Abstract

The effect of mechanical activation on the structure and thermal reactions of glasses has been studied on the example of Na–Al–Fe phosphate glasses. These glasses are used in nuclear technology for immobilization of radioactive waste. The glasses were activated by grinding in a planetary mill. Mechanical activation causes a decrease of the T g temperature as well as of the glass crystallization temperature. The type of crystalline phases formed and the quantitative proportions between them are changing. Analysis of inter-atomic interactions in the structure of glass was applied to explain the observed regularities governing the crystallization of the activated glasses.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The effect of mechanical energy on the chemical reactions as well as the physical and chemical transformation of a substance has been observed for many years, especially in high-molecular compounds. It is caused by mechanical stresses arising in crystal structure as a result of shearing forces and as a result of the increase in the specific surface area as well as surface energy.

At present, there is a lack of information available in the world literature on the use of mechano-chemistry for production of glass, glass–ceramics, and other glass-derived materials. The polymeric structure of glasses allows one to expect that mechanical activation will have an effect on the thermal transformations of glasses.

This study has the purpose of determining the effect of mechanical activation on phosphate glasses, their structure, and on their properties. These glasses serve to immobilize dangerous wastes by means of enclosing them into the structure of glass (vitrification) [1].

Phosphate glasses containing sodium and aluminum as their main constituents and glasses in which part of the aluminum are replaced by iron has been selected for study. They are specific in that they have the capability to accept significant amounts of heavy metals into their structures, which, in silicate glasses, can only be present in trace amounts. Furthermore, they exhibit large chemical durability. This makes it possible to use them for immobilization of high level waste (HLW) from nuclear power stations (waste glass). These are relatively new glasses, and knowledge regarding their structure and properties is scarce. In chemical terms, they are polyphosphates, and in terms of the structural classification of glasses, they belong to mixed network glasses [2, 3].

Experimental

Glasses from the P2O5–Na2O–Al2O3 system, containing more than 50% wt of glass-forming P2O5, were subjected to study. These compositions were extended by replacing part of the Al2O3 with Fe2O3 or by adding B2O3 (Table 1). The composition of glasses was taken from [4].

Synthesis of the glasses was carried out using the conventional method of melting the mixture of raw materials in an electric furnace at a temperature of 1050 °C and holding it at this temperature for 2 h. The melt was poured onto a steel plate for it to vitrify. Glass samples were not annealed. All glasses were initially crushed and then milled in a Pulverisette 6 planetary ball mill of the Fritsch company with a speed of 250 rpm during different periods of time: 20 min, 2 h, and an additional period of 4 h in the case of the Aa and Ac glasses were applied.

For the purpose of learning the thermal properties of the glasses, their thermal analysis was carried out. DSC measurements were taken using the STA 449 Jupiter F3 apparatus of the Netzsch company. Samples of a mass of 50 mg were placed in the platinum crucibles of the apparatus and heated at a rate of 10 °C/min in an N2 atmosphere. Glass crystallization was realized in an electric tube furnace at temperatures determined from the DSC curves, and these temperatures were maintained for a period of 2 h.

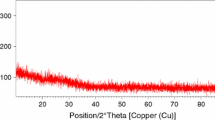

Crystalline phases created during the cooling of the glass, as well as those forming during their heating, were determined using the DSH method by means of an X-ray diffractometer (DRON-1.5) for Cu Kα radiation (λ = 1.54 Å). Quantitative proportions between the crystallized phases were estimated using Rietveld refinement method.

Changes in the structures of glass after various times of mechanical activation were determined based on IR spectra (FTIR). Measurements were carried out using the DigiLab Bio-rad FTS60 apparatus.

Results

Infrared spectroscopy

Spectra in the middle infrared range (MIR) of the melted glasses (Figs. 1, 2) are characterized by a wide absorption band in the range of 1,350–800 cm−1, which has its origin in the phosphate network. It is formed by several narrower bands overlapping each other, and these are:

-

a band of about 1,160 cm−1, which can be attributed to stretching vibrations of P=O bonds;

-

a band of about 1,100 cm−1 corresponding to the stretching vibrations of P–O–P oxygen bridges of pyrophosphate groups;

-

a band of about 990 cm−1, which may have its origin in the stretching vibrations of P–O–P oxygen bridges in the chains, which is characteristic of the structure of metaphosphates and occurs within the range of 1,200–880 cm−1, depending on the composition of the glass.

A band of about 720–745 cm−1 is present in the spectra of all the obtained glasses. A similar band is characteristic for the spectrum of crystalline AlPO4 [5] and also occurs for aluminate glasses having a tetrahedral [AlO4] network [6]. It can also be attributed to the vibrations of Al–O–P bridges.

Below 600 cm−1, there are rocking bands originating from the bonds of [PO4] tetrahedrons with Na+, Al3+, and Fe3+ cations, with the most intensive band being about 550 cm−1. For glass also containing Fe2O3 alongside Al2O3, a band of about 506 cm−1 becomes visible.

As it was observed in the studied glasses, the bands of the phosphate network change their shape depending on the Na2O content, which, in this case, determines the molar proportion of Na2O/P2O5. This is shown by the spectrum of the Bb glass (Fig. 2). This glass has a proportion of Na2O/P2O5 = 0.65, thus, significantly smaller than 1. Such a value is characteristic for the structure of ultra-phosphates, which are built of cross-linked phosphate groups. However, the remaining glasses have the ratio Na2O/P2O5 = 1, as in the case of meta-silicates built of phosphate rings or chains [7]. The spectrum of the Bb glass (Fig. 2) is distinguished by a narrow absorption band with extremes at 1,170 and 1,080 cm−1, and in the place of the band in the range of 1,000–980 cm−1, a band of 920 cm−1 is distinguished.

Mechanical activations cause changes in the structure of the studied glasses. These changes become visible in MIR spectra, as a tendency of shifting band maximums in the direction of lower wave numbers. This is already observable after 20 min of activation and sometimes increases when activation is prolonged up to 2 h. Longer activation, e.g., for 4 h, does not bring any visible changes (Fig. 1). The decrease of the wave number of bands signifies an increase in the frequency of vibrations, and so, a decrease in the length of bonds.

Thermal transformations of glasses

As seen from the results of thermal analysis, the studied glasses are characterized by a low transformation temperature (T g) of about 430 °C. Just after the glass transformation effect, crystallization commences, which is made visible by one, and in glasses containing Fe, by two exothermic peaks on the DSC curves. Above 600 °C, the formed crystalline phases melt, giving endothermic effects (Figs. 3, 4). Mechanical activation decidedly decreases the crystallization temperature of all tested glasses. These changes are the most visible when the milling time is extended from 20 min to 2 h.

The temperatures of the exothermic peaks on DTA/DSC curves of glasses were taken as the temperatures in which the glasses were heat treated for crystallization. Crystallized glasses were subjected to XRD investigations (Fig. 5). Judging from the intensiveness of the lines on the XRD patterns, mechanically activated glasses reach a high degree of crystallization in a period of 20 min. Increasing the time of activation of glasses to 2 h causes a further increase in the degree of their recrystallization.

In non-activated glasses, AlPO4 crystallizes, and in some, also Al2O3 (corundum). The latter is not present when the glass contains iron. Aluminum also forms the sodium aluminate NaAl11O17, and iron is present in the form of the phosphate NaFeP2O7.

20-min and 2-h activation of glasses changes the quantitative proportions between the formed phases. In all glasses, Al2O3 (corundum) crystallizes and becomes the quantitatively dominating constituent, constituting 35–73 wt% of the entirety of the crystallized compounds. Furthermore, berlinit AlPO4 (5–35 wt%) was observed, and in glasses with the highest Al2O3, the pyrophosphate AlP3O9 (5–14 wt%) is present. Characteristic constituents are the sodium aluminate NaAl11O17 (7–35 wt%) and in iron containing glasses the pyrophosphate NaFeP2O7 (13–24 wt%). The activation time, in changing the crystallization temperature, also influences the quantitative proportions between these compounds.

Discussion of results/summary

Spectroscopy in the MIR has shown that the structure of the studied glasses contains pyrophosphate groups and phosphate chains similar to those occurring in the crystalline structure of meta-phosphates. Thus, the trivalent Al3 and Fe3+ cations are located between them, binding them. In this way, the structure of the glasses has the nature of a three-dimension cross-linked phosphate network.

Mechanical activation causes changes in the structure of the studied glasses, visible in MIR spectra as a tendency of shifting band maximums in the direction of lower wave numbers. This is already observable after 20 min of activation and sometimes increases when activation is prolonged up to 2 h. Longer activation, e.g., for 4 h, does not bring any further changes. The decrease of the wave number of bonds signifies an increase in the frequency of vibrations, and so, a decrease in the length of bonds. These changes can be explained as being a result of the decrease of stresses present in the amorphous, non-equilibrium glass structure created through undercooling of the melt, due to the effect of the applied mechanical energy. This has an effect on the phase transformations occurring during the heating of glasses.

It is expressed by a decrease of the T g temperature as well as the temperatures of individual stages of crystallization, which is tantamount to a decrease of their activation energy. A change in the course of crystallization also takes place, separating it into two or even three separate stages (Figs. 3, 4). It can be observed that the differences in crystallization shown by the DSC curves are especially marked in relation to the change in Na2O content, which has a depolymerizing effect on the phosphate network, weakening it, which results in a decrease in the viscosity of glass.

The first stage of crystallization is related to the transformation of the vitreous state, and the DSC effect of thermal transformation passes directly into the exothermic effect of formation of crystalline phases. Due to the high viscosity of glass in the transformation range (1015 Pa s), its structure as appropriate for a solid state is maintained in a large degree, and the ability of atoms to move (mobility) remains limited; therefore, crystallization takes place through the reorganization of the middle range ordering domains. A fine-crystalline or even nanometric crystalline phase dispersed in the vitreous matrix is then created [8, 9]. As the temperature increases, destruction of the glass network takes places, its constituents are released, and their mobility is increased. This allows for the growth of the earlier formed grains or for the crystallization of new compounds, which is accompanied by the generation of crystallization heat, which is marked by the appropriate exothermic peaks on the DSC curve.

In phosphate, sodium aluminate glasses Aa and Ab, crystallization leads to the formation of Al2O3 as the main phase and to the formation of aluminum ortho- and meta-phosphates as well as sodium aluminate. Activation increases the percentage of Al2O3 and aluminum phosphates and decreases the percentage of sodium aluminates in crystallizing phases and even leads to their disappearance. In glasses containing Al2O3 and Fe2O3, the main phase is the iron and sodium phosphate NaFeP2O7, where aluminum is present as sodium aluminate and subordinately as AlPO4.

The phenomena described here can be understood through the analysis of atomic interactions in the structure of the studied glasses [10, 11], based on Görlich’s concept of ionicity of chemical bonds (x G) and their values [12]. The ionicity values of oxygen bridges present in the structures of these glasses was calculated under the assumption that they are equal to the difference of the ionicity (Δi G) of the bonds of oxygen with the elements comprising them, and are as follows: P–O–FeIII 0.215, P–O–Al 0.232, P–O–Na 0.493, Na–O–Al 0.261, Na–O–Fe 0.278 (eV).

Bridge ionicity is the measure of the chemical affinity of elements comprising the bridge and is, at the same time, the indicator of the strength of bridges. Judging from the calculated values, it can be acknowledged that Na has the greatest affinity to phosphorus, and strong oxygen bridges bind these two elements together. At the same, it explains the strong ability of Na+ to depolymerize the phosphate network in glass. [PO4] tetrahedra in phosphate glasses build rings and chains that are bound with sodium. They are cross linked by Al3+ and Fe3+ ions. Judging from the Δi G value, it appears that the oxygen bridges binding them with phosphorus are significantly weaker than P–O–Na bridges and are comparable in strength to Al–O–Na and Fe–O–Na bridges. Therefore, these bridges are easily broken, and the main crystallizing phase becomes Al2O3. Ability of Al to form common oxygen bridge with Na is slightly higher than to phosphorus, and so, the next significant phase is sodium aluminate, and most likely only the remaining Al is bound in the glass structure directly to [PO4] tetrahedra and forms aluminum phosphates. The slightly higher affinity of Fe to form oxygen bridges with sodium relative to Al and the higher strength of the Na–O–Fe bridge, with a weaker Fe–O–P bond, causes Fe3* to bind with [PO4] tetrahedra through Na–O–P bridges. This is possible despite the fact that Na is formally univalent, because it creates ionic, non-directional bonds with surrounding anions as it is known from halide glasses. The crystallization of the NaFeP2O7 phosphate as the main phase is confirmation of this.

Conclusions

The studies carried out showed that mechanical activation through grinding causes changes of the thermal properties of glasses, which are visible after only 20 min of grinding. These changes are expressed through the decrease of the transformation temperature (T g) and the crystallization temperature. Crystallization takes place in several stages instead of in one stage. Aluminum crystallizes as: Al2O3, NaAl11O17, and aluminum phosphates AlP3O9 and AlPO4 as subordinate constituents. Iron exclusively forms the NaFeP2O7 phosphate. Activation changes the quantitative proportions between these phases.

The causes for such a course of crystallization can explained through atomic interactions analysis of the glass structure components. Aluminum, in comparison to the remaining constituents of glass, creates the weakest bridges with oxygen in the phosphate network. They are the bridges destroyed first by thermal vibrations, and liberated aluminum crystallizes as an oxide after exceeding the T g temperature or forms a compound with sodium and P2O5 as appropriate to the degree of affinity to these elements. The affinity of iron toward sodium, which, in turn, is distinguished by a high affinity toward phosphates and creates very stable oxygen bridges with it, is caused by the formation of NaFeP2O7. This is the only iron compound that was observed.

References

Ojovan MI, Lee WE. An introduction to nuclear waste immobilisation. London: Elsevier Science; 2005.

Stoch L. Structural classification of phosphate glasses. Ceramics. 1993;43:267–74.

Stoch L. Structure and crystallization of multicomponent glasses. High Temp Mater Process. 1992;10:245–64.

Donald IW, Metcalfe BL, Taylor RNJ. The immobilization of high level radioactive wastes in ceramics and glasses. J Mater Sci. 1997;32:5851–87.

Sitarz M, Rokita M, Handke M. The aluminium effect on the phospho-silicate materials. J Mol Struct. 2002;61:289–99.

Stoch L, Środa M. Infrared spectroscopy in the investigation of oxide glasses structure. J Mol Struct. 1999;511–512:77–84.

Stoch L, Aboud T. Structural classification of phosphate glasses. Ceramics. Papers of the Polish Academy of Science, Krakow Div. 1993;43:267–75.

Stoch L. Early stages of crystal structure organization in SiO2–Al2O3–MgO(ZnO) and SiO2·BPO4 glasses—HREM study. Phys Chem Glasses Eur J Glass Sci Technol B. 2008;49(4):220–8.

Stoch L, Stoch P. Crystal structure formation in glass from view of HRTM. J Therm Anal Calorim. 2007;88:577–82.

Stoch L. Crystallochemical aspects of structure controlled processes in oxide glasses. Opt Appl. 2008;38:225–35.

Stoch L. Thermochemistry of solids with flexible structures. J Therm Anal. 1998;54:9–24.

Görlich E. The effective nuclear charge and the electronegativity. Krakow: Polish Academy of Art and Science; 1997.

Acknowledgements

The study was supported by Project NN507458037 of the Ministry of Science and Higher Education of Poland.

Open Access

This article is distributed under the terms of the Creative Commons Attribution Noncommercial License which permits any noncommercial use, distribution, and reproduction in any medium, provided the original author(s) and source are credited.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This is an open access article distributed under the terms of the Creative Commons Attribution Noncommercial License (https://creativecommons.org/licenses/by-nc/2.0), which permits any noncommercial use, distribution, and reproduction in any medium, provided the original author(s) and source are credited.

About this article

Cite this article

Ciecinska, M., Stoch, P. The effect of mechanical activation on the thermal reactions of P2O5–Al2O3–Fe2O3–Na2O phosphate glasses. J Therm Anal Calorim 108, 711–715 (2012). https://doi.org/10.1007/s10973-011-1999-2

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-011-1999-2