Abstract

Tragacanth, an anionic polysaccharide, is a natural material widely investigated for the synthesis of aerogels as drug delivery vehicles. Its biocompatibility, biodegradability, and affordability are all key features for its use in pharmaceutical applications. In this study, tragacanth and tragacanth alginate composite aerogels were prepared using the sol-gel technique followed by supercritical drying. Paracetamol was selected as a model drug for drug loading and release studies owing to its high solubility in ethanol and low solubility in supercritical carbon dioxide. The paracetamol loading into the aerogel pores was confirmed by infrared spectroscopy (IR) and x-ray diffraction (XRD) spectra of the resulting samples. Scanning electron microscopy (SEM) images showed that all aerogels were porous with a macroporous-mesoporous network. Due to the high porosity of the prepared aerogels, a loading of 99 wt% (mg drug/mg aerogel) for tragacanth and 114 wt% (mg drug/mg aerogel) for composite aerogels was achieved. Moreover, the release rate of the drug could be modified by manipulating the aerogel composition. Tragacanth aerogels had a faster release rate, while the addition of alginate prolonged the release rate of the model drug. Various empirical release models were investigated and the release rate was found to follow the Korsmeyer-Peppas (Power Law) model suggesting a diffusion-based release kinetics. Based on the results, the feasibility of utilizing tragacanth for the preparation of drug-loaded aerogels was shown.

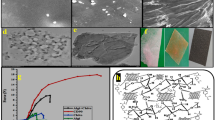

Graphical Abstract

Highlights

-

Tragacanth is a suitable polysaccharide for the synthesis of aerogels.

-

Macropores/mesopores of all synthesized aerogels are suitable for drug loading.

-

The presence of alginate retards the release of the model drug up to 20% at each time point.

-

The release kinetics of the synthesized aerogels follow the Korsmeyer-Peppas model.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Nanostructured aerogels have shown great promise in various pharmaceutical applications during the last few decades. They are considered potential candidates for the encapsulation, adsorption, and delivery of various compounds owing to their large surface area, large pores, and tunable structures achieved by controlling the composition and synthesis conditions [1]. Additionally, the wide variety of materials available for synthesis (e.g., polymers, ceramics, and others), ease of fabrication, and ability to produce a variety of shapes have increased their popularity in different fields [2, 3]. The use of biocompatible aerogels in medicine was first suggested and patented in 1996 [4]. Since then, aerogels have gained increasing attention in the literature as drug delivery vehicles due to their structure and high porosity which enable high loadings of pharmaceutical agents. Pharmaceutical agents can be loaded into the pores of aerogels in different stages during their synthesis such as during gel formation, solvent exchange, or supercritical drying [5]. Additionally, aerogels offer the opportunity to control drug release, show protection against biodegradation, and increase the bioavailability of poorly soluble drugs [6].

Over the years, various materials have been investigated to prepare aerogels [7, 8]. Amongst many, silica aerogels have been widely evaluated as drug carriers and have shown great promise [9,10,11]. However, they are non-biodegradable which limits their use in medical applications [12]. On the other hand, the use of organic materials, polysaccharides [5, 13,14,15,16,17], can be preferred for pharmaceutical applications particularly due to both their biocompatibility and biodegradability [18].

Upon delivery, hydrophilic polysaccharides can swell and quickly degrade in biological environments which can cause the early release of drugs, especially when highly hydrophilic polysaccharides are used [19]. A physical or chemical crosslinker can be added to alter the physical and mechanical properties of the porous network [20]. Cross-linking of polysaccharide aerogels can enhance the three-dimensional structural integrity and reduce swelling by tightly bounding the network, which can overcome the issue of early drug liberation and obtain sustained drug release [21, 22]. Nevertheless, the use of cross-linking agents in pharmaceutical applications is limited due to their possible drug deactivation or cytotoxic effect [23]. To avoid toxicity and compatibility issues, the physical properties of polysaccharide aerogels can be modified by incorporating another material to prepare composite aerogels [24]. Composite aerogels of two or more materials possess different properties than their constituents alone, and these properties can be utilized to control the release of drug(s) loaded [25].

Among different polysaccharides, tragacanth gum is an anionic natural polysaccharide derived from the exudate of some trees obtained from the Astragalus family. It has gained interest as it is derived from renewable sources and is already used in various biomedical applications for the preparation of drug carriers and wound healing purposes. It has the benefits of being biocompatible, non-toxic, and relatively inexpensive [26]. Tragacanth is composed of two parts. Once tragacanth is placed in water, the water-soluble part (tragacanthic acid) dissolves, whereas the water-insoluble part (bassorin) swells forming a gel [27]. Tragacanth/acrylic acid hydrogels were developed for oral delivery of amphotericin B to increase the drug’s bioavailability while reducing the adverse effects associated with standard i.v. administration [28]. Results indicated that this novel formulation showed low toxicity and enhanced therapeutic index of the drug. Recently, a tragacanth-polyvinyl alcohol aerogel was vacuum-impregnated with silymarin as an oral delivery system [29]. The high porosity of the produced aerogels facilitated efficient loading and release of silymarin which presents the possibility of using these systems as an oral drug vehicle. Tragacanth has also been investigated for the development of mucoadhesive gel by providing the proper matrix needed for drug loading and delivery [30]. Thus, the feasibility of using tragacanth as a source to synthesize efficient drug delivery systems makes it an attractive polymer that should be further investigated.

Another polysaccharide that is utilized to prepare novel drug delivery systems is alginate. It has been extensively investigated owing to its excellent properties including biodegradability, biocompatibility, and gel-forming ability [14, 31]. Alginate can be extracted from brown seaweed, including Laminaria hyperborea, Laminaria digitata, Laminaria japonica, Ascophyllum nodosum, and Macrocystis pyrifera [32]. It is comprised of blocks of (1,4)-linked β-d-mannuronate (M) and α-l-guluronate (G). The ratio of these blocks varies depending on the source of extraction. Many alginate-based aerogels have been already reported as effective drug-delivery systems for various applications [33]. Sodium alginate aerogel microspheres were investigated as a potential drug carrier for several drugs including loratadine and ibuprofen [34]. In another study, the feasibility of utilizing alginate-chitosan aerogels for the topical delivery of levomycetin was evaluated [35]. These aerogels were found to be mechanically stable with a high sorption capacity which can be utilized to absorb wound exudate, while enabling controlled release of levomycetin up to 95% in 4 h.

In this research, novel organic polysaccharide aerogels were synthesized using tragacanth and alginate. The purpose was to evaluate the use of tragacanth and tragacanth-alginate composite aerogels as potential oral drug delivery systems. Sodium alginate is a widely used polymer in pharmaceutical formulation, including commercially available drug products. It is easily accessible and affordable which can reduce the cost of the product. Despite its unique physicochemical properties, when used as drug delivery system, generally it requires the addition of crosslinking agents to obtain a stable network structure. Tragacanth is non-toxic, non-allergenic, abundant and has low production cost, and good thermal stability. Herein, we aimed to combine the advantages of each polymer and synthesize composite aerogels without additional crosslinker. Different compositions of aerogels were prepared by altering the amounts of tragacanth and alginate to manipulate the physical properties of the resulting aerogels. Various characterization methods were used to understand the physiochemical properties of the resulting samples and to confirm the presence of the model drug in the aerogels. The effect of the different compositions of composite aerogels on the release rate of the model drug, paracetamol, was investigated. To the best of our knowledge, this is the first study focusing on the use of tragacanth-alginate composite aerogels as novel drug delivery systems. This system presented a novel and completely biodegradable approach to drug delivery which can show great promise for future applications.

2 Materials and methods

2.1 Synthesis of aerogels

As shown in Fig. 1, tragacanth (Sigma Aldrich) with or without alginate (Sigma Aldrich) was added into distilled water (3% to 5% w/v) and left overnight for the complete dispersion and dissolution to prepare tragacanth and tragacanth alginate composite aerogels. The next day, 10% v/v ethanol (Sigma Aldrich) was added to the mixtures to increase the rate of the coagulation process [36]. Samples were stirred until their viscosity began to increase. Viscous but pourable solutions were then transferred into cylindrical molds and covered with ethanol. After the formation of alcogels, they were washed with ethanol 3 times to ensure that the water within the pores of the alcogel was exchanged with ethanol. Then, the alcogels were supercritically dried at 40 °C and 100 bar.

2.2 Preparation of drug-loaded aerogels

To obtain drug-loaded aerogels, paracetamol (PC) was used as the model drug due to its high solubility in the exchange solvent, ethanol, allowing for a higher drug loading via diffusion. Moreover, paracetamol has a very low solubility in supercritical carbon dioxide (scCO2) which would prevent its dissolution during the drying step. After the solvent exchange step, alcogels were placed into a paracetamol-ethanol solution (0.5 M) and left overnight to allow the diffusion of paracetamol into the pores of the alcogels until equilibrium. It was previously shown that a minimum of 5–6 h was necessary to achieve equilibrium for an alcogel with a volume of approximately 0.55 mL [37]. Subsequently, supercritical drying was performed at the same conditions (100 bar and 40 °C). However, the addition of ethanol inside the high-pressure vessel was skipped to prevent the loss of paracetamol on the surface of the gels due to its high solubility. The vessel was directly closed and filled with scCO2 after the gels were placed inside. During supercritical drying, the extraction of ethanol from the pores by scCO2 was accompanied by the precipitation of paracetamol inside the pores due to its reduced solubility in ethanol which can be described as a gas antisolvent process inside the pores [38].

2.3 Characterization of aerogels

A digital caliper was used to determine the dimensions of the alcogels and aerogels. Subsequently, their density was determined by simply dividing their mass by volume. The porosity of the aerogels was calculated using the following equation:

Where is ρb bulk density of tragacanth with or without alginate (computed using the weight percent) and ρa is the density of the aerogel.

Swelling studies were carried out using the weighted amount of aerogel samples free of paracetamol. Aerogel samples were initially immersed in 40 mL phosphate buffer solution (PBS; pH 5.8) and then were removed from the solution at predetermined times, dried slightly and gently with filter paper, and then weighed again. Three parallel measurements were performed each time. The swelling ratio (SR) was calculated as follows,

Where wt is the weight of the swollen gel sample and wd the weight of the dried (initial) gel sample.

IR spectra were recorded using a spectrophotometer (Shimadzu). For IR analysis, a small amount of sample in powder form was sufficient. Samples were obtained by crushing a piece of aerogel to be analyzed. XRD patterns of the samples were collected on a Bruker D8 ADVANCE Diffractometer (Cu-Kα; 1.54018 Å) using a focused beam with a Goebel mirror and equipped with a Vantec detector or a Bruker D2 phaser. Moreover, their pore structure was analyzed with Zeiss Ultra Plus Field Emission Scanning Electron Microscope (SEM) after coating aerogels with gold (~5 nm).

2.4 In vitro drug release studies

The drug release experiments were conducted using a USP type 2 dissolution apparatus (Pharmatest, Germany) at 37 °C under constant stirring. PBS adjusted to pH 5.8 with 6 M HCl solution was used as the dissolution medium according to USP32–NF27 pharmacopoeia [39]. A PC-loaded aerogel sample was primarily weighed and then placed in a wire cage to ensure that the sample would be entirely submerged in the glass vessel containing freshly prepared dissolution medium (900 mL). At previously determined time points, 1 mL sample was taken, and 1 mL fresh PBS was simultaneously added to the release medium to maintain sink condition throughout the experiment and to keep the total volume constant. The PC content in the samples withdrawn was analyzed using a UV-spectrophotometer at 242 nm due to the specific maximum absorption obtained for PC at this wavelength. No significant absorbance was seen at 242 nm when aerogels free of paracetamol were analyzed as control samples, confirming that the absorbance measured should be the result of PC alone. The concentration of PC in samples was estimated using the calibration curve of paracetamol in PBS (pH 5.8) (r2 = 0.99). The percent release was calculated by Eq. (3) given below.

Where CPC is the concentration of PC in the sample solution, Vsol is the volume of the release medium and mt is the total amount of paracetamol loading.

3 Results and discussion

3.1 Physicochemical properties of aerogels

Based on experimental results and SEM imaging discussed below it was concluded that highly porous aerogels with very low densities were obtained. The density of tragacanth aerogels ranged from 0.03 g/cm3 to 0.05 g/cm3. The addition of the alginate altered the density which then ranged from 0.047 g/cm3 to 0.06 g/cm3 as shown in Table 1. Variations in the porosity of aerogels were also observed for different aerogel compositions.

The swelling of all aerogels synthesized within this study was evaluated as it might have a significant impact on the release kinetics. As soon as the aerogels were submerged in the release medium used for swelling studies, they shrank before beginning to swell (Fig. 2a). This shrinkage can be attributed to the initial collapse of the porous network due to the effect of capillary forces [40]. The swelling ratio (Eq. (2)) was calculated to be around 10 for different types of aerogels within the time interval used for the release studies. However, it was shown that tragacanth aerogels swelled more at the beginning of the experiment compared to composite ones, as seen in (Fig. 2b). As a result of swelling, the distance between the chains forming the gel network increases. This higher distance can also explain the reason for a faster drug release observed during the first hours of the release studies, as discussed below.

In similar studies, pectin and chitosan-coated pectin aerogels were investigated for the loading and release of curcumin [41]. Pectin aerogels demonstrated a burst release profile completing the release in 3 h, due to their higher swelling ratio. Whereas chitosan-coated aerogels presented a prolonged release up to 24 h due to the presence of a protective chitosan layer inhibiting the swelling and therefore retarding the release. The swelling studies of tragacanth-polyvinyl alcohol aerogel demonstrated that increasing the tragacanth content in aerogels results in a higher swelling ratio with a weaker structure [29], these findings were in correlation with the release rate of the loaded drug. Swelling results indicate that by incorporating tragacanth and alginate together, the resulting matrix is more intertwined with better integrity, resulting in decreased swelling.

To verify the presence of PC within the aerogel networks, IR spectroscopy was used. As shown in IR spectra (Fig. 3a), characteristic peaks of paracetamol around 3000–3500 cm−1 belonging to vibrational peaks of OH and CH3 and around 1000 cm−1 belonging to absorption peaks of CO stretching and CN stretching were also visible in the PC-loaded aerogels confirming its presence in an intact form in the aerogel matrix [42]. XRD results revealed that aerogels were amorphous while the sharp peaks observed in the XRD patterns of PC-loaded aerogels indicate the presence of crystalline paracetamol within the structure (Fig. 3b). In line, the absence of a crystalline network in the PC-free tragacanth sample enabled a more straightforward observation of the paracetamol within the PC-loaded aerogels.

According to SEM images, all aerogels were porous with various-sized pores (Fig. 4a, b). Besides, it can be concluded that increasing the solid polymer content (i.e. the TG amount) in aerogel resulted in thicker fibers forming the network of aerogels. Composite aerogels showed a similar network compared to tragacanth aerogels (Fig. 5a, b) and the addition of alginate did not have any significant effect on the network formation. Composite aerogels only appeared to have complex structures with a more entangled network. All aerogel compositions were shown to be mostly macroporous and also mesoporous having pores in the range of both pore types.

3.2 Drug loading studies

It can be suggested that the high pore volumes of aerogels and the high solubility of PC in the solvent could enable high drug loadings as the loading is based on the diffusion of the drug which in turn is dependent on molecular diffusivity, pore properties such as the porosity and the tortuosity of the matrix and the initial concentration of the loading solution [37]. Another crucial factor affecting the loading amount is the time of contact which depends on the diffusion rate of the loaded drug in the pore liquid.

As seen in Table 2, loadings were as high as the mass of the aerogel itself indicating that high loadings were obtained.

The drug loading capacity of the synthesized aerogels was comparable to different types of aerogels that have been previously reported as shown in Table 3.

Since the amount of drug loaded inside the gel network depends on the porosity, pore volume, loading method, and solubility of the loaded drug in the loading medium, the combination of the very high porosity of the prepared systems and the high solubility of PC in ethanol yielded very high loadings which were higher when compared with the loading of different drugs in previously reported systems.

3.3 Drug release studies

It is demonstrated that the addition of alginate within the aerogel structure slowed the release rate of paracetamol compared to tragacanth aerogels which showed a faster release as evidenced in Fig. 6. According to swelling studies, tragacanth aerogels swelled more compared to composite ones. Thus, it can be suggested that the loosening of the network during swelling facilitated the release of the pharmaceutical compound from TG aerogels. Moreover, a faster release was observed from native aerogels containing a lower amount of TG probably because of the less condensed network leading to higher swelling. On the other hand, composite aerogel samples swelled to a lesser extent as a result of the addition of alginate, which strengthens and entangles the aerogel network. As a result, the release of the loaded drug is retarded.

The release from synthesized aerogels was observed to last approximately 6–7 h revealing that the release profile can be altered by modifying the composition of aerogels. Thereby, it can be suggested that these structures can be used for controlled release applications and can be tailored depending on the desired drug release rate.

The initial shrinkage observed when aerogel samples were immersed in the release medium might have closed some of the pores slowing down the release by diffusion. Subsequent swelling relaxing the network might have resulted in an increased diffusion rate, especially for tragacanth aerogels which had higher swelling ratios. A slightly faster release in the first hours for 3%TG aerogel was observed which can be attributed to its larger pores and looser network with thinner fibers allowing a faster release. With the addition of alginate in the network, a slower release rate was observed with almost 20% reduction at each time point, allowing for the prolonged release of PC.

It has been reported that surface functionalization also can be used to tailor the release rate from drug-loaded silica aerogels [43]. It was shown that surface hydrophobization can be very effective in retarding the rate of drug release while preserving the structural integrity of the aerogels. However, altering aerogel composition can be proposed as an easier and simpler approach which can be used to control drug release profile.

In recent years, numerous alginate-based composite aerogel systems have been evaluated as controlled release systems for the delivery of therapeutic agents in several applications. A chitosan-alginate aerogel was proposed for the delivery of cisplatin for lung cancer therapy, showing 76% loading efficacy and a sustained first-order release for over 6 h [44]. Alginate-chitosan aerogels were also investigated for wound-healing applications [35]. Thus, it can be concluded that the results obtained for aerogels in this study are in line with previous findings.

Release data were also fitted to different empirical models to have an insight into the release kinetics (Table 4). Based on the investigated empirical release models, the best results were obtained with Korsmeyer-Peppas (Power Law). The computed n values (for cylindrical slabs) indicated a diffusion-mediated drug release.

4 Conclusion

There is an increasing number of research studies investigating the potential application of aerogels as drug delivery systems. Different release profiles of the pharmaceutical compounds have been already achieved with diverse aerogel types. In this study, a natural polysaccharide, tragacanth, was used to synthesize aerogels. Alginate, another polysaccharide that is widely used in health sciences was also incorporated in the structure to form composite aerogels. No chemical crosslinker was used. Tragacanth and tragacanth-alginate composite aerogels were successfully synthesized by sol-gel method followed by supercritical drying. Aerogels were found to have mesoporous and macroporous structures and showed very low densities ranging from 0.03 g/cm3 to 0.06 g/cm3.

Tragacanth aerogels showed loading as high as 99 wt. % (mg drug/mg aerogel) of the model drug paracetamol whereas 114 wt. % (mg drug/mg aerogel) loading was obtained for composite aerogels. It was shown that high drug loadings can be achieved inside the pores via this method while maintaining the monolithic structure and the porous characteristics intact. When alginate was added, the release rate of the drug was decreased by strengthening the porous network which decreased swelling and therefore, provided controlled drug release. Furthermore, it was observed that drug release was governed by the Korsmeyer Peppas model indicating that the release was controlled by diffusion. Thereby, it can be concluded that as an alternative to the various approaches used to tailor drug release from aerogels, alternations in the composition of aerogels can be utilized as a practical, simple way to modify drug release rate. As presented in this study, tunability of the release profile of tragacanth can be achieved through the addition of another polymer, alginate, as it enhances the structural integrity by entangling with tragacanth, producing a more complex network. This approach not only eliminates the need for a crosslinker alleviating impurities from the system but also offers the opportunity to develop novel biodegradable delivery systems for controlled drug release.

The novel composite aerogels present several favorable properties such as very low density, high porosity, high loading efficacy, prolonged release, and relative ease of synthesis and could be suggested as potential biodegradable drug delivery systems.

References

Smirnova I (2011) Pharmaceutical applications of aerogels. In Aerogels Handbook (pp. 695–717). Springer, New York. https://doi.org/10.1007/978-1-4419-7589-8_31

Barrios E, Fox D, Li Sip YY et al. (2019) Nanomaterials in advanced, high-performance aerogel composites: A review. Polymers 11:726. https://doi.org/10.3390/polym11040726

Liu Z, Ran Y, Xi J, Wang J (2020) Polymeric hybrid aerogels and their biomedical applications. Soft Matter 16:9160–9175. https://doi.org/10.1039/D0SM01261K

Berg A, Droege MW, Fellmann JD, et al. (1996) Medical use of organic aerogels and biodegradable organic aerogels (GB Publication No. WO/1995/001165). https://patentscope.wipo.int/search/en/detail.jsf?docId=WO1995001165

Liu Z, Zhang S, He B et al. (2021) Synthesis of cellulose aerogels as promising carriers for drug delivery: a review. Cellulose 28:2697–2714. https://doi.org/10.1007/s10570-021-03734-9

Maleki H, Durães L, García-González CA et al. (2016) Synthesis and biomedical applications of aerogels: Possibilities and challenges. Adv Colloid Interface Sci 236:1–27. https://doi.org/10.1016/j.cis.2016.05.011

Abdul Khalil HPS, Bashir Yahya E, Jummaat F et al. (2023) Biopolymers based aerogels: A review on revolutionary solutions for smart therapeutics delivery. Prog Mater Sci 131:101014. https://doi.org/10.1016/j.pmatsci.2022.101014

Ulker Z, Erkey C (2014) An emerging platform for drug delivery: Aerogel based systems. J Controlled Rel 177:51–63. https://doi.org/10.1016/j.jconrel.2013.12.033

Smirnova I, Suttiruengwong S, Seiler M, Arlt W (2004) Dissolution rate enhancement by adsorption of poorly soluble drugs on hydrophilic silica aerogels. Pharm Dev Technol 9:443–452. https://doi.org/10.1081/PDT-200035804

Guenther U, Smirnova I, Neubert RHH (2008) Hydrophilic silica aerogels as dermal drug delivery systems – Dithranol as a model drug. Eur J Pharm Biopharm 69:935–942. https://doi.org/10.1016/j.ejpb.2008.02.003

Suttiruengwong S (2005) Silica aerogels and hyperbranched polymers as drug delivery systems. Ph.D., Friedrich-Alexander-Universitaet Erlangen-Nuernberg (Germany)

Mehling T, Smirnova I, Guenther U, Neubert RHH (2009) Polysaccharide-based aerogels as drug carriers. J Non-Cryst Solids 355:2472–2479. https://doi.org/10.1016/j.jnoncrysol.2009.08.038

Wei S, Ching YC, Chuah CH (2020) Synthesis of chitosan aerogels as promising carriers for drug delivery: A review. Carbohydr Polym 231:115744. https://doi.org/10.1016/j.carbpol.2019.115744

He L, Shang Z, Liu H, Yuan Z (2020) Alginate-based platforms for cancer-targeted drug delivery. BioMed Res Int 2020:e1487259. https://doi.org/10.1155/2020/1487259

Veronovski A, Tkalec G, Knez Ž, Novak Z (2014) Characterisation of biodegradable pectin aerogels and their potential use as drug carriers. Carbohydr Polym 113:272–278. https://doi.org/10.1016/j.carbpol.2014.06.054

Glenn GM, Stern DJ (1999) Starch-based microcellular foams. U S Dep Agric Pat

Kumar R, Butreddy A, Kommineni N et al. (2021) Lignin: Drug/gene delivery and tissue engineering applications. Int J Nanomed 16:2419–2441. https://doi.org/10.2147/IJN.S303462

Zhao J, Lu C, He X et al. (2015) Polyethylenimine-grafted cellulose nanofibril aerogels as versatile vehicles for drug delivery. ACS Appl Mater Interfaces 7:2607–2615. https://doi.org/10.1021/am507601m

Hoare TR, Kohane DS (2008) Hydrogels in drug delivery: Progress and challenges. Polymer 49:1993–2007. https://doi.org/10.1016/j.polymer.2008.01.027

Muhammad A, Lee D, Shin Y, Park J (2021) Recent progress in polysaccharide aerogels: Their synthesis, application, and future outlook. Polymers 13:1347. https://doi.org/10.3390/polym13081347

Pal P, Pandey JP, Sen G (2018) Sesbania gum based hydrogel as platform for sustained drug delivery: An ‘in vitro’ study of 5-Fu release. Int J Biol Macromol 113:1116–1124. https://doi.org/10.1016/j.ijbiomac.2018.02.143

parhi R (2017) Cross-linked hydrogel for pharmaceutical applications: A review. Adv Pharm Bull 7:515–530. https://doi.org/10.15171/apb.2017.064

Guastaferro M, Reverchon E, Baldino L (2021) Agarose, alginate and chitosan nanostructured aerogels for pharmaceutical applications: A short review. Front Bioeng Biotechnol 9:688477. https://doi.org/10.3389/fbioe.2021.688477

Zhao F, Yao D, Guo R et al. (2015) Composites of polymer hydrogels and nanoparticulate systems for biomedical and pharmaceutical applications. Nanomaterials 5:2054–2130. https://doi.org/10.3390/nano5042054

Buwalda SJ (2020) Bio-based composite hydrogels for biomedical applications. Multifunct Mater 3:022001. https://doi.org/10.1088/2399-7532/ab80d6

Nazarzadeh Zare E, Makvandi P, Tay FR (2019) Recent progress in the industrial and biomedical applications of tragacanth gum: A review. Carbohydr Polym 212:450–467. https://doi.org/10.1016/j.carbpol.2019.02.076

Andrews B (1993) Industrial gums. Polysaccharides and their derivatives. Food Chem 48:329. https://doi.org/10.1016/0308-8146(93)90152-6

Mohamed HA, Radwan RR, Raafat AI, Ali AE-H (2018) Antifungal activity of oral (Tragacanth/acrylic acid) Amphotericin B carrier for systemic candidiasis: in vitro and in vivo study. Drug Deliv Transl Res 8:191–203. https://doi.org/10.1007/s13346-017-0452-x

Niknia N, Kadkhodaee R, Eshtiaghi MN (2020) Gum tragacanth-polyvinyl alcohol aerogel for oral delivery of silymarin. Int J Biol Macromol 157:151–157. https://doi.org/10.1016/j.ijbiomac.2020.04.202

Hesari Z, Emmamzadehhashemi MSB, Aboutaleb E (2023) Tragacanth and xanthan gum natural polymers for formulation of clotrimazole mucoadhesive gel. Acta Sci Health Sci 45:e55651–e55651. https://doi.org/10.4025/actascihealthsci.v45i1.55651

Hariyadi DM, Islam N (2020) Current status of alginate in drug delivery. Adv Pharm Pharm Sci 2020:e8886095. https://doi.org/10.1155/2020/8886095

Smidsrød O, Skja˚k-Br˦k G (1990) Alginate as immobilization matrix for cells. Trends Biotechnol 8:71–78. https://doi.org/10.1016/0167-7799(90)90139-O

Hegde V, Uthappa UT, Altalhi T et al. (2022) Alginate based polymeric systems for drug delivery, antibacterial/microbial, and wound dressing applications. Mater Today Commun 33:104813. https://doi.org/10.1016/j.mtcomm.2022.104813

Lovskaya DD, Lebedev AE, Menshutina NV (2015) Aerogels as drug delivery systems: In vitro and in vivo evaluations. J Supercrit Fluids 106:115–121. https://doi.org/10.1016/j.supflu.2015.07.011

Gorshkova N, Brovko O, Palamarchuk I et al. (2021) Preparation of bioactive aerogel material based on sodium alginate and chitosan for controlled release of levomycetin. Polym Adv Technol 32:3474–3482. https://doi.org/10.1002/pat.5358

Tkalec G, Knez Ž, Novak Z (2015) Formation of polysaccharide aerogels in ethanol. RSC Adv 5:77362–77371. https://doi.org/10.1039/C5RA14140K

Ulker Z, Erkey C (2015) Experimental and theoretical investigation of drug loading to silica alcogels. J Supercrit Fluids 106:34–41. https://doi.org/10.1016/j.supflu.2015.06.025

Ulker Z, Erkey C (2017) An advantageous technique to load drugs into aerogels: Gas antisolvent crystallization inside the pores. J Supercrit Fluids 120:310–319. https://doi.org/10.1016/j.supflu.2016.05.033

USP32–NF27 Pharmacopeial Forum, Acetaminophen Tablets. In: Phamacopeia Online. http://www.uspbpep.com/usp32/pub/data/v32270/usp32nf27s0_m200.html. Accessed 27 Dec 2023

Marin MA, Mallepally RR, McHugh MA (2014) Silk fibroin aerogels for drug delivery applications. J Supercrit Fluids 91:84–89. https://doi.org/10.1016/j.supflu.2014.04.014

Pantić M, Horvat G, Knez Ž, Novak Z (2020) Preparation and characterization of chitosan-coated pectin aerogels: Curcumin case study. Molecules 25:1187. https://doi.org/10.3390/molecules25051187

Mk T (2015) Effect of biofield treatment on spectral properties of paracetamol and piroxicam. Chem Sci J 6. https://doi.org/10.4172/2150-3494.100098

Giray S, Bal T, Kartal AM et al. (2012) Controlled drug delivery through a novel PEG hydrogel encapsulated silica aerogel system. J Biomed Mater Res A 100A:1307–1315. https://doi.org/10.1002/jbm.a.34056

Alsmadi MM, Obaidat RM, Alnaief M et al. (2020) Development, in vitro characterization, and in vivo toxicity evaluation of chitosan-alginate nanoporous carriers loaded with cisplatin for lung cancer treatment. AAPS PharmSciTech 21:191. https://doi.org/10.1208/s12249-020-01735-8

Horvat G, Pantić M, Knez Ž, Novak Z (2018) Encapsulation and drug release of poorly water soluble nifedipine from bio-carriers. J Non-Cryst Solids 481:486–493. https://doi.org/10.1016/j.jnoncrysol.2017.11.037

Acknowledgements

Work carried out in the frame of the COST Action “Advanced Engineering and Research of aeroGels for Environment and Life Sciences” (AERoGELS) and funded by the European Commission under grant agreement No. CA18125 and also supported by the Scientific Research Projects Coordination Unit of Altınbaş University, Project Number: PB2018-GÜZ-ECZ-5.

Author contributions

All authors contributed to the study conception and design. Material preparation, data collection and analysis were performed by ZU and AA. The first draft of the manuscript was written by ZU and AA and all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Funding

Open access funding provided by the Scientific and Technological Research Council of Türkiye (TÜBİTAK).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Al-barudi, A., Sinani, G. & Ulker, Z. Biodegradable polysaccharide aerogels based on tragacanth and alginate as novel drug delivery systems. J Sol-Gel Sci Technol 109, 748–756 (2024). https://doi.org/10.1007/s10971-024-06312-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10971-024-06312-0