Abstract

Activated carbons have been obtained by physical activation of residue left after supercritical extraction of hops. The effect of pyrolysis temperature on the physicochemical properties of the adsorbents prepared was tested. The carbonaceous materials were characterised by low-temperature nitrogen sorption, determination of pH and the number of surface oxygen groups. The thermal properties of the chars and activated carbons were identified by thermogravimetric analysis and differential thermogravimetry. The products of thermochemical treatment of the starting hops were carbonaceous adsorbents of specific surface area ranging from 2 to 416 m2 g−1, showing definitely basic character of the surface and moderate thermal stability as evidenced by a considerable mass loss at about 300–400 °C. The results obtained in our study have proved that residue left after supercritical extraction of hops (or similar plant materials) can be cheap, easily accessible and promising precursor for activated carbons. The results have also shown that future research should be aimed at the optimum choice of the temperature of carbonation and activation in order to significantly improve the textural parameters of the activated carbons as well as their thermal stability.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Activated carbons have been commonly used for separation and purification processes in gas and liquid phases [1–3]. Adsorption from gas phase is used e.g. to remove carbon dioxide, toxic gases, gases containing sulphur (sulphur dioxide and hydrogen sulphide) and nitrogen oxides being particularly toxic components of exhaust gases [4–6]. Carbon sorbents are also used for removal of a number of organic pollutants from liquid phase, in particular organic dyes. The presence of dyes in even very small concentrations can be harmful as they seriously disturb the living processes in water. Moreover, besides being highly toxic and mutagenic, the majority of dyes are very stable and hardly biodegradable [7–9]. In view of the above, careful purification of waste water from organic dyes before release back to the natural environment is very important.

Industrial production of activated carbons is based on the two methods of activation chemical and physical ones. The process of physical activation is realised in two steps, the first is pyrolysis of precursor in a neutral gas atmosphere and the second is the activation of the char obtained with carbon dioxide, steam or their mixture. The chemical activation involves impregnation of precursor with the activating agent (ZnCl2, H3PO4, KOH) and then annealing at high temperatures in a neutral gas atmosphere [10–14].

Recently, much attention has been devoted to obtaining activated carbons from post-agricultural and post-industrial waste products, for example from walnut shells, fruit skins and stones, timber production waste [15–19], used car tyres or phenol–formaldehyde resins and waste sediments posing serious challenge to waste management [20–23]. The possibility of their use for production of carbon adsorbents can significantly contribute to resolution of the problems with utilisation of waste products. The demand for activated carbon adsorbents continually increases stimulating the search for their new precursor.

An important group of activated carbon precursors is that of post-industrial waste left after supercritical extraction of plants or their parts with supercritical CO2. This process is used for instance for isolation of dyes, aromas or fatty acids, being an effective alternative to the conventional methods of extraction used on industrial scale in cosmetic, pharmaceutical or food industries [24–28]. The method of supercritical extraction is classified as a ‘green chemistry’ process [29–31], which encourages its use and importance. As a consequence, the amount of waste products left after this process considerably increases from 1 year to another. The waste of this type after specific thermochemical treatment can be a cheap precursor material for carbon absorbents to be applied for removal of pollutants. Obtaining of activated carbons of specific physicochemical properties needs the application of specific parameters of thermal treatment [32–34]. A method very useful for optimisation of activated carbons production and establishing thermal stability of the activation products is the thermogravimetric analysis [35, 36].

The aim of this study was to obtain activated carbons by physical activation of the waste left after supercritical extraction of hops, provided by the Institute of New Chemical Syntheses in Puławy (Poland). The effect of the temperature of pyrolysis on the development of the porous structure of activated carbons, their acid–base properties and thermal stability was tested.

Experimental

Material and preparation of activated carbons

The precursor of activated carbons was residue after supercritical extraction of hops (P). The initial material was first subjected to pyrolysis process at two temperatures 500 (P5) and 700 °C (P7). This process was carried out in a quartz tubular reactor heated by horizontal furnace under a stream of nitrogen with a flow rate of 170 mL min−1. In the final temperature, samples were kept for 1 h and then it was cooled in inert atmosphere. After that, the chars were subjected to physical activation (A) at temperature of 800 °C under a stream of carbon dioxide (rate flow 250 mL min−1), for 1 h.

Analytical procedures

Elemental analysis

The elemental composition of the precursor, chars and activated carbons was determined on an elemental analyser Vario EL III. The standard test method ASTM D2866-94 (2004) for the ash content determination was applied.

Textural parameters

Characterisation of the porous structure of activated carbons was determined by nitrogen adsorption–desorption isotherms measured on Autosorb iQ at −196 °C. Surface area of activated carbons was calculated by Brunauer–Emmett–Teller method. The total pore volume was calculated at a relative pressure of approximately p/p 0 = 0.99. The average pore diameter (D) was determined on the basis of surface area and the total pore volume. Micropore volume and area were calculated using t-plot method.

pH, surface oxygen groups

The pH of precursor, chars and activated carbons was measured using the following procedure: 0.2 g of each sample was added to 10 mL of distilled water and the suspension was stirred overnight to reach equilibrium. After that, pH of the suspension was measured. The content of surface oxygen functional groups was determined according to the Boehm method [37]. A total of 0.25 g of each sample was placed in 25 mL of 0.1 M HCl or NaOH solutions. The vials were sealed and shaken for 24 h, and then 10 mL of each filtrate was pipetted and the excess of base or acid was titrated with 0.1 M NaOH or HCl, respectively.

Thermal analysis

To characterise thermal stability of the chars and activated carbons prepared, each sample was subjected to thermogravimetric measurements performed on a NETZSCH STA 409 C/CD, under the following operational conditions: heating rate 10 °C min−1, a dynamic atmosphere of argon (125 mL min−1) in the temperature range of 30–1000 °C.

Results and discussion

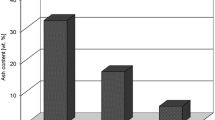

Low content of C daf in the initial material (P) makes it a rather unattractive as a precursor of carbon sorbents. That is why the waste left after extraction with supercritical CO2 was at first subjected to pyrolysis and then to physical activation. As follows from the data presented in Table 1, the products of pyrolysis (especially char P7) show not only much higher contribution of C daf but also much higher content of ash than the initial material. The increase in the content of C daf is accompanied by a significant decrease in the content of oxygen and hydrogen, as a result of the effect of high temperature on the least thermally stable structural elements of the initial material. The changes in the contents of the other heteroatoms (sulphur and nitrogen) are much smaller.

The process of physical activation results in further changes in the carbon structure, but not as pronounced as those taking place as a result of pyrolysis. The effect of CO2 and high temperature leads to small changes in the content of C daf. The activated carbons showed a considerable decrease in the content of H daf with respect to that in the corresponding chars, caused mostly by the proceeding aromatisation of carbon structure. Gasification of the surface of both chars by the activating agent is accompanied by an increase in the content of oxygen, sulphur and ash, while the magnitudes of particular changes differ for individual samples P5A and P7A.

Table 2 presents the textural parameters of chars and activated carbons. According to these data, irrespective of the pyrolysis temperature, the materials show very small surface area of only 2 m2 g−1. The samples P5 and P7 contain mostly macropores, which is confirmed by the lack of micropores and the mean pore diameters ranging from 58.1 to 76.9 nm.

Much better textural parameters characterised the samples obtained as a result of activation of both chars at 800 °C. Their surface area varied from 413 to 416 m2 g−1, while the total pore volume ranged from 0.201 to 0.204 cm3 g−1. As follows from analysis of the data presented in Table 2, the effect of pyrolysis temperature on the surface area of the samples is insignificant. In contrast to chars, both samples of activated carbons show the dominant presence of micropores, making over 60 % of all pores, and the adsorption–desorption isotherms recorded for these samples and shown in Fig. 1 have the shape of type I isotherm, corresponding, according to IUPAC classification, to microporous solids. The mean pore diameter estimated as 3.88–3.91 nm and the presence of a hysteresis loop in the adsorption–desorption isotherms indicate that the second type of pores present in the activated carbon samples is small mesopores.

Analysis of the Table 3 data also implies that the materials obtained at particular stages of production of activated carbons show different acid–base properties. The surface of the precursor has definitely acidic character as follows from the pH value of 4.9 and about 8 times higher number of acidic functional groups than basic ones. Pyrolysis of the residue left after supercritical extraction of hops considerably changes its acid–base properties. In contrast to the precursor, the chars show strongly basic surface, characterised by pH from the range 10.1–10.8, and a significant prevalence of functional groups of basic character, especially in char P5. The activated carbons are even more basic as they contain on their surface almost exclusively basic functional groups in the amount of 4.77–4.87 mmol g−1. So, high amount of basic groups is a consequence of a high temperature of activation and the type of activator used (CO2), which favour generation of basic groups on the surface of carbon materials.

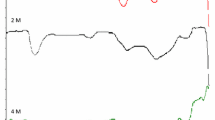

According to the data presented in Figs. 2, 3 and Table 4, the chars and activated carbons differ in some degree in thermal stability. The least thermally stable is char P5, as its total mass loss is 38.24 %. The highest thermal stability (total mass loss = 29.64 %) shows sample P5A obtained by activation of char P5. According to the DTG curves, thermal decomposition of all materials under investigation takes place in three more or less well-evidenced stages, with significant mass losses. The first of them could be ascribed to release of adsorbed water, takes place from 40 to 180 °C. The second stage, of slow thermal decomposition of the organic carbon structure, takes place in a wider range, from about 300 to 600 °C. So, wide temperature range of this stage observed for P5 char is most probably a consequence of a relatively low temperature of pyrolysis of the initial material (500 °C), which did not guarantee completion of the primary degassing. The third stage of decomposition is the secondary degassing which is manifested on the DTG curve as a band with a well-marked minimum at 713 °C. The DTG curve for char P7 also shows three phases of decomposition, but the loss of mass accompanying them is quite different and takes place in much narrower temperature ranges. The mass loss related to dehydration is comparable for both chars. More pronounced differences appear in further course of the curves. For sample P7, a clear minimum appears at 485 °C, accompanied by about 7 % mass loss. The greatest differences are observed at the third stage of decomposition. Mass loss for P5 is by 10.22 % greater than for P7 char, and the maximum mass loss for sample P7 is shifted towards higher temperature of 732 °C. According to DTA data, at the third stage of decomposition of chars P5 and P7, the endothermic transformations take place and the enthalpy of these processes is almost twice higher for char P7.

Interestingly, a similar character of TG and DTG curves is observed for the samples obtained by the activation of chars with CO2, in particular for sample P7A. The DTG curves of activated carbons P5A and P7A show a very strong minimum at 132 and 129 °C, (respectively) assigned to the release of water adsorbed in micropores, indicating a high hydrophilicity of the activated carbon surface. The mass loss for both activated carbon samples at this stage of decomposition is by 1.1–1.4 % greater than for the corresponding chars. The next mass loss, giving a much stronger signal for sample P7A, is noted at temperature 477 °C. With high probability, it corresponds to decomposition of surface functional groups of low stability, generated upon activation. The curves of both activated carbon samples also show a drastic mass loss above 700 °C, which can correspond to the decomposition of functional groups and to partial gasification of the least thermally stable fragments of carbon structure. However, exact assignment of this signal needs further studies and the use of more advanced research methods such as e.g. coupled methods (TG/DSC/MS) [38–41]. The mass loss at this stage of decomposition is very similar for both activated carbons and equals to a bit more than 19 %; however, the enthalpy of the energetic transformations is by 21.46 J g−1 higher for P5A.

Conclusions

The above presented results indicate that the residue left after supercritical extraction of hops and other resources of plant origin can in near future become a cheap and effective precursor of carbon adsorbents of interesting physicochemical properties. The activated carbon adsorbents obtained by physical activation with CO2 show not well-developed porous structure and surface area, so further studies should be aimed at optimisation of textural parameters. A possible solution is the use of much more reactive activating agents, e.g. potassium carbonate or phosphoric acid. It should be noted that the sorbents obtained from hops have very high content of mineral substances and a high content of functional groups of basic character; therefore, they can be effective adsorbents of gas and liquid pollutants of acidic character.

References

Belhachemi M, Jeguirim M, Limousy L, Addoun F. Comparison of NO2 removal using date pits activated carbon and modified commercialized activated carbon via different preparation methods: effect of porosity and surface chemistry. Chem Eng J. 2014;253:121–9.

Wang YX, Ngo HH, Guo WS. Preparation of a specific bamboo based activated carbon and its application for ciprofloxacin removal. Sci Total Environ. 2015;533:32–9.

Shahkarami S, Azargohar R, Dalai AK, Soltan J. Breakthrough CO2 adsorption in bio-based activated carbons. J Environ Sci. 2015;34:68–76.

Nowicki P, Skibiszewska P, Pietrzak R. Hydrogen sulphide removal on carbonaceous adsorbents prepared from coffee industry waste materials. Chem Eng J. 2014;248:208–15.

Atanes E, Nieto-Márquez A, Cambra A, Ruiz-Pérez MC, Fernández-Martínez F. Adsorption of SO2 onto waste cork powder-derived activated carbons. Chem Eng J. 2012;211–12:60–7.

Pietrzak R, Bandosz TJ. Interactions of NO2 with sewage sludge based composite adsorbents. J Hazard Mater. 2008;154:946–53.

Ghaedi M, Shojaeipour E, Ghaedi AM, Sahraei R. Isotherm and kinetics study of malachite green adsorption onto copper nanowires loaded on activated carbon: artificial neural network modeling and genetic algorithm optimization. Spectrochim Acta A. 2015;142:135–49.

Amin NK. Removal of reactive dye from aqueous solutions by adsorption onto activated carbons prepared from sugarcane bagasse pith. Desalination. 2008;223:152–61.

Cherifi H, Fatiha B, Salah H. Kinetic studies on the adsorption of methylene blue onto vegetal fiber activated carbons. Appl Surf Sci. 2013;282:52–9.

Bansal RCh, Goyal M. Activated carbon adsorption. Boca Raton: Taylor & Francis Group; 2005.

Daud WMAW, Ali WSW, Sulaiman MZ. The effects of carbonization temperature on pore development in palm-shell-based activated carbon. Carbon. 2000;38:1925–32.

Ach Lua, Guo J. Activated carbon prepared from oil palm stone by one-step CO2 activation for gaseous pollutant removal. Carbon. 2000;38:1089–97.

Marsh H, Rodriguez-Reinoso F. Activation carbon. London: Elsevier; 2006.

Ling Tseng R. Physical and chemical properties and adsorption type of activated carbon prepared from plum kernels by NaOH activation. J Hazard Mater. 2007;147:1020–7.

Pietrzak R, Nowicki P, Kazmierczak J, Kuszynska I, Goscianska J, Przepiórski J. Comparison of the effects of different chemical activation methods on properties of carbonaceous adsorbents obtained from cherry stones. Chem Eng Res Des. 2014;92:1187–91.

Nowicki P, Pietrzak R, Wachowska H. Sorption properties of active carbons obtained from walnut shells by chemical and physical activation. Catal Today. 2010;150:107–14.

Kazmierczak-Razna J, Gralak-Podemska B, Nowicki P, Pietrzak R. The use of microwave radiation for obtaining activated carbons from sawdust and their potential application in removal of NO2 and H2S. Chem Eng J. 2015;269:352–8.

Foo KY, Hameed BH. Preparation and characterization of activated carbon from pistachio nut shells via microwave-induced chemical activation. Biomass Bioenergy. 2011;35:3257–61.

Nowicki P, Wachowska H, Pietrzak R. Active carbons prepared by chemical activation of plum stones and their application in removal of NO2. J Hazard Mater. 2010;181:1088–94.

Gupta VK, Nayak A, Agarwal S, Tyagi I. Potential of activated carbon from waste rubber tire for the adsorption of phenolics: effect of pre-treatment conditions. J Colloid Interf Sci. 2014;417:420–30.

Pietrzak R, Bandosz TJ. Activated carbons modified with sewage sludge derived phase and their application in the process of NO2 removal. Carbon. 2007;45:2537–46.

Acevedo B, Barriocanal C. Texture and surface chemistry of activated carbons obtained from tyre waste. Fuel Process Technol. 2015;134:275–83.

Hofman M, Pietrzak R. Adsorbents obtained from waste tires for NO2 removal under dry conditions at room temperature. Chem Eng J. 2011;170:202–8.

Pourmortazavi SM, Hajimirsadeghi SS. Supercritical fluid extraction in plant essential and volatile oil analysis. J Chromatogr A. 2007;1163:2–24.

Brunner G. Supercritical fluids: technology and application to food processing. J Food Eng. 2005;67:21–33.

Lang Q, Wai ChM. Supercritical fluid extraction in herbal and natural product studiem—a practical review. Talanta. 2001;53:771–82.

Perrut M. Supercritical Fluid Applications: industrial developments and economic issues. Ind Eng Chem Res. 2000;39:4531–5.

Larkeche O, Zermane A, Meniai A-H, Crampon C, Badens E. Supercritical extraction of essential oil from Juniperus communis L. needles: application of response surface methodology. J Supercrit Fluids. 2015;99:8–14.

Reverchon E, De Marco I. Supercritical fluid extraction and fractionation of natural matter. J Supercrit Fluids. 2006;38:146–66.

de Melo MMR, Silvestre AJD, Silva CM. Supercritical fluid extraction of vegetable matrices: Applications, trends and future perspectives of a convincing green technology. J Supercrit Fluids. 2014;92:115–76.

Alieva AM, Radjabov GK, Musaev AM. Dynamics of supercritical extraction of biological active substances from the Juniperus communis var. saxatillis. J Supercrit Fluids. 2015;102:66–72.

Amicarelli V, Baldassarre G, Liberti L. Investigation of low-temperature regeneration of activated carbon. J Therm Anal Calorim. 1980;18:155–60.

Murillo YS, Giraldo L, Moreno-Piraján JC. Determination of partial immersion enthalpy in the interaction of water and activated carbon. J Therm Anal Calorim. 2011;104:555–9.

Giraldo L, Moreno-Piraján JC. Calorimetric determination of activated carbons in aqueous solutions. J Therm Anal Calorim. 2007;89(2):589–94.

Makomski G, Ciesińska W, Zieliński J. Thermal properties of pitch—polimer compositions and derived activated carbons. J Therm Anal Calorim. 2012;109:767–72.

Tsai WT, Chang CY, Lee SL, Wang SY. Thermogravimetric analysis of corn cob impregnated with zinc chloride for preparation of activated carbon. J Therm Anal Calorim. 2000;63:351–7.

Boehm HP. Some aspects of the surface chemistry of carbon blacks and other carbons. Carbon. 1994;32:759–69.

Kaźmierczak J, Biniak S, Świątkowski A, Radeke K-H. Interdependence of different parameters characterizing the chemistry of an activated carbon surface. J Chem Soc Faraday Trans. 1991;87:3557–61.

Calvo LF, Sánchez ME, Morán A, García AI. TG-MS as a technique for a better monitoring of the pyrolysis, gasification and combustion of two kinds of sewage sludge. J Therm Anal Calorim. 2004;78(2):587–98.

Wu SH, Hsieh CC, Chiang CC, Horng JJ, Pan WP, Shu CM. Thermal analyses of home-made zeolite by DSC and TG. J Therm Anal Calorim. 2012;109:945–50.

Martins S, Fernandes JB. A simple method to prepare high surface area activated carbon from carboxyl methyl cellulose by low temperature physical activation. J Therm Anal Calorim. 2013;112:1007–11.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Bazan, A., Nowicki, P., Półrolniczak, P. et al. Thermal analysis of activated carbon obtained from residue after supercritical extraction of hops. J Therm Anal Calorim 125, 1199–1204 (2016). https://doi.org/10.1007/s10973-016-5419-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-016-5419-5