Abstract

Barium titanate materials are currently a special topic for scientific research due to their effective technological applications. The tetragonal BaTi1-xZrxO3 (0.0 ≤ x ≤ 0.3) nanoparticles (NPs) were synthesized using a modified citrate technique. The current work provides a comparative approach for the calculation of crystallite size, stress, strain, and elastic characteristics based on X-ray diffraction (XRD) patterns. Various models have been developed to analyze XRD data; these models differ in their assumptions, mathematical approaches, and the type of information they provide. The Scherrer model ignores lattice micro-structures that develop in nanostructures, such as intrinsic strain. To overcome such drawbacks, three Williamson-Hall models, (the uniform deformation model (UDM)), the uniform stress deformation model (USDM), and the uniform deformation energy density model (UDEDM) have been discussed. According to the USDM model, with increasing Zr ion concentrations, interplanar space increases, causing a drop in Young’s modulus. All the previous approaches take into account the diffraction angle (2θ)-dependent peak broadening, which is thought to represent a combination of size and strain-driven induced broadening.

Graphical Abstract

Highlights

-

The BaTi(1−x)Zr(x)O3; (0.0 ≤ x ≤ 0.3) single phase tetragonal structure was successfully prepared using a modified citrate method.

-

The interplanar spacing increases with higher Zr ion concentrations, resulting in a decrease in Young’s modulus.

-

The Uniform Stress Deformation Model (USDM), and the Uniform Deformation Energy Density Model (UDEDM) have been discussed.

-

The type of intrinsic ε has been identified by analyzing the mathematical formulas of the various models.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The BaTiO3 matrix has ferroelectric and dielectric properties that are interesting for a variety of technological applications. The chemical structure is more stable when Zr4+ ions replace Ti4+ ions because they have larger ionic radii than Ti4+ ions. More significantly, a B-site substitution of this kind can enhance the dielectric performance [1,2,3]. By adjusting the Zr/Ti ratio, it is possible to regulate the type of ferroelectric response in this material [4,5,6]. Thus, zirconium titanate can be a perfect material for a variety of applications.

One of the most powerful methods for determining quantitative and qualitative crystallographic data is XRD. The shape and position of diffraction peaks can be used to determine the nature of the materials. Peak broadening can occur as a result of either size restriction or strain impact [7]. Crystal defects are closely connected to lattice strain.

Coherency stresses, triple junction, sinter or contact stresses, and stacking defects are the most common sources of strain [8, 9].

Most researchers resort to different models to evaluate crystalline size (L) and microstrain (ε) and its effect on the physical properties of their samples.

M. Hasan et al. [10], employed standard solid-state procedures to synthesize crystalline Ba(1−x)(Sr0.5Ni0.5)xTiO3. The authors used the Scherrer equation as well as the Williamson-Hall (W-H) plot approach to estimate the crystallite size (L). When the internal stress is zero, the W-H plot approach’s underlying equation transforms into the Scherrer equation, which estimates the L for a single peak. This means that when a phase includes many peaks, it is always better to use the W-H plot technique since stress-induced peak broadening is appropriately considered when evaluating L. The estimated L is between 28 and 36 nm from the Scherrer equation. However, the estimated ones by using the W-H plot approach are between 22 and 34 nm.

S. Kazi et al. [11] synthesized BaxPb1−xTiO3 (PBT) using the solid state reaction technique with different sintering temperatures. The authors applied the Scherrer equation as well as the W-H and SSP approaches to estimate the L and ε. The authors obtained results for L estimated by the various methods that were significantly different from each other; however, they did not propose a preferred model when dealing with their samples. The authors also studied the reflections in the XRD patterns that describe phase growth in a polycrystalline PBT structure. All PBT structures have a strong orientation about the (110) plane relative to other planes; however, the orientation varies from 2.42 to 1.33.

M. M. Mohammad et al. [12] studied the Ba1−xSrxTi0.93Sn0.07O3 (x = 0.00, 0.10, 0.20, and 0.30) perovskite ceramics produced by the solid-state reaction method. The authors obtained results for the crystal size and strain using the W-H method. The crystal size reduced from 76.44 to 50.81 nm with increasing Sr content, while the strain increased from 22 × 10−4 to 33.1 × 10−4 with increasing Sr content.

In this study the authors aimed to address the previous disadvantage and recommend the most effective approach.

The primary goal of this study is to estimate the structural parameters using different techniques and compare them. The micro-strain, density of dislocations, lattice stress, energy density, and crystallite size of BaTi1−xZrxO3 were estimated.

Numerous techniques were utilized to evaluate the elastic properties and crystallite size (L), including a unique approach to the Scherrer equation, WHA, size-strain plot analysis, and the Halder-Wagner approach.

2 Experimental work

2.1 Preparation method

BaTi1−xZrxO3 (0.0 ≤ x ≤ 0.3) NPs were prepared using the modified citrate procedure. The precursors Ba(NO3)2, 99.9% (Sigma-Aldrich), [Ti(OC4H9)]4, 97%, ZrOCl2, 99.9% (Sigma-Aldrich), and C6H8O7 were used. In separate beakers, 1-mol of Ba(NO3)2 and 2-mol of C6H8O7 were dissolved in a sufficient amount of deionized water to form homogeneous solutions, and (x)-mol of ZrOCl2 solution was added to a (1−x)-mol of [Ti(OC4H9)]4 suspension and thoroughly mixed with the citric acid solutions on the magnetic stirrer at 70 °C for 1 h. Subsequently, Ba(NO3)2 solution was added. Then the power of hydrogen (pH) was adjusted to 8. The mixture was heated to 120 °C and swirled constantly until all of the volatile components and water in the beaker had evaporated. After that, the mixture seemed thick and sticky, and it was allowed to burn completely on the hot plate, resulting in a black, fluffy mass. Then, it was ground well to obtain a fine powder. In a furnace, the black powder was annealed to 1100 °C at a rate of 5 °C per minute for 120 min [1]. The flowchart for the preparation technique is shown in Fig. 1.

2.2 Characterizations and measurements

The crystallinity of the samples was examined using XRD on a Bruker advanced D8 X-ray diffractometer. The pattern was captured using Cu-Kα radiation in the 2θ range of 20–80°. The XRD pattern was indexed using card number 04-016-2039 from the International Centre for Diffraction Data (ICDD).

3 Results and discussion

3.1 XRD analyses

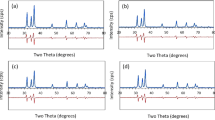

Figure 2a shows the XRD patterns of the samples with the general formula BaTi1−xZrxO3; (x: 0.0, 0.1, 0.2, and 0.3). The investigated samples were crystallized in a single-phase possessing the tetragonal space group P4mm with one molecule per unit cell. The crystallite size (L = 19–38 nm), and the lattice parameters (a and c), and the tolerance factor (t) for the investigated samples were calculated and reported in our previous work [1].

a XRD pattern of BaTi(1−x)Zr(x)O3 (0.0 ≤ x ≤ 0.3) [1], b The elemental mapping of BaTi0.9Zr0.1O3

The lattice parameters were calculated from the XRD patterns compared with the ICDD card number (04-016-2039). The values of the lattice parameters (a and c) increase with an increase in Zr content (from x = 0.0 to x = 0.3) from 4.005 Å to 4.059 Å and from 4.023 Å to 4.071 Å for the parameters, respectively. Therefore, by increasing the Zr content (from x = 0.0 to x = 0.3), the unit cell volume increased. The reason behind this increment is the substitution of the Ti4+ ion (ionic radius = 0.605 Å) with a larger ion (Zr4+ ionic radius = 0.72 Å) [13, 14], so it increases the interplanar spacing; therefore, it increases the lattice parameters and hence the unit cell volume as well.

The c/a ratio decreased after Zr entered the crystal lattice, signifying a decrease in tetragonality. The theoretical density (Dx) was also calculated, and it increased from 6.002 to 6.057, 6.070, and 6.093 gm/cm3, for x values of 0.0, 0.1, 0.2, and 0.3 respectively. This increase occurred despite the volume increase, because the molecular weight of the doped BaTi1−xZrxO3 samples increased by a greater percentage than the volume augmentation as the zirconium concentration increased.

The elemental mapping shown in Fig. 2b illustrates the homogeneous distribution of constituent elements in BaTi(1−x)Zr(x)O3.

In the current work, the XRD data are examined further to establish L, and elastic characteristics. Numerous techniques are utilized to evaluate the microstructure, including a unique approach to the Scherrer equation, Williamson-Hall analysis, size-strain plot analysis, and the Halder-Wagner approach.

3.1.1 The hypotheses, assumptions, and boundary conditions for the utilized approaches

Various models have been developed to analyze XRD data and extract valuable information. Each model has its advantages and limitations, and the choice of model depends on the specific characteristics of the material being analyzed. In fact, calculating the crystallite size (L) with extreme accuracy is a very challenging issue. According to the literature, the various models of X-ray analysis, including the models referred to in this paper, are persistent attempts to understand microstrain and calculate crystal size. There is no clear or defined dependence of the L on the crystallographic direction. For example, depending on the synthesis method, crystallite can have different shapes, and the dependencies mentioned herein can change. Each model differs from the other in trying to improve the results by dealing with peak broadening. Several models except Scherer’s model take into account the contribution of microstrain along with crystallite size when dealing with peak broadening [15, 16]. Then the various models differ among themselves in dealing with the peak shape and the suitable function, which can closely fit the peak to take into account all the details contributing to the formation of that peak.

Researchers often use a combination of these models to obtain a comprehensive understanding of the material’s structure and properties. Here are some of the commonly used models:

-

1.

Scherrer Model: The Scherrer equation is used to estimate the average crystallite size of a material from the broadening of diffraction peaks. It assumes that the peak broadening is solely due to crystallite size and does not consider other factors like microstrain. The Scherrer model is more suitable for dealing with the particles with a spherical shape [15].

-

2.

Williamson-Hall Analysis (WHA): The WHA is an extension of the Scherrer model that considers the effects of L and lattice strain (ε) on peak broadening. This model comes in three approaches [10,11,12,13, 15, 17,18,19]:

-

a.

Uniform Deformation Model (UDM): In this model, the lattice strain is assumed to be evenly distributed across the crystal, resulting in isotropic peak broadening.

-

b.

Uniform Stress Deformation Model (USDM): The (USDM) is a developed model that assumes that the stress due to lattice deformation is harmonic across all directions of the lattice plane.

-

c.

Uniform Deformation Energy Density Model (UDEDM): The (UDEDM) is used, to investigate the homogeneous anisotropic lattice strain in all crystallographic orientations.

For (USDM) and (UDEDM), the anisotropic strain could be carried out if Young’s modulus is available for the system or could be computed.

-

a.

-

3.

The size-strain plot (SSP) is used in some models to perform peak profile examinations. It assumes that the peak profile of the XRD is a mixture of Lorentzian and Gaussian functions, Lorentz functions are identified on size-broadened XRD profiles, and Gaussian functions are annotated on strain-broadened profiles [18].

-

4.

Halder-Wagner Approach (HWA): The HWA method is another approach to estimating crystallite size and microstrain using XRD data. It involves fitting a modified Voigt function to experimental peaks, considering both instrumental and sample contributions to peak broadening. When diffraction peak overlap is small, this approach focuses on the peaks at small and moderate angles [10, 19].

3.1.2 Scherrer’s method

The Scherrer equation is related to the diffraction peak presented in Eq. (1) [20], where L is the crystallite size; K is the shape factor (≅0.9), λ is the X-ray wavelength (1.5406 Å for Cu Kα radiation); θ is the peak diffracted angle; and β is the corrected full width at half maximum (FWHM) of the X-ray peak on the 2θ axis in radians. Furthermore, peak widening is associated with both physical and instrumental broadening [15].

For detecting the corrected broadening (β) due to the sample only and reducing the error caused by the instrumental broadening, Eq. (2) can be used:

where βm is measured broadening, and βi is instrumental broadening.

The Origin software is used to fit all of the observed peaks in the investigated samples using Gaussian fitting to obtain βm. For calibration of position and βi computations, crystalline silicon or (c-Si) is used as a typical reference material. Using the corrected physical broadening (β), besides the Scherrer equation, L is determined in more than one manner.

Average model

This method was mentioned in our previous work [1], taking into account the four most intense peaks, where the L was determined from each peak, and the average for all of them was taken to obtain the average L. Furthermore, the dislocation line length per unit volume of the crystal is summed up as the density of dislocations (δ), which identifies the sample’s defects and is associated with the crystallite size (L) as follows [21]:

where n equals 1, which is the minimal density of the dislocation. The densities of dislocation from various methodologies are also calculated. Table 1 shows the L, and δ values using different Scherrer approaches.

Scherrer plots model

In this method, the Scherrer Eq. (1) can be rearranged as follows:

This equation represents a straight-line equation with a slope equals 1

Figure 3 represents the Scherrer plots for the investigated samples by fitting a straight line using the Origin software. The L can be determined and the obtained data is tabulated in Table 1. The obtained results are not far from those estimated by Scherrer’s average method, except for the x = 0.0 sample.

Modified Scherrer equation (Monshi–Scherrer model)

The sharpest peak is commonly used to calculate the average L. Munshi et al. [22] modified the Scherrer Eq. (4) (MSM) with minor adjustments and estimated the following formula:

The modified Scherrer formula is based on the fact that we must use the least squares approach to mathematically reduce the source of errors and obtain the average value of L through all peaks (or any number of selected peaks). The MSM minimizes the overall absolute amount of errors, \(\Sigma {(\mp \Delta \mathrm{ln}{\rm{\beta }})}^{2}\) to deliver a more precise estimate of L from all or part of the distinct peaks [19]. Figure 4 provides the MSM plots. It also represents a straight-line equation with the slope adjusted to 1, the L is estimated from the intercept on the Y-axis.

The estimated values of L are tabulated in Table 1. These results are also not far from those calculated by Scherrer’s average method and Scherrer’s plot method, except for the x = 0.0 sample. However, the results of the three methods according to the Scherrer equation are all within an acceptable range.

3.1.3 Williamson-Hall analysis (W-HA)

The Scherrer equation only considers the influence of crystallite size on X-ray diffraction peak broadening and ignores lattice micro-structures, such as intrinsic strain (ε) that arises in nanostructures due to point defects, triple junctions, grain boundaries, and stacking faults [19]. There are several techniques, including the W-HA and the Warren-Averbach method (W-AM), that take into account the impact of strain (ε)- induced XRD peak widening and can be used to calculate ε as well as L. Among these strategies, the W-H approach is one of the most basic and straightforward [11].

For the study of W-H, the correlation between L and the ε broadening effects is provided as Eq. (6).

Modified W-H is utilized in the current work, and models included UDM, USDM, and UDEDM, which will be described in the following subsections.

Uniform deformation model (UDM)

Although most nanocrystals are structurally defective, the presented UDM is evenly dispersed in all crystallographic orientations and isotropic in nature [10, 11]. For the strain associated with the nanocrystals, the UDM technique yields the following equation:

As a result, the overall broadening owing to ε and L of a specific peak with the hkl value can be written as,

This expression can be rearranged to get Eq. (9) [23]:

Equation (9) demonstrates the UDM model, which takes into account the crystals’ isotropic nature. Figure 5 represents the UDM equation, applying the term (4 sin θ) versus \(({\beta }_{{hkl}}\cdot \cos \theta )\) to every peak of BaTi1−xZrxO3. This illustrates linear fitting that fits all of the data with a correlation coefficient (R2 ≈ 0.8) in all samples except for x = 0.0. The line’s slope represents the the average L whereas it can be calculated from the line’s intersection on the Y-axis.

The atomic arrangement of nanocrystals is minimally changed due to size restrictions, so lattice strain formation typically occurs for lattice dilation or constriction. However, due to the size limitation, numerous defects are generated in the lattice structure, resulting in lattice strain. The average values of L obtained from UDM are presented in Table 2. The slope of the UDM appeared to be positive, demonstrating the extension of the lattice [7]. As a consequence, the nanocrystals have intrinsic ε as shown in the table.

Uniform stress deformation model (USDM)

The UDM model assumes that the sample is homogeneous and isotropic, which is not true when dealing with a real crystal as crystals are anisotropic. The developed model is known as USDM, and it assumes that the stress (σ) due to lattice deformation is uniform in all directions of the lattice plane with a small microstrain [24]. According to Hooke’s law, the Young’s modulus or the elasticity modulus (Yhkl) can be represented by the following equation:

Due to size constraints, the crystals’ intrinsic strain causes a modest degree of internal stress (σ). USDM considered stress-induced widening of the XRD peak as well as the anisotropic behavior of Young’s modulus [25].

Subrogating the values of ε from Eq. (10) and rewriting it, the following equation is obtained:

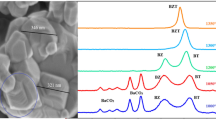

That’s the developed WH equation. Figure 6 represents this model, where the terms (\(\frac{4\sin \theta }{{Y}_{{hkl}}}\)) versus (\({\beta }_{{hkl}}\cdot \cos \theta\)) are illustrated which correspond to every diffraction peak for BaTi1−xZrxO3 NPs. The next paragraph will explain how to compute Young’s modulus (Yhkl). The straight line intersection gives a mean crystallite size of 25–29 nm, while the slope provides an energy density value of 17–223 kJ/m3. The obtained results are presented in the table.

Interestingly, Zhang et al. [26], discovered that there is a relationship between elastic compliances, sij, and the crystal lattice plane (hkl) for the crystalline materials. Consequently, for tetragonal structures, Young’s modulus may be stated using Eq. (12) [27, 28].

Where s11, s12, s13, s33, s44, and s66 [27, 28] are the elastic compliances of BaTiO3 ceramics, and their values and average value of Young’s modulus (Yave) are given in Table 3.

Figure 7a represents the interplanar spacing (d-spacing(dhkl)) for the planes (101), (111), (002), and (112), and the average value of Young’s modulus (Yave) vs. Zr content. As mentioned in the previous work [1], there is a shift towards the lower 2θ with increasing Zr content. This shift contributes to the increase in the interplanar spacing, and it is the main issue for the observed reduction in Young’s modulus (Fig. 7b)

By using Eq. (12), and Eq. (13), to relate Yhkl and d-spacing (dhkl), one can get Eq. (14).

According to Eq. (14), more than one factor influences Yhkl, including lattice parametrics and d-spacing (dhkl).

Uniform Deformation Energy Density Model (UDEDM)

The USDM model proposes a linear relationship between stress and strain based on Hooke’s Law, in contrast to the UDM model’s assumption that the crystal is isotropic. However, the isotropic property and linear relationship of stress and strain cannot be taken into account in actual crystals because different defects, dislocations, and agglomerates cause imperfections in nearly all crystals. Therefore, a unique model is required for researching the various crystal microstructures.

As a result of this, the UDEDM is utilized, in which the homogeneous anisotropic lattice strain is investigated in all crystallographic orientations, and the density of the energy of deformation is the source of the homogeneous anisotropic lattice strain [17]. Hooke’s Law states that energy density (u) is linked to ε via the relationship (15):

By substituting the values of ε into Eq. (9), Eq. (16) is obtained.

Equation (16) is a straight-line equation that represents the UDEDM [27, 28]. The energy density value of the crystals may be estimated using this model. Figure 8 represents the relation between \(4\sin \theta \sqrt{\frac{2}{{Y}_{{hkl}}}}\) and \({\beta }_{{hkl}}\cdot \cos \theta\) conforming to each diffraction peak of the BaTi1−xZrxO3 NPs. The straight-line intercept provides the average L varying between 29 and 38 nm, while the slope yields u values ranging from 66 to 488 KJ/m 3. The values of (L), (ε), (σ), and (u) have been computed based on the straight-line intersection, and the slope as tabulated in Table 2.

In summary, one can conclude that the type of intrinsic ε can be identified by analyzing the mathematical formulas of the different approaches. According to the three WHA models, the slope in Eqs. (9), (11), and (16) is related to ε. Consequently, if the slopes in WHA models are positive, that indicates the existence of tensile strain, while negative slopes suggest that the strain corresponding with the lattice structure is compressive [29]. According to the three WHA models, our samples exhibit tensile strain. because entering Zr4+ at the expense of Ti4+ increases the distortion as well as the interplanar spacing. The lattice expanded, indicating an increase in the intrinsic strain as illustrated in Table 2.

3.1.4 Size-strain plot (SSP)

The W-H method assumes that the broadening of peaks in the XRD pattern is mostly isotropic, implying that the diffracting domains in the crystal are isotropic [18]. This model takes into account the diffraction angle (2θ)-dependent peak broadening, which is thought to represent a combination of size and strain-driven induced broadening. However, some models perform peak profile examinations. One instance of this approach is the size-strain plot (SSP), which assumes that the peak profile of the XRD is a mixture of Lorentzian and Gaussian functions, with Lorentz functions identified on size-broadened XRD profiles and Gaussian functions annotated on strain-broadened profiles.

Hence, the broadening of (SSP) may be described as:

Where βL and βG are the Lorentz and Gaussian function peak broadening, respectively. Those values can be obtained by applying the Voigt fit using the Origin software.

The (SSP) approach usually delivers a superior isotropic broadening result because it prioritizes small angles, where accuracy and precision are better, over higher reflection angles. This is due to the deterioration in XRD data at higher diffracting angles, where the peaks are frequently significantly merged. Consequently, the (SSP) calculation is performed using Eq. (18) as follows [11, 18].

Figure 9 The size-strain plot (SSP), using Eq. (18), a plot with \(\left({d}_{{hkl}}^{2}\cdot {\beta }_{{hkl}}\cdot \cos \theta \right)\) on the horizontal axis and \({{{(d}_{{hkl}}\cdot \beta }_{{hkl}}\cdot \cos \theta )}^{2}\) on the vertical axis conforming to every BaTi1-xZrxO3 nanocrystal diffraction peak.

The slope of the straight- line gives the (L) of the BaTi1−xZrxO3 NPs, which ranges from 24 to 48 nm, while the intrinsic strain computed from the intercept of the graphs ranges from 1.79 × 10−2 to 3.69 × 10−2. The values of (L), (ε), (σ), and (u) have been computed based on the (SSP) method and are given in Table 4.

3.1.5 Halder-Wagner Approach (HWA)

The strain broadening of the XRD peak is assumed to be a Gaussian function in the (SSP) approach, whereas the size broadening is supposed to be a Lorentzian function. However, diffraction peaks are neither Gaussian nor Lorentzian functions. The peak’s summit in diffraction corresponds to a Gaussian function, but a peak’s tail descends too rapidly and corresponds to a Lorentzian function. Peak broadening, according to the Halder-Wagner approach, is a symmetric Voigt function resulting from the convolution of the Lorentzian and Gaussian functions [10, 11]. When diffraction peak overlap is small, this approach focuses on the peaks at small and moderate angles. The profile’s entire width at half maximum may be expressed as:

So, the Halder-Wagner equation can be expressed as:

where,

A straight line is obtained by plotting a graph between \(\Big({\frac{{\beta }_{{hkl}}^{* }}{{d}_{{hkl}}^{*}}\Big)}^{2}\) versus \(\frac{{\beta }_{{hkl}}^{* }}{{d}_{{hkl}}^{* 2}}\), which represents the Halder-Wagner plot as illustrated in Fig. 10. The reciprocal of the slope represents the mean crystallite size (L), while the intersection is proportional to the ε. The mean L, the ε, the stress, and the energy density have been computed based on the (HWA), and are given in Table 4.

Looking at the different approaches used to calculate the mean L, ε, σ, and lattice energy density (u). As shown in Fig. 11, the sample (x = 0.2) has the highest values of the calculated parameters. The average L values produced from the various models are more or less equal, suggesting that the addition of ε in different ways effects the average crystallite size [30].

To interpret the reason behind the change in the stress (σ) as tabulated in Tables 2 and 4, one can calculate the average force constant k and effective mass μ of the Ti-O bond for each Zr content using the vibrational wave number corresponding to the Ti-O from the FTIR spectra (\(\bar{\nu }\)) [1]. The μ is given by the following equation [20]:

where \({{\rm{m}}}_{{\rm{Ti}}}\), \({{\rm{m}}}_{{\rm{Zr}}}\), and \({{\rm{m}}}_{{\rm{O}}}\) represent the atomic masses of Ti, Zr, and O, respectively.

The k of the Ti–O bond is determined by the equation [20, 31]:

where c is the speed of light in vacuum

To determine the average Ti–O bond length (r), the following equation is used [31]:

The (μ), (k), and Ti-O (r), are tabulated in Table 5.

From the table, we observe that both k and μ values increase with increasing Zr content, which is expected due to the larger atomic mass of Zr (91.224 u) compared to Ti (47.867 u) [32]. Additionally, as the Zr concentration increases up to x = 0.2, k increases while r decreases. This trend can be explained by the replacement of the small ionic radius of Ti4+ cation (0.605 Å) with the larger Zr4+ cation (0.72 Å) [13], bringing oxygen atoms closer to the metal cation and shortening the Ti-O bond length [30]. Consequently, Zr4+ doping results in an increase in the average force constant, potentially causing the stress to increase with higher Zr4+ ion concentration, as indicated by the analysis of various XRD models.

On the other hand, the lattice energy density (u) of materials is influenced by several factors, such as elasticity, the nature of internal stress, electronic bonding, inter-planar spacing, volume change with deformation, and resilience. The variation in u with deformation obtained using the aforementioned approaches increases with the Zr content up to x = 0.2 and then decreases at x = 0.3, as shown in Tables 2, and 4. This finding is consistent with those obtained, by G. E. Adesakin et al. [33]. The abnormality of x = 0.3 in all models can be attributed to the increase in deformation in the lattice with increasing Zr concentration which is consistent with the values of the tolerance factor of the prepared samples as mentioned in the previous work [1].

3.1.6 Comparison with reported literature

M. S. Mostari et al. [34] prepared a tetragonal phase of BaTiO3, Ba(Mg0.01Ti0.99)O3, Ba(Mg0.015Ti0.985)O3, Ba(Mg0.02Ti0.98)O3, and Ba(Mg0.01Zr0.15Ti0.84)O3 ceramics through the conventional solid-state route. A tensile strain was obtained upon applying the Williamson-Hall Analysis (WHA) to the lattice. The addition of Mg2+ and Zr4+ resulted in an increase in tensile strain due to lattice changes caused by the substitution of Ti4+ ions with larger Mg2+ and Zr4+ ions. The same behavior was observed in the present samples upon introducing Zr4+ ions into the BaTiO3 lattice. The lattice strain obtained from WHA for BaTiO3 was 16 × 10−4, which is in total agreement with our result.

M. Khan et al. [30] synthesized a tetragonal phase of BaTiO3 ceramics prepared by a sol-gel auto-combustion method. The calculated L of the developed BaTiO3 NPs by the Scherrer method, modified Scherrer method, W-H plot, and SSP plot was found to be 56.4, 62.4, 72.7, and 62.1 nm, respectively. We obtained a L that is relatively smaller than that obtained by M. Khan et al. (38, 20, 34, and 37 nm), respectively, for BaTiO3 NPs. The lattice strains obtained through the W−H and SSP methods are 3.7 × 10−4 and 30.9 × 10−4, respectively. Compared to our investigated sample for the same concentration, we obtained a higher strain (16 × 10−4 and 179 × 10−4).

4 Conclusion

The BaTi(1−x)Zr(x)O3; (0.0 ≤ x ≤ 0.3) single phase tetragonal structure was successfully prepared by a modified citrate method. The Crystallite size, stress, lattice energy density, and strain as a function of Zr ion concentration were estimated using different XRD approach. The interplanar spacing increases with increasing Zr ion concentrations, leading to a reduction in Young’s modulus. The sample with x = 0.2 has the highest values for the calculated parameters.

References

Reda M, El-Dek SI, Arman MM (2022) Improvement of ferroelectric properties via Zr doping in barium titanate nanoparticles. J Mater Sci Mater. Electron 33(21):16753–16776. https://doi.org/10.1007/s10854-022-08541-x

Chen JS et al. (2017) Effects of B-site substitution and annealing on the structural and microwave dielectric properties of CaTiO3 ceramics. J Mater Sci Mater Electron 28(1):317–322. https://doi.org/10.1007/s10854-016-5526-x

Ateia EE, Gawad D, Mosry M, Arman MM (2023) Synthesis and functional properties of La2FeCrO6 based nanostructures. J Inorg Organomet Polym Mater 33(9):2698–2709. https://doi.org/10.1007/s10904-023-02699-5

Yu Z, Ang C, Guo R, Bhalla AS (2002) Piezoelectric and strain properties of Ba (Ti 1−x Zr x) O 3 ceramics. J Appl Phys 92(3):1489–1493

Maiti T, Guo R, Bhalla AS (2008) Structure‐property phase diagram of BaZrxTi1− xO3 system. J Am Ceram Soc 91(6):1769–1780

Maiti T, Guo R, Bhalla AS (2011) Evaluation of experimental resume of BaZrxTi1−xO3 with perspective to ferroelectric relaxor family: an overview. Ferroelectrics 425(1):4–26

Sarkar S, Das R (2018) Shape effect on the elastic properties of ag nanocrystals. Micro Nano Lett 13(3):312–315. https://doi.org/10.1049/mnl.2017.0349

Ungár T (2007) Characterization of nanocrystalline materials by X-ray line profile analysis. J Mater Sci 42(5):1584–1593. https://doi.org/10.1007/s10853-006-0696-1

Al-Shakarchi EK, Mahmood NB (2011) Three techniques used to produce BaTiO fine powder. J Mod Phys 02(11):1420–1428. https://doi.org/10.4236/jmp.2011.211175

Hasan M, Hossain AKMA (2023) Exploring the multifunctional properties of (Sr, Ni) co-doped BaTiO3: Rietveld refinement, structural characterization, and electromagnetic characteristics. SSRN Electron. J. https://doi.org/10.2139/ssrn.4426643

Kazi S et al. (2020) Sintering temperature dependent structural and mechanical studies of BaxPb1−xTiO3 ferroelectrics. J Nano Electron Phys 12(4):1–5. https://doi.org/10.21272/jnep.12(4).04018

Mohammad MM, Al-Araj B, Al-Din NS (2023) Effect of Sr-doping on structural, morphological and dielectric properties of BaTi0.93Sn0.07O3 ferroelectric ceramics. Open Ceram 15. https://doi.org/10.1016/j.oceram.2023.100368

Shannon BYRD, M. H, Baur NH, Gibbs OH, Eu M, Cu V (1976) Revised effective ionic radii and systematic studies of interatomie distances in halides and chaleogenides. Acta Cryst A32:751–767

Travis W, Glover ENK, Bronstein H, Scanlon DO, Palgrave RG (2016) On the application of the tolerance factor to inorganic and hybrid halide perovskites: a revised system. Chem Sci 7(7):4548–4556

Nath D, Singh F, Das R (2020) X-ray diffraction analysis by Williamson-Hall, Halder-Wagner and size-strain plot methods of CdSe nanoparticles- a comparative study. Mater Chem Phys 239:122021. https://doi.org/10.1016/j.matchemphys.2019.122021

Ateia EE, Arman MM, Badawy E (2019) Role of coupling divalent cations on the physical properties of SmFeO 3 prepared by citrate auto ‑ combustion technique. Appl Phys A 125(8):1–7. https://doi.org/10.1007/s00339-019-2795-2

Mote V, Purushotham Y, Dole B (2012) Williamson-Hall analysis in estimation of lattice strain in nanometer-sized ZnO particles. J Theor Appl Phys 6(1):2–9. https://doi.org/10.1186/2251-7235-6-6

Prabhu YT, Rao KV, Kumar VSS, Kumari BS (2014) X-ray analysis by Williamson-Hall and size-strain plot methods of ZnO nanoparticles with fuel variation. World J Nano Sci Eng 04(01):21–28. https://doi.org/10.4236/wjnse.2014.41004

Rabiei M, Palevicius A, Monshi A, Nasiri S, Vilkauskas A, Janusas G (2020) Comparing methods for calculating nano crystal size of natural hydroxyapatite using X-ray diffraction. Nanomaterials 10(9):1–21. https://doi.org/10.3390/nano10091627

Kumar U et al. (2022) Fabrication of Europium-doped barium titanate/polystyrene polymer nanocomposites using ultrasonication-assisted method: structural and optical properties. Polymers 14(21). https://doi.org/10.3390/polym14214664

Ateia EE, Ateia MA, Arman MM (2022) Assessing of channel structure and magnetic properties on heavy metal ions removal from water. J Mater Sci Mater Electron 33(11):8958–8969. https://doi.org/10.1007/s10854-021-07008-9

Monshi A, Foroughi MR, Monshi MR (2012) Modified Scherrer equation to estimate more accurately nano-crystallite size using XRD. World J Nano Sci Eng 02(03):154–160. https://doi.org/10.4236/wjnse.2012.23020

Ateia EE, Rabie O, Mohamed AT (2023) Multi-susceptible single-phased hexaferrite with significant magnetic switching properties by selectively doping. Phys Scr 98(6). https://doi.org/10.1088/1402-4896/acd230

Sarkar S, Das R (2018) Determination of structural elements of synthesized silver nano-hexagon from X-ray diffraction analysis. Indian J Pure Appl Phys 56(10):765–772

Deligoz E, Colakoglu K, Ciftci Y (2006) Elastic, electronic, and lattice dynamical properties of CdS, CdSe, and CdTe. Phys B Condens Matter 373(1):124–130. https://doi.org/10.1016/j.physb.2005.11.099

Zhang SH, Zhang RF (2017) AELAS: automatic ELAStic property derivations via high-throughput first-principles computation. Comput Phys Commun 220:403–416. https://doi.org/10.1016/j.cpc.2017.07.020

Ooi ZV, Saif AA (2017) A study on Er3+ substitution in sol-gel BaTiO3 thin films using X-ray line profile analysis. Medziagotyra 23(no. 3):193–199. https://doi.org/10.5755/j01.ms.23.3.16225

Rajender G, Giri PK (2016) Strain induced phase formation, microstructural evolution and bandgap narrowing in strained TiO2 nanocrystals grown by ball milling. J Alloys Compd 676:591–600. https://doi.org/10.1016/j.jallcom.2016.03.154

Fernandez J, Bindhu B, Prabu M, Sandhya KY (2022) Effects of hafnium on the structural, optical and ferroelectric properties of sol-gel synthesized barium titanate ceramics. J Korean Ceram Soc 59(2):240–251. https://doi.org/10.1007/s43207-021-00170-0

Khan M, Mishra A, Shukla J, Sharma P (2019) X-ray analysis of BaTiO 3 ceramics by Williamson-Hall and size strain plot methods. AIP Conf Proc 2100:1–6. https://doi.org/10.1063/1.5098692

Singh H, Yadav KL (2015) Structural, dielectric, vibrational and magnetic properties of Sm doped BiFeO3 multiferroic ceramics prepared by a rapid liquid phase sintering method. Ceram. Int. 41(8):9285–9295. https://doi.org/10.1016/j.ceramint.2015.03.212

Reda M, Ateia EE, El-Dek SI, Arman MM (2024) New insights into optical properties, and applications of Zr-doped BaTiO3. Appl Phys A Mater Sci Process 130(4). https://doi.org/10.1007/s00339-024-07381-2

Adesakin GE et al. (2017) Effects of deformation on strain energy density of metals. Int Res J Pure Appl Phys 5(2):8–18. www.eajournals.org

Mostari MS, Haque MJ, Rahman Ankur S, Matin MA, Habib A (2020) Effect of mono-dopants (Mg2+) and co-dopants (Mg2+, Zr4+) on the dielectric, ferroelectric and optical properties of BaTiO3ceramics. Mater Res Express 7(6):66302. https://doi.org/10.1088/2053-1591/ab7e4c

Funding

Open access funding provided by The Science, Technology & Innovation Funding Authority (STDF) in cooperation with The Egyptian Knowledge Bank (EKB).

Author information

Authors and Affiliations

Contributions

Mahasen Reda put the idea of the paper, material preparation, data collection and analysis, discussing the results of the structure, preparation of the first draft, and editing of the final manuscript. Ebtesam E. Ateia, S. I. El-Dek, and M. M. Arman were sharing: planning; Data curation; Formal analysis; discussing the results of the structure. All authors writing draft and revising final form.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Ateia, E.E., Reda, M., El-Dek, S.I. et al. A comparative approach for estimating microstructural characteristics of BaTi1−xZrxO3 (0.0 ≤ x ≤ 0.3) nanoparticles via X-ray diffraction patterns. J Sol-Gel Sci Technol (2024). https://doi.org/10.1007/s10971-024-06389-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10971-024-06389-7