Abstract

Surface functionalization of porous materials with sulfonic acid (SO3H) groups is of particular interest in applications involving ion exchange, acidic catalysis and proton conduction. Macro-mesoporous silica monoliths are ideal support structures for these applications, as they combine advection-dominated mass transport in the macropores with short diffusion lengths and a large surface area (available for functionalization) in their mesoporous skeleton. Here, we report on SO3H functionalized sol–gel silica monoliths with bimodal pore systems exhibiting macro- and mesoporosity, prepared according to a simple, efficient in situ synthesis protocol. Based on the co-condensation approach, thiol groups were introduced homogeneously into the pore structure, followed by their oxidation to SO3H groups and the simultaneous removal of the template. The macropore size, specific surface area, and coverage with SO3H groups are easily adjusted in this synthesis route. Importantly, the hybrid monoliths have a substantially narrower mesopore size distribution (relative standard deviation ~25%) than conventional sol–gel materials (>40%) and can be engineered crack-free in a robust column design (suitable for high-pressure flow-through operation) with mean mesopore size down to ~7 nm. They are characterized by IR spectroscopy, thermogravimetry, and elemental analysis as well as 13C and 29Si solid state NMR to corroborate the simple, efficient combination of sol–gel-based material synthesis, surface functionalization, and template removal (i.e., polymer extraction). Complementary, inverse gas chromatography is presented as a new approach to characterize the incorporated SO3H groups via surface energy analysis and particularly resolve changes in the Lewis acid–base characteristics engendered by that functionalization.

Highlights

-

Co-condensation sol–gel process for hierarchical, sulfonic acid functionalized silica monoliths.

-

Simultaneous extraction of the template (PEO) and oxidation of thiol to sulfonic acid groups.

-

Macropore size, specific surface area, and surface coverage with sulfonic acid groups adjusted.

-

Comprehensive characterization including surface energy analysis by inverse gas chromatography.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Hierarchically porous silica monoliths with bimodal pore structure are widely used for chemical separation, thermal insulation, electrochemical processes, CO2 adsorption, and heterogeneous catalysis [1,2,3,4,5,6,7,8,9]. Macro-mesoporous silica monoliths, in particular, are ideal support structures in these applications, because the macropores enable fast, advection-dominated transport through the material and the mesoporous skeleton provides a large external surface (thus, a large contact area) for efficient mass transfer between macroporous and mesoporous domains, as well as a large internal surface available for functionalization [10]. Silica monoliths are also characterized by more homogeneous structural features (distribution of pore-size and skeleton thickness) than alternative bimodal support structures like packed beds of mesoporous particles, which again enhances transport and overall performance [11]. Due to their high porosity, low bulk density, pore interconnectivity, mechanical stability, and large surface, silica monoliths can be approached with various functionalization strategies [12, 13].

Functionalization with organic species leads to organic–inorganic hybrid materials, whereby the synthesis routes can be quite versatile. A common strategy is to graft the surface with functional groups by traditional chemical bonding (involving the silanol groups of the silica surface), for which alkoxysilanes have proven to be well-suited linkers [14,15,16,17]. However, this approach faces a number of disadvantages, such as the intrinsic drawbacks of multistep synthesis procedures, the inhomogeneous distribution of active sites and a low coverage due to pore-blocking effects and hindered diffusion issues [18]. Furthermore, it has been shown that the grafting procedure with a trifunctional precursor may not result in a homogeneous monolayer of the linker, but rather in the formation of oligomers with ladder-like structures [19]. An alternative is the co-condensation process, in which alkoxysilanes are hydrolyzed simultaneously with suitable silica precursors during sol–gel synthesis [7, 20]. The hydrolyzed precursors compete with each other during condensation and form a homogeneous porous hybrid material. The sol–gel process itself is extremely sensitive to parameter changes, so that even slight modifications regarding, for example, the polarity or pH affect the properties of the resulting monoliths. It implies that the synthesis has to be optimized individually for each material and functionality [14, 21,22,23].

Functionalization of porous materials with sulfonic acid (SO3H) groups is of special interest in applications involving ion exchange, acidic catalysis, and proton conduction. Marshall et al. [24,25,26] investigated the synthesis of sulfonic acid modified mesoporous materials (like MCM-41 and SBA-15) and their particular property of a high proton conductivity. Other studies focused on the preparation of SO3H-functionalized mesoporous silicas (MCM-41, SBA-15, and KIT-6) for application in the heterogeneously catalyzed esterification of monoglycerides or fatty acids for the synthesis of biodiesel [27,28,29]. Dias et al. [30] examined the dehydration of xylose to furfural with SO3H-modified MCM-41 materials. The direct synthesis of sulfonic acid functionalized porous silicas based on the sol–gel process, however, has received little attention. Wilson et al. [31] used the co-condensation method to prepare SO3H-functionalized mesoporous materials applied in the esterification of butan-1-ol with acetic acid. As one of the first, Xu and Lee [32] adopted the co-condensation approach to synthesize SO3H-modified, macro-mesoporous sol–gel monoliths (involving polymer-induced phase separation) intended for the microextraction of anesthetics followed by capillary electrophoretic separation. Apparently, the polymer has not been removed from the monolith prior to that application, which is expected to affect transport properties and impair the targeted functionality.

The preparation of sol–gel silica monoliths with bimodal pore-size distribution can be divided into four steps: (1) the sol–gel transition with concurrent, polymer-induced phase separation to form a macro-microporous gel; (2) the widening process by hydrothermal treatment to enlarge micropores to mesopores and ripening the pore structure; (3) the solvent exchange and drying, which should yield a dry, mechanically stable monolith; and (4) calcination to remove organic matter on the inner surface [21]. However, if the co-condensation method is adapted to incorporate organic groups into the pore system, then calcination cannot be applied, because the functional groups will also be removed. Therefore, an alternative process that guarantees efficient removal of the template (polymer) becomes one of the keys in a general route to these hierarchical hybrid materials.

We introduce a rapid and efficient synthesis procedure for the preparation of macro-mesoporous silica monoliths with homogeneously incorporated sulfonic acid functionalities by adapting the co-condensation sol–gel process. Through integration of a mild extraction step, the polymer can be removed without losing the organic functionality. Importantly, full oxidation of the initially introduced thiol groups to sulfonic acid groups occurs concurrently with the polymer extraction, resulting in hybrid monoliths with conveniently adjustable macropore size, specific surface area, and SO3H coverage. The simplicity and efficiency of this novel synthesis route are corroborated with a portfolio of characterization methods. Notably, inverse gas chromatography (IGC) is a powerful approach to quantify by surface energy analysis the impact of the SO3H groups on the interfacial properties of these hybrid materials and address, in particular, the changes in Lewis acid–base behavior occurring upon SO3H functionalization.

2 Experimental section

2.1 Chemicals

Tetraethoxysilane (TEOS, 99%) came from abcr (Karlsruhe, Germany). Poly(ethylene oxide) (PEO) with an average molecular weight of 100,000 was obtained from Alfa Aesar (Haverhill, MA). (3-mercaptopropyl)trimethoxysilane (MPTMS, ≥95%) and hydrogen peroxide (30%) were purchased from Merck (Darmstadt, Germany). Urea came from Caesar & Loretz (Hilden, Germany), sulfuric acid (95%) (AnalaR NORMAPUR® ACS, Reag. Ph. Eur.) and nitric acid (65%) from VWR International (Darmstadt, Germany). All reagents were used without further purification.

2.2 Synthesis

Sulfonic acid modified silica monoliths were prepared by a co-condensation sol–gel synthesis, adapting the synthesis procedure described in Kohns et al. [14]. In the prepared set of monoliths, only the PEO and MPTMS contents were varied. With increasing MPTMS content the TEOS content was reduced by the respective equivalent. Complementary, a reference material without MPTMS was synthesized. Starting compositions employed for the set of monolithic materials are summarized in Table S1 in the Electronic Supplementary Material (ESM).

First, PEO (1.5–1.8 g) and urea (2.4 g) were added to distilled water (18 g) under vigorous stirring. After stirring for 30 min at room temperature, sulfuric acid (1.26 g) and TEOS (12.7–14.6 g) were added. After an additional 30 min of vigorous stirring MPTMS (0–2.11 g) was added to the solution, which was stirred for 10 min. Each mixture was poured into a PTFE tube (7 mm i.d., filled to 10-cm height). PTFE inlets were placed in a small lab autoclave, which was put in an oven for gelation (24 h at 55 °C) and subsequent hydrothermal treatment (20 h at 120 °C). After cooling, wet gels were washed by submersion in stirred water, refreshed 4–5 times until pH was neutral (~5 h). Each gel was then placed in its own plastic vessel, submerged with water, and dried in an oven (24 h at 105 °C). The drying process is based on the procedure described in Kohns et al. [33]. Dried monolithic rods had a diameter of ~0.5 cm and a length of ~9 cm and were trimmed to a length of 5 cm. Remaining pieces served as reference to evaluate the success of the oxidation/extraction procedure.

The removal of the polymer was performed according to the procedure described by Patarin [34]. Importantly, the reagents also oxidized the thiol to sulfonic acid groups. Briefly, each MPTMS-functionalized silica rod was stirred in a mixture of hydrogen peroxide (30%) and nitric acid (65%) at a ratio of silica:H2O2:HNO3 of 1 g:37 g:92 g at room temperature. After 1 h, the solvent was refreshed and the mixture heated to 60 °C for 18 h. Subsequently, silica rods were placed in a small lab Teflon autoclave with refreshed H2O2/HNO3 solution and heated in an oven for 2 h at 120 °C. After cooling, the wet gels were washed by submersion in stirred water, refreshed 5–6 times (~5 h). Each rod was then placed in its own plastic vessel, submerged with water, and dried in an oven (24 h, 105 °C) to obtain crack-free monoliths. For later comparison, several monolith pieces were calcined in a muffle furnace for 8 h, using a heating rate of 3 °C min−1 from room temperature up to 600 °C.

2.3 Characterization

Silica rods were examined by mercury intrusion porosimetry (MIP) measurements on a Pascal 140/440 porosimeter (Thermo Fisher Scientific, Waltham, MA) over the pressure range of 0.015–400 MPa. Pore-size distributions were derived from the MIP data with Pascal software according to the Washburn equation setting the mercury contact angle to 141°. The pressure range corresponds to pore diameters between 3.7 nm and 100 µm.

Scanning electron microscope (SEM) images were recorded with a FEI Nanolab 200 (Hillsboro, OR). Sample pieces were vapor-deposited with Au at 10 kV. This step was omitted for energy-dispersive X-ray analysis (SEM-EDX).

Nitrogen physisorption measurements were carried out at −196 °C on an Autosorb-iQ sorption analyzer (Quantachrome Instruments, Boynton Beach, FL). Prior to the measurements, samples were evacuated for 10 h at 105 °C. Total pore volumes (Vmeso) were obtained with the Gurvich rule at a relative pressure of p/p0 = 0.95, specific surface areas (SBET) were determined by means of the Brunauer–Emmett–Teller equation in a range of 0.05 ≤ p/p0 ≤ 0.3. Pore-size distributions were derived from the adsorption branches of the physisorption isotherms using the non-local density functional theory (NLDFT) method with a cylindrical pore model [35].

Elemental analysis (CHNS) was conducted on a vario Micro cube (Elementar, Langenselbold, Germany). Thermogravimetry (TG/DTA) was carried out in a temperature range of 25–600 °C with a 10 °C min−1 heating rate using a Netzsch STA 409 (Selb, Germany). Diffuse reflectance infrared Fourier transform spectroscopy (DRIFTS) was performed using a Vector 22 FT-IR spectrometer (Bruker, Billerica, MA) in the range of 700–4000 cm−1.

Magic-angle spinning (MAS) 13C and 29Si NMR spectra were recorded on an Avance-III 400-MHz WB NMR spectrometer (Bruker BioSpin, Rheinstetten, Germany) equipped with a 4 mm MAS BB/1H probe at a Larmor frequency of 400.15 MHz for protons, 100.62 MHz for 13C, and 79.49 MHz for 29Si, respectively. All spectra were collected at a spinning speed of 12 kHz at 20 °C and referenced externally to TMS at 0 ppm. For cross-polarization (CP) experiments, 1024 scans were accumulated with a recycle delay of 5 s. Polarization transfer from protons to 29Si and 13C, respectively, was conducted for a contact time of 8 ms. For high-power decoupled (HPDEC) experiments, 256 scans were accumulated with a 90° pulse width of 6 µs (29Si) and a recycle delay of 60 s. The offset was set at −50 ppm and the spectral width to 32 kHz in both experiments. During acquisition, heteronuclear decoupling was reached, using a SWf-TPPM at a radio-frequency field of 100 kHz [36]. Before conducting the NMR measurements, the monoliths had to be crushed.

IGC experiments were carried out on a Clarus580 GC apparatus (PerkinElmer, Waltham, MA) equipped with flame ionization detector and controlled by IGC software (Adscientis SARL, Wittelsheim, France). To conduct the IGC measurements, the rods had to be transferred into a robust column format. For that purpose, the rods were embedded in a stainless-steel tubing (10.6 mm i.d./12.6 mm o.d. × 5 cm length; Swagelok, Solon, OH) using UHU® PLUS 300 epoxy resin adhesive (UHU, Bühl, Germany) with a composition of 1:1 (v/v) tube binder and hardener, adapting the method from Kohns et al. [14]. Columns were completed by attaching zero-volume reducing unions (Swagelok) to the stainless-steel tubes (Fig. S1 in the ESM). Prior to the investigations, the columns were conditioned overnight at 80 °C with a helium flow (20 mL min−1). All IGC experiments were run at the same temperature and flow rate. Molecular probe molecules (C6–C9 n-alkanes, dichloromethane, chloroform, diethyl ether, acetonitrile, and benzene) were injected at least three times onto each column to derive retention times. Methane served as inert reference.

3 Results and discussion

3.1 Pore-space properties of the functionalized materials

To present a novel preparation sequence for sulfonic acid functionalized sol–gel monoliths with hierarchically structured pore systems, we adapted the strategy of a co-condensation synthesis procedure. The starting sol comprised a sulfuric acid solution of TEOS as silica precursor, water as solvent, PEO as porogen, urea as pore-size controlling agent (especially for mesopores), and MPTMS as functionalization precursor. MPTMS was added 30 min after starting the hydrolysis of TEOS, as it hydrolyses faster due to the methoxy groups. Following the well-known and established synthesis steps (gelation, hydrothermal treatment, washing, and drying), an extraction and at the same time oxidation step was implemented in order to obtain hierarchically structured sulfonic acid functionalized silica rods [1, 14, 20, 33]. To confirm the success of the synthesis, samples were preserved untreated in their pristine state and (in some cases) subsequently calcined. The terminology for sample denotation is as follows: P-X stands for the initial weight of PEO and S-X for the initial volume of MPTMS. Abbreviations ext and c denote extracted and calcined. If not stated otherwise, results are presented for the modification after the oxidation/extraction procedure, referring to the sulfonic acid functionalized silica. All monoliths were examined by SEM and subjected to porosimetry analysis (Table 1).

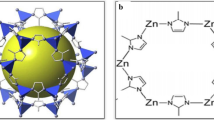

First, it is important to note that bimodal pore systems with interconnected pore structures were obtained for all synthesized samples. SEM images and MIP results for samples P-1.5-S-1 (lower end of polymer variation), P-1.8-S-1 (upper end of polymer variation), and P-1.8-S-2 (highest MPTMS content) are compared in Fig. 1. The images visualize that the polymer-induced phase separation conserved an interconnected pore structure resulting from spinodal decomposition. As the amount of polymer (PEO) increases, macropores and silica skeleton become much finer while the general morphology is preserved, as known for these sol–gel systems [1, 21]. The sponge-like pore structure is also recognized for the sample with the highest MPTMS content, although no state of spinodal decomposition could be frozen with a lower polymer content. This can be explained by the fact that MPTMS affects the polarity of the sol. This parameter (among others) has a significant influence on the gelation and phase separation [14, 21, 22].

MIP analysis (mercury intrusion curves and pore-size distributions as cumulative and relative pore volumes, respectively) and SEM images for selected sulfonic acid functionalized silica monoliths with hierarchically structured pore systems (Table 1)

The MIP-based pore-size distributions correlate well with a visual analysis of Fig. 1. The mean macropore size (dmacro) decreases with increasing PEO content from ~8.2 to ~1.2 µm (Table 1), reflecting a familiar trend [21, 22, 37]. However, the macropore size is also influenced by the MPTMS concentration. With increasing amount of MPTMS, the size of the macropores increases, which becomes clear by comparing the respective samples with a PEO content of 1.7 or 1.8 g (Table 1): dmacro increases from ~1.1 µm (for the reference sample P-1.7-S-0) to ~2.2 µm (P-1.7-S-1) to ~4.8 µm (P-1.7-S-1.5). Similarly, with an increase in MPTMS concentration by a factor of two from sample P-1.8-S-1 to P-1.8-S-2, dmacro increases from ~1.2 to ~2.4 µm. Apparently, the MPTMS influences the sol–gel process in such a way (polarity) that a later state of spinodal decomposition is frozen, allowing larger pore structures to emerge. Interestingly, this behavior is opposite to that observed with urea [14]. In that work, we found that increasing the urea content of the starting sol comprising a sulfuric acid solution of TEOS, PEO, and urea from 3 to 24 wt% decreased dmacro from 2.3 to 0.6 μm and the skeleton thickness from 2.0 to 0.4 μm. Supposedly, with increasing urea content, phase separation, and gelation are retarded as well as shifted closer together, so that the formed monolithic structures represent a less evolved state of spinodal decomposition, preserving smaller macropores and a thinner skeleton.

The total porosities of the sulfonic acid modified materials are comparable to that of the calcined reference material of εtotal = 0.88 (Table 1). However, the samples prepared with larger amounts of MPTMS (P-1.7-S-1.5 and P-1.8-S-2) do not that closely approach that value, which is mainly caused by their smaller mesopore volumes (Vmeso). Mean mesopore sizes (dmeso) based on the MIP data are similar for all samples (dmeso = 10–13 nm), but the actual pore-size distributions suggest that MIP is not appropriate for the investigation of the mesoporosity in these samples. It may be possible that organic matter inside the mesopores is compressed at the high pressures up to 4000 bar, which would bias the results except for the calcined reference material. Nitrogen physisorption measurements were therefore additionally conducted. Figure 2 shows the isotherms and derived pore-size distributions for selected sulfonic acid modified, hierarchically structured sol–gel monoliths and the calcined reference sample P-1.7-S-0.

Nitrogen physisorption isotherms (left) and pore-size distributions (right) for sulfonic acid functionalized silica monoliths and the calcined reference material (cf. Table 1)

The pore-size distributions in Fig. 2 reveal an impact of the MPTMS content on the mesopore formation. The reference material has a very wide distribution of pore sizes after pore widening, ranging from about 10 to 50 nm (mean pore diameter, dmeso = 26 nm). In contrast, the functionalized materials have relatively narrow pore-size distributions after pore widening, with dmeso ≈ 9 nm (decreasing to 7 nm as the amount of MPTMS is increased, Table 1). One reason for this observation may be that the formation of micropores is influenced during the sol–gel process, especially during condensation of the primary particles, resulting in smaller micropores with higher MPTMS concentrations [31]. On the other hand, hydrothermal treatment could be affected, in which urea decomposes to ammonia, resulting in a basic pore widening (syneresis and Ostwald ripening). During this process, micropores formed in the sol–gel step are widened to mesopores. It makes the pore system more stable and the material can also be easier dried with larger pores under ambient conditions [33, 38]. The functionalization that is covalently bonded to the surface could mitigate the effects of syneresis and Ostwald ripening, so that the pore widening is milder and more homogenous. At this point, it should be mentioned that the drying of crack-free monoliths was possible even with the smallest mesopores (dmeso = 7 nm). The simple drying method of Kohns et al. [33] was adapted here with a lower temperature (105 °C) to prevent damage of the organic component.

Narrowed mesopore size distributions, as observed in Fig. 2, are advantageous in applications that rely on size-selective effects, such as size-exclusion chromatography [39] and catalysis under confinement [40, 41]. This has been demonstrated recently for the ring-closing metathesis of various dienes, where the catalyst was selectively immobilized inside the mesopores of the support [42]. A narrow pore-size distribution with carefully adjusted mean pore size (relative to the size of the dienes) is essential here to define a narrow operational window for optimal macrocyclization selectivity. Larger pores quickly increase the risk of unfavored oligomerization (decreasing the selectivity) and smaller ones ultimately impede the favored macro(mono)cyclization as well as diffusive transport into and out of the mesopores, which decreases conversion. For the materials compared in Fig. 2, we note a substantial narrowing of the mesopore size distribution from the calcined reference material (standard deviation >10 nm, relative standard deviation >40%) to the functionalized materials, characterized by a standard deviation of only ~2 nm and a relative standard deviation of ~25%. If the calcined sample were subsequently functionalized via post-grafting, its wide mesopore size distribution would be largely retained.

The difference between the functionalized and pure silica materials is also seen in the isotherms in Fig. 2. All isotherms belong to type IV, whereby the sulfonic acid functionalized materials display a clear H2(a) hysteresis. The other materials (not included) have a similar characteristic. In contrast, the hysteresis behavior of the pure silica materials can be assigned to type H1 (but for a disordered pore system). For this isotherm no plateau is reached, as the larger pores could not be completely filled during condensation [43]. The impact of the functionalization reagent on the pore-space properties is also expressed in the specific surface areas (SBET). The pure sol–gel material has a significantly smaller surface area (195 m2 g−1) than the functionalized materials (Table 1), for which SBET increases to 418–470 m2 g−1 (mainly due to the smaller mesopore diameters, dmeso = 9 nm). Although the total pore volume of the non-functionalized material (1.21 cm3 g−1) is not reached, Vtotal of the functionalized materials increases systematically from 0.88 to 1.1 cm3 g−1 with the amount of polymer, which is consistent with the SBET-values. The increase of the MPTMS content does not have a major effect on Vtotal, but SBET increases further (up to 576 m2 g−1 for sample P-1.8-S-2) and becomes similar to values reported in the literature for pure and sulfonic acid modified bimodal sol–gel monoliths [3, 32, 44].

To understand the impact of the oxidation/extraction step, sample P-1.7-S-1 was exemplarily examined by nitrogen physisorption before that treatment (in pristine form), after the treatment (sulfonic acid functionalization), and after calcination. Isotherms and pore-size distributions are summarized in Fig. S2 (ESM). We also recorded isotherms for the reference material P-1.7-S-0 in untreated and calcined forms for comparison. For sample P-1.7-S-1, mesopore size increases from dmeso = 8 nm (SH) to 9 nm (SO3H) to 10 nm (calcined), whereas no change is seen for the reference material (Table S2, ESM). More importantly, the specific surface area of the pristine form is 273 m2 g−1, rising to 469 m2 g−1 after oxidation/extraction. After calcination, the specific surface area increases just slightly further to 479 m2 g−1. By contrast, for the reference material P-1.7-S-0, SBET only increases from 164 to 195 m2 g−1. The sharp increase in SBET for sample P-1.7-S-1 after the oxidation/extraction step strongly indicates the successful removal of the polymer from its pore system.

3.2 Efficiency of the in situ functionalization and extraction procedure

To examine our general synthesis procedure for its usefulness, various characterization methods were applied. Qualitative and quantitative techniques were selected to verify the approach and its individual steps. They provide results, which altogether allow to reach clear conclusions on the success of the presented synthesis procedure.

3.2.1 Elemental analysis and SEM-EDX measurements

The prepared materials were subjected to elemental analysis for a first assessment of the amount of incorporated sulfonic acid groups. These data also help to evaluate the extraction procedure that we implemented in order to remove the polymer. Table 2 summarizes the carbon, hydrogen and sulfur contents of pristine samples before and after the oxidation/extraction step. Nitrogen is not listed, because its content remained below the detection limit.

A first qualitative identification can be based on the significant sulfur contents of all materials, except for sample P-1.7-S-0 (synthesized without MPTMS). As the MPTMS content increases (P-1.7-S-1.5), also the sulfur content increases from ~3 to ~4%. A further increase to twice the initial MPTMS amount (P-1.8-S-2), however, does not increase the sulfur content further in the formed material (Table 2). Because the condensation of additional MPTMS is unsuccessful, we assume that the system is saturated with functional groups. Based on the carbon contents of the pristine samples, the increasing amount of organic species (PEO, MPTMS) during the synthesis can be easily recognized. In comparison, the carbon content of the reference material (P-1.7-S-0) is much lower due to the absence of the functionalization reagent. Comparing extracted with pristine samples helps to verify the success of the extraction step. Carbon contents decrease significantly after extraction, as documented in a loss of 70–73%. The impact of the extraction step can be evaluated most clearly by inspecting the reference material, in which the amount of organic component is reduced by 69%. Therefore, the extracted reference material still contains carbon, suggesting that the polymer has not been completely removed. This is not that obvious for the functionalized materials, because we also introduce carbon with the propyl chain at the sulfur. On the other hand, the sulfur contents differ only slightly before and after the extraction step. Here, an exceptional loss of 14% is observed for sample P-1.5-S-1, but the sulfur loss for all other extracted samples remains below 6%.

With the determined sulfur contents, the loadings of the bulk materials with sulfonic acid groups can be calculated. For materials prepared with the standard amount of 1 ml MPTMS, the SO3H loading increases slightly with increasing amount of PEO in the synthesis from 0.78 mmol g−1 for sample P-1.5-S-1 to 0.84 mmol g−1 (P-1.6-S-1) to 0.87 mmol g−1 (P-1.7-S-1). As expected, samples P-1.7-S-1.5 and P-1.8-S-2 have a higher SO3H loading (1.2 mmol g−1). Assuming that all sulfur atoms are on the pore surface, the number of SO3H groups/nm2 can be estimated using the SBET-values from Table 1 and the Avogadro constant. This allows to provide SO3H loadings of 1.12 nm−2 (P-1.5-S-1), 1.17 nm−2 (P-1.6-S-1), 1.11 nm−2 (P-1.7-S-1), 1.31 nm−2 (P-1.7-S-1.5), and 1.24 nm−2 (P-1.8-S-2), which are comparable to those for purely mesoporous materials that were also synthesized through the co-condensation procedure [24]. There, it has been emphasized that co-condensation ensures significantly higher SO3H loadings than achieved using common grafting methods. Interestingly, the monolithic materials prepared with the standard amount of 1 ml MPTMS all end up with very similar numbers of SO3H groups/nm2, despite their different morphological properties (particularly mesopore volume and specific surface area) caused by the different PEO contents used in their synthesis. It should also be noted that the pore-widening process has no significant influence on the sulfur content (Table S3 in the ESM).

Using the SO3H loadings, sulfur and carbon contents can be interrelated to estimate the fraction of the organic component belonging to the functionalization. Considering the stoichiometry of the introduced functional chain (S:C = 1:3), about 17–19% of the residual carbon content is due to polymer, except for sample P-1.5-S-1 (27%). For materials prepared with larger amounts of MPTMS, it is only ~10%. Therefore, we started further investigations of the extraction process by extending the duration of the hydrothermal treatment with H2O2/HNO3 from 2 h to 4 and 6 h (Table S4 in the ESM). These results showed that an extended hydrothermal treatment further reduced the carbon content, but also the sulfur content significantly (by ~28%). Consequently, extending the hydrothermal treatment for polymer extraction is no viable alternative, as the associated loss of sulfur (sulfonic acid groups) is undesirable. At this point, it cannot be clarified if the polymer remains on the surface of the materials (and prevents access to functional groups) or inside the pores due to diffusion limitations during the washing process.

SEM-EDX measurements support the data from elemental analysis. Figure 3 shows SEM images and EDX mappings for the pristine and extracted forms of sample P-1.7-S-1. Red dots represent the presence of carbon atoms on the surface, which can be attributed to PEO (employed for the polymer-induced phase separation during the sol–gel synthesis) and the functionalization. Blue dots indicate the sulfur atoms incorporated by the functionalization reagent MPTMS during the gelation process. From the EDX mapping, it is seen that the functionalization is homogeneously distributed over the surface of the materials, which we explain with the effect of the in situ co-condensation. Further, based on Fig. 3 it can be assumed that, while carbon atoms are removed to a substantial degree by the extraction step, the sulfonic acid functionalization remains largely intact. This suggests that a carefully timed extraction can indeed be used to selectively remove the polymer from the material, without impairing the functionalization.

Calculated compositions demonstrate this effect more clearly. The untreated sample (top row in Fig. 3) consists of 24 at.% C, 1 at.% S, 52 at.% O, and 21 at.% Si (rounded values). Here, the ratio between carbon and silicon contents appears uncharacteristic. However, we have to recall that EDX is surface sensitive and the bulk of the material (which mainly consists of silicon and oxygen) cannot be detected in this way. After extraction (bottom row), the atomic composition is 15 at.% C, 1 at.% S, 56 at.% O, and 26 at.% Si. The loss of organic matter is mainly attributed to the removal of polymer, as the sulfur content does not change. It is confirmed by the increase of the silicon content. More silicon can be detected after removing the polymer, which no longer obscures part of the surface.

For samples prepared with larger MPTMS amounts, SEM-EDX measurements were carried out to provide information particularly on the sulfur content. These materials were examined in the oxidized/extracted form. Sample P-1.7-S-1.5 has a sulfur content of 1.4 at.% (2.3 wt.%), which is an increase compared to sample P-1.7-S-1 (1.0 at.%, 1.7 wt.%). The increase is even stronger for sample P-1.8-S-2, which has a sulfur content of 1.6 at.% (2.5 wt.%). It shows that the sulfur content can be increased while preserving an interconnected pore structure.

For better evaluation of the polymer extraction step, SEM-EDX measurements were conducted for the reference material P-1.7-S-0 in pristine, extracted, and calcined forms (Fig. S3, ESM). The pristine sample reveals 11 at.% C, 0.2 at.% S, 59 at.% O, and 28 at.% Si. After extraction, the carbon content decreases to 1 at.%, while the sulfur content is constant at 0.2 at.%. The oxygen content increased (slightly) to 61 at.% and the silicon content to 36 at.%. After calcination, the atomic composition did not change with respect to the extracted sample (1 at.% C, 0.2 at.% S, 61 at.% O, and 36 at.% Si). According to these results, the extraction process (which also serves to oxidize the thiol to sulfonic acid groups) is as effective as the calcination step in removing the polymer. The small amounts of carbon and sulfur remaining after extraction and calcination may be due to residues physisorbed on the surface. It could not be finally clarified why sulfur was detected. Because quantification by SEM-EDX is known to be difficult for heterogeneous porous materials, we rely on the data from elemental analysis in this regard. The SEM-EDX analysis then serves for visual representation of the homogeneous distribution of the functionality.

3.2.2 FT-IR spectroscopy and thermogravimetric analysis

To verify specifically the oxidation of thiol to sulfonic acid groups (occurring simultaneously during polymer extraction) DRIFTS and TGA were applied. DRIFT spectra were collected for sample P-1.7-S-1 in pristine, oxidized/extracted, and calcined forms (Fig. 4a). All three samples exhibit vibrations typical for the silica skeleton: Si–O–Si stretching vibrations in the range of 1000–1250 cm−1 and the corresponding deformation vibrations at about 800 cm−1. In addition, all spectra show intense absorptions due to O–H stretching (3400–3600 cm−1) and deformation vibrations (~1640 cm−1) caused by adsorbed water.

The sharp band at ~3750 cm−1 in the calcined material can be assigned to Si–O–H stretching vibrations. The almost complete disappearance of this silanol vibration in pristine and oxidized samples suggests the successful incorporation of a covalently bonded functionalization. For the pristine material (blue) we note three additional absorptions: At ~2580 cm−1 the S–H vibration of the thiol group (indicating successful functionalization) and in the range of 2850–2950 cm−1 and 1450–1500 cm−1 the C–H stretching and deformation vibrations, respectively, by the propyl chain of the functionalization and by the polymer. These vibrations can also be identified in the oxidized material (red), but they are much weaker. It suggests that the polymer has been largely removed, so that absorption either originates from the propyl chain of the functionalization or residual polymer. Most importantly, however, the explicit loss of the S–H vibration confirms a successful oxidation of thiol to sulfonic acid groups. Vibrations typical for the sulfonic acid, as shown by Marshall et al. [24] and Wilson et al. [31], could not be assigned, because they overlap with the strong Si–O–Si stretching vibrations (1145–1200 cm−1 for –SO2–OR, ~1050 cm−1 for S = O). In comparison, the calcined sample (black) only shows vibrations typical for silica and adsorbed water, which indicates complete removal of organic moieties.

The TGA data, plotted as differential mass loss in a temperature range of 30–600 °C (Fig. 4b), support the conclusions derived from DRIFTS. All modifications of sample P-1.7-S-1 exhibit a peak below 120 °C caused by the loss of water, but in different intensity. The pristine sample (blue) reveals a thiol decomposition peak at ~350 °C (no further decompositions are recorded). The actual mass loss is high, because the polymer also starts to decompose in this temperature range. For the oxidized/extracted sample (red) a pronounced mass loss is observed, indicating the presence of the sulfonic acid functionalities. Decomposition begins at lower temperatures already (~340 °C), which suggests the presence of residual polymer. All these observations agree with the results of previous studies [45].

3.2.3 MAS NMR spectroscopy

NMR was used to corroborate our previous conclusions about the synthesis of the sulfonic acid functionalized silicas. These studies were performed exemplarily with sample P-1.7-S-1 before oxidation/extraction, after this treatment, and after the calcination step in order to compare the different surface modifications (thiol, sulfonic acid, and no functionalization). For this purpose, 13C and 29Si spectra were recorded.

Figure 5a shows CP/MAS 13C NMR spectra of the sample before (blue) and after (red) extraction of the polymer (we did not expect any signals for the calcined material). The spectrum of the pristine material reveals three peaks at 11.3, 27.0, and 71.1 ppm. The first resonance at 11.3 ppm is caused by the carbon atom C3 of the functionalization in direct neighborhood to the silicon atom. The peak at 27.0 ppm is due to the central carbon atom of the propyl chain (C2) and the carbon atom C1 that directly binds to the thiol group. Both resonances overlap, as known from the literature [46]. The peak at 71.1 ppm can be assigned to the carbon atoms of the polymer (CPEO) that is still on the silica surface [47]. The treated material (red spectrum) also exhibits three signals, localized at 11.8, 17.6, and 53.3 ppm. However, the signal from the polymer is not visible any longer. It indicates the successful extraction of PEO, whereas our previous study by elemental analysis could not confirm this. The resonances at 11.8 and 17.6 ppm are caused by the carbon atom binding to the silicon atom (C3) and the adjacent carbon (C2). The peak at 53.3 ppm can be assigned to the carbon in direct neighborhood to the sulfonic acid functionality (C1, strongly shielded by the oxygens), which agrees with data for sulfur groups from the literature [46]. Based on this insight, we conclude that the thiol groups have been converted into sulfonic acid groups and that the polymer has been removed at the same time, confirming the goals targeted with the adapted oxidation/extraction step.

To support this qualitative proof of functionalization from Fig. 5a, CP/MAS 29Si NMR spectra (Fig. 5b) were recorded in addition. They can be used to define connectivities between coupled nuclei and investigate the dynamics in solids. As the technique is based on heteronuclear dipolar interactions, it is sensitive to internuclear distances and the mobility of functional groups [48]. All three materials exhibit the typical signals of Q4 (SiO4), Q3 (SiO3OH), and Q2 (SiO2(OH)2) silicon species in their spectra (see Fig. S4 in the ESM for additional illustration). The calcined sample (black spectrum in Fig. 5b) reveals no other signals than from the Q-species, which implies that the functionalization has been removed during the calcination step. Silicon species with nearby protons, such as Q2 and Q3, are significantly enhanced compared to Q4 species in CP/MAS due to polarization transfer during acquisition. The peak with the Q-species can be broad actually due to the heterogeneity of the silica skeleton regarding bond lengths and angles [49]. Taking a closer look at the spectra of the untreated functionalized sample (blue) and the oxidized/extracted sample (red), T-species can now be identified (cf. Fig. S4) and assigned in agreement with literature [50]. T2-signals (SiO2(OH)(CH2R)) around −66 ppm are prominent in both spectra. A T3-signal (SiO3(CH2R)) is only detected for the untreated material (−76.6 ppm). Furthermore, the T1-signal (SiO1(OH)2(CH2R)) is only weakly distinctive here (−57.6 ppm). On the other hand, no T3-signal is detected in the treated (SO3H) material, whereas the T1-signal at −56.9 ppm is much more pronounced. This may be caused by bonds on the surface (primarily functionalization) that have been broken during the extraction step, whereby more single (T2) and geminal (T1) silanol groups were formed, which would be consistent with the loss of some sulfonic acid groups already indicated by elemental analysis and SEM-EDX.

This assumption is confirmed by the HPDEC spectra in Fig. 5c. That technique can be used to derive quantitative evidence about the respective silicon species by a direct stimulation of each silicon atom. For this purpose, areas of the individual peaks in a spectrum were calculated by integration (exemplarily shown for the untreated sample P-1.7-S-1 in Fig. S4, ESM) and related to each other. From these relations, conclusions can be derived regarding the actual bonding in the materials that improve verification of the synthesis procedure. Based on the HPDEC spectra in Fig. 5c, it is clear that the Q4 species is the main constituent in all three modifications. This was expected, as it represents the bulk backbone of the monoliths. Furthermore, in both pristine (blue) and oxidized/extracted (red) materials, only T2-species are detected. Here, the signal for the sulfonic acid functionalized sample is weak, which further supports our assumption about the partial loss of functionalization in the extraction step. In the (blue) spectrum of the untreated material, two peaks are visible side by side (cf. Fig. S4). As they appear exactly in the range for T2-species, we took them as one T2 (SiO2(OH)(CH2R)) signal [50].

Quantification becomes more meaningful with the percentages of the individual silicon species, as calculated from the peak areas and summarized in Table 3. As mentioned, the Q4 is the most prominent species. It dominates with 91% in the calcined material compared to 72% and 71% in SH- and SO3H-functionalized samples. The calcination step enhances the formation of siloxane bonds (Q4) by dehydration of surface silanols. When cooling to room temperature, this process is somewhat reversed by atmospheric humidity, resulting in the low Q3 and Q2 quantities for sample P-1.7-S-1_ext_c. A comparison of the samples before and after the oxidation/extraction step shows that Q4 quantities do not differ much. It should be noted that for each T-signal a Q4-signal is detected, as a siloxane bond is added due to the functionalization reagent. Furthermore, the T2-species decrease from 6 to 4% after the extraction, as suggested by our previous results. This is accompanied by a significant increase in Q2-species (from 4 to 9%), which is consistent, because the silicon atom most likely replaces the cleaved functionalization by a hydroxyl group. As a consequence, a Q2-species is formed from a T2-species. Still, the T2-signal is detected for the oxidized/extracted material (sample P-1.7-S-1_ext), which supports the presented synthesis scheme. It was not possible to quantify the site occupancy with respect to the condensation, as described by Ide et al. [51], because the surfaces of the materials were manipulated by the sample preparation (grinding) required for the NMR measurements. The generation of small particles increases the number of surface silanol groups (Q3- and Q2-species), because additional surface (previously bulk) is created and the ratio of T- to Q3-species shifts. Nevertheless, the results of the NMR investigations are very instructive and demonstrate clearly that sulfonic acid functions were covalently bound to the surfaces of the prepared hierarchically structured silica monoliths to a significant extent.

The NMR investigations generally substantiate our approach. The 13C spectra demonstrate that it was possible to extract the polymer and at the same time oxidize thiol to sulfonic acid groups. Complementary, the 29Si spectra corroborate this important step by detecting silicon T-species, which represent the attachment of carbon atoms to silicon.

3.3 Inverse gas chromatography (IGC)

IGC is a source of physicochemical data for a variety of materials. The term indicates that the stationary phase of a chromatographic column is the material of interest and in turn examined through its interactions with well-known probe molecules. It was therefore necessary to prepare the monolithic rods in a column format suitable for the IGC equipment. The cladding approach of Kohns et al. [14] was used, in which the rods were first inserted into a stainless-steel tube and then embedded by epoxy resin. The attachment of zero-volume reducing unions completed the setup (Fig. S1 in the ESM). For the IGC investigations, a series of probe molecules (C6–C9 n-alkanes, dichloromethane, chloroform, diethyl ether, acetonitrile, and benzene) were injected individually and at least three times onto all columns for the determination of retention times. Sulfonic acid functionalized materials with different SO3H-loadings (samples P-1.7-S-1 and P-1.7-S-1.5) and the reference material without functionalization (P-1.7-S-0) were examined.

IGC characterizes the strength of interaction between an adsorbate and a solid surface through the total surface energy γst, covering dispersive (Van der Waals) and polar/specific (Lewis acid–base) interactions. To describe surface properties (e.g., acidity, wettability) comprehensively, both terms (dispersive component γsd and specific component γssp of the surface energy) have to be taken into account. The dispersive component can be calculated from interactions between n-alkanes and the solid surface. Dorris and Gray [52] introduced calculations based on the linear relationship between free energy of adsorption and molecular weight of n-alkanes, the so-called n-alkane line, to access the dispersive component of the surface energy. The specific component is determined from interactions of polar molecules with the surface. These interactions involve specific as well as dispersive contributions, which makes a distinction more difficult. Here, the dispersive component of the free adsorption enthalpy (as obtained from the n-alkane reference line) can be subtracted from the experimental free adsorption enthalpy to isolate the specific component. Details about these calculations are given in the ESM.

Free energies of adsorption (ΔGads) obtained by IGC reflect the strength of adhesive interaction with dispersive and specific contributions for each individual probe. By plotting ΔGads against the number of carbon atoms (expressed with the topological index χT), the interactions can also be represented graphically (Fig. 6). The topological index was introduced to compare retention data of different probes despite their different molecular properties (such as adsorption area and interaction strength). Brendlé and Papirer [53, 54] developed the χT-parameter based on the Wiener index for linear, branched, and cyclic alkanes, also taking polar eluents into account.

The data plotted in Fig. 6 show that both dispersive and specific interactions are intensified with increasing amount of MPTMS in the synthesis and thus, with increasing sulfonic acid loading in the formed material. For example, the n-alkane line shifts significantly to higher ΔGads values (accompanied by an increasing slope), indicating stronger adhesion of the alkanes to the surface as we progress from sample P-1.7-S-0 to P-1.7-S-1.5. A clear influence of the introduced SO3H groups is also seen for the polar probe molecules, ΔGads for sample P-1.7-S-1 increases strongly compared to the reference material. Interactions are intensified for Lewis-base (benzene, diethyl ether, and acetonitrile) as well as Lewis acid probes (DCM, chloroform). This indicates an increase in electron-donor and -acceptor capabilities of the materials upon silane incorporation. From the data in Fig. 6, dispersive and specific components and the resulting total surface energy of the respective material can be calculated (Table 4).

The data in Table 4 confirm our expectations that the specific component (γssp) dominates over the dispersive component (γsd) for silica due to the surface silanols (sample P-1.7-S-0). The total surface energy (122 mJ m−2) is composed of approximately one-third dispersive and two-thirds specific interactions. Upon functionalization (sample P-1.7-S-1), γssp increases significantly, but also the dispersive part increases from 35 to 47 mJ m−2, which can be attributed to the nonpolar propyl chain of the introduced group. Rückriem et al. [55] have described the gain in polarizability for modified silica surfaces with each additional methylene unit. Nonetheless, the specific part increases much stronger and this also raises the total surface energy drastically to 215 mJ m−2. By increasing the SO3H loading (sample P-1.7-S-1.5), γst rises further to twice the value of the reference material (246 mJ m−2), but the specific component does not increase as much as the dispersive component. Thus, the surfaces of the functionalized materials can be still described as polar, even as the interaction with nonpolar probe molecules is enhanced. To conclude, and with respect to characterizations already discussed, we can assume a covalently bonded sulfonic acid modification with different coverages on the surface of these hierarchically structured sol–gel silica monoliths.

Lewis acid–base characteristics of the monolith surfaces were subsequently analyzed using the concept of Gutmann [56]. Accordingly,

where \({\Delta}H_{{\mathrm{ads}}}^{{\mathrm{sp}}}\) is the enthalpy of sorption of a polar probe molecule, KA is the electron-acceptor number (acid) of the investigated surface and KD is the corresponding electron-donor number (base). DN and AN are Gutmann’s donor and acceptor numbers used to quantify the acid–base properties of the probe molecules. DN-values are calculated by calorimetric measurements from the sorption of the probe molecules (electron donor) onto SbCl5 (electron acceptor). AN-values are derived by 31P NMR measurements from the chemical shift of Et3PO (electron donor) in the presence of an electron acceptor [57,58,59,60]. The enthalpy of sorption \({\Delta}H_{{\mathrm{ads}}}^{{\mathrm{sp}}}\) is obtained by IGC (using at least three different temperatures) with the following equation:

Repeating this procedure for each probe molecule to estimate KA and KD values would be very time-consuming. During these periods aging effects can occur for labile samples at the elevated temperatures required for the measurements [61]. We therefore made a common simplification by using the specific interaction parameter \({\Delta}G_{{\mathrm{ads}}}^{{\mathrm{sp}}}\) for calculation of KA and KD. Both temperature dependent values can be received from the slope and the intercept of a linear plot of \({\Delta}G_{{\mathrm{ads}}}^{{\mathrm{sp}}}\)/AN against DN/AN, as illustrated in Fig. S5 (ESM) [62, 63]. It should be noted that acid–base parameters for solid surfaces derived by IGC measurements depend on the employed approach and the DN and AN reference values [57, 59]. In that respect, all measurements were performed under identical conditions and with the same evaluation routines. KA and KD values resulting from IGC analysis are summarized in Table 4. The acid–base character of the monolith surfaces can be described by the ratio KA/KD. A ratio larger than 1.1 indicates acidic character of the surface, KA/KD < 0.9 reflects basic character [64].

The Lewis acid parameter KA increases from 0.57 to 0.77 after introduction of the sulfonic acid functionality into the pore network (Table 4), which is a clear sign that the surface has become more acidic. Generally, the density of surface silanol groups should decrease after binding of a functionalization, which should also cause KA to drop. However, in our synthesis procedure KA increases significantly, which indicates a more acidic surface and corroborates the introduction of the sulfonic acid groups, which are more acidic than the silanol groups. KA/KD ratios for the functionalized materials are just slightly elevated with respect to the non-functionalized sample. Apparently, the increase in acidity is compensated by the simultaneously increasing Lewis-base parameter KD, as already noted with the ΔGads values for acidic probe molecules.

Bauer et al. [63] demonstrated a significant change in KA/KD value for porous glass upon MPTMS functionalization (leading to the SH modification), where a strong basic character of the surface was observed. With respect to our synthesis, it is not possible to analyze the materials with their non-oxidized (SH) modification, because the polymer that is still in the pores prevents unbiased interaction of probe molecules with the surface. However, it can be concluded that the increase in MPTMS concentration does not affect acidity, because the KA/KD value for sample P-1.7-S-1.5 remains at 1.6 and KA at 0.77 (Table 4). It may be assumed that the surface is saturated with functional groups. Even though smaller changes are noticeable for these SO3H loadings of 1.11 nm−2 (P-1.7-S-1) and 1.31 nm−2 (P-1.7-S-1.5), as detected by surface energy analysis (Table 4), Lewis acid–base parameters of these samples remain constant. The increase in polar interaction does not contradict constant acidity, because both acidic and basic polar probe molecules show stronger adhesive interactions for the higher SO3H loading (cf. Fig. 6).

4 Conclusions

Organic–inorganic hybrid sol–gel materials with hierarchical pore systems were synthesized by a simple, efficient synthesis route via co-condensation of TEOS and MPTMS, resulting in SO3H functionalized macro-mesoporous silica monoliths. The polymer (template) used for generation of the macroporosity was removed with an extraction step, in which the introduced thiol groups were simultaneously oxidized to sulfonic acid groups, leading to hybrid materials with uniform distribution of the SO3H groups inside the mesopores. The macropore size, specific surface area, and coverage with SO3H groups are conveniently adjusted in this synthesis route. For example, macropores formed by the polymer-induced phase separation were generated with median sizes from 1.2 to 8.2 µm at conserved mesopore diameters of 7–9 nm, and the materials offer specific surface areas of up to 576 m2 g−1. Using the co-condensation process, SO3H loadings of 1.1–1.3 groups/nm2 were realized by varying the initial MPTMS content. Higher MPTMS content also resulted in larger macropore sizes due to its influence on the phase separation. Importantly, the extraction of the polymer was facilitated while keeping most of the organic functionality intact. Altogether, it demonstrates that the co-condensation approach offers a simple, efficient route to functionalized sol–gel materials. Elemental analysis, SEM-EDX, thermogravimetry, DRIFTS, 13C and 29Si solid state NMR, and IGC provided detailed qualitative and quantitative evidence on the formation of surface-bound SO3H groups. With IGC, in particular, the effect of the SO3H groups could be quantified by analyzing dispersive and specific components of the total surface energy as well as Lewis acid–base parameters of these surfaces. Notably, the changes in surface acidity upon SO3H functionalization could be excellently monitored.

The prepared hybrid monoliths are primarily useful for processes involving ion exchange, acid catalysis, or proton conduction, where morphological properties like macropore size and surface area will be easily adjusted in addition to the density of the SO3H groups. However, their narrow mesopore size distribution further helps in applications that benefit from size-selective transport like chromatographic (e.g., biomolecular) separations or catalysis under spatial confinement. In this respect, the cladding approach applied to the monolithic rods in this work for IGC analysis also offers a robust column design for their convenient future use as a fixed-bed adsorber and/or reactor.

Change history

02 August 2021

The following OA funding note is addressed above reference section: Open Access funding enabled andorganized by Projekt DEAL.

10 August 2021

A Correction to this paper has been published: https://doi.org/10.1007/s10971-021-05594-y

References

Nakanishi K, Tanaka N (2007) Sol–gel with phase separation. Hierarchically porous materials optimized for high-performance liquid chromatography separations. Acc Chem Res 40:863–873. https://doi.org/10.1021/ar600034p

Tan I, Zarafshani Z, Lutz J-F, Titirici M-M (2009) PEGylated chromatography: efficient bioseparation on silica monoliths grafted with smart biocompatible polymers. ACS Appl Mater Interfaces 1:1869–1872. https://doi.org/10.1021/am900461a

Sachse A, Galarneau A, Fajula F, Di Renzo F, Creux P, Coq B (2011) Functional silica monoliths with hierarchical uniform porosity as continuous flow catalytic reactors. Microporous Mesoporous Mater 140:58–68. https://doi.org/10.1016/j.micromeso.2010.10.044

Hayase G, Kugimiya K, Ogawa M, Kodera Y, Kanamori K, Nakanishi K (2014) The thermal conductivity of polymethylsilsesquioxane aerogels and xerogels with varied pore sizes for practical application as thermal superinsulator. J Mater Chem A 2:6525–6531. https://doi.org/10.1039/C3TA15094A

Cuce E, Cuce PM, Wood CJ, Riffat SB (2014) Toward aerogel based thermal superinsulation in buildings: a comprehensive review. Renew Sust Energ Rev 34:273–299. https://doi.org/10.1016/j.rser.2014.03.017

von der Lehr M, Seidler CF, Taffa DH, Wark M, Smarsly BM, Marshall R (2016) Proton conduction in sulfonated organic-inorganic hybrid monoliths with hierarchical pore structure. ACS Appl Mater Interfaces 8:25476–25488. https://doi.org/10.1021/acsami.6b08477

Ko YG, Lee HJ, Kim JY, Choi US (2014) Hierarchically porous aminosilica monolith as a CO2 adsorbent. ACS Appl Mater Interfaces 6:12988–12996. https://doi.org/10.1021/am5029022

Galarneau A, Sachse A, Said B, Pélisson C-H, Boscaro P, Brun N, Courtheoux L, Olivi-Tran N, Coasne B, Fajula F (2016) Hierarchical porous silica monoliths: a novel class of microreactors for process intensification in catalysis and adsorption. C R Chimie 19:231–247. https://doi.org/10.1016/j.crci.2015.05.017

Maleki H, Hüsing N (2018) Current status, opportunities and challenges in catalytic and photocatalytic applications of aerogels: environmental protection aspects. Appl Catal B 221:530–555. https://doi.org/10.1016/j.apcatb.2017.08.012

Enke D, Gläser R, Tallarek U (2016) Sol–gel and porous glass-based silica monoliths with hierarchical pore structure for solid-liquid catalysis. Chem Ing Tech 88:1561–1585. https://doi.org/10.1002/cite.201600049

Müllner T, Unger KK, Tallarek U (2016) Characterization of microscopic disorder in reconstructed porous materials and assessment of mass transport-relevant structural descriptions. New J Chem 40:3993–4015. https://doi.org/10.1039/C5NJ03346B

Noisser T, Reichenauer G, Hüsing N (2014) In situ modification of the silica backbone leading to highly porous monolithic hybrid organic-inorganic materials via ambient pressure drying. ACS Appl Mater Interfaces 6:1025–1029. https://doi.org/10.1021/am404005g

Stoeckel D, Kübel C, Hormann K, Höltzel A, Smarsly BM, Tallarek U (2014) Morphological analysis of disordered macroporous-mesoporous solids based on physical reconstruction by nanoscale tomography. Langmuir 30:9022–9027. https://doi.org/10.1021/la502381m

Kohns R, Haas CP, Höltzel A, Splith C, Enke D, Tallarek U (2018) Hierarchical silica monoliths with submicron macropores as continuous-flow microreactors for reaction kinetic and mechanistic studies in heterogeneous catalysis. React Chem Eng 3:353–364. https://doi.org/10.1039/C8RE00037A

Xie C, Hu J, Xiao H, Su X, Dong J, Tian R, He Z, Zou H (2005) Preparation of monolithic silica column with strong cation-exchange stationary phase for capillary electrochromatography. J Sep Sci 28:751–756. https://doi.org/10.1002/jssc.200400101

El Kadib A, Chimenton R, Sachse A, Fajula F, Galarneau A, Coq B (2009) Functionalized inorganic monolithic microreactors for high productivity in fine chemicals catalytic synthesis. Angew Chem Int Ed 48:4969–4972. https://doi.org/10.1002/anie.200805580

Timm J, Marshall R (2018) A novel versatile grafting procedure: toward the highest possible sulfonation degree of mesoporous silica. Adv Sustain Syst 2:1700170. https://doi.org/10.1002/adsu.201700170

Reich S-J, Svidrytski A, Hlushkou D, Stoeckel D, Kübel C, Höltzel A, Tallarek U (2018) Hindrance factor expression for diffusion in random mesoporous adsorbents obtained from pore-scale simulations in physical reconstructions. Ind Eng Chem Res 57:3031–3042. https://doi.org/10.1021/acs.iecr.7b04840

Bauer F, Czihal S, Bertmer M, Decker U, Naumov S, Wassersleben S, Enke D (2017) Water-based functionalization of mesoporous siliceous materials, Part 1: Morphology and stability of grafted 3-aminopropyltriethoxysilane. Microporous Mesoporous Mater 250:221–231. https://doi.org/10.1016/j.micromeso.2016.01.046

Yan L, Zhang Q, Zhang J, Zhang L, Li T, Feng Y, Zhang L, Zhang W, Zhang Y (2004) Hybrid organic-inorganic monolithic stationary phase for acidic compounds separation by capillary electrochromatography. J Chromatogr A 1046:255–261. https://doi.org/10.1016/j.chroma.2004.06.024

Nakanishi K (1997) Pore structure control of silica gels based on phase separation. J Porous Mater 4:67–112. https://doi.org/10.1023/A:1009627216939

Nakanishi K, Komura H, Takahashi R, Soga N (1994) Phase separation in silica sol–gel system containing poly(ethylene oxide). I. Phase relation and gel morphology. Bull Chem Soc Jpn 67:1327–1335. https://doi.org/10.1246/bcsj.67.1327

Feinle A, Elsaesser MS, Hüsing N (2016) Sol–gel synthesis of monolithic materials with hierarchical porosity. Chem Soc Rev 45:3377–3399. https://doi.org/10.1039/C5CS00710K

Marschall R, Rathousky J, Wark M (2007) Ordered functionalized silica materials with high proton conductivity. Chem Mater 19:6401–6407. https://doi.org/10.1021/cm071164i

Marshall R, Bannat I, Feldhoff A, Wang L, Lu GQ, Wark M (2009) Nanoparticles of mesoporous SO3H-functionalized Si-MCM-41 with superior proton conductivity. Small 5:854–859. https://doi.org/10.1002/smll.200801235

Marschall R, Tölle P, Cavalcanti WL, Wilhelm M, Köhler C, Frauenheim T, Wark M (2009) Detailed simulation and characterization of highly proton conducting sulfonic acid functionalized mesoporous materials under dry and humidified conditions. J Phys Chem C 113:19218–19227. https://doi.org/10.1021/jp904322y

Bossaert WD, De Vos DE, Van Rhijn WM, Bullen J, Grobet PJ, Jacobs PA (1999) Mesoporous sulfonic acids as selective heterogeneous catalysts for the synthesis of monoglycerides. J Catal 182:156–164. https://doi.org/10.1006/jcat.1998.2353

Dacquin J-P, Lee AF, Wilson K (2012) Pore-expanded SBA-15 sulfonic acid silicas for biodiesel synthesis. Chem Commun 48:212–214. https://doi.org/10.1039/C1CC14563K

Pirez C, Caderon J-M, Dacquin J-P, Lee AF, Wilson K (2012) Tunable KIT-6 mesoporous sulfonic acid catalysts for fatty acid esterification. ACS Catal 2:1607–1614. https://doi.org/10.1021/cs300161a

Dias AS, Pillinger M, Valente AA (2005) Dehydration of xylose into furfural over micro-mesoporous sulfonic acid catalysts. J Catal 229:414–423. https://doi.org/10.1016/j.jcat.2004.11.016

Wilson K, Lee AF, Macquarrie DJ, Clark JH (2002) Structure and reactivity of sol–gel sulphonic acid silicas. Appl Catal A 228:127–133. https://doi.org/10.1016/S0926-860X(01)00956-5

Xu L, Lee HK (2008) Preparation, characterization and analytical application of a hybrid organic-inorganic silica-based monolith. J Chromatog. A 1195:78–84. https://doi.org/10.1016/j.chroma.2008.04.068

Kohns R, Anders N, Enke D, Tallarek U (2020) Influence of pore space hierarchy on the efficiency of an acetylcholinesterase-based support for biosensorics. Adv Mater Interfaces. https://doi.org/10.1002/admi.202000163

Patarin J (2004) Mild methods for removing organic templates from inorganic host materials. Angew Chem Int Ed 43:3878–3880. https://doi.org/10.1002/anie.200301740

Cychosz KA, Guillet-Nicolas R, García-Martínez J, Thommes M (2017) Recent advances in the textural characterization of hierarchically structured nanoporous materials. Chem Soc Rev 46:389–414. https://doi.org/10.1039/C6CS00391E

Thakur RS, Kurur ND, Madhu PK (2006) Swept-frequency two-pulse phase modulation for heteronuclear dipolar decoupling in solid-state NMR. Chem Phys Lett 426:459–463. https://doi.org/10.1016/j.cplett.2006.06.007

Tanaka N, Kobayashi H, Ishizuka N, Minakuchi H, Nakanishi K, Hosoya K, Ikegami T (2002) Monolithic silica columns for high-efficiency chromatographic separations. J Chromatogr A 965:35–49. https://doi.org/10.1016/s0021-9673(01)01582-5

Brinker CJ, Scherer GW (1990) Sol–gel science: the physics and chemistry of sol–gel processing. Academic Press, New York

Gritti F, Hochstrasser J, Svidrytski A, Hlushkou D, Tallarek U (2020) Morphology-transport relationships in liquid chromatography: application to method development in size exclusion chromatography. J Chromatogr A. https://doi.org/10.1016/j.chroma.2020.460991

Goettmann F, Sanchez C (2007) How does confinement affect the catalytic activity of mesoporous materials? J Mater Chem 17:24–30. https://doi.org/10.1039/B608748P

Yu C, He J (2012) Synergic catalytic effects in confined spaces. Chem Commun 48:4933–4940. https://doi.org/10.1039/C2CC31585H

Ziegler F, Teske J, Elser I, Dyballa M, Frey W, Kraus H, Hansen N, Rybka J, Tallarek U, Buchmeiser MR (2019) Olefin methathesis in confined geometries: a biomimetic approach towards selective macrocyclization. J Am Chem Soc 141:19014–19022. https://doi.org/10.1021/jacs.9b08776

Thommes M, Kaneko K, Neimark AV, Olivier JP, Rodriguez-Reinoso F, Rouquerol J, Sing KSW (2015) Physisorption of gases, with special reference to the evaluation of surface area and pore size distribution (IUPAC Technical Report). Pure Appl Chem 87:1051–1069. https://doi.org/10.1515/pac-2014-1117

Ma X, Sun H, Yu P (2008) A novel way for preparing high surface area silica monolith with bimodal pore structure. J Mater Sci 43:887–891. https://doi.org/10.1007/s10853-007-2189-2

Margolese D, Melero JA, Christiansen SC, Chmelka BF, Stucky GD (2000) Direct Syntheses of ordered SBA-15 mesoporous silica containing sulfonic acid groups. Chem Mater 12:2448–2459. https://doi.org/10.1021/cm0010304

Freeman F, Angeletakis CN (1983) 13C NMR chemical shifts of thiols, sulfinic acids, sulfinyl chlorides, sulfonic acids and sulfonic anhydrides. Org Magnet Res 21:86–93. https://doi.org/10.1002/omr.1270210204

Yamamoto K, Maruta A, Shimada S (2001) Structure and molecular motion of poly(ethylene oxide) chains tethered on silica by solid-state 13C NMR method. Polym J 33:584–589. https://doi.org/10.1295/polymj.33.584

Kolodziejski W, Klinowksi J (2002) Kinetics of cross-polarization in solid-state NMR: a guide for chemists. Chem Rev 102:613–628. https://doi.org/10.1021/cr000060n

Lutz W, Täschner D, Kurzhals R, Heidemann D, Hübert C (2009) Characterization of silica gels by 29Si MAS NMR and IR spectroscopic measurements. Z Anorg Allg Chem 635:2191–2196. https://doi.org/10.1002/zaac.200900237

Bein T, Carver RF, Farlee RD, Stucky GD (1988) Solid-state silicon-29 NMR and infrared studies of the reactions of mono- and polyfunctional silanes with zeolite Y surfaces. J Am Chem Soc 110:4546–4553. https://doi.org/10.1021/ja00222a010

Ide M, El-Roz M, De Canck E, Vicente A, Planckaert T, Bogaerts T, Van Driessche I, Lynen F, Van Speybroeck V, Thybault-Starzyk F, Van der Voort P (2013) Quantification of silanol sites for the most common mesoporous ordered silicas and organosilicas: total versus accessible silanols. Phys Chem Chem Phys 15:642–650. https://doi.org/10.1039/c2cp42811c

Dorris GM, Gray DG (1980) Adsorption of n-alkanes at zero surface coverage on cellulose paper and wood fibers. J Colloid Interface Sci 77:353–362. https://doi.org/10.1016/0021-9797(80)90304-5

Brendlé E, Papirer E (1997) A new topological index for molecular probes used in inverse gas chromatography for the surface nanorugosity evaluation. J Colloid Interface Sci 194:207–216. https://doi.org/10.1006/jcis.1997.5104

Brendlé E, Papirer E (1997) A new topological index for molecular probes used in inverse gas chromatography. J Colloid Interface Sci 194:217–224. https://doi.org/10.1006/jcis.1997.5105

Rückriem M, Inayat A, Enke D, Gläser R, Einicke W-D, Rockmann R (2010) Inverse gas chromatography for determining the dispersive surface energy of porous silica. Colloids Surf A 357:21–26. https://doi.org/10.1016/j.colsurfa.2009.12.001

Gutmann V (1976) Empirical parameters for donor and acceptor properties of solvents. Electrochim Acta 21:661–670. https://doi.org/10.1016/0013-4686(76)85034-7

Gutmann V (1978) The donor-acceptor approach to molecular interactions. Plenum Press, New York

Riddle FL, Fowkes FM (1990) Spectral shifts in acid-base chemistry. 1. Van der Waals contributions to acceptor numbers. J Am Chem Soc 112:3259–3264. https://doi.org/10.1021/ja00165a001

Fekete E, Móczó J, Pukánsky B (2004) Determination of the surface characteristics of particulate fillers by inverse gas chromatography at infinite dilution: a critical approach. J Colloid Interface Sci 269:143–152. https://doi.org/10.1016/S0021-9797(03)00719-7

Grajek H, Paciura-Zadrozna J, Witkiewicz Z (2010) Chromatographic characterisation of ordered mesoporous silicas. Part II: Acceptor-donor properties. J Chromatogr A 1217:3116–3127. https://doi.org/10.1016/j.chroma.2010.02.029

Poole CF (2012) Gas chromatography. Elsevier, Oxford

Saint Flour C, Papirer E (1983) Gas-solid chromatography: a quick method of estimating surface free energy variations induced by the treatment of short glass fibers. J Colloid Interface Sci 91:69–75. https://doi.org/10.1016/0021-9797(83)90314-4

Bauer F, Meyer R, Czihal S, Bertmer M, Decker U, Naumov S, Uhlig H, Steinhart M, Enke D (2019) Functionalization of porous siliceous materials, Part 2: surface characterization by inverse gas chromatography. J Chromatogr A 1603:297–310. https://doi.org/10.1016/j.chroma.2019.06.031

Lara J, Schreiber HP (1991) Specific interactions and adsorption of film-forming polymers. J Coating Technol 63:81–90

Acknowledgements

The authors thank Niklas Olinski for preliminary lab studies.

Funding

Open Access funding enabled and organized by Projekt DEAL.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Kohns, R., Meyer, R., Wenzel, M. et al. In situ synthesis and characterization of sulfonic acid functionalized hierarchical silica monoliths. J Sol-Gel Sci Technol 96, 67–82 (2020). https://doi.org/10.1007/s10971-020-05383-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10971-020-05383-z