Abstract

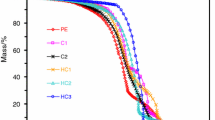

In the present work, the effective use of polyethylene-grafted maleic anhydride (PE-g-MA) copolymer as a compatibilizer in high-density polyethylene composites containing 10–50 mass% hemp fibers was evaluated through mechanical and thermal properties measurements. The results revealed a significant reinforcement on the tensile strength of the composites as a consequence of the incorporation of the compatibilizer. Less pronounced effects were found on the elongation at break and impact strength of the composites. The notable enhancement of tensile strength on the compatibilized composites was related to the improved adhesion of hemp with the matrix in the presence of PE-g-MA, which was revealed through scanning electron microscopy observations. Furthermore, Fourier transform infrared spectroscopy analyses suggested that covalent bonding occurs between the fibers and the matrix in the highest PE-g-MA concentrations. Differential scanning calorimetry experiments revealed that the presence of compatibilizer increases the crystallinity of the composites. Thermogravimetry studies revealed that for low compatibilizer concentrations the thermal stability of the composites is further reduced, while for the highest concentration, when bonding occurs, it is enhanced. The biodegradation studies of all the composites revealed that the incorporation of compatibilizer enhances the stability of the composites, especially in the higher concentrations, and reduces their final residue.

Similar content being viewed by others

References

Bikiaris DN. Nanocomposites of aliphatic polyesters: an overview of the effect of different nanofillers on enzymatic hydrolysis and biodegradation of polyesters. Polym Degrad Stabil. 2013;98(9):1908–28. doi:10.1016/j.polymdegradstab.2013.05.016.

Bledzki AK, Gassan J. Composites reinforced with cellulose based fibres. Prog Polym Sci. 1999;24(2):221–74. doi:10.1016/S0079-6700(98)00018-5.

Sam ST, Ismail H, Ahmad Z. Soil burial of polyethylene-g-(maleic anhydride) compatibilised LLDPE/soya powder blends. Polym Plast Technol. 2011;50(8):851–61. doi:10.1080/03602559.2011.551977.

Terzopoulou ZN, Papageorgiou GZ, Papadopoulou E, Athanassiadou E, Alexopoulou E, Bikiaris DN. Green composites prepared from aliphatic polyesters and bast fibers. Ind Crop Prod. doi:10.1016/j.indcrop.2014.08.034.

Shahzad A. Hemp fiber and its composites—a review. J Compos Mater. 2012;46(8):973–86. doi:10.1177/0021998311413623.

La Rosa AD, Recca G, Summerscales J, Latteri A, Cozzo G, Cicala G. Bio-based versus traditional polymer composites. A life cycle assessment perspective. J Clean Prod. 2014;74:135–44. doi:10.1016/j.jclepro.2014.03.017.

Ahmad F, Choi HS, Park MK. A review: natural fiber composites selection in view of mechanical, light weight, and economic properties. Macromol Mater Eng. 2014. doi:10.1002/mame.201400089.

Terzopoulou ZN, Papageorgiou GZ, Papadopoulou E, Athanassiadou E, Reinders M, Bikiaris DN. Development and study of fully biodegradable composite materials based on poly(butylene succinate) and hemp fibers or hemp shives. Polym Compos. 2014. doi:10.1002/pc.23194.

Han HC, Gong XL. One-step green treatment of hemp fiber used in polypropylene composites. Polym Compos. 2014;. doi:10.1002/pc.23191.

Baghaei B, Skrifvars M, Rissanen M, Ramamoorthy SK. Mechanical and thermal characterization of compression moulded polylactic acid natural fiber composites reinforced with hemp and lyocell fibers. J Appl Polym Sci. 2014;131(15). doi:10.1002/app.40534.

Etaati A, Pather S, Fang Z, Wang H. The study of fibre/matrix bond strength in short hemp polypropylene composites from dynamic mechanical analysis. Compos Part B Eng. 2014;62:19–28. doi:10.1016/j.compositesb.2014.02.011.

Terzopoulou ZN, Papageorgiou GZ, Papadopoulou E, Athanassiadou E, Alexopoulou E, Bikiaris DN. Green composites prepared from aliphatic polyesters and bast fibers. Ind Crop Prod. 2014. doi:10.1016/j.indcrop.2014.08.034.

Terzopoulou ZN, Papageorgiou GZ, Papadopoulou E, Athanassiadou E, Reinders M, Bikiaris DN. Development and study of fully biodegradable composite materials based on poly(butylene succinate) and hemp fibers or hemp shives. Polym Compos. 2014. doi:10.1002/pc.23194.

Wambua P, Ivens J, Verpoest I. Natural fibres: can they replace glass in fibre reinforced plastics? Compos Sci Technol. 2003;63(9):1259–64. doi:10.1016/S0266-3538(03)00096-4.

Eichhorn SJ, Baillie CA, Zafeiropoulos N, Mwaikambo LY, Ansell MP, Dufresne A, et al. Review: Current international research into cellulosic fibres and composites. J Mater Sci. 2001;36(9):2107–31. doi:10.1023/A:1017512029696.

Saheb DN, Jog JP. Natural fiber polymer composites: a review. Adv Polym Technol. 1999;18(4):351–63. doi:10.1002/(SICI)1098-2329(199924)18:4<351::AID-ADV6>3.0.CO;2-X1.

Pracella M, Chionna D, Anguillesi I, Kulinski Z, Piorkowska E. Functionalization, compatibilization and properties of polypropylene composites with Hemp fibres. Compos Sci Technol. 2006;66(13):2218–30. doi:10.1016/j.compscitech.2005.12.006.

Lu N, Oza S. Thermal stability and thermo-mechanical properties of hemp-high density polyethylene composites: effect of two different chemical modifications. Compos Part B Eng. 2013;44(1):484–90. doi:10.1016/j.compositesb.2012.03.024.

Durmus A, Kasgoz A, Macosko CW. Linear low density polyethylene (LLDPE)/clay nanocomposites. Part I: structural characterization and quantifying clay dispersion by melt rheology. Polymer. 2007;48(15):4492–502. doi:10.1016/j.polymer.2007.05.074.

Sánchez-Valdes S, Méndez-Nonell J, Medellín-Rodríguez FJ, Ramírez-Vargas E, Martínez-Colunga JG, Soto-Valdez H, et al. Effect of PEgMA/amine silane compatibilizer on clay dispersion of polyethylene-clay nanocomposites. Polym Bull. 2009;63(6):921–33. doi:10.1007/s00289-009-0170-8.

Varela C, Rosales C, Perera R, Matos M, Poirier T, Blunda J, et al. Functionalized polypropylenes in the compatibilization and dispersion of clay nanocomposites. Polym Compos. 2006;27(4):451–60. doi:10.1002/pc.20179.

López-Quintanilla ML, Sánchez-Valdés S, Ramos de Valle LF, Guedea Miranda R. Preparation and mechanical properties of PP/PP-g-MA/Org-MMT nanocomposites with different MA content. Polym Bull. 2006;57(3):385–93. doi:10.1007/s00289-006-0555-x.

Qiu W, Endo T, Hirotsu T. A novel technique for preparing of maleic anhydride grafted polyolefins. Eur Polym J. 2005;41(9):1979–84. doi:10.1016/j.eurpolymj.2005.03.016.

Sailaja RRN, Chanda M. Use of maleic anhydride–grafted polyethylene as compatibilizer for HDPE–tapioca starch blends: effects on mechanical properties. J Appl Polym Sci. 2001;80(6):863–72. doi:10.1002/1097-4628(20010509)80:6<863:AID-APP1164>3.0.CO;2-R.

Bikiaris D, Panayiotou C. LDPE/starch blends compatibilized with PE-g-MA copolymers. J Appl Polym Sci. 1998;70(8):1503–21

Gassan J, Bledzki AK. The influence of fiber-surface treatment on the mechanical properties of jute-polypropylene composites. Compos Part A Appl Sci. 1997;28(12):1001–5. doi:10.1016/S1359-835X(97)00042-0.

Felix JM, Gatenholm P. The nature of adhesion in composites of modified cellulose fibers and polypropylene. J Appl Polym Sci. 1991;42(3):609–20. doi:10.1002/app.1991.070420307.

Zhao X, Li RKY, Bai S-L. Mechanical properties of sisal fiber reinforced high density polyethylene composites: effect of fiber content, interfacial compatibilization, and manufacturing process. Compos Part A Appl Sci. 2014;65:169–74. doi:10.1016/j.compositesa.2014.06.017.

Willats WT, McCartney L, Mackie W, Knox JP. Pectin: cell biology and prospects for functional analysis. Plant Mol Biol. 2001;47(1–2):9–27. doi:10.1023/A:1010662911148.

Pickering KL, Sawpan MA, Jayaraman J, Fernyhough A. Influence of loading rate, alkali fibre treatment and crystallinity on fracture toughness of random short hemp fibre reinforced polylactide bio-composites. Compos Part A Appl Sci. 2011;42(9):1148–56. doi:10.1016/j.compositesa.2011.04.020.

Kim H-S, Lee B-H, Choi S-W, Kim S, Kim H-J. The effect of types of maleic anhydride-grafted polypropylene (MAPP) on the interfacial adhesion properties of bio-flour-filled polypropylene composites. Compos Part A Appl Sci. 2007;38(6):1473–82. doi:10.1016/j.compositesa.2007.01.004.

Wunderlich B, Jin Y, Boller A. Mathematical description of differential scanning calorimetry based on periodic temperature modulation. Thermochim Acta. 1994;238:277–93. doi:10.1016/S0040-6031(94)85214-6.

Borysiak S. Influence of cellulose polymorphs on the polypropylene crystallization. J Therm Anal Calorim. 2013;113(1):281–9. doi:10.1007/s10973-013-3109-0.

Yang H-S, Gardner D, Kim H-J. Viscoelastic and thermal analysis of lignocellulosic material filled polypropylene bio-composites. J Therm Anal Calorim. 2009;98(2):553–8. doi:10.1007/s10973-009-0324-9.

Ku H, Wang H, Pattarachaiyakoop N, Trada M. A review on the tensile properties of natural fiber reinforced polymer composites. Compos Part B Eng. 2011;42(4):856–73. doi:10.1016/j.compositesb.2011.01.010.

Mwaikambo LY, Ansell MP. Chemical modification of hemp, sisal, jute, and kapok fibers by alkalization. J Appl Polym Sci. 2002;84(12):2222–34. doi:10.1002/app.10460.

Ouajai S, Shanks RA. Composition, structure and thermal degradation of hemp cellulose after chemical treatments. Polym Degrad Stabil. 2005;89(2):327–35. doi:10.1016/j.polymdegradstab.2005.01.016.

Krimm S, Liang CY, Sutherland GBBM. Infrared spectra of high polymers. II. Polyethylene. J Chem Phys. 1956;25(3):549–62.

Krimm S. Infrared spectra of high polymers Fortschritte Der Hochpolymeren-Forschung. Advances in Polymer Science. Berlin: Springer; 1960. p. 51–172.

Coates J. Interpretation of infrared spectra. A practical approach. Encyclopedia of analytical chemistry. New York: Wiley; 2006.

Snyder RG, Maroncelli M, Strauss HL, Hallmark VM. Temperature and phase behavior of infrared intensities: the poly(methylene) chain. J Phys Chem. 1986;90(22):5623–30. doi:10.1021/j100280a030.

Akovali G, Atalay A. Comparison of crystallinities of high density polyethylene determined by different techniques. Polym Test. 1997;16(2):165–71. doi:10.1016/s0142-9418(96)00037-2.

Hagemann H, Snyder RG, Peacock AJ, Mandelkern L. Quantitative infared methods for the measurement of crystallinity and its temperature-dependence—polyethylene. Macromolecules. 1989;22(9):3600–6. doi:10.1021/ma00199a017.

Snyder RG. Vibrational study of the chain conformation of the liquid n-paraffins and molten polyethylene. J Chem Phys. 1967;47(4):1316–60.

Ibrahim A, Wahit M, Yussuf A. Effect of fiber reinforcement on mechanical and thermal properties of poly(ɛ-caprolactone)/poly(lactic acid) blend composites. Fibers Polym. 2014;15(3):574–82. doi:10.1007/s12221-014-0574-4.

Spoljaric S, Genovese A, Shanks RA. Polypropylene–microcrystalline cellulose composites with enhanced compatibility and properties. Compos Part A Appl Sci. 2009;40(6–7):791–9. doi:10.1016/j.compositesa.2009.03.011.

Baghaei B, Skrifvars M, Berglin L. Manufacture and characterisation of thermoplastic composites made from PLA/hemp co-wrapped hybrid yarn prepregs. Compos Part A Appl Sci. 2013;50:93–101. doi:10.1016/j.compositesa.2013.03.012.

Ahmad EEM, Luyt AS. Morphology, thermal, and dynamic mechanical properties of poly(lactic acid)/sisal whisker nanocomposites. Polym Compos. 2012;33(6):1025–32. doi:10.1002/pc.22236.

Masirek R, Kulinski Z, Chionna D, Piorkowska E, Pracella M. Composites of poly(L-lactide) with hemp fibers: morphology and thermal and mechanical properties. J Appl Polym Sci. 2007;105(1):255–68. doi:10.1002/app.26090.

Sanchez-Garcia MD, Gimenez E, Lagaron JM. Morphology and barrier properties of solvent cast composites of thermoplastic biopolymers and purified cellulose fibers. Carbohydr Polym. 2008;71(2):235–44. doi:10.1016/j.carbpol.2007.05.041.

Song Y, Liu J, Chen S, Zheng Y, Ruan S, Bin Y. Mechanical properties of poly (lactic acid)/hemp fiber composites prepared with a novel method. J Polym Environ. 2013;21(4):1117–27. doi:10.1007/s10924-013-0569-z.

Ramezani Kakroodi A, Kazemi Y, Rodrigue D. Mechanical, rheological, morphological and water absorption properties of maleated polyethylene/hemp composites: effect of ground tire rubber addition. Compos Part B Eng. 2013;51:337–44. doi:10.1016/j.compositesb.2013.03.032.

Carmona V, de Campos A, Marconcini J, Mattoso L. Kinetics of thermal degradation applied to biocomposites with TPS, PCL and sisal fibers by non-isothermal procedures. J Therm Anal Calorim. 2014;115(1):153–60. doi:10.1007/s10973-013-3259-0.

Yang H-S, Kiziltas A, Gardner D. Thermal analysis and crystallinity study of cellulose nanofibril-filled polypropylene composites. J Therm Anal Calorim. 2013;113(2):673–82. doi:10.1007/s10973-012-2770-z.

Beltrami LVR, Bandeira JAV, Scienza LC, Zattera AJ. Biodegradable composites: Morphological, chemical, thermal, and mechanical properties of composites of poly(hydroxybutyrate-co-hydroxyvalerate) with curaua fibers after exposure to simulated soil. J Appl Polym Sci. 2014;131(17). doi:10.1002/app.40712.

Pang MM, Pun MY, Ishak ZAM. Thermal, mechanical, and morphological characterization of biobased thermoplastic starch from agricultural waste/polypropylene blends. Polym Eng Sci. 2014;54(6):1357–65. doi:10.1002/pen.23684.

Sebestyén Z, May Z, Réczey K, Jakab E. The effect of alkaline pretreatment on the thermal decomposition of hemp. J Therm Anal Calorim. 2011;105(3):1061–9. doi:10.1007/s10973-010-1056-6.

Araújo JR, Waldman WR, De Paoli MA. Thermal properties of high density polyethylene composites with natural fibres: coupling agent effect. Polym Degrad Stabil. 2008;93(10):1770–5. doi:10.1016/j.polymdegradstab.2008.07.021.

Lee JM, Mohd Ishak ZA, Mat R, Law TT, Law TT, Ahmad Thirmizir MZ. Mechanical, thermal and water absorption properties of kenaf-fiber-based polypropylene and poly(butylene succinate) composites. J Polym Environ. 2013;21(1):293–302. doi:10.1007/s10924-012-0516-4.

Chen K, Wilkie CA, Vyazovkin S. Nanoconfinement revealed in degradation and relaxation studies of two structurally different polystyrene − clay systems. J Phys Chem B. 2007;111(44):12685–92. doi:10.1021/jp0759168.

Roumeli E, Pavlidou E, Avgeropoulos A, Vourlias G, Bikiaris DN, Chrissafis K. Factors controlling the enhanced mechanical and thermal properties of nanodiamond reinforced cross-linked high density polyethylene. J Phys Chem B. 2014. doi:10.1021/jp504531f.

Chattopadhyay SK, Khandal RK, Uppaluri R, Ghoshal AK. Bamboo fiber reinforced polypropylene composites and their mechanical, thermal, and morphological properties. J Appl Polym Sci. 2011;119(3):1619–26. doi:10.1002/app.32826.

Joseph PV, Joseph K, Thomas S, Pillai CKS, Prasad VS, Groeninckx G, et al. The thermal and crystallisation studies of short sisal fibre reinforced polypropylene composites. Compos Part A Appl Sci. 2003;34(3):253–66. doi:10.1016/S1359-835X(02)00185-9.

Elkhaoulani A, Arrakhiz FZ, Benmoussa K, Bouhfid R, Qaiss A. Mechanical and thermal properties of polymer composite based on natural fibers: Moroccan hemp fibers/polypropylene. Mater Design. 2013;49:203–8. doi:10.1016/j.matdes.2013.01.063.

Abdul Wahab MK, Ismail H, Othman N. Compatibilization effects of PE-g-MA on mechanical, thermal and swelling properties of high density polyethylene/natural rubber/thermoplastic tapioca starch blends. Polym Plast Technol. 2012;51(3):298–303. doi:10.1080/03602559.2011.639331.

Acknowledgements

This work was supported by the Greek National Competitiveness and Entrepreneurship Programme (National Strategic Reference Framework 2007–2013) and the European Regional Development Fund under the Project: New Lightweight and Nanotechnology Enhanced Bio-composites from Lignocellulosic Materials, No. 12CHN322.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Roumeli, E., Terzopoulou, Z., Pavlidou, E. et al. Effect of maleic anhydride on the mechanical and thermal properties of hemp/high-density polyethylene green composites. J Therm Anal Calorim 121, 93–105 (2015). https://doi.org/10.1007/s10973-015-4596-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-015-4596-y