Abstract

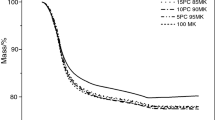

The hydration and hardening processes of Portland cements prepared from clinkers mineralized with sodium fluoride and/or oxides (SnO2 or CuO) was studied. Type I cements (CEM I) were prepared by grinding with gypsum (5%) of clinkers obtained by the burning of an industrial raw mix with different mineralizers: sodium fluoride, oxides (CuO and SnO2) or mixtures of sodium fluoride and oxide (NaF + CuO or NaF + SnO2). The influence of foreign ions on the clinker morphology was assessed by scanning electronic microscopy (SEM) and energy dispersive X-ray spectrometry (EDX). The hydration processes of modified cements were examined by X-ray diffraction analysis (XRD) and thermal analysis techniques (TG and DTA). The main properties of the cements, i.e., flexural and compressive strengths, setting time, and soundness were also determined. A good correlation between the chemically bound water or portlandite content in pastes hydrated 2–28 days and compressive strength developed by mortars was observed. The influence of mineralizers on the kinetic of hydration processes and main properties of cements is different—0.5% NaF and 0.5% SnO2 and their mixture increase the rate of cement hydration and hardening processes, opposite to 0.5% CuO that reduce the rate.

Similar content being viewed by others

Notes

LSF = %CaO/(2.8% SiO2 + 1.1% Al2O3 + 0.7% Fe2O3).

AR = % Al2O3/%Fe2O3.

SR = % SiO2/(%Al2O3 + %Fe2O3).

References

Bhatty JI. Role of minor elements in cements manufacture and use. IL: Portland Cement Association; 1995.

Niculae G. Impact of waste co-incineration in the clinker kilns on the emissions and on the clinker and cement. PhD Thesis, University Politehnica from Bucharest; 2009.

Perraki M, Perraki T, Kolosov K, Tsivilis S, Kakali G. Secondary raw materials in cement industry. Evaluation of their effect on the sintering and hydration process by thermal analysis. J Therm Anal Calorim. 2002;70:143–50.

Engelsen CJ. Effect of mineralizers in cement. State of the art. SINTEF report; 2007.

Ma S, Shem X, Gong X, Zhong B. Influence of CuO on the formation and coexistence of 3CaO·SiO2 and 3CaO·3Al2O3·CaSO4 minerals. Cem Concr Res. 2006;36:1784–7.

Emanuelson A, Hansen S, Viggh E. A comparative study of the ordinary and mineralised Portland cement clinker from two different production units. Part. II. Characteristics of the calcium silicates. Cem Concr Res. 2003;33:1623–30.

Moir GK. Improvements in the early strength properties of Portland cement. Philos Trans R Soc Lond A. 1983;310:127–36.

Sanjaasuren R, Rymyantsev PF. Synthesis of low temperature Portland cement clinker by using composite mineralizer. In: Justness H, editor. Proceedings of the 10th international congress of the chemistry of cement, Gothenburg; 1997. p. 1i037–46.

Teoreanu I, van Huynh T, Stoleriu S. Thermal studies regarding the influence of flour containing mineralisators on calcium carbonate dissociation of Portland clinkers formation. Rev Roum Chim. 2003;48:947–53.

Kacimi L, Simon-Masseron A, Ghomari A, Derriche Z. Influence of NaF, KF and CaF2 addition on the clinker burning temperature and its properties. C R Chim. 2006;9:154–63.

Kolovos GK, Dousis G, Tsivilis S, Kakali G. The effect of SnO2 on the burnability or raw meal, the structure and the properties of cement clinker. Zem Kalk Gyps. 2005;25:81–7.

Kolosov KG. Waste ammunition as secondary mineralizing raw material in Portland cement production. Cem Concr Compos. 2006;28:133–43.

Hill J, Sharp JH. The hydration products of Portland cement in the presence of tin (II) chloride. Cem Concr Res. 2003;33:121–4.

Paceagiu J, Amzica F, Chendrean T, Paraschiv T. Effect on NaF and SnO2 on portland cement clinker fabrication. In: D. Acierno, A. D’Amore, L. Grassia, editors. Proceeding of the IV international conference times of polymers (TOP) and composites. Vol 1042. American Institute of Physics; 2008. p. 258–60.

Badanoiu A, Paceagiu J, Voicu G. Evaluation of some mineral additions effect on the burnability of raw mix in cement production. Sci Bull Univ Politeh Buchar B. 2009;71:23–36.

Taylor HFW. Cement chemistry. London: Academic Press; 1990.

Campbell DH. Microscopical examination and interpretation of Portland cement and clinker. IL: Portland Cement Association; 1999.

Kolosov K, Tsivilis S, Kakali G. SEM examination of clinkers containing foreign elements. Cem Concr Compos. 2005;27:163–70.

Badanoiu A, Georgescu M, Puri A. The study of DSP binding systems by thermogravimetry and differential thermal analysis. J Therm Anal. 2003;74:65–75.

Ramachandran VS, Paroli RM, Beaudoin JJ, Delgado AH. Handbook of thermal analysis of construction material. New York: William Andrew Publishing/Noyes; 2002.

Stepkowska E, Perez-Rodriguez JL, de Haro MCJ, Sayagues MJ. Study of hydration of two cements of different strength. J Therm Anal Calorim. 2002;69:187–204.

Mitchell LD, Margeson JC. The effects of solvents on C–S–H as determined by thermal analysis. J Therm Anal Calorim. 2006;86:591–4.

Stepkowska E, Perez-Rodriguez JL, Sayagues MJ, Martinez Blanes JM. Calcite, vaterite and aragonite forming on cement hydration from liquid and gaseous phase. J Therm Anal Calorim. 2003;73:247–69.

Goni S, Puertas F, Hernandez MS, Palacios M, Guerrero A, Dolado JS, Zanga B, Baroni F. Quantitative study of hydration of C3S and C2S by thermal analysis. Evolution and composition of C–S–H gels formed. J Therm Anal Calorim. doi:10.1007/s10973-010-0816-7.

Nochaiya T, Wongkeo W, Pimraska K, Chaipanich A. Microstructural, physical and thermal analysis of Portland cement-fly ash-calcium hydroxide blended pastes. J Therm Anal Calorim. 2010;100:101–8.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bădănoiu, A., Paceagiu, J. & Voicu, G. Hydration and hardening processes of Portland cements obtained from clinkers mineralized with fluoride and oxides. J Therm Anal Calorim 103, 879–888 (2011). https://doi.org/10.1007/s10973-010-1125-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-010-1125-x