. https://www.sciencedirect.com/science/article/pii/S0735193317300039.

Solomon BA, Mathew A, Ramachandran K, Pillai BC, Karthikeyan VK. Thermal performance of anodized two phase closed thermosyphon (TPCT). Exp Therm Fluid Sci. 2013;48:49–57.

Chen Y, Mo D, Zhao H, Ding N, Lu S. Pool boiling on the superhydrophilic surface with TiO2 nanotube arrays. Sci China Ser E Technol Sci. 2009;6:1596–600.

Furberg R. Enhanced boiling heat transfer on a dendritic and micro-porous copper structure. Int J Heat Mass Transf. 2011;31:3595–603.

Senthil Kumar C, Krishnan AS. Experimental studies on heat transfer characteristics of screen mesh wick heat pipe. Therm Sci. 2017;21:S497–502.

Holman JP. Experimental methods for engineers. 8th ed. New York: McGraw-Hill; 2012.

Kumaresan G, Vijayakumar P, Ravikumar M, Kamatchi R, Selvakumar P. Experimental study on effect of wick structures on thermal performance enhancement of cylindrical heat pipe. J Therm Anal Calorim. 2018. https://doi.org/10.1007/s10973-018-7842-2.

Acknowledgements

Authors would like to acknowledge the technical support of Mr. Jeyaseelan, Centre for Research in Material Science and Thermal Management, Karunya Institute of Technology and Sciences, Coimbatore, India, during the fabrication of hardwares.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Senthilkumar, C., Krishnan, A.S. & Solomon, A.B. Effect of thin porous copper coating on the performance of wickless heat pipe with R134a as working fluid. J Therm Anal Calorim 139, 963–973 (2020). https://doi.org/10.1007/s10973-019-08176-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-019-08176-x